Patents

Literature

78results about How to "Good energy saving and heat preservation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

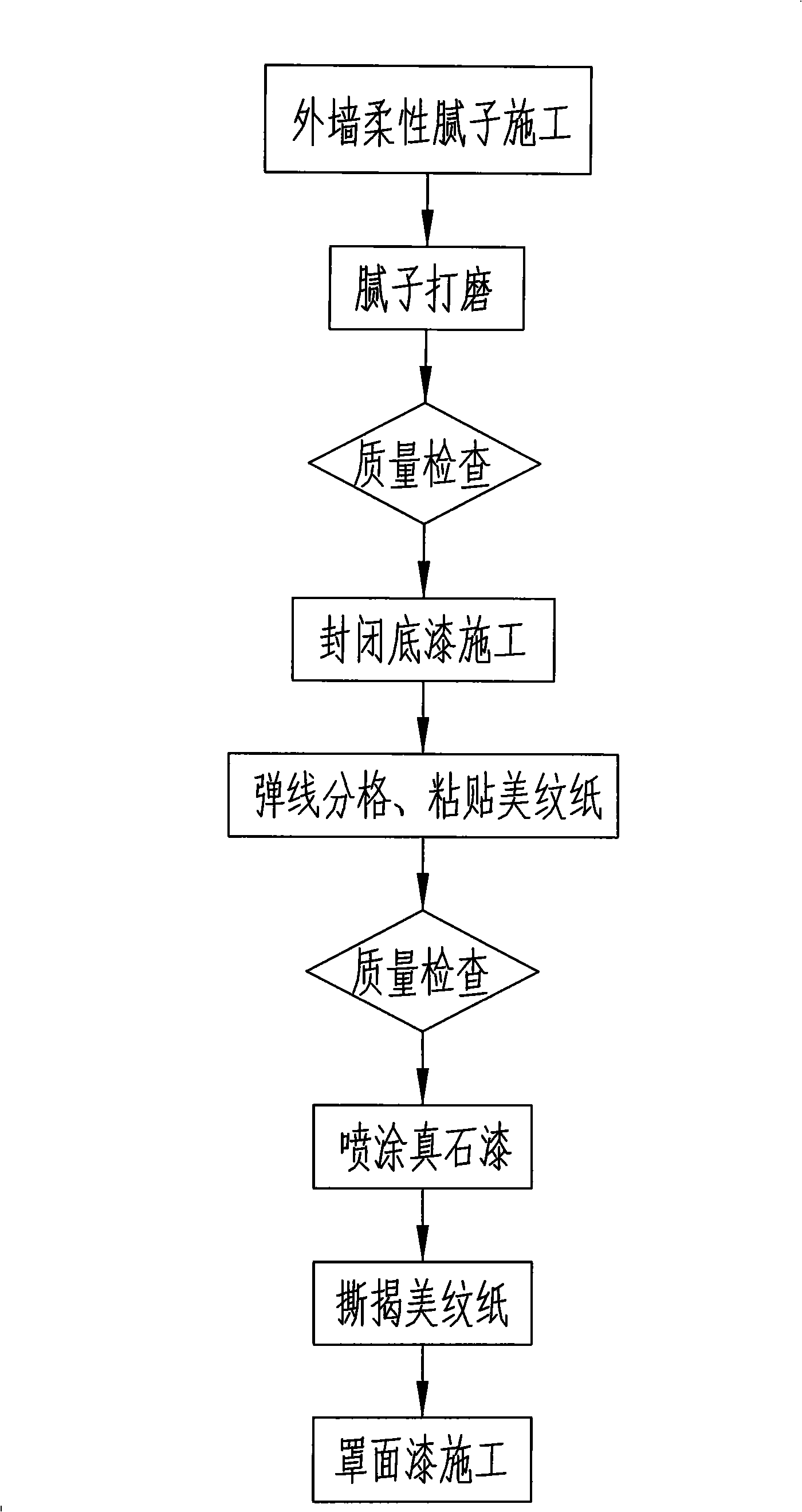

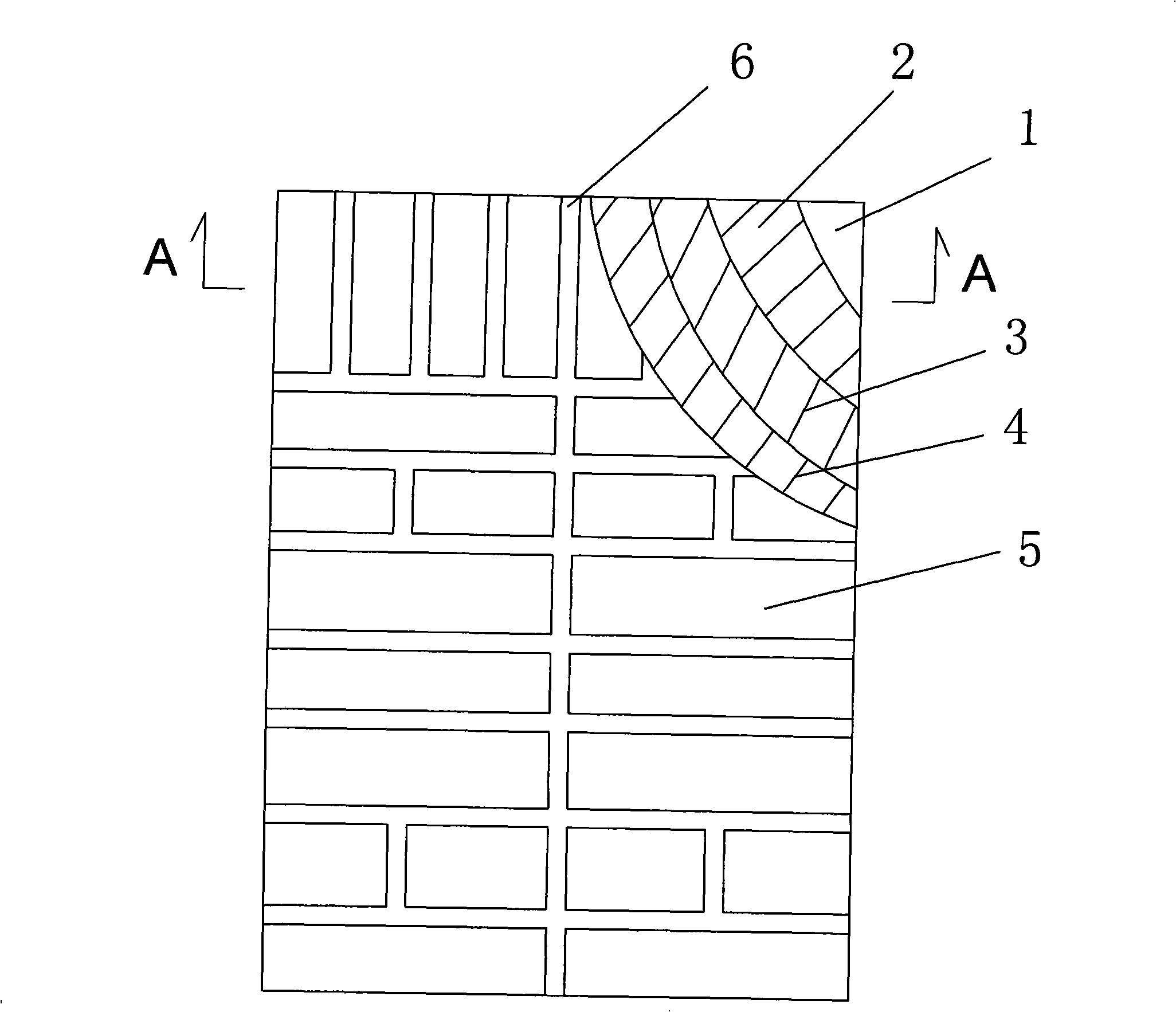

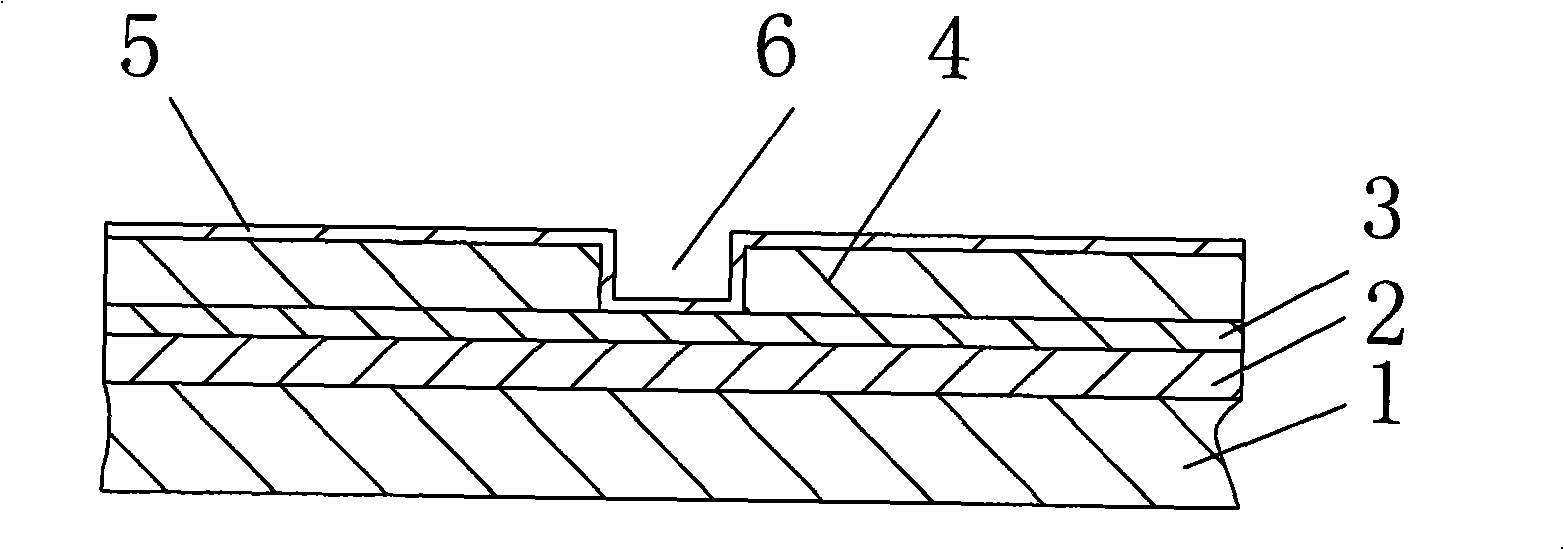

Construction method of ture mineral varnish face brick-imitation construction exterior wall

InactiveCN101319552ASolve the problem of decorative aesthetic effectSimple methodCovering/liningsBrickLacquer

The invention relates to a construction method for building external walls with real stone lacquer imitation tiles, which effectively solves the problem that the decoration of an external wall of a public building and a residential building not only realizes heat insulation and energy conservation but also can realize beautiful decorative effect. The technical proposal to be solved by the construction method is as follows: by adoption of the external wall as a fundamental plane, a base of the external wall is coated and rubbed down by filler plaster, and a primer layer is arranged on the base by primer; snapline division is performed on the primer layer, and beautiful paper tape is applied according to divided snaplines; real stone lacquer is sprayed, the beautiful paper tape is torn off in time after spray painting, and decorative grooves are left on the paper tape; and a layer of mask lacquer is sprayed finally. The method is simple, is easy to operate, has low cost, quick construction speed and good effect, and not only has good effects of energy conservation and heat insulation but also has beautiful decorative effect. The technique is not reported publicly until now, is an innovation architecturally, and has significant economic and social effects.

Owner:勾希杰 +1

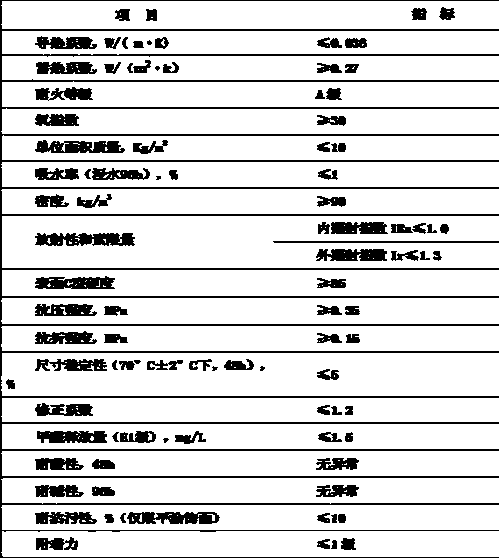

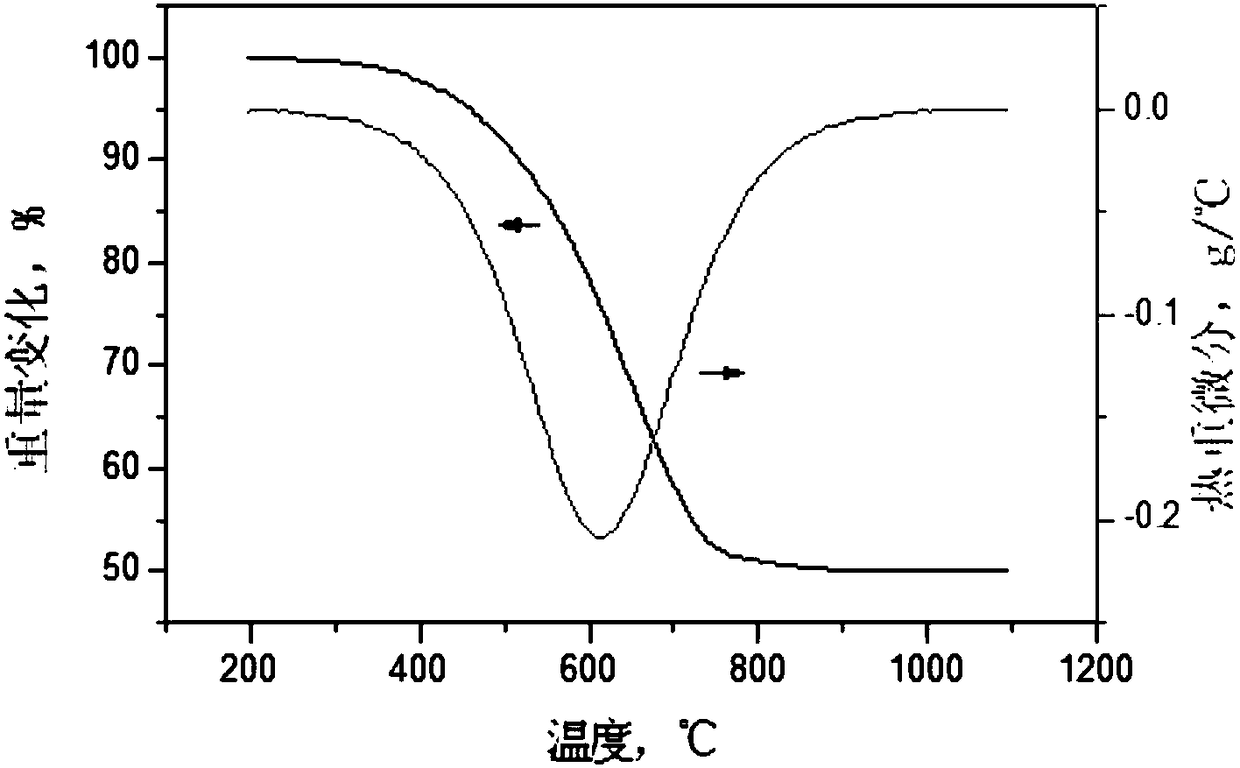

Phase change energy storage plant fiber composite heat insulation board and preparation method thereof

InactiveCN102850007AHigh latent heatGood reversibilityHeat-exchange elementsThermal insulationMirabilite

The invention relates to a phase change energy storage plant fiber composite heat insulation board and a preparation method of the composite heat insulation board; the phase change energy storage plant fiber composite heat insulation board is prepared from the raw materials in parts by weight: 30-50 parts of phase-change material and 50-70 parts of plant fiber, wherein the phase-change material is one selected from mirabilite, calcium chloride hexahydrate, n-caprylic acid and butyl stearate; crop straw, straw or Chinese alpine rush is adopted as the plant fiber, so that the local materials can be used, the waste straw resource is utilized, and the waste is changed into valuable; the energy storage characteristic of the phase-change material is combined, so that energy conservation and consumption reduction are realized; and the produced composite heat insulation board has the advantages of being fireproof, flame retardant, light in mass, high in compression strength, good in energy-saving effect, non-toxic, harmless and environment-friendly, and has the functions of heat insulation and sound insulation.

