Assembled wall assembled on side of main building structure in held manner

A main building, prefabricated technology, applied in building components, building structures, buildings, etc., can solve problems such as misleading building energy conservation, affecting building durability, affecting building energy conservation and emission reduction, and achieving good structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

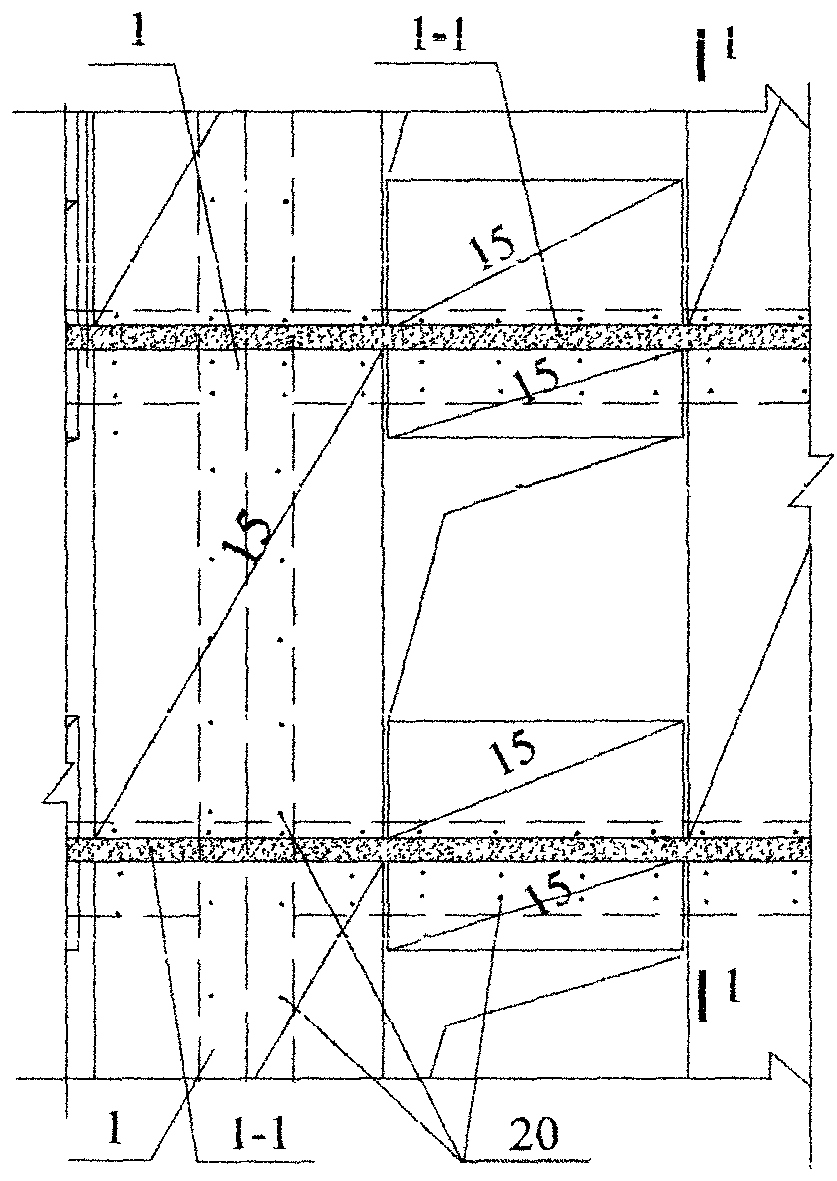

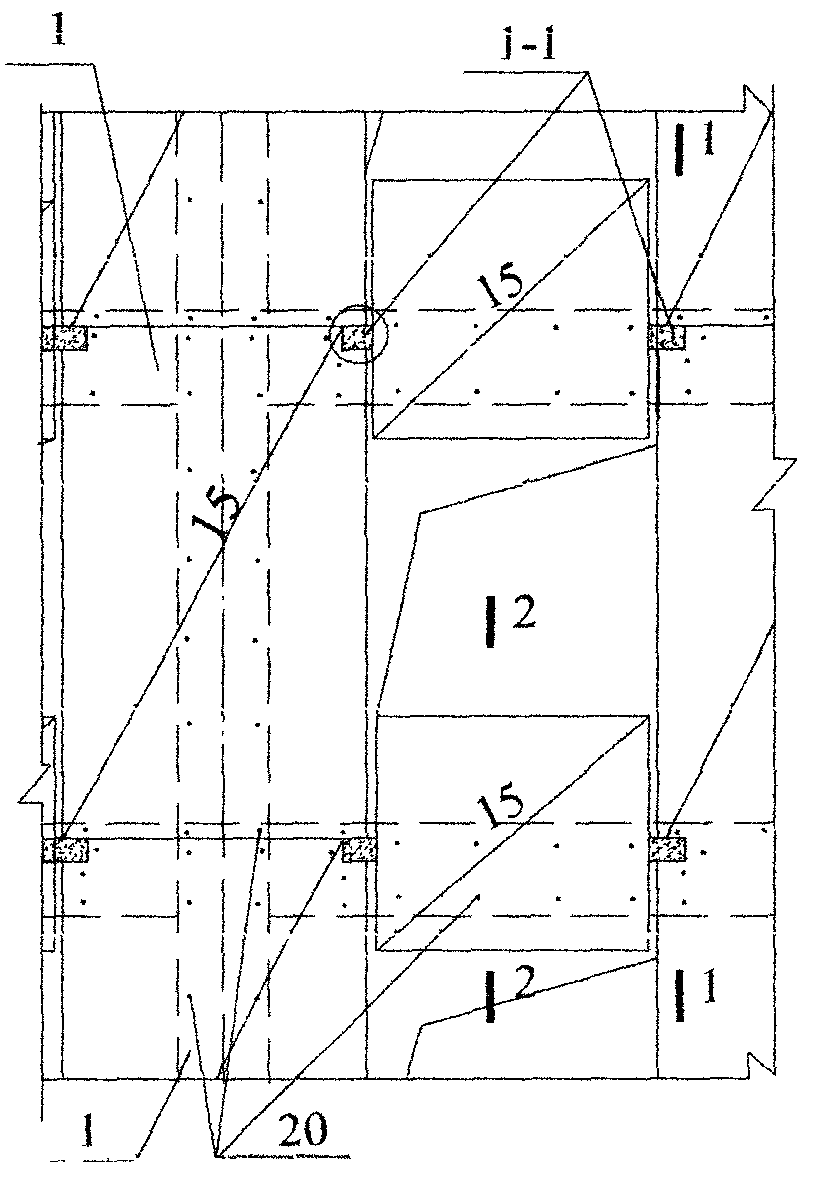

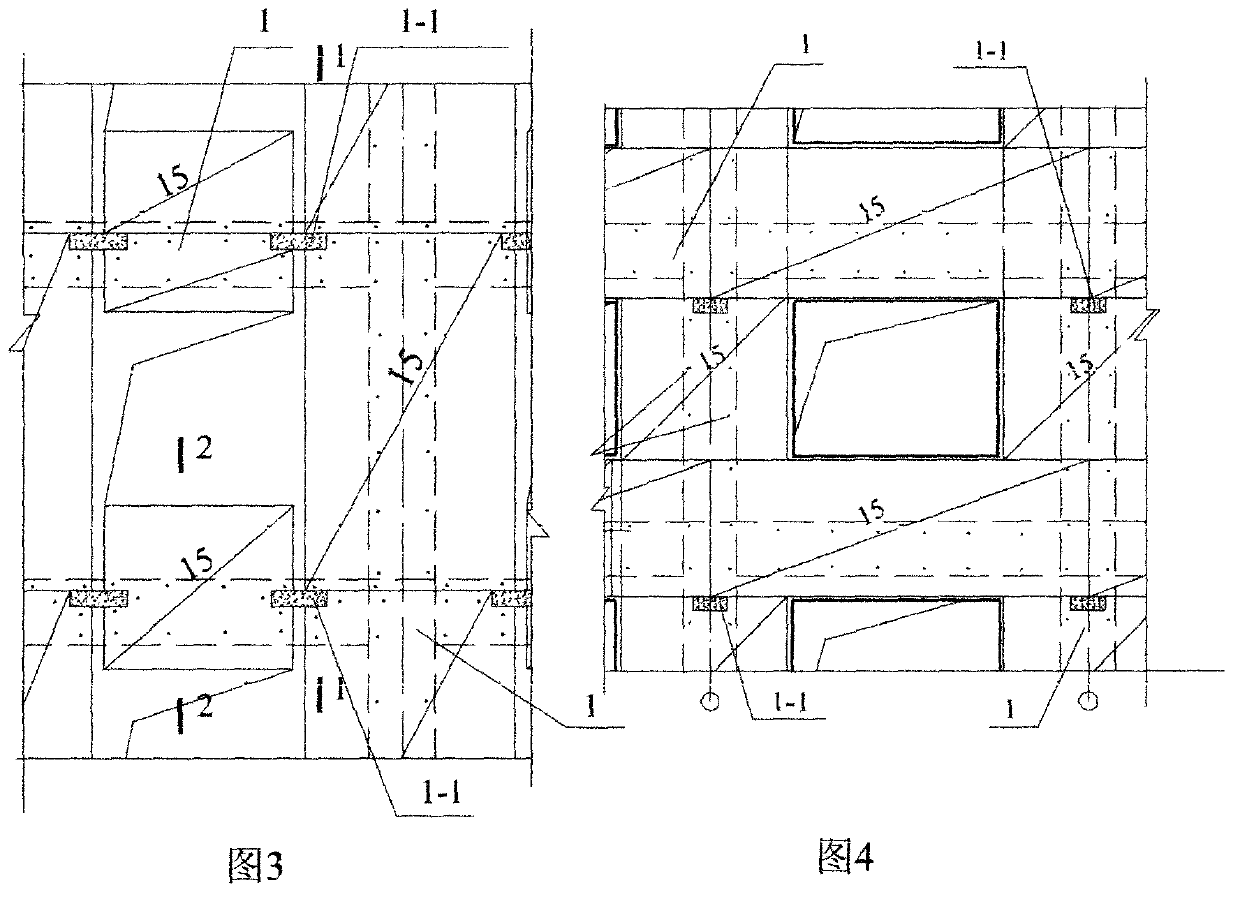

[0051] Implementation mode one: see Figure 1 to Figure 14 , a kind of prefabricated wall supported and installed on the side of the main building structure in this embodiment is composed of the main building structure 1 and prefabricated wall panels 15; the main building structure 1 is a beam, plate, column wall and foundation, and the main building Structure 1 can be a concrete frame structure, a steel-shaped concrete frame structure, a frame-shear structure, a steel frame structure, a mixed frame structure of concrete and steel, a steel-wood frame structure, a shear wall structure, or a bamboo-wood frame structure;

