Novel filler wall for green assembly mode

A technology of filling walls and patterns, applied to walls, buildings, building components, etc., can solve problems such as poor fire resistance, non-recyclability, and cumbersome wall dismantling procedures, achieving the effect of flexible location, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

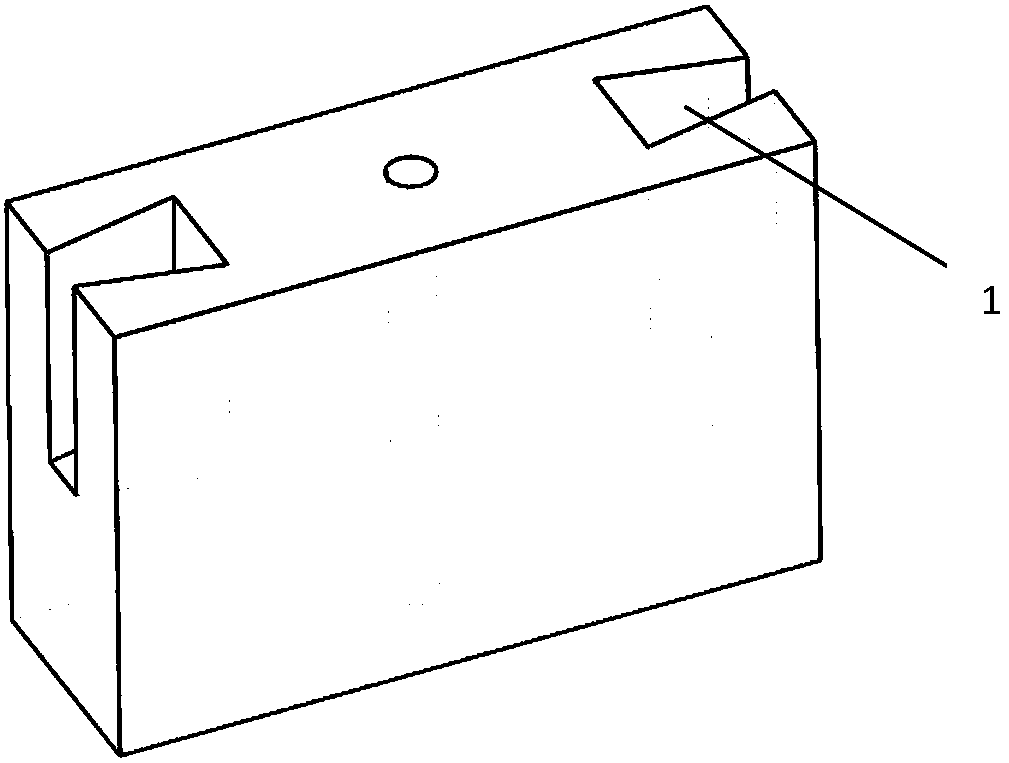