Owner:信阳天意节能技术股份有限公司

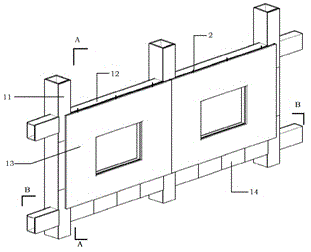

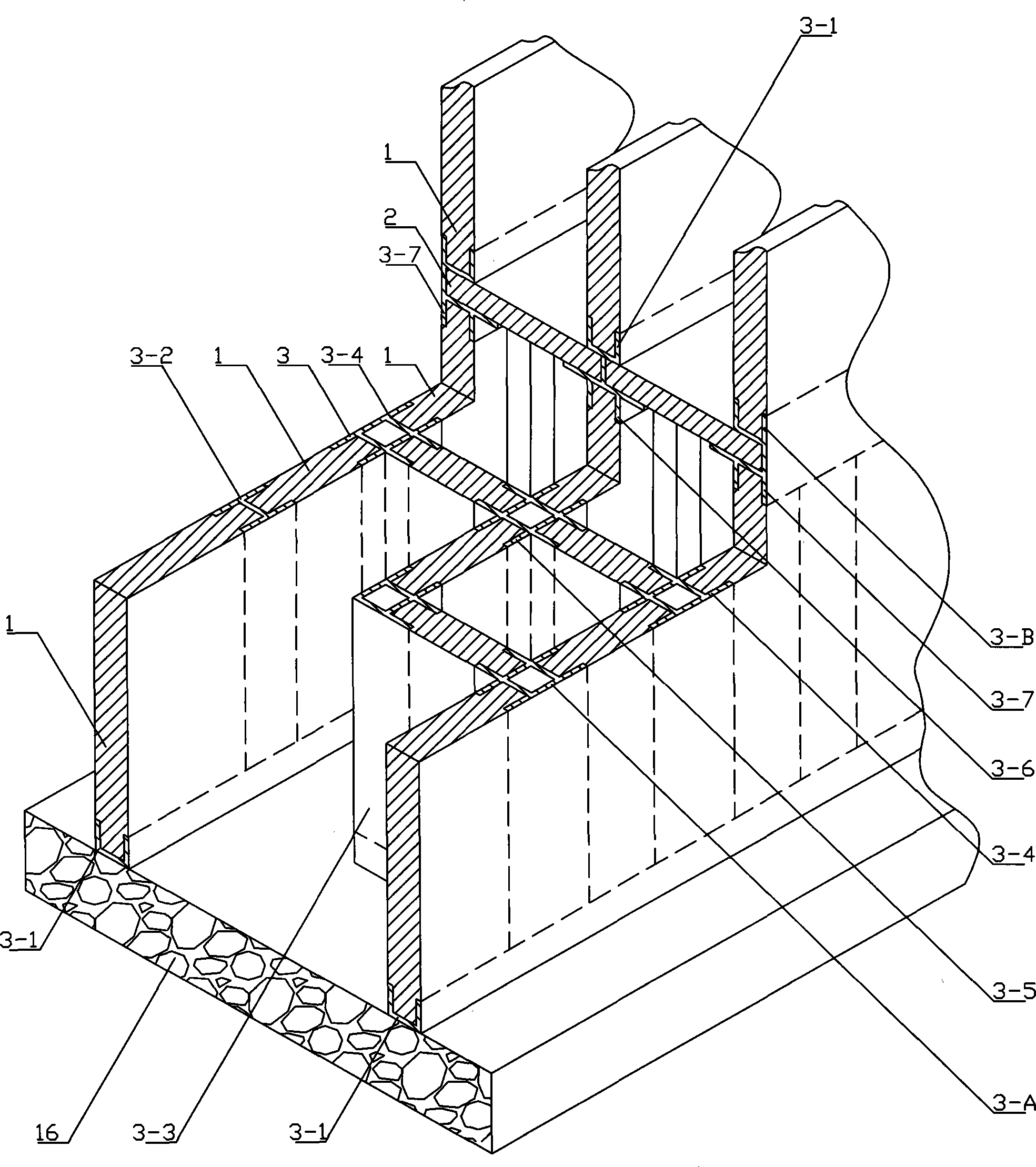

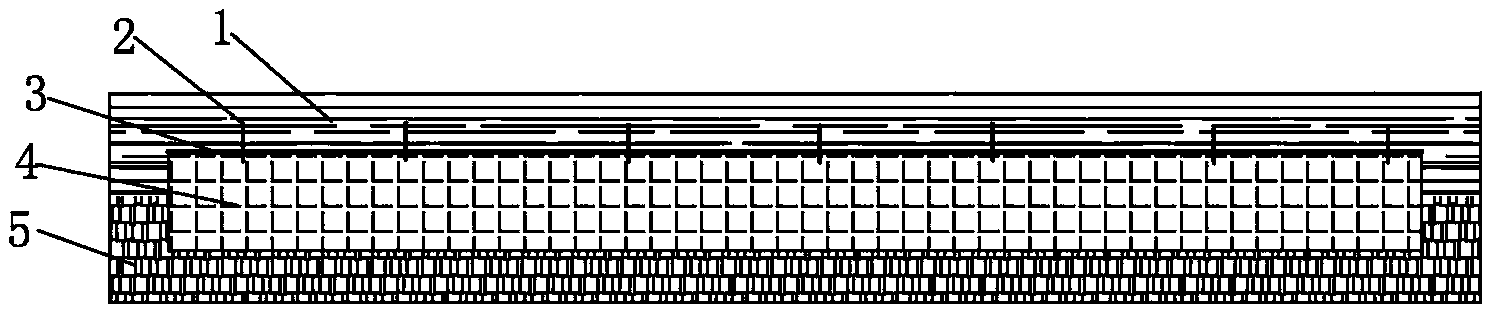

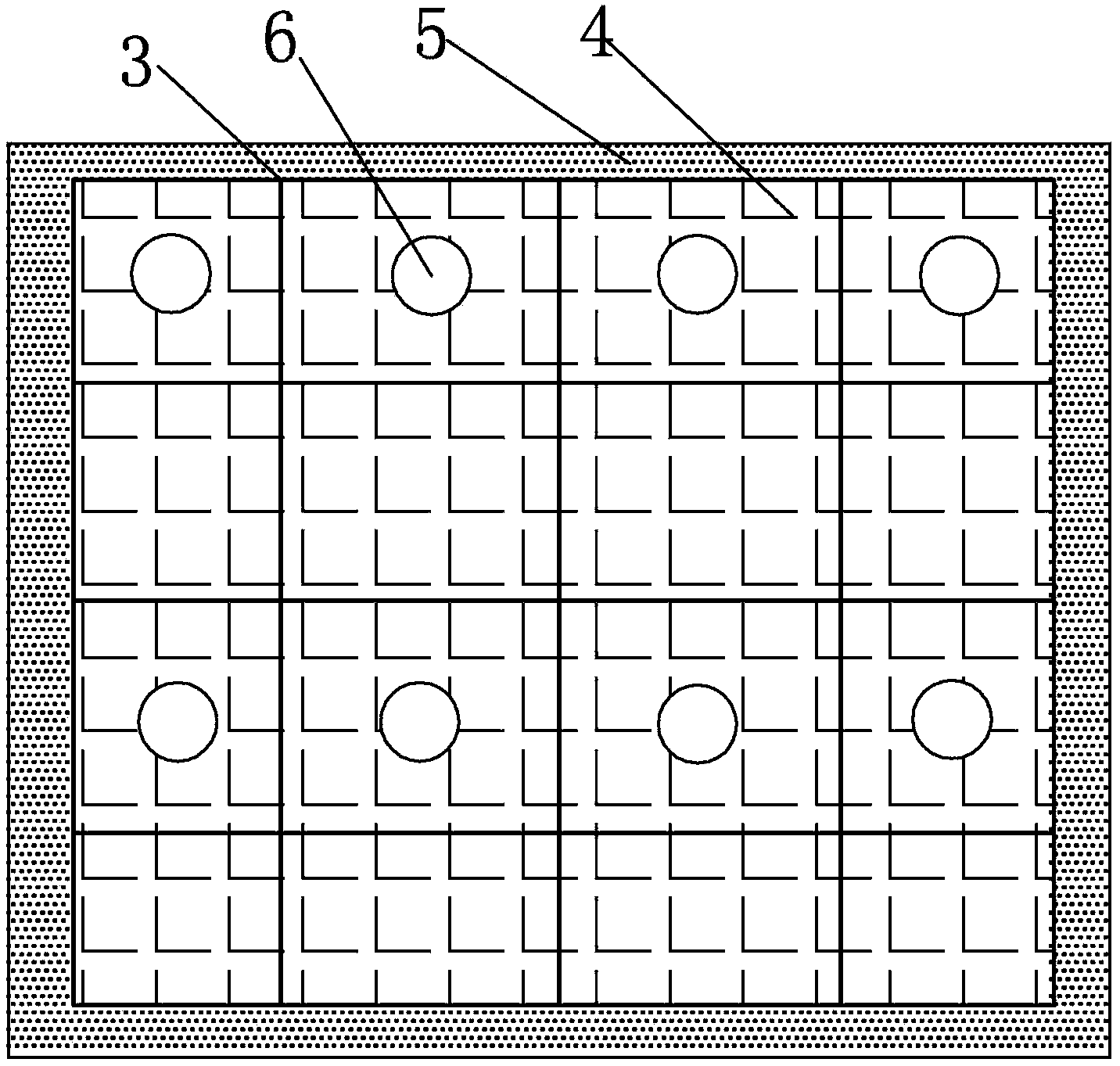

Steel structure assembled type EPS (Electric Power Storage) module sandwiched heat-insulation composite wall body

InactiveCN105672535AImprove insulation effectHeat conduction barrierWallsWater-setting substance layered productInsulation layerReinforced concrete

The invention provides a steel structure assembled type EPS (Electric Power Storage) module sandwiched heat-insulation composite wall body. The wall body comprises a steel structure framework composed of a profile steel stand column and a profile steel transverse beam, and a wall plate mounted on the steel structure framework, wherein the wall plate is a sandwiched heat-insulation composite wall plate composed of a reinforced concrete enhancement layer, an EPS module heat-insulation layer and a steel wire net concrete protection layer; an outer edge of the EPS module heat-insulation layer is arranged at the periphery of the reinforced concrete enhancement layer; the size of the EPS module heat-insulation layer is the same as that of the steel wire net concrete protection layer; pre-embedded connection pieces are arranged on four side surfaces of the reinforced concrete enhancement layer; the reinforced concrete enhancement layer of the sandwiched heat-insulation composite wall plate is partially nested in the steel structure framework and is connected with the steel framework through the pre-embedded connection pieces; the outer edge of the EPS module heat-insulation layer, which is located at the periphery of the reinforced concrete enhancement layer, covers the outer surface of the steel structure framework. The steel structure assembled type EPS module sandwiched heat-insulation composite wall body is rapid in construction speed and has a good whole energy-saving and heat-insulation effect and small heat energy loss.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

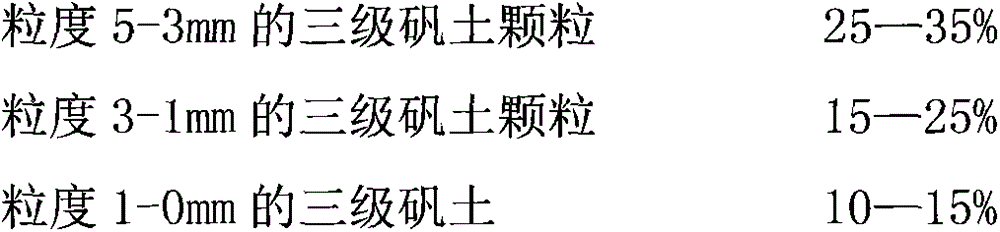

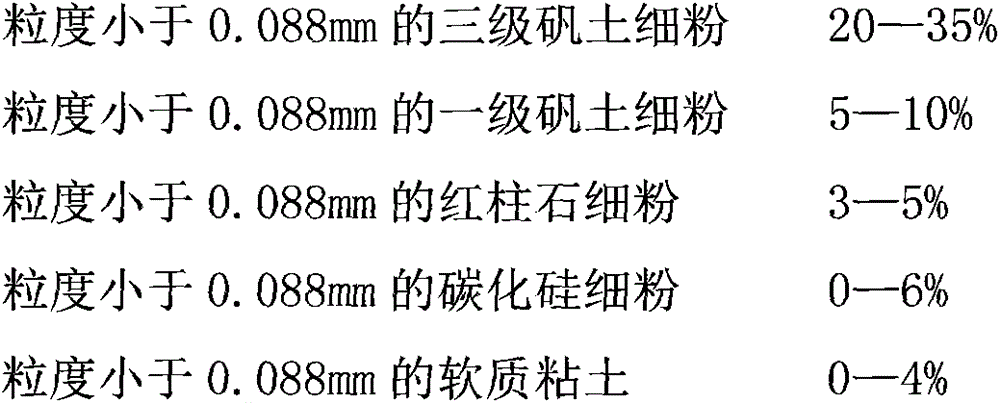

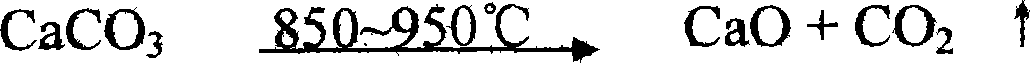

Modified high-alumina brick for cold ends of calcining zone and transitional zone of cement kiln and method for preparing high-alumina brick