[0052] The prefabricated wall panels 15 are placed outside the beams, columns and shear walls of the main building structure 1;

[0053] The beams and columns of the main building structure 1 and the concrete slabs 1-2 outside the shear walls support the prefabricated wall panels 15, and the prefabricated wall panels 15 are connected to the outer surface of the...

Embodiment approach 2

[0071] Implementation mode two: see Figure 1 to Figure 8 The difference between this embodiment and Embodiment 1 is that the connection between the prefabricated wall and the main building structure 1 of this embodiment also has the following methods, and one or more methods of connection are selected:

[0072] 1), use the anchor bolt 20 to fix the side of the prefabricated wall panel 15 and the main building structure 1;

[0073] 2) Bonding the prefabricated wall panel 15 to the side of the beam, slab column and shear wall of the main building structure 1 with a cementing material, or / and bonding to the side of the additional abutting member 1-3;

[0074] 3) Bond the end of the prefabricated wall panel 15 with the structural supporting member 1-1 or the concrete slab 1-2 with a cementing material, or set a mesh tensile material in the cementing material between the bonding surfaces 5 (such as Figure 5 ; Figure 8 When the bonding length between the lower end of the prefa...

Embodiment approach 3

[0080]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in this embodiment, there is a fireproof material in or on the surface of the protective layer 8 at the outer end of the anchor bolt 20, or the local protective layer 8 at the outer end of the anchor bolt 20 meets the requirements of fire prevention. The required protective layer enables the anchor bolt 20 to meet the fire protection requirements: the structural supporting member 1-1 is set locally or along the perimeter of the building (such as the perimeter of the concrete cornice), or is a floor slab or a foundation slab.

[0081] For example, the surface of the anchor bolt or the surface of the protective layer is partially painted with fireproof paint, or the fireproof material is added to a certain range of plastering protective layer on the anchor bolt, or the protective layer itself is a fireproof material that can meet the fireproof requirements, such as thermal insulation mortar he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com