Modified polyurethane material, exterior-wall decorative energy-saving plate and preparation method thereof

A polyurethane material and exterior wall decoration technology, which is applied in construction, building structure, covering/lining, etc., can solve the problems of poor decoration effect, complicated construction, and heavy quality of decorative insulation boards, and achieve good energy-saving insulation effects and decorative Good effect, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A kind of modified polyurethane material, preferably it is made of the following raw materials by weight: 60 parts of aromatic polyester polyols; 55 parts of foaming agent (cyclopentane); foam stabilizer (polyether modified 0.3 parts of dibutyltin oxide; 12 parts of melamine; 20 parts of flame retardant (TCPP); Diamine) 55 parts.

[0035] The filler is one or a combination of glass microspheres, diatomaceous earth, calcium carbonate, vitrified microspheres, and wood chips.

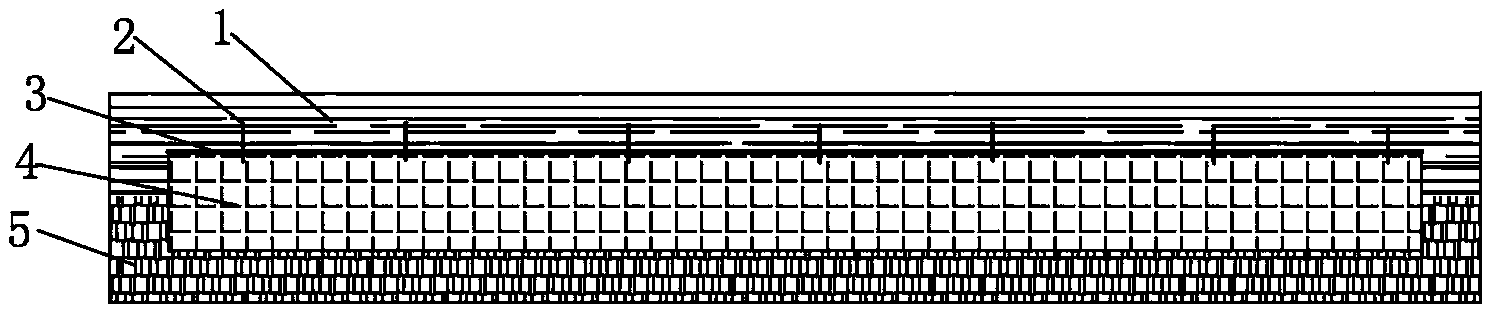

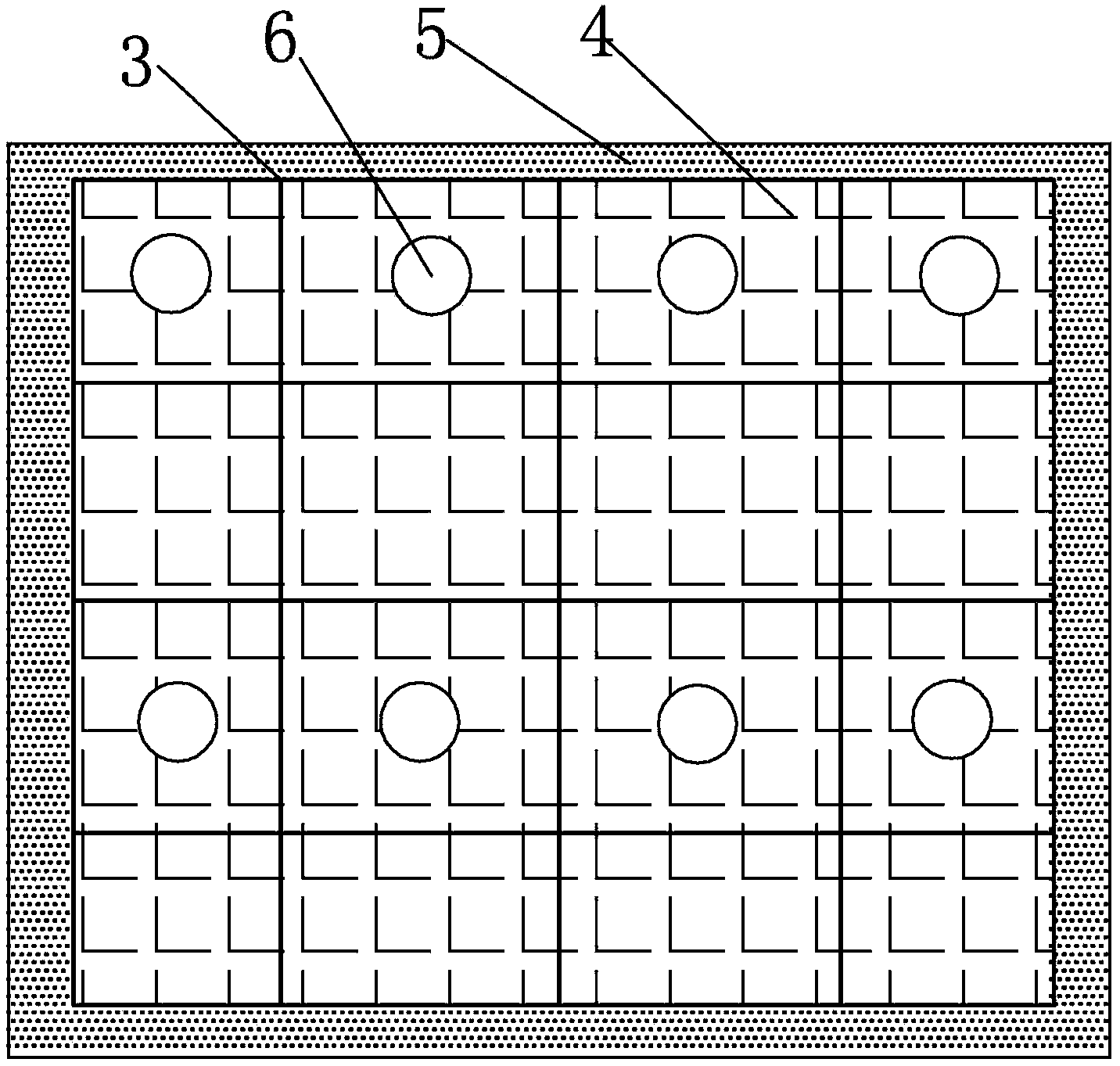

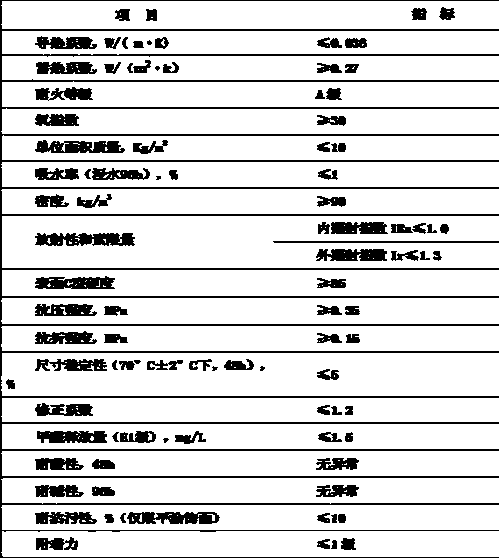