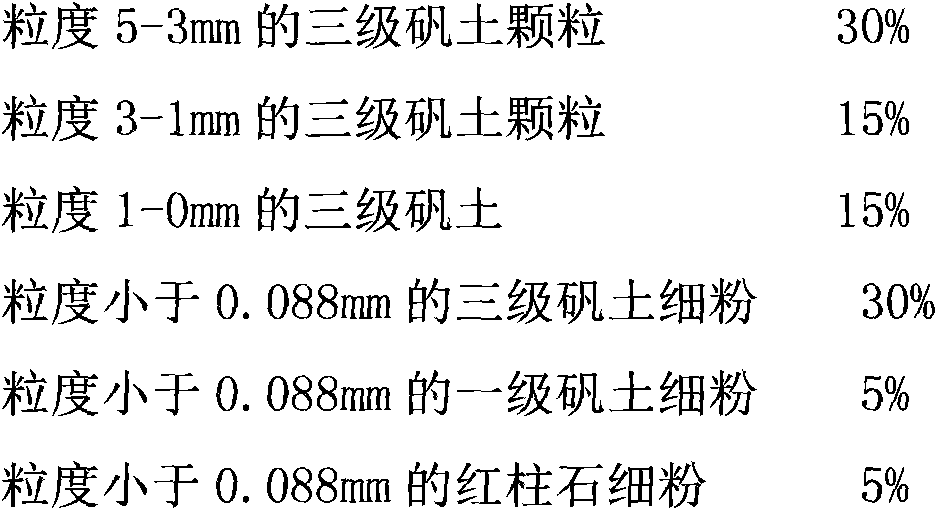

The invention relates to a modified high-alumina brick for cold ends of a calcining zone and a transitional zone of a cement kiln and a preparation method of a high-alumina brick. The modified high-alumina brick comprises the following materials: 25-35 percent of tertiary alumina particles with granularity of 5-3mm, 15-25 percent of tertiary alumina particles with granularity of 3-1mm, 10-1 percent of tertiary alumina with granularity of 1-0mm, 20-35 percent of tertiary alumina fine powder with granularity of smaller than 0.088mm, 5-10 percent of primary alumina fine powder with granularity of smaller than 0.088mm, 3-5 percent of andalusite fine powder with granularity of smaller than 0.088mm, 0-6 percent of silicon carbide fine powder with granularity of smaller than 0.088%, 0-4 percent of soft clay with granularity of smaller than 0.088mm, and a binding agent which accounts for 3-7 percent of the gross weight of the above raw materials. The preparation method comprises the following steps: mixing and rolling the raw materials according to proportion, then ageing for 16-24h, pressing for shaping, introducing the shaped material into a kiln to be dried for more than 24h at the temperature of 120-140 DEG C, calcining at the firing temperature of 1300-1400 DEG C, and carrying out heat preservation for 6-8h to obtain the high-alumina brick. The modified high-alumina brick is reasonable in alkali resistance and thermal shock resistance and better in energy-saving and heat-insulating effects.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

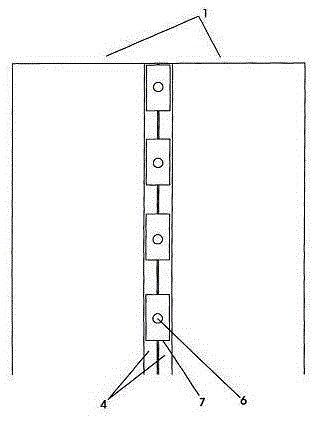

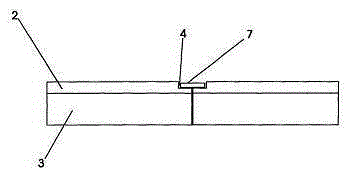

Light steel composite plate assembled house

The invention discloses a light steel composite plate assembled house. The house comprises a foundation, wall plates, floor plates and connecting profiles with grooves. The connecting profiles comprise foundation connecting profiles, wall plate connecting profiles and floor plate connecting profiles. The foundation connecting profiles are fixed on the house foundation, the wall plate connecting profiles are vertically fixed on the foundation connecting profiles, and bottoms of the wall plates are inserted and fixed in grooves of the foundation connecting profiles; the top ends of the wall plate connecting profiles are fixedly connected with the floor plate connecting profiles, and the tops of the wall plates are inserted and fixed in grooves of bottoms of the floor plate connecting profiles; and the floor plates are connected with the floor plate connecting profiles in an inserting or lap joint mode. The light steel composite plate assembled house has the advantages that a mixed structural system formed by the connecting profiles (a light steel structure can be selected) and the wall plates and the floor plates made of high-strength composite insulating plates is provided, parts such as outer wall plates, inner wall plates and the floor plates are effectively integrated with the connecting profiles serving as building unit plate connecting members, and a single-story or multi-story building house is formed.

Owner:陈久旺

Oil shale slag lightweight high-strength haydite and producing method thereof

InactiveCN101215145AHas paddingFunctionalCeramic materials productionCeramicwareSlagExpanded clay aggregate

The invention relates to oil shale slag haydites with light mass and high strength and the production method thereof, which belongs to constructional material. The invention is composed of oil shale slag, gas evolution materials, plasticizing materials and stable gas evolution materials according to the ratio of weight parts, grinding with materials, stirring with pre-watering, granulating by granulator after even agitation, then being sent into rotating kiln with double cylinders by belt conveyer for preheating, drying, roasting and cooling, the rotating kiln with double cylinders takes coal powders as the fuel, spraying the coal powders into the rotating kiln with double cylinders according to the speed and the dosage via speed variable motor driving screw conveyer and fan, controlling the preheating temperature between 450-850 DEC G and the calcination temperature between 1150-1250 DEC G. The invention has the advantages that utilizing the discarded oil shale slag to produce the haydite is an innovation. Further, the invention not only changes waste into valuable, but also is environment-friendly and has distinctive economic benefit and social benefit.

Owner:吉林省建筑材料工业设计研究院

Heat-insulating energy-saving flame-retardant material for external wall

InactiveCN102173680AGood energy saving and heat preservation effectGood flame retardant performanceCeramicwarePolypropylenePerlite

Owner:应急管理部四川消防研究所

Preparation method of integral-type vacuum heat insulation and temperature preservation plate

InactiveCN102635171AHas a leak rateReduce air leakage rateClimate change adaptationInsulation improvementInorganic materialsGetter

The invention discloses a preparation method of an integral-type vacuum heat insulation and temperature preservation plate, and belongs to the technical field of an outer temperature preservation material for building outer walls. The technical scheme to be solved is that a preparation method of a vacuum heat insulation and temperature preservation plate which has a plate-type core material, has good integrity, is low in air leakage rate, and prevents cold and hot bridge is provided. According to the technical scheme, the preparation method comprises the following steps of: step one, manufacturing a core material plate; step two, loading the core material plate, and step three, vacuumizing and packaging. According to the invention, different from the prior art that the core material is in a powder shape, the plate provided by the invention has the advantages that an inorganic material is synthesized into the plate material, and a special bonding material is adopted for bonding the core material and the packaging layer together, thus the temperature preservation plate has the integrity; the core material plate is adopted and drilled for holding an air absorption agent, the quantity and position are distributed scientifically, and the long-lasting vacuum degree is ensured; and the air leakage rate is lowered by a dual-seal mode.

Owner:陈宏宇

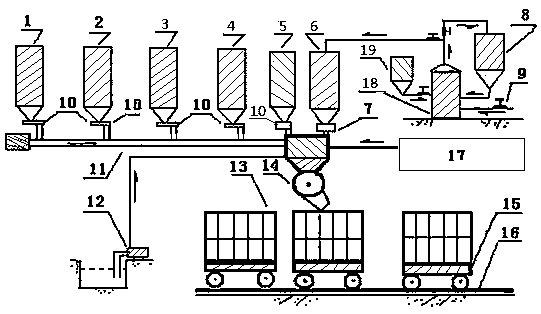

Production method for iron furnace slag light building block

InactiveCN106393416AEasy to buryImprove machinabilityMixing operation control apparatusCeramic shaping plantsEcological environmentSlag

The invention discloses a production method for an iron furnace slag light building block. A formula of the iron furnace slag light building block comprises iron furnace slag, chimney ash, perlite and cement which form dry blend; every ton of dry blend is mixed with polystyrene particles, water and various additives; a production system consists of hoppers, a stock bin, a polystyrene granule extruder, electronic scales, a scraper conveyer, a water pump, a stirrer, a mould assembly, a light rail and various additive bins. The production system is characterized in that the outlet of each hopper and the outlet of each bin are equipped with the electronic scale controlled by a computer, and each electronic scale is in butt joint with the scraper conveyor; the scraper conveyor is connected with a feed end of the stirrer; an outlet of a polystyrene granule bin is connected with the stirrer; the extruder is connected with a steam pipe; the stirrer is connected with a water outlet tube of the water pump; a mould car is arranged on the light rail; the mould assembly is arranged on the mould car, and is in butt joint with the outlet of the stirrer; and a mould is filled with a wet mixture for moulding, the wet mixture is manually de-molded, and is maintained by applying water. According to the production method disclosed by the invention, waste can be changed into things of value, and the formula is non-toxic, flavorless and free of radioactive contamination, and therefore, the iron furnace slag light building block is a pure natural, green, healthy and ecological environment-friendly wall.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

Modified polyurethane material, exterior-wall decorative energy-saving plate and preparation method thereof

The invention discloses a modified polyurethane material, an exterior-wall decorative energy-saving plate and a preparation method thereof, aims at solving technical problems that the existing decorative thermal-insulation plate is heavy, water-funk, inflammable, easy to crack, easy to drop and complex in construction. The modified polyurethane comprises the following components: polyester polyol, a foaming agent, a foam stabilizer, tin dibutyl, melamine, a flame retardant, glass beads, isocyanate and a catalyst; the exterior-wall decorative energy-saving plate made of the polyurethane comprises a base layer, a decorative layer and a thermal-insulation flame-retardant layer packaged between the base layer and the decorative layer; and the production method of the exterior-wall decorative energy-saving plate comprises seven steps. The exterior-wall decorative energy-saving plate produced by the preparation method in the invention has the advantages of being good in decorative effect, thermal-insulation, fireproof, waterproof, high in strength, un-cracked, long in service life, simple to construct, and the like.

Owner:HENAN SIHONG IND

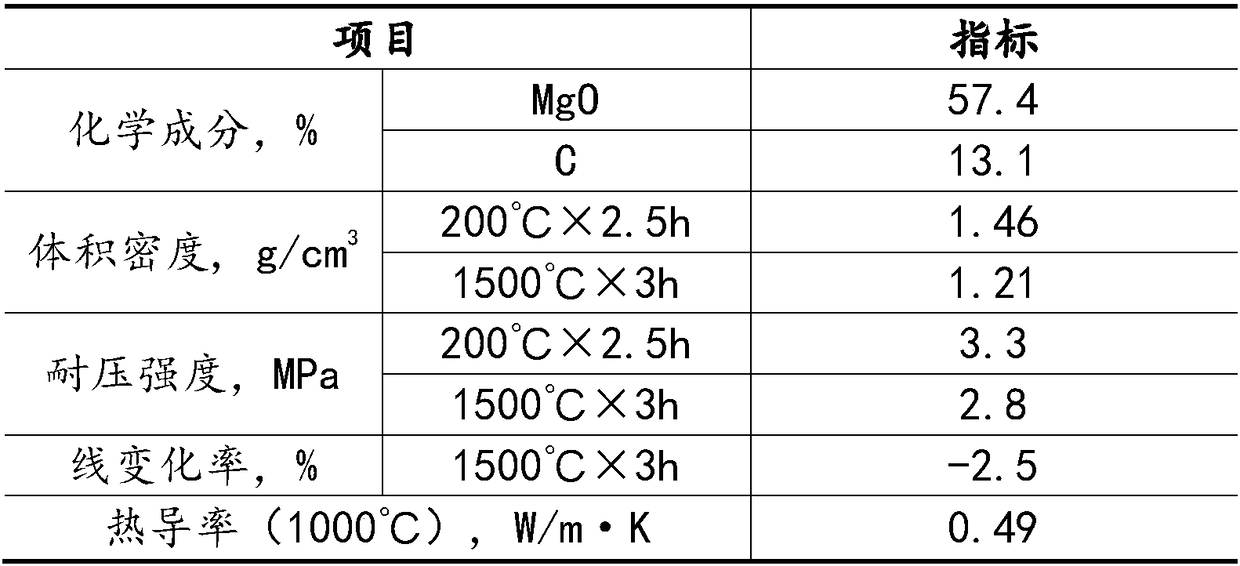

Light tundish working lining and method for preparing same

ActiveCN108530090AImprove corrosion resistanceObvious volume shrinkage (≤-4.0%) phenomenonCeramic materials productionClaywaresFiberBrick

The invention discloses a light tundish working lining and a method for preparing the same. Ingredients for the light tundish working lining comprise waste magnesia-carbon bricks, magnesite tailing, aluminum oxide, fibers, compound bonding agents and additives. The method for preparing the light tundish working lining includes dry vibration forming or wet smearing forming. The light tundish working lining and the method have the advantages that the light tundish working lining prepared by the aid of the method is low in volume density, erosion rate, cost and consumption and long in service life, energy can be saved, and the like. Besides, the problem of excessive consumption of resources of existing refractory raw materials (including waste magnesia-carbon brick reclaimed materials and thelike), the problems in the aspects of energy conservation and heat preservation and the like can be solved by the aid of the light tundish working lining and the method.

Owner:PUYANG REFRACTORIES GRP CO LTD

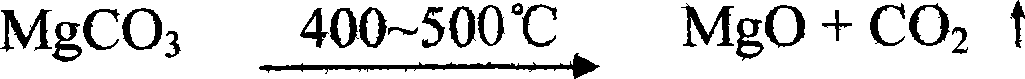

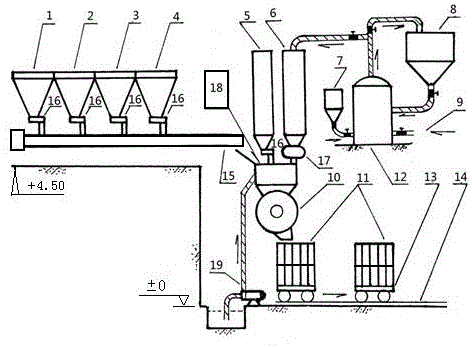

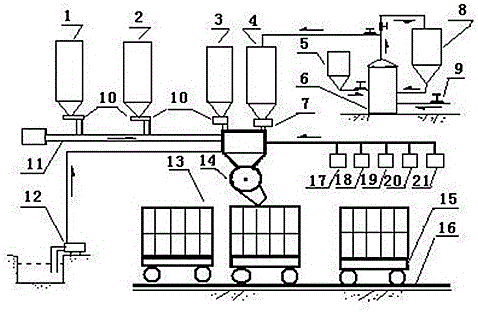

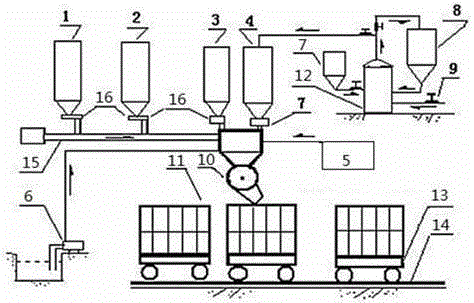

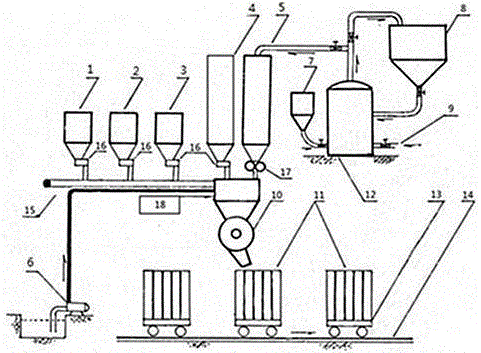

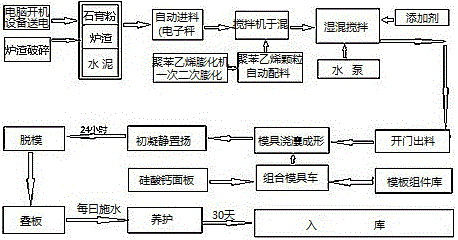

Coal ash foam building block production method

InactiveCN106042144AGood energy saving and heat preservationLow thermal conductivityFeeding arrangmentsLight railGypsum

