All-insulation pouring tubular bus and preparation method thereof

A fully insulated, poured tube technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems that affect the service life of tubular busbars, poor fire protection, anti-corrosion and anti-aging performance, and achieve guaranteed strength and impact resistance. , Good insulation and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

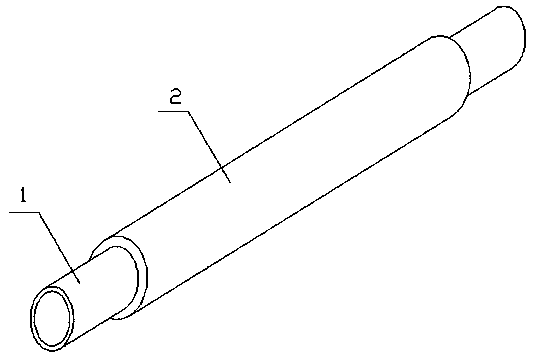

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

[0024] Tubular busbar is one of the key equipment in the power transmission and transformation system, and plays a vital role in the safe and reliable operation of the transmission and transformation system and power equipment. Tubular busbar is mainly used in the conductor connection between the power grid transmission wire and the substation transformer in my country's electric power construction projects, the jumper wire in the transmission line, the connecting conductor in the power equipment, and the overcurrent conductor in the high-current DC ice melting device. A new conductor that replaces the traditional rectangular, slotted, bar-shaped busbars and soft wires is one of the key equipment in the power transmission system. At present, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com