[0036] Energy-saving panels for exterior wall decoration containing the above-mentioned modified polyurethane materials, such as figure 1 , figure 2 As shown; including the base layer 5, the decoration layer 1, the thermal insulation and flame-retardant layer 4 wrapped between the base layer 5 and the decoration layer 1, the base layer 5 and the decoration layer 1 are all made of the above-mentioned modified polyurethane material, The thermal insulation and flame-retardant layer is...

Embodiment 2

[0051] Example 2, the same as Example 1 will not be stated, the difference is: the reinforcement layer is a fishing net, and the components and parts by mass of the modified polyurethane are: 55 parts of aromatic polyester polyol: 45 parts of cyclopentane; 2 parts of polyether modified silicone; 0.2 part of dibutyltin oxide; 11 parts of melamine; 1 part of TCPP; 230 parts of methane diisocyanate; 50 parts of triethylene diamine.

Embodiment 3

[0052] Example 3, the same as Example 1 will not be stated, the difference is: the reinforcement layer is a reed mat or a bamboo net, and the components and parts by mass of the modified polyurethane are: aromatic polyester 65 parts of polyol: 65 parts of cyclopentane; 4 parts of polyether modified silicone; 0.4 parts of dibutyltin oxide; 13 parts of TCPP; 25 parts of flame retardant; 160 parts of microbeads or sawdust; 250 parts of methane diisocyanate; 60 parts of triethylene diamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com