The invention provides a coal ash foam building block production method. According to a formula, a dry blend is composed of coal ash, blast furnace slag, gypsum powder, perlite and cement, and polystyrene particles, water and various additives are added in each ton of dry blend. A production system is composed of hoppers, stock bins, a polystyrene particle puffing machine, electronic scales, an auger conveyor, a water pump, a stirring machine, mold trolleys, a light rail and a bin for the various additives. The production system is characterized in that the electronic scales which are controlled by a computer are installed at outlets of the stock bins correspondingly and are in butt joint with the auger conveyor, the auger conveyor is connected with the feeding end of the stirring machine, and an outlet of a polystyrene particle bin is connected with the stirring machine; the puffing machine is connected with a steam pipe; the stirring machine is connected with a water pump water outlet pipe; the mold trolleys are arranged on the light rail, and mold assemblies are arranged on the mold trolley and are in butt joint with an outlet of the stirring machine; and wet blends are poured into molds for formation, manual demolding is conducted, and water is poured for curing. According to the coal ash foam building block production method, waste can be changed into valuable materials, the formula is nontoxic and free of odor and radioactive contamination, and coal ash foam building blocks produced through the method are pure-natural, green, healthy, ecological and environment-friendly wall materials.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

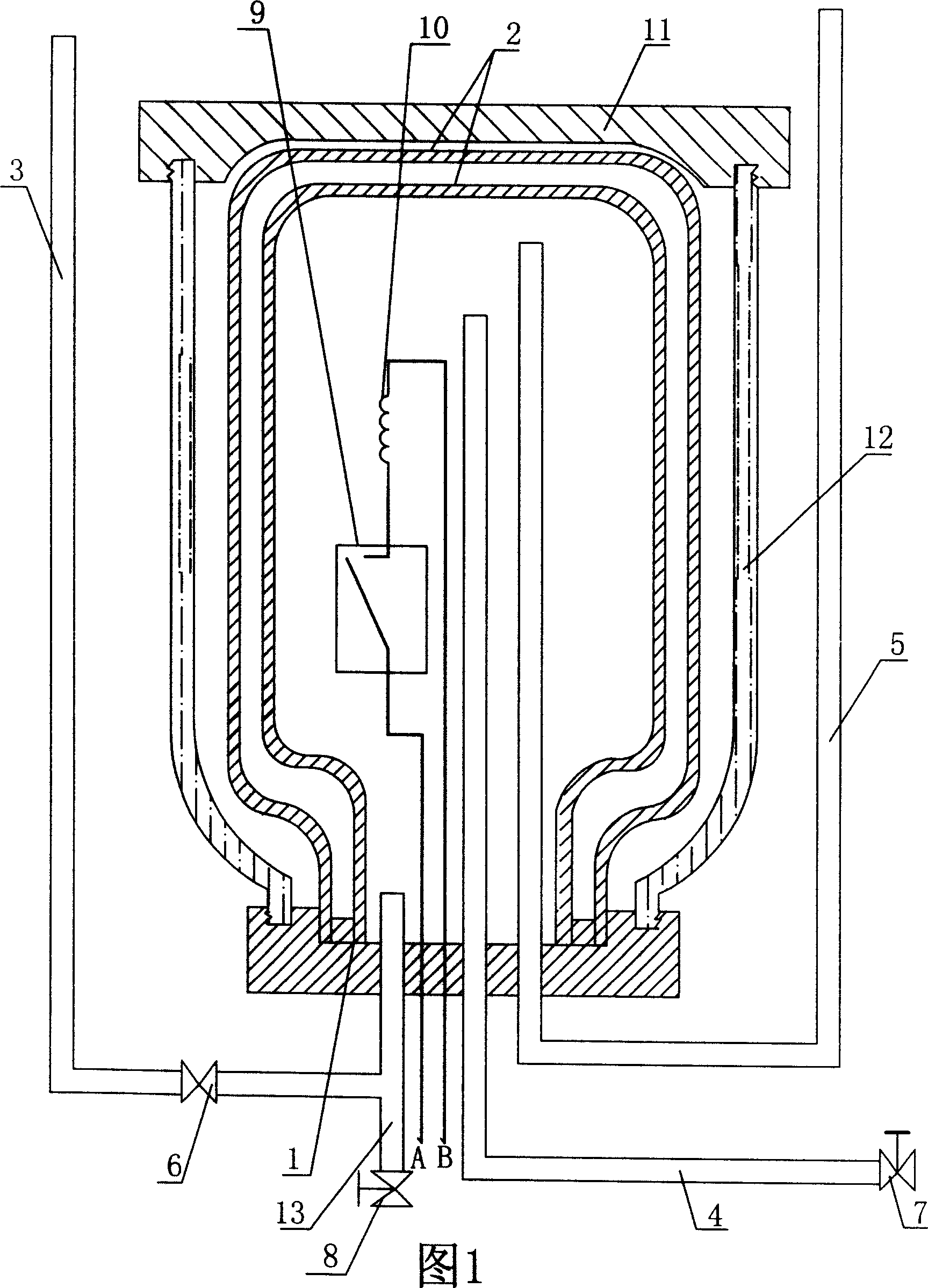

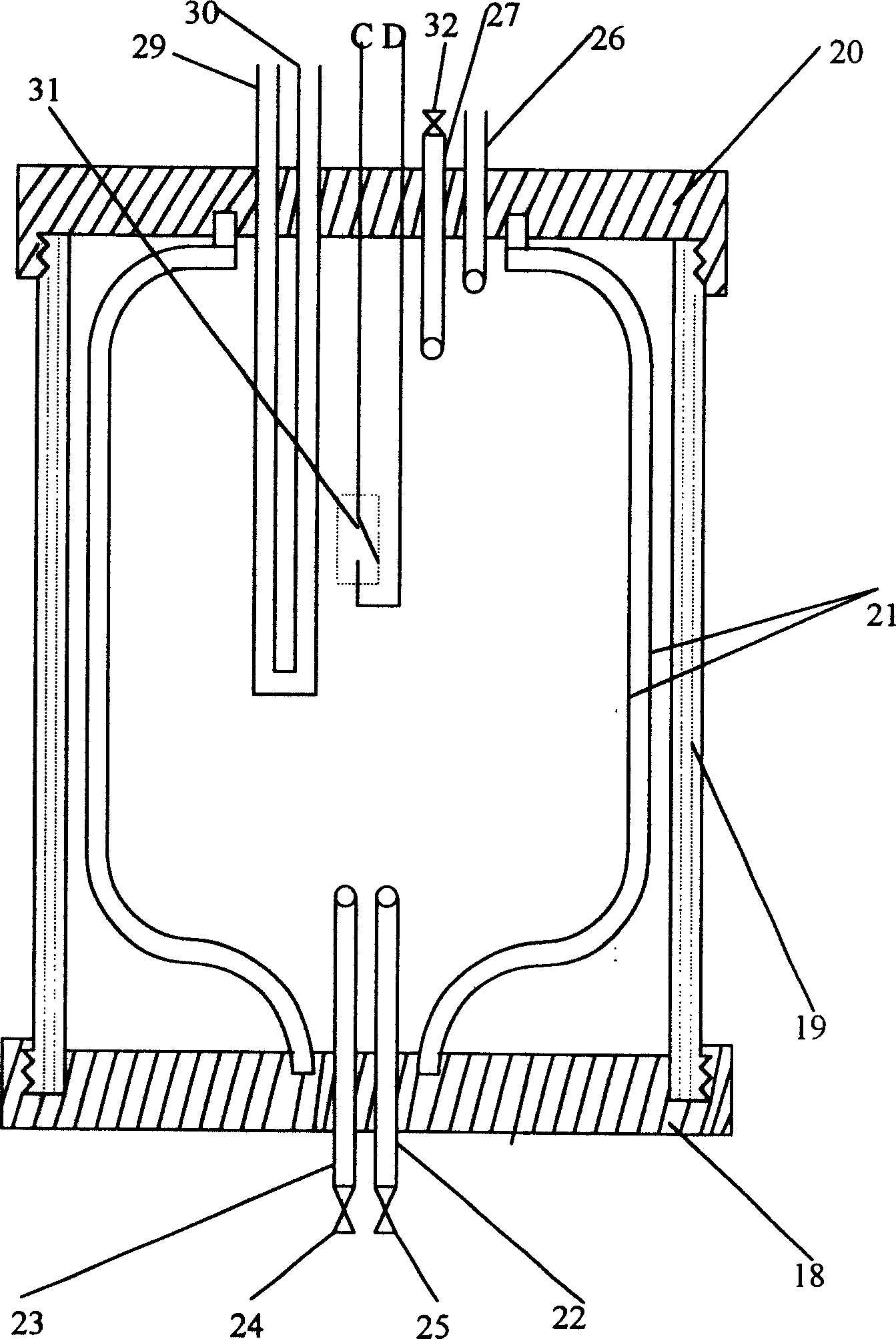

Energy saving drinking water apparatus

InactiveCN1751636AGood energy saving and heat preservation effectImprove thermal insulation and energy savingLiquid flow controllersBeverage vesselsRefrigeration compressorIce water

An energy-saving drinking water appliance is composed of an insulating hot water bottle A with a plug A, the water outlet tube, water inlet tube, air tube and blow-off tube, all of which pass through the plug A, the serially connected electric heater and temp-controlled switch in said bottle A, an insulated ice water bottle B with a plug B, the refrigerating tubes, water inlet tube and air tube, which are arranged on the plug B, and the water outlet tube and blow-off tube, which are arranged on another plug. Said bottle A and B have a dual-layer vacuum structure and a heat reflecting layer plated on their inner surfaces.

Owner:黄跃明

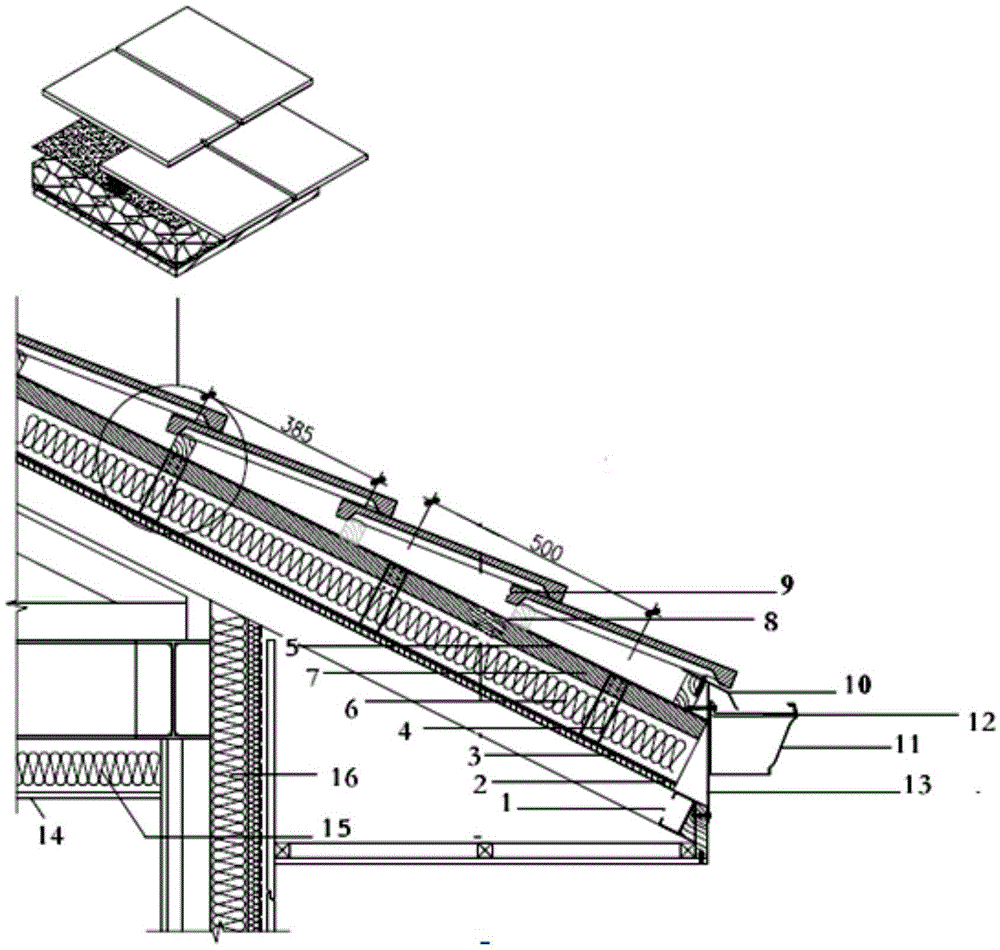

Light steel structure passive type low-energy-consumption energy-saving roof system and dry construction method

ActiveCN105649251AGood energy saving and heat preservation effectSimple construction processBuilding roofsRoof covering insulationsArchitectural engineeringDeep processing

The invention provides a light steel structure passive type low-energy-consumption energy-saving roof system and a dry construction method. The construction method of the roof system comprises the steps of laying an oriented structural board (OSB) on a galvanized steel roof truss; laying a first waterproof roll on the oriented structural board (OSB); mounting counter batten supports on the first waterproof roll at an equal interval, and laying a second waterproof roll on the top faces of the counter batten supports; embedding second insulation boards between the first waterproof roll and the second waterproof roll at an equal interval; mounting counter batten between the second insulation boards and the second waterproof roll; fixing multiple roof battens on the second waterproof roll at an equal interval; overlapping multiple roof tiles at the top of each roof batten in a staggered mode. The light steel structure passive type low-energy-consumption energy-saving roof system and the dry construction method have the advantages that on the basis that building expense is not increased and even decreased, the excellent energy-saving and heat preservation effect is achieved through deep processing of the building structure, the construction process is simple, safety and high efficiency are achieved, no pollution is caused, and the system is a safe, firm and livable building which can achieve housing industrialization.

Owner:LJLZ BEIJING BUILDING MATERIALS CO LTD

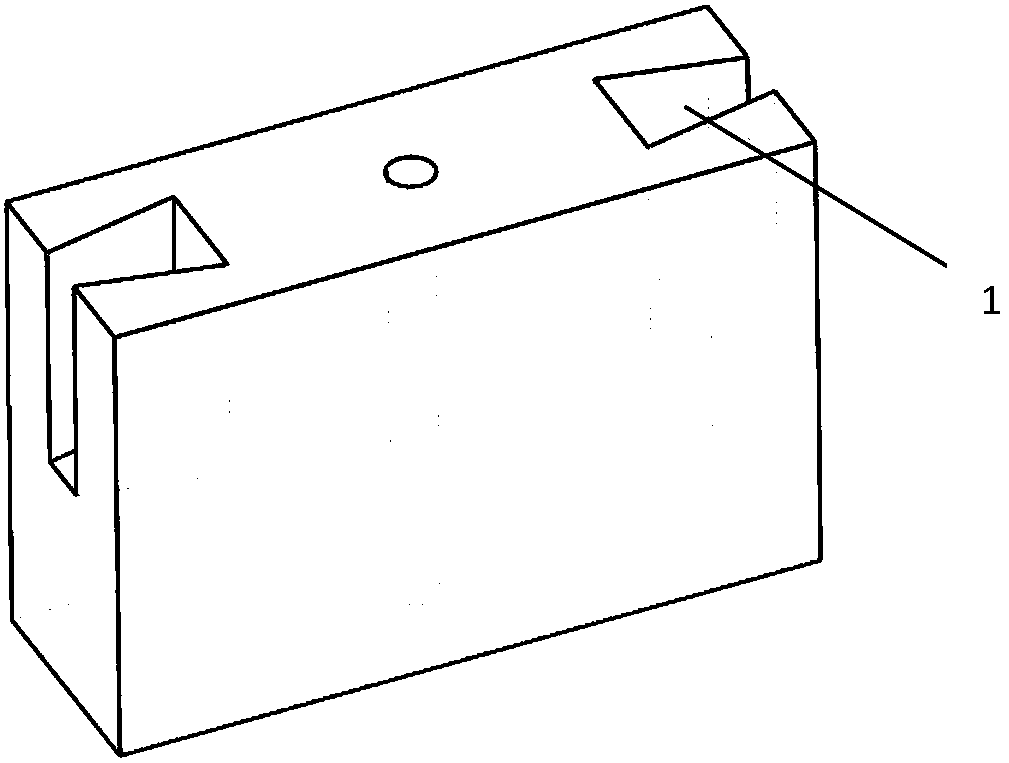

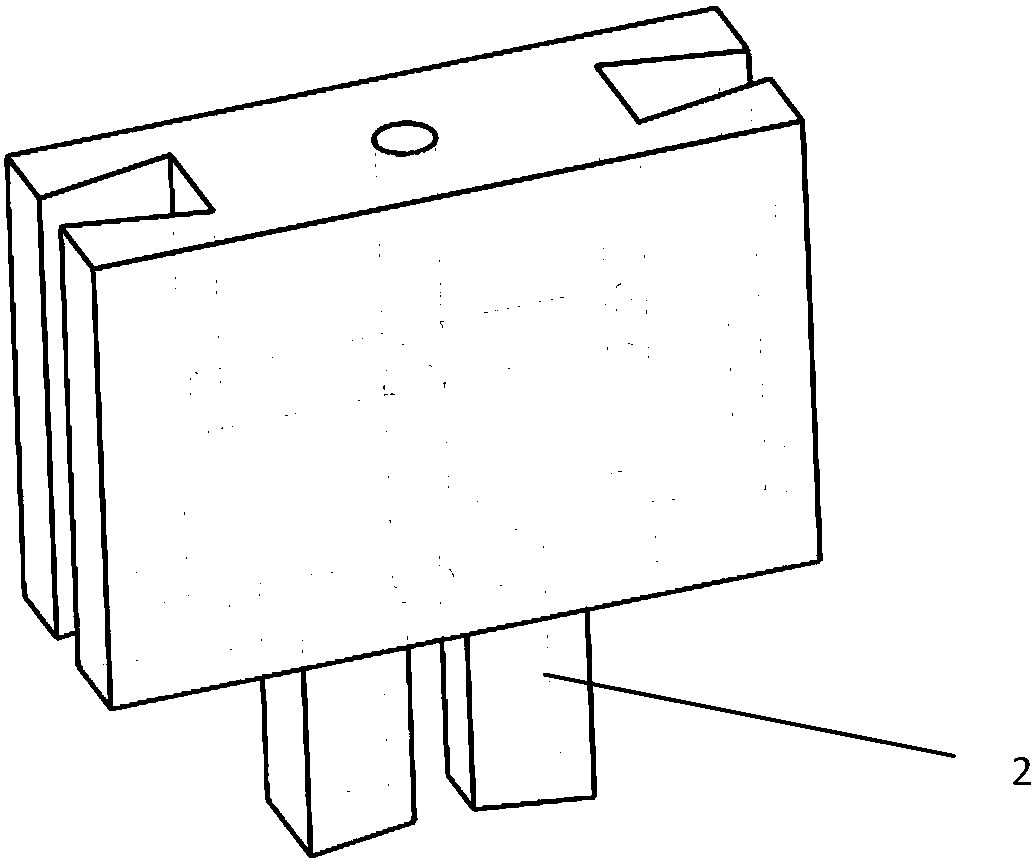

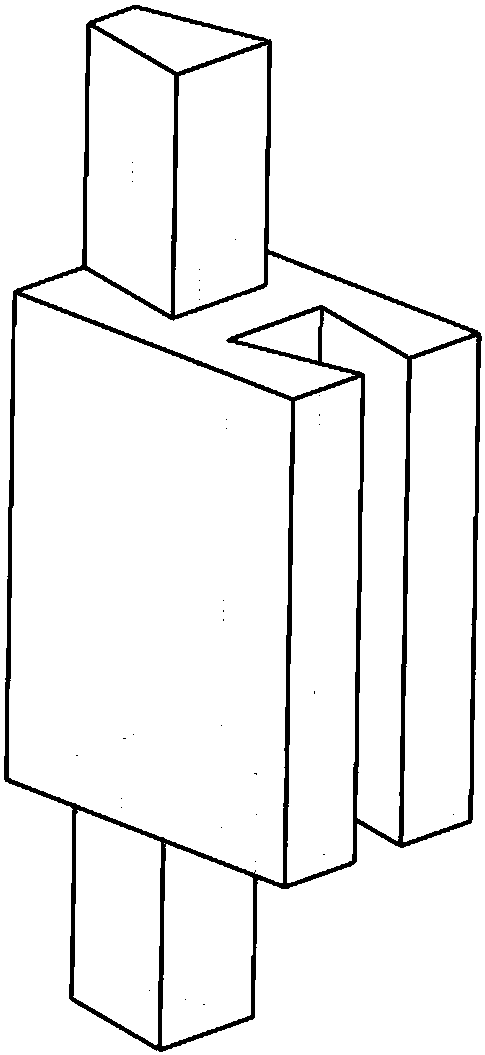

Novel filler wall for green assembly mode

The invention provides a novel filler wall for a green assembly mode. The filler wall is formed by assembling components which comprise a lower plate, a middle connecting plate, an end connecting plate, an L-shaped connecting plate and / or T-shaped connecting plate and an upper cover plate. For the connecting mode of the components, traditional bonding with mortar is abandoned but a new locking connecting mode is adopted; all components are linked with one another and it seems like that the components are locked; not a single one can be dispensed with while the components are inhibited mutually; the installation is proper and the filler wall has excellent integrity. The components are provided with power lines therein which are easy to install and uninstall. The components of the wall are overlapped vertically so as to avoid problems such as water seepage and air leakage; the wall has excellent energy insulation effect and is durable; the top of the wall adopts rubber damping member toconnect with the floor for excellent damping performance. The components are mainly made of wood chips and wood flame retardants, which reduces design cost and reduce the consumption of building material.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

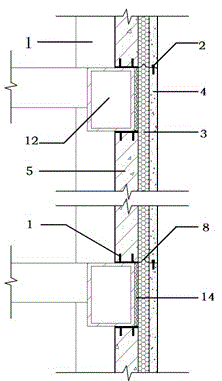

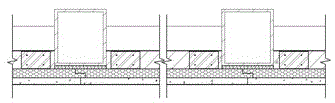

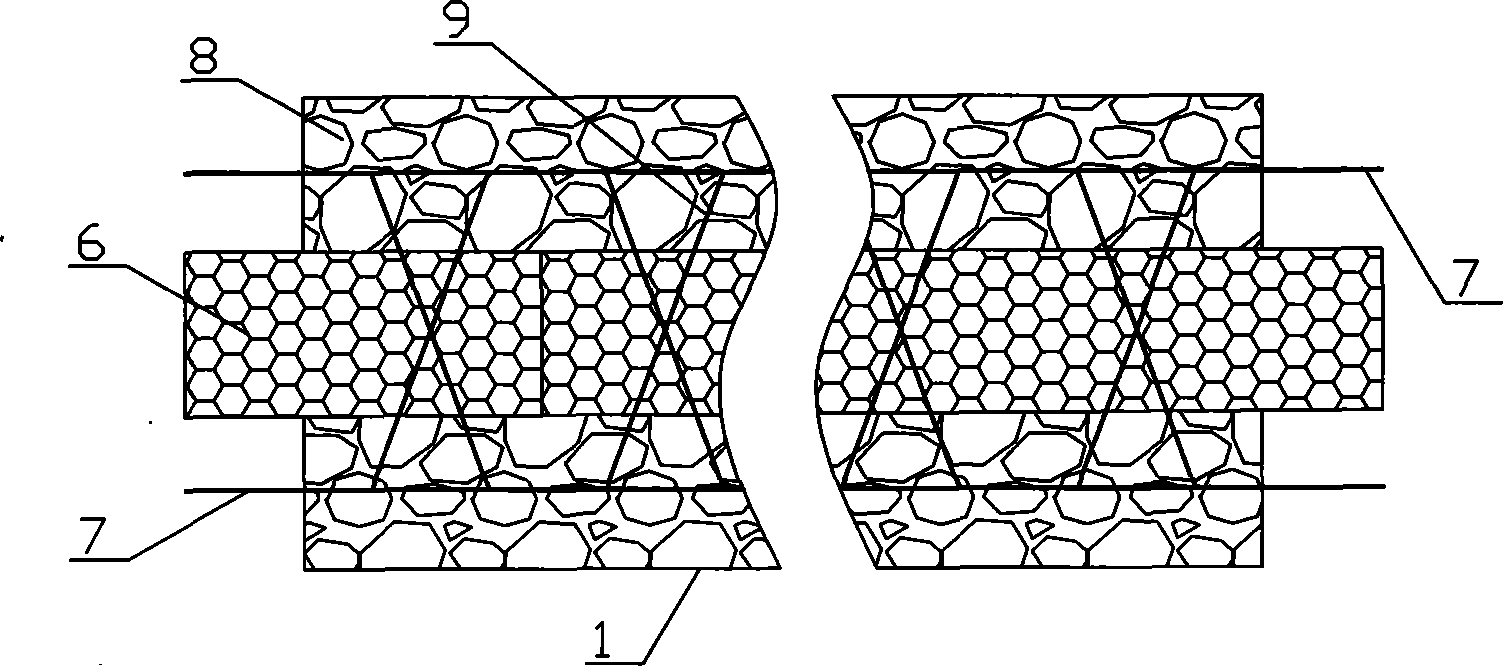

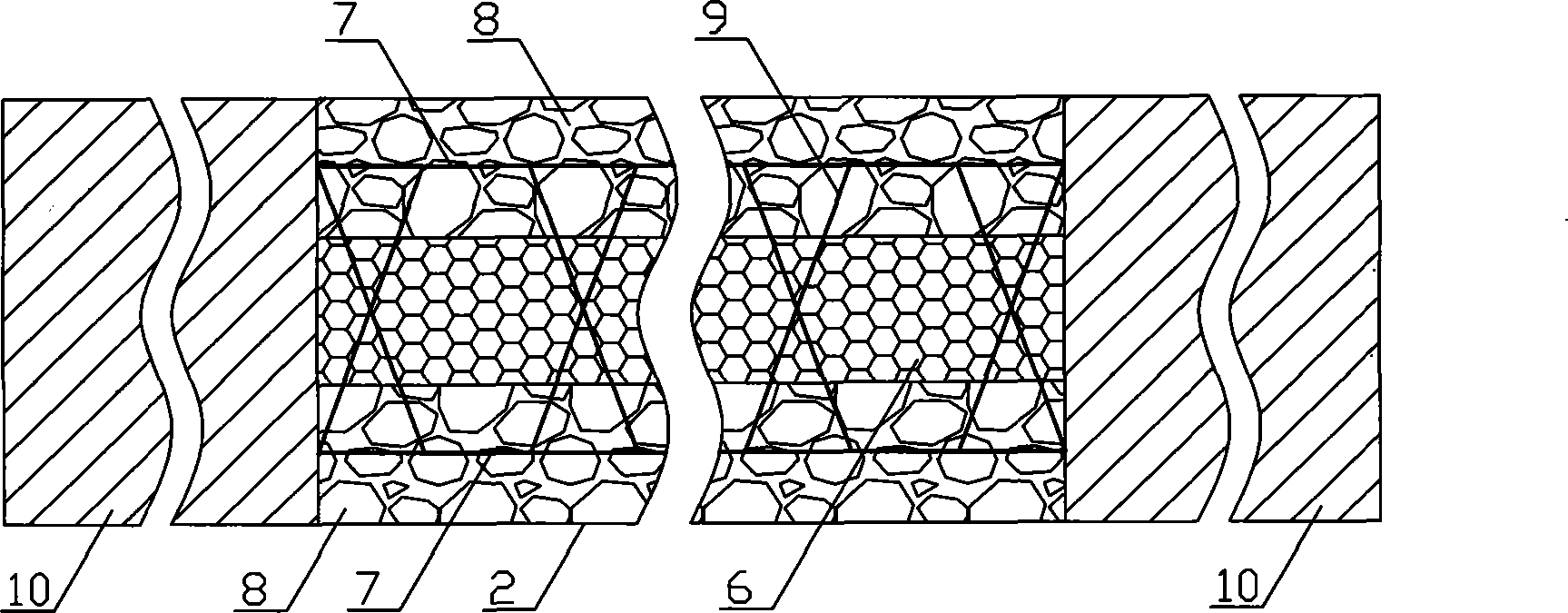

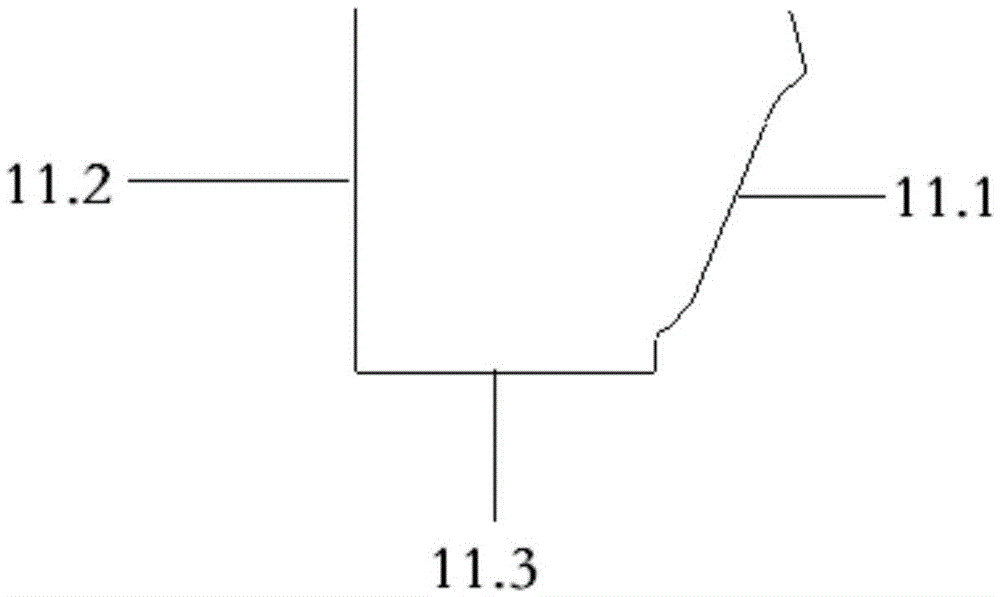

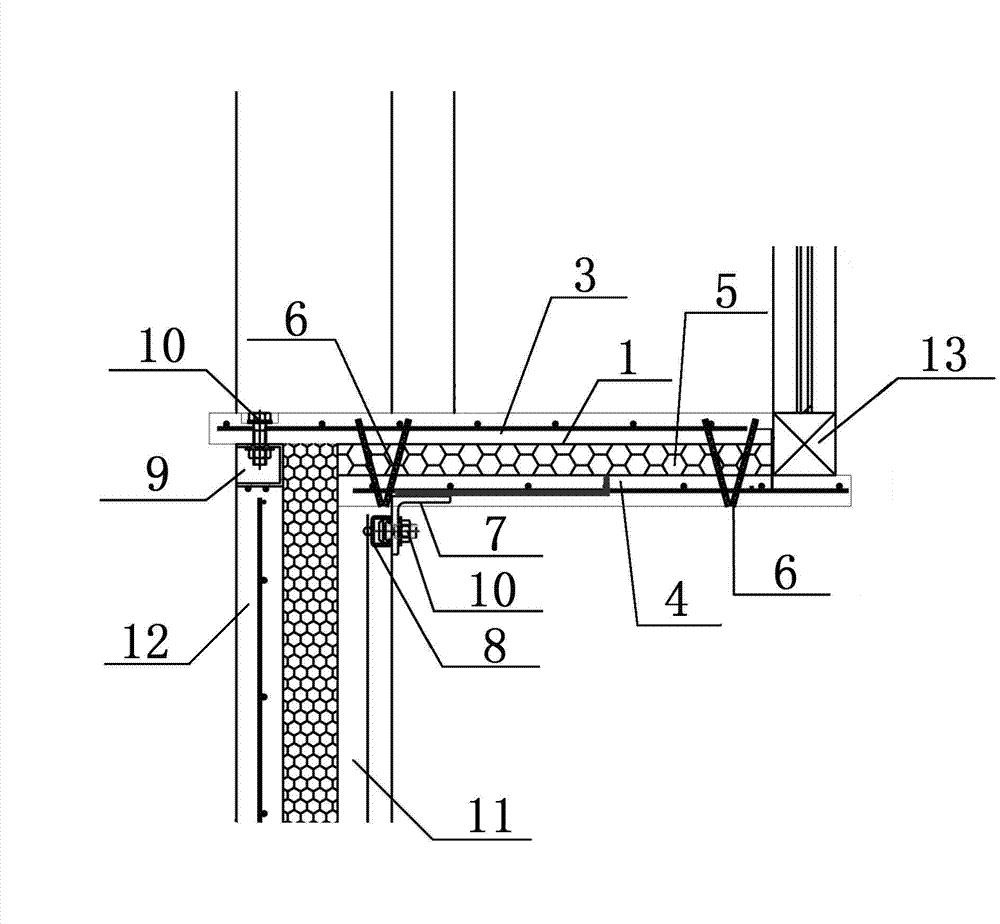

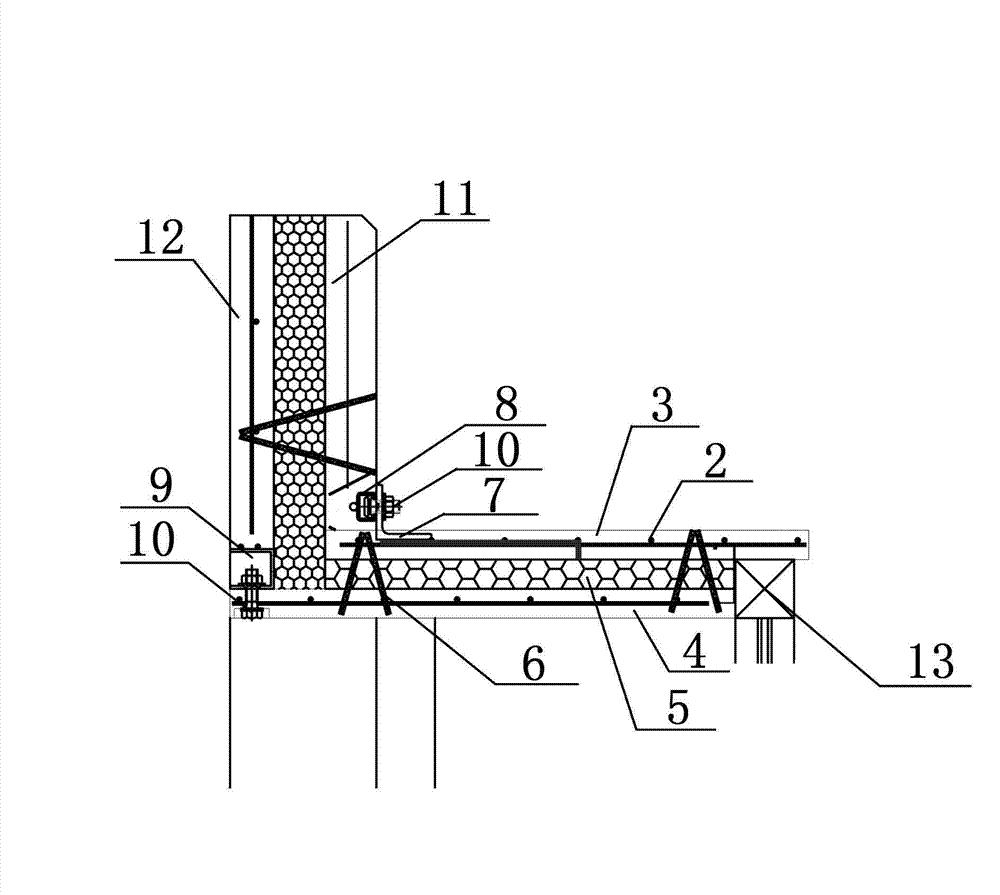

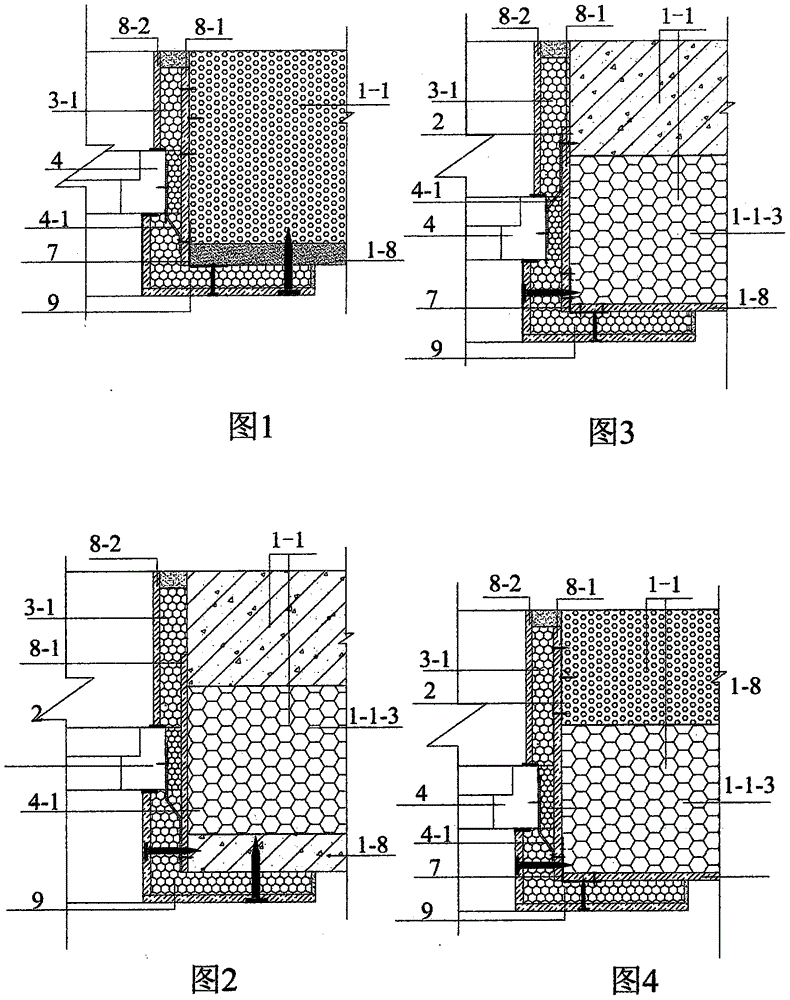

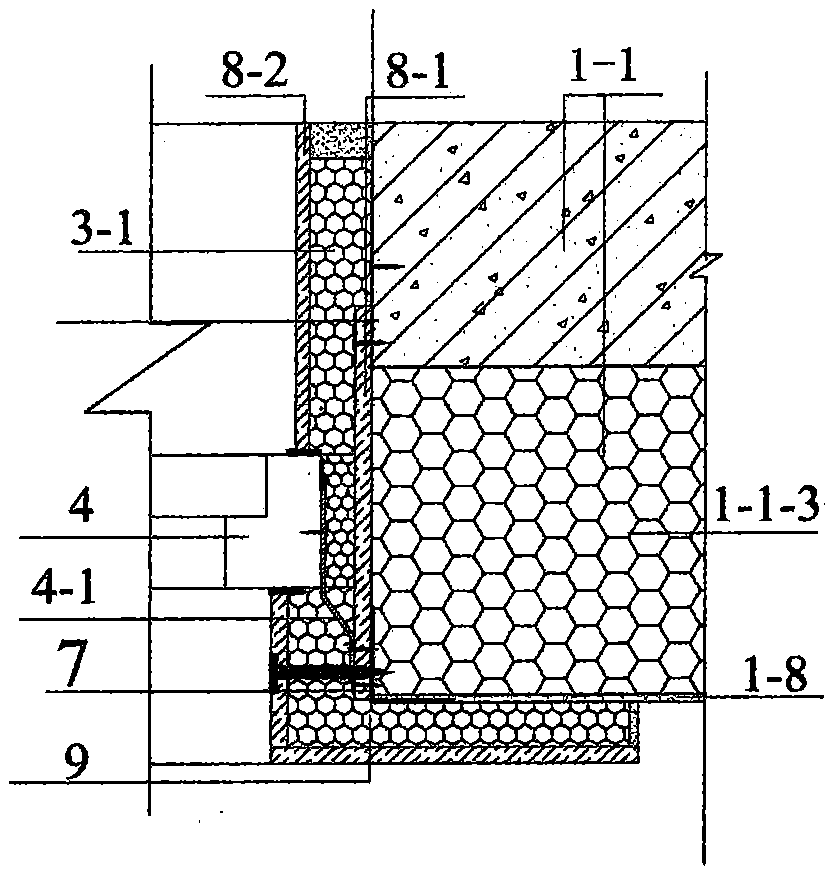

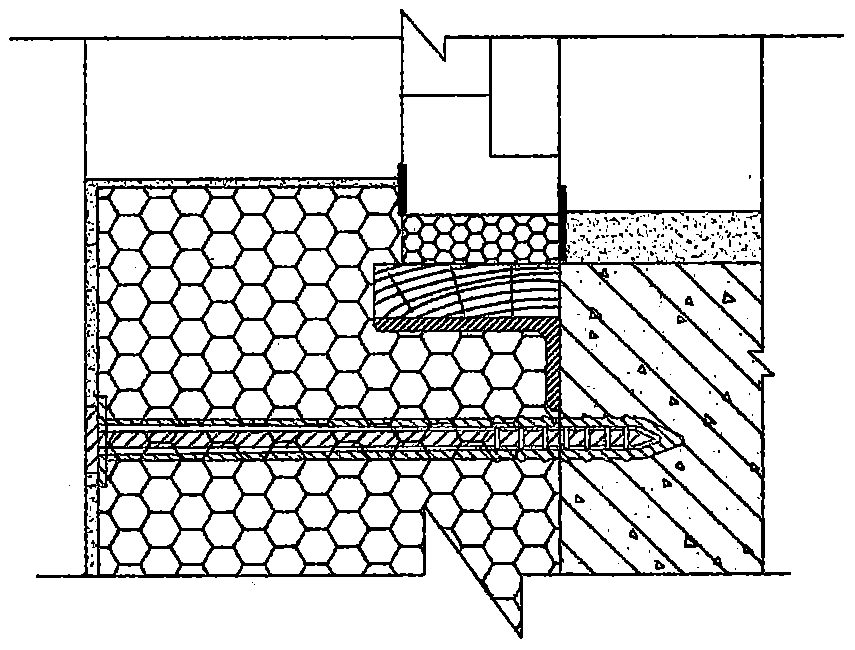

Heat-bridge-insulation bay window

ActiveCN103089113AImprove transportation efficiencyPrevent intrusionSills/thresholdHeat proofingHeat transmissionEmbedded system

A heat-bridge-insulation bay window comprises a bay-window upper window board and a bay-window lower window board. The bay-window upper window board and the bay-window lower window board are laminboards with thermal insulated materials. Inner boards and outer boards of the laminboards are obliquely connected in a bidirectional mode by nonmetal complex fiber reinforcement. Angle steel connectors are embedded in the bay-window upper window boards and the bay-window lower window boards. Connecting grooves and embedded steel boxes are respectively embedded in an outer sandwiched heat-insulation wall panel and an inner sandwiched heat-insulation wall panel. The bay-window upper window boards and the bay-window lower window boards are respectively fixedly connected with the embedded connecting grooves of the outer sandwiched heat-insulation wall panel and the embedded steel boxes of the inner sandwiched heat-insulation wall panel through ultra-strong connecting bolts. The heat-bridge-insulation bay window can effectively insulate heat transmission from outside to achieve heat preservation in an energy-saving way, factory-like mass manufacturing and field assembly can be realized, construction is convenient, and manufacturing efficiency is high.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

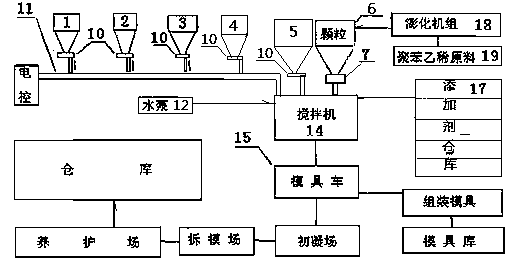

Slag partition wall light building block producing method

The invention discloses a slag partition wall light building block producing method.According to the formula, a dry mixture is composed of 25-30% of coal slag ash, 20-25% of slag and 45-50% of 425#cement, and 2.3-2.5 cubic meters of polystyrene particles, 23-25% of water and 1.5% of various additives are added into each ton of the dry mixture.A producing system is composed of stock bins, a polystyrene particle bulking machine, electronic balances, a packing auger conveyor, a water pump, a stirring machine, a mold vehicle, a light rail and various additive libraries.The producing system is characterized in that outlets of the stock bins are provided with computer-controlled electronic balances to be butt-jointed to the packing auger conveyor, the packing auger conveyor is connected with the feeding end of the stirring machine, an outlet of the polystyrene particle stock bin is connected with the stirring machine, the bulking machine is connected with a steam pipe, the stirring machine is connected with a water pump water outlet pip, the light rail is provided with the mold vehicle, the mold vehicle is provided with a mold assembly, and the mold assembly is butt-jointed to the stirring machine.The method can recycle waste materials, the formula is nontoxic, odorless and free of radioactive contamination, and a slag partition wall light building block is the pure natural, pollution-free, healthy, ecological and environment-friendly wall material.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

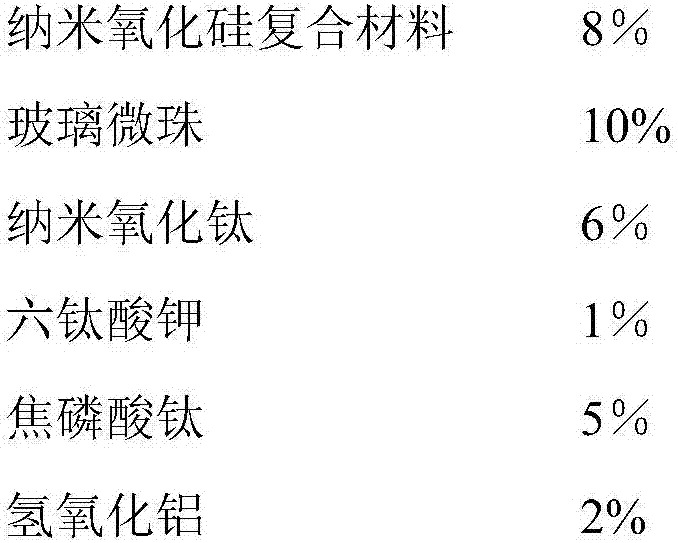

Aqueous heat-insulation heat-preservation fireproof material and preparation method thereof

ActiveCN107057479AReduce heat transfer efficiencyRealize heat self-consumption functionFireproof paintsReflecting/signal paintsMetasilicateAluminum silicate

The invention discloses an aqueous heat-insulation heat-preservation fireproof material. The aqueous heat-insulation heat-preservation fireproof material is prepared from the following components in percentage by weight: 8 to 20 percent of nano silicon oxide composite material obtained by compounding structurally-controlled nano silicon oxide powder and a nano silicon oxide cake material with an ultrahigh specific surface area according to a proportion of 0.5:(1-5):1, 3 to 15 percent of glass micro-beads, 4 to 10 percent of nano titanium oxide, 1 to 8 percent of potassium titanate, 1 to 8 percent of titanium pyrophosphate, 1 to 3 percent of aluminum hydroxide, 1 to 3 percent of zinc borate, 1 to 3 percent of barium borate, 1 to 3 percent of calcium sodium metasilicate, 1 to 10 percent of aluminum silicate, 20 to 28 percent of acrylic hybrid emulsion, 1.5 to 3 percent of other assistants, and the balance of water. According to the aqueous heat-insulation heat-preservation fireproof material disclosed by the invention, the nano silicon oxide composite material obtained by compounding structurally-controlled nano silicon oxide powder and the nano silicon oxide cake material with the ultrahigh specific surface area as a core material, and by the components and corresponding optimized improvement of the proportions, the product has a good heat-flow stagnation function; and the heat conduction coefficient of the product is not more than 0.03W / (m.K), and the waterproof performance reaches A level.

Owner:上饶市安纳拓新材料有限公司

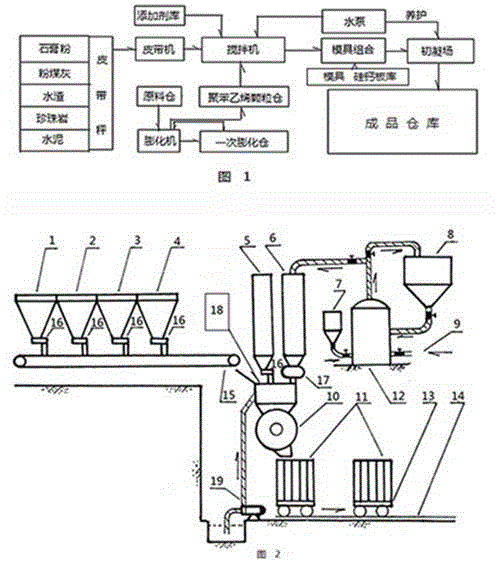

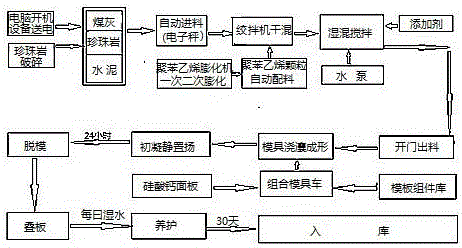

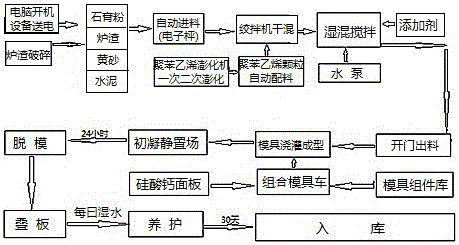

Coal cinder wallboard production method

The invention discloses a coal cinder wallboard production method. Raw materials, such as gypsum powder, coal ash, water granulated slag, perlite and cement, are prepared into a dry mixture; each tonnage of the dry mixture is added with polystyrene particles, water and additives. A production system consists of hoppers, a cement stock bin, a polystyrene particle bin, a raw material bin, a one-time swelled feed bin, a steam pipe, a stirring machine, a die combination, a particle swelling machine, a die trolley, a light rail, a belt machine, belt weighers, a volume meter, an additive base and a water pump. The coal cinder wallboard production method is characterized in that a forklift loads materials into the hoppers; the belt weighers controlled by a computer and the stirring machine butted with a belt conveyer for realizing feeding are arranged at the outlets of the hoppers and the outlet of the cement stock bin; a polystyrene raw material enters the polystyrene particle bin after being subjected to secondary swelling and then is conveyed into the stirring machine through the volume meter; water is added into the water pump for stirring, and a water mixture is poured into a die for forming; the die trolley transports products into an initial setting and purifying area for artificial demolding after the setting period; the products are taken down from the die trolley for stacking and subjected to watering maintenance everyday; after the final setting period, the products are delivered and installed; the whole production process is conducted under normal temperature; the products are purely natural, green, healthy, ecological and environment-friendly wall materials.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

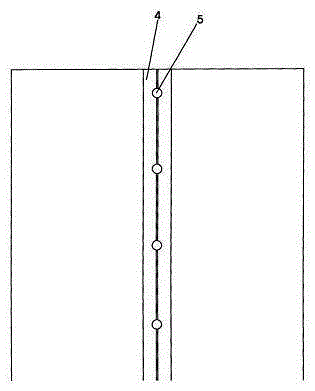

Integral-type vacuum heat insulation and temperature preservation plate

InactiveCN102635170AImprove integrityGood energy saving and heat preservationClimate change adaptationInsulation improvementLong lastingGetter

The invention discloses an integral-type vacuum heat insulation and temperature preservation plate, and belongs to the technical field of an outer temperature preservation material for building outer walls. According to the invention, the vacuum heat insulation and temperature preservation plate has a plate-type core material, has good integrity, is low in air leakage rate, and prevents cold and hot bridge. According to the technical scheme, a core material plate is positioned between two package layers; the peripheries of the two package layers are fused and connected; the plate surfaces of the core material plate are uniformly provided with a plurality of through holes; and air absorption agents are filled in the through holes; bonding agents are coated on two plate surfaces of the core material plate, thus the package layers and the surfaces of the core material plate are connected into a whole. According to the invention, different from the prior art that the core material is in a powder shape, the plate provided by the invention has the advantages that an inorganic material is synthesized into the plate material, and a special bonding material is adopted for bonding the core material and the packaging layer together, thus the temperature preservation plate has the integrity; the core material plate is adopted and drilled for holding the air absorption agents, the quantity and position are distributed scientifically, and the long-lasting vacuum degree is ensured; and the air leakage rate is lowered by a dual-seal mode.

Owner:陈宏宇

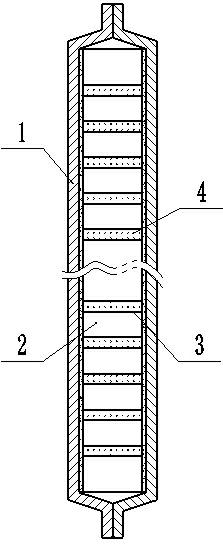

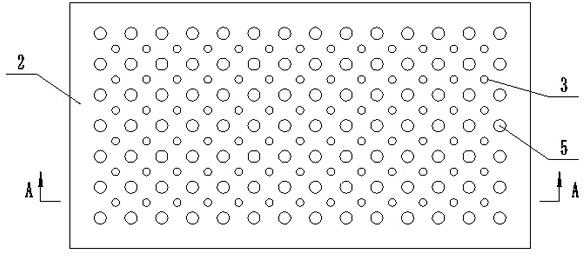

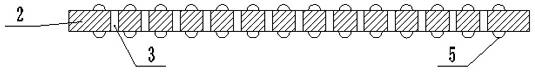

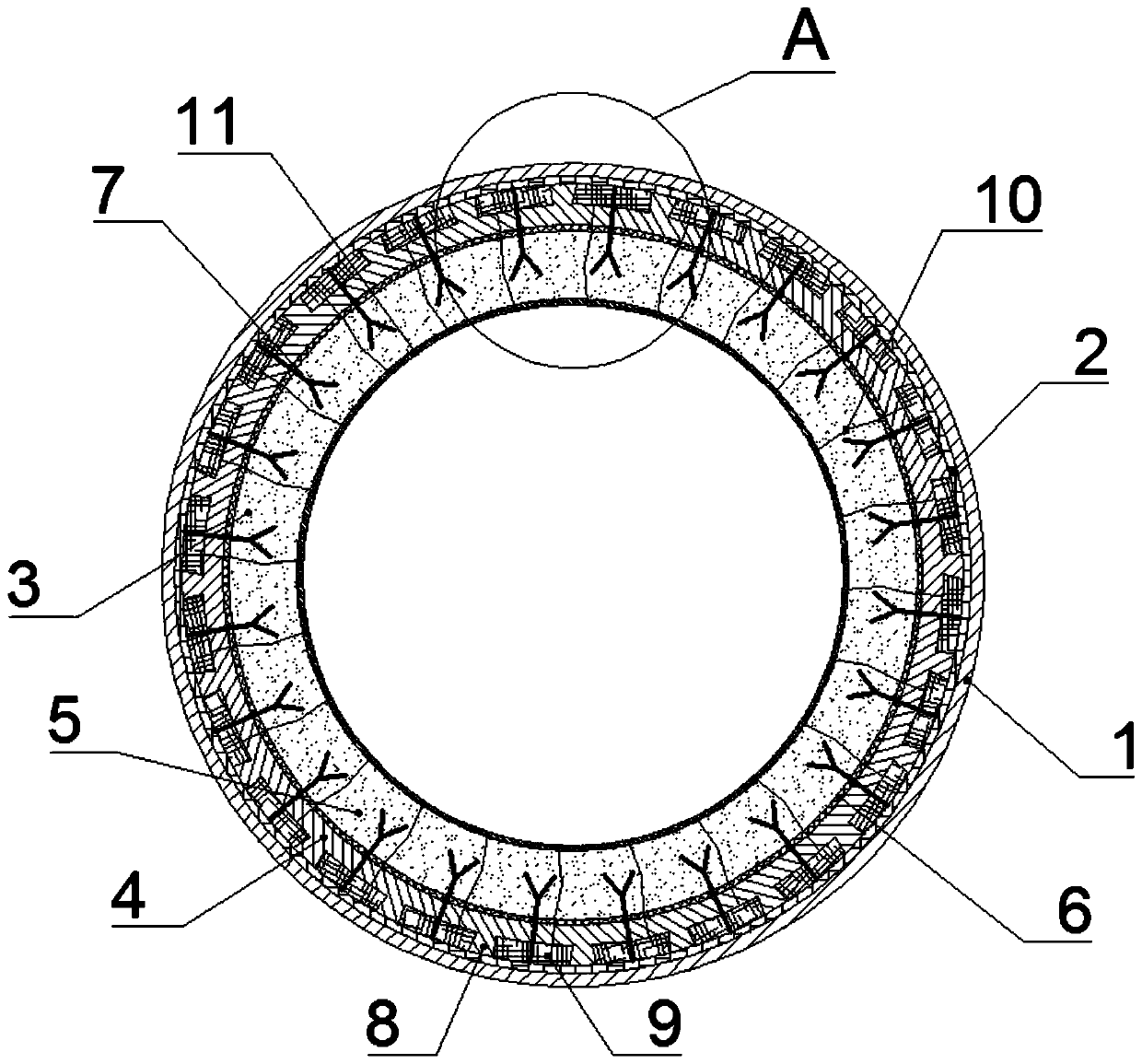

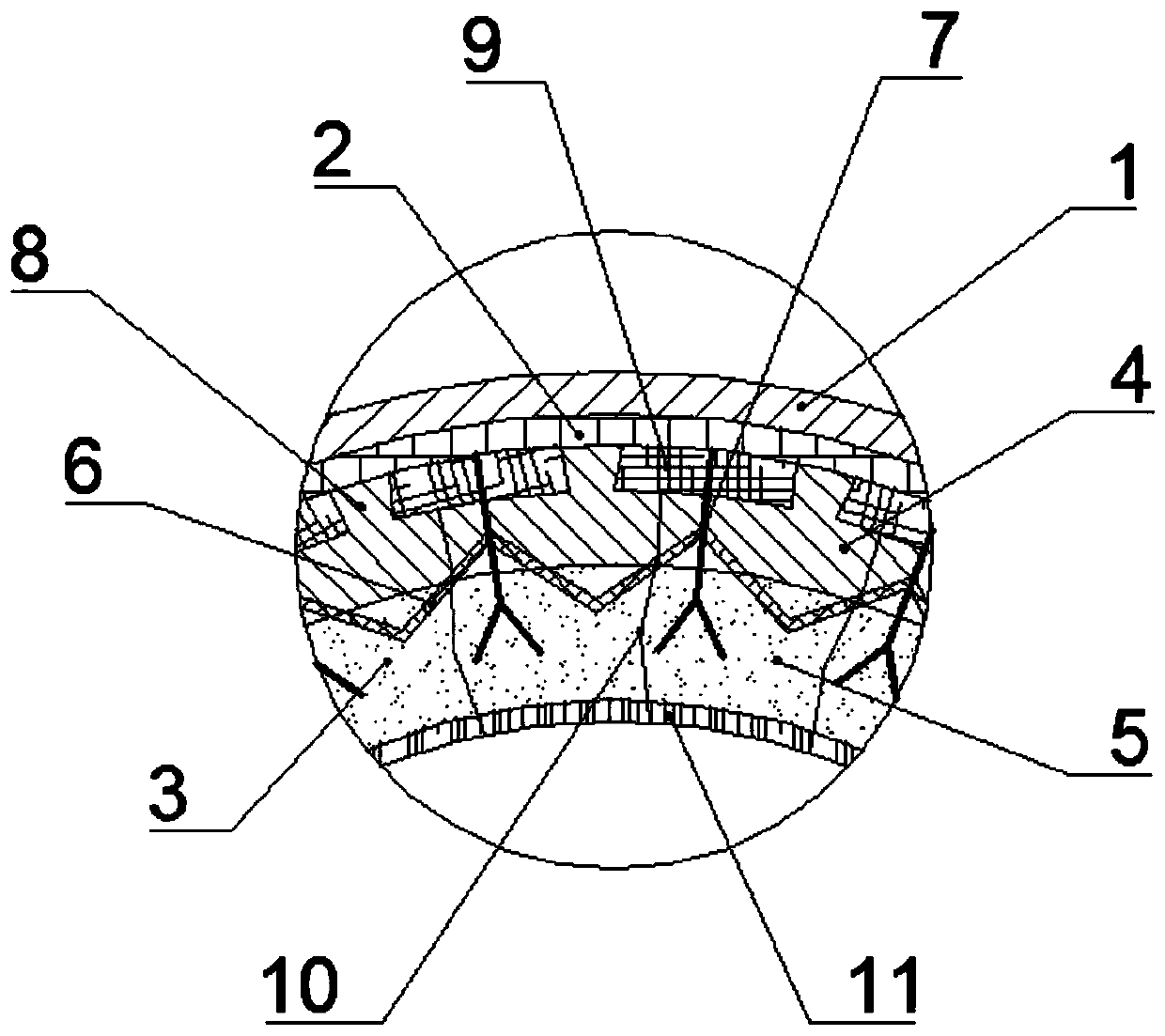

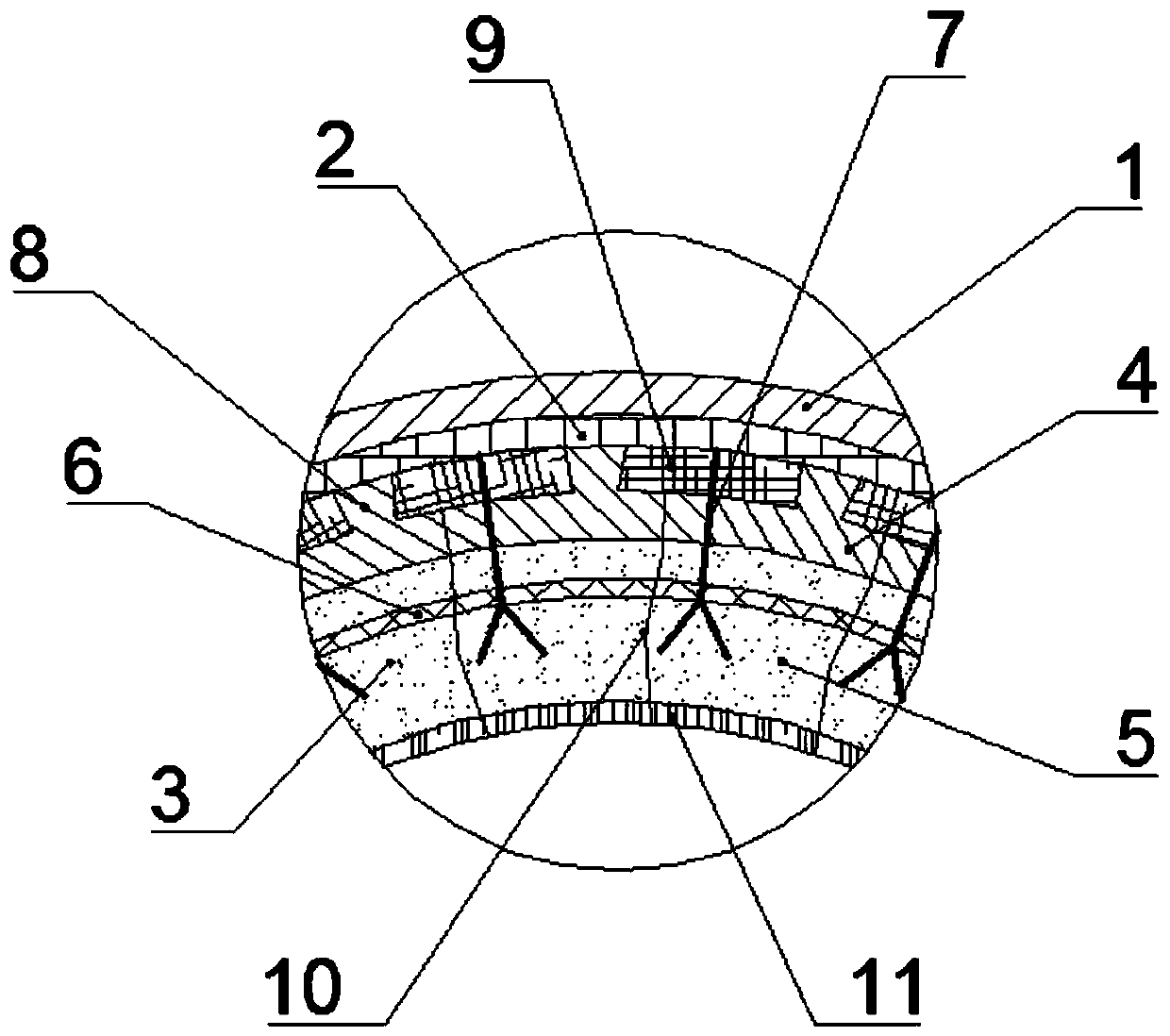

Rotary kiln lining structure

PendingCN109827427AAvoid damageImprove insulation performanceFurnace componentsRotary drum furnacesInsulation layerRefractory

The invention provides a rotary kiln lining structure. The rotary kiln lining structure comprises a rotary kiln barrel body and a lining. A heat preservation layer is laid on the inner wall of the rotary kiln barrel body and is arranged between the rotary kiln barrel body and the lining. The lining is formed by surrounding and piling refractory bricks. The refractory bricks comprise heat insulation layers, refractory fiber layers and refractory layers, wherein the heat insulation layers, the refractory fiber layers and the refractory layers are sequentially distributed and are internally provided with penetrating anchoring nails. A plurality of protruding connecting arms are connected to the outer sides, close to the heat preservation layer, of the refractory layers and are in rigid contact with the heat preservation layer. Cavities are formed between adjacent connecting arms and the heat preservation layer. Heat preservation cotton is filled in the cavities. Broken-line-shaped construction gaps are formed between refractory layers of the adjacent refractory bricks. By means of the rotary kiln lining structure, the heat preservation effect is good, and energy is not easy to lose. The rotary kiln lining structure is not easy to damage, and the service life is prolonged.

Owner:镇江东亚碳素焦化有限公司

Heat insulation panel and preparation method thereof

The invention relates to a thermal insulation board and a preparation method thereof. It is prepared from the following raw materials in parts by weight: 30 to 50 parts of phase change materials and 50 to 70 parts of plant fibers. Any one phase change material in calcium, n-octylic acid and butyl stearate; the plant fiber adopts crop straw, or rice straw, or asparagus, which can be obtained locally, and waste straw resources can be used to turn waste into Combining the energy storage characteristics of phase change materials to achieve energy saving and consumption reduction, the production has the advantages of fire and flame retardancy, light weight, high compressive strength, good energy saving effect, thermal insulation and sound insulation, non-toxic and harmless, and green environmental protection. .

Owner:孙超

Preparation method of integral-type vacuum heat insulation and temperature preservation plate

InactiveCN102635171BHas a leak rateReduce air leakage rateClimate change adaptationInsulation improvementInorganic materialsGetter

The invention discloses a preparation method of an integral-type vacuum heat insulation and temperature preservation plate, and belongs to the technical field of an outer temperature preservation material for building outer walls. The technical scheme to be solved is that a preparation method of a vacuum heat insulation and temperature preservation plate which has a plate-type core material, has good integrity, is low in air leakage rate, and prevents cold and hot bridge is provided. According to the technical scheme, the preparation method comprises the following steps of: step one, manufacturing a core material plate; step two, loading the core material plate, and step three, vacuumizing and packaging. According to the invention, different from the prior art that the core material is in a powder shape, the plate provided by the invention has the advantages that an inorganic material is synthesized into the plate material, and a special bonding material is adopted for bonding the core material and the packaging layer together, thus the temperature preservation plate has the integrity; the core material plate is adopted and drilled for holding an air absorption agent, the quantity and position are distributed scientifically, and the long-lasting vacuum degree is ensured; and the air leakage rate is lowered by a dual-seal mode.

Owner:陈宏宇

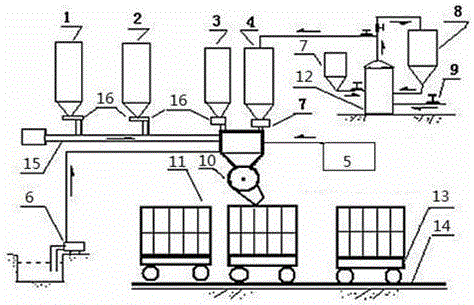

Production method for foam sandwich type wall panels

InactiveCN106003370AImprove water resistanceHigh compressive strengthCeramic shaping apparatusCalcium silicateMixed materials

The invention discloses a production method for foam sandwich type wall panels. A raw material of the foam sandwich type wall panel comprises a dry mixed material composed of coal ash, perlite and cement; the dry mixed material is added with polystyrene particles, water and an additive to form a wet mixed material; and the additive comprises hydroxyl propyl methyl cellulose, dispersible emulsion powder, an early strength agent, a water reducing agent and an air entraining agent. A production system is composed of a raw material warehouse, a polystyrene particle warehouse, belt scales, a scrapper, a water pump, a stirrer, mold trolleys, mold assemblies, a light railway and an additive storeroom and is characterized in that outlets of all the material warehouses are provided with the belt scales which are controlled by a computer and in but joint with a chain scraper conveyor, the chain scraper conveyor is connected with the feeding end of the stirrer, and the dry mixed material is added with the polystyrene particles, the water and the various additive bodies and is stirred sufficiently; and then the mixture is poured in the mold assemblies which are arranged on the light railway and provided with calcium silicate panel bodies to be formed, and the mixture starts to be solidified after being formed. By means of the production method for the foam sandwich type wall panels, the waste can be made profitable, the labor intensity of workers is relieved, and the products are wall materials which are pure natural, environmentally friendly, healthy and ecological.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

Furnace slag foam wallboard production method

InactiveCN106003406AGood processing performanceSmall footprintCeramic shaping plantsMixing operation plantHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a furnace slag foam wallboard production method. The furnace slag foam wallboard production method adopts the following raw materials: gypsum powder, furnace slag, yellow sand and cement form a dry mixture; the dry mixture is mixed with polystyrene particles, water and additives to form a wet mixture; the additives include hydroxypropyl methyl cellulose, dispersible latex powder, an early strength agent, a water reducing agent and an air entraining agent; and a production system consists of a raw material bin, a polystyrene particle bin, belt weighers, an auger conveyor, a water pump, a blender, mold vehicles, mold combinations, a light rail and an additive storehouse. The furnace slag foam wallboard production method is characterized in that outlets of all the stock bins are equipped with the belt weighers controlled by computer which are in a butt joint with the auger conveyor; the auger conveyor is connected with the feed end of the blender; the dry mixture is added with the polystyrene particles, the water and various additives to be fully mixed; and the mixture is filled in the mold combinations on the mold vehicles equipped with a calcium silicate panel on the light rail to be formed. The furnace slag foam wallboard production method can change wastes into treasures and relieve the labor intensity of workers; and products are pure natural, green, healthy, ecological and environment-friendly wall materials.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

Production technology for partition bricks

According to a production technology for partition bricks, various raw material bins, a polystyrene particle bin, a polystyrene raw material bin, a bulking machine, a volume measuring device, a primary bulking bin, electronic balances, a screw conveyor, a water pump, a mold combination, a stirring machine, a mold vehicle and an additive warehouse are included. The technology is characterized in that the electronic balances are mounted at outlets of the various raw material bins to be butt-jointed with the screw conveyor, and an outlet of the screw conveyor is connected with the stirring machine; addition of polystyrene particles is controlled by the volume measuring device, water is added, various additives are added manually, stirring is performed, and the water mixture is poured into themold combination to be molded; solidification is started after the water mixture is poured into the mold combination and left to stand; a formula is as follows: lime residues, boiling slag, lime powder, fine sand and cement form a dry mixture; each ton of the dry mixture is mixed with the polystyrene particles, the water and the additives to form a wet mixture; the lime residues and the boiling slag are used as aggregate, and the aggregate has the certain strength after being solidified; manual demolding is performed after bricks are transported by the mold vehicle after mold filling to the standing field for 24 h, the bricks are stacked, water is applied for maintenance, the bricks are stored after the final setting period, and the bricks are purely nature, green, healthy, ecological andenvironment-friendly wall materials.

Owner:杨朴

Method for producing calcium silicate sandwich wall panel

InactiveCN105835223AGood installation footprintSmall footprint for installationMixing operation control apparatusCeramic shaping plantsCalcium silicateEcological environment

A method for producing a calcium silicate sandwich wall panel is disclosed. Raw materials include gypsum powder, furnace slag particles and cement, which are mixed as a dry blend; the dry blend is mixed with polystyrene particles, water and additives to form a wet blend; the additives include hydroxypropyl methylcellulose, dispersible latex powder, an early strength agent, a water reducing agent and an air entraining agent. A production system comprises a raw material bin, a polystyrene particle bin, belt scales, a belt conveyor, a water pump, a mixer, a mold vehicle, a mold combination, a light rail and an additive storage. The method for producing the calcium silicate sandwich wall panel is characterized in that the belt scales controlled by a computer are installed at outlets of the bins and connected to the belt conveyor that is connected to a feed end of the mixer, and the dry blend is added with the polystyrene particles, water and various additives and stirred sufficiently; the mixture is poured into the mold combination on the mold vehicle provided with a calcium silicate panel on the light rail to be molded and then solidified. The method for producing the calcium silicate sandwich wall panel is capable of turning waste into wealth and reducing the labor intensity of a worker, with the product being a pure natural, green, healthy and ecological environment protection wall material.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

Wall door and window structures

InactiveCN105672526AReduce carbon emissions and dust emissionsImprove air qualityWallsClimate change adaptationElectrical and Electronics engineeringFiber

Disclosed are wall door and window structures. The problems that an existing wall door and window structure has multiple heat bridges and are poor in fireproofness and waterproofness, and poor in structural safety are solved. The first structure comprises a door window and a door window side edge protective layer, wherein the door window side edge protective layer is a prefabricated panel protective layer, and the prefabricated panel protective layer is a cement fiber board or a calcium silicate board or a magnesite board; the door window side edge protective layer is installed on the door window side edge; a window is installed on the door window side edge protective layer or a window is installed on the wall of the door window. The second structure comprises a door window, a door window side edge protective layer and a tensile net, wherein the door window side edge protective layer is a plastering protective layer, and the tensile net is arranged inside the plastering protective layer; a window is installed on the door window side edge protective layer or a window is installed on the wall of the door window. According to the wall door window structures, the number of window heat bridges is the minimum, the window energy-saving insulation effect is better than the effect of a currently-best passive energy-saving room, the fireproofness and waterproofness are good, the structural safety is good, and the wall is not likely to be broken during an earthquake.

Owner:吴淑环

Novel energy-saving and environmental-friendly decorative plate

The invention discloses a novel heat-preservation and energy-saving composite decorative plate which is formed by compounding a decorative plate body and a heat preservation layer up and down. Every two composite decorative plates are tightly connected. A rectangular edge groove with the depth being 3 mm and the width being 4 mm is formed in the side edge of a decorative plate body of each composite decorative plate. The connecting part of every two adjacent rectangular edge grooves is provided with a plurality of connecting holes straightly penetrating through the wall surface at intervals in a drilled mode, wherein each connecting hole is provided with a flat plate metal piece with a through hole, and the flat plate metal pieces are tightly pressed on the surface of the connecting part of every two adjacent rectangular edge grooves through the mode that screws penetrate through the through holes to be connected with expansion plastic buckles, located in the wall surface, of the bottoms of the connecting holes. The structure is convenient to mount, durable and better in energy-saving effect and heat preservation effect.

Owner:哈尔滨万向迎欣科技开发有限公司

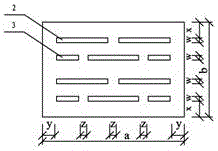

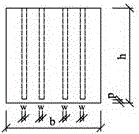

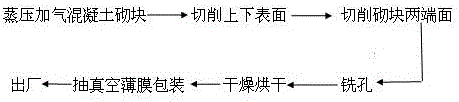

Autoclaved aerated concrete block

ActiveCN104088393BHigh compressive strengthPromote formationBuilding componentsPorosityStructural engineering

An autoclaved aerated concrete block, which is characterized in that 2 to 4 rows of flat strip-shaped vertical blind holes are opened downward along the upper surface of the block, the hole width is 16 mm to 18 mm, and the distance between the bottom ends of the blind holes is The distance between the bottom plane of the block body is 10±0.5 mm; 1≤the number of blind holes in each row is ≤4, the distance between blind holes and blind holes must be greater than 30 mm, and the distance between two rows of blind holes must be ≥30 mm And ≤60 mm; the side ribs at the two ends of the block body along the length direction shall not be less than 30 mm, and the side ribs on both sides along the width direction shall not be less than 40 mm; the core hole ratio of autoclaved aerated concrete blocks shall not exceed 24.0%.

Owner:山东省建筑科学研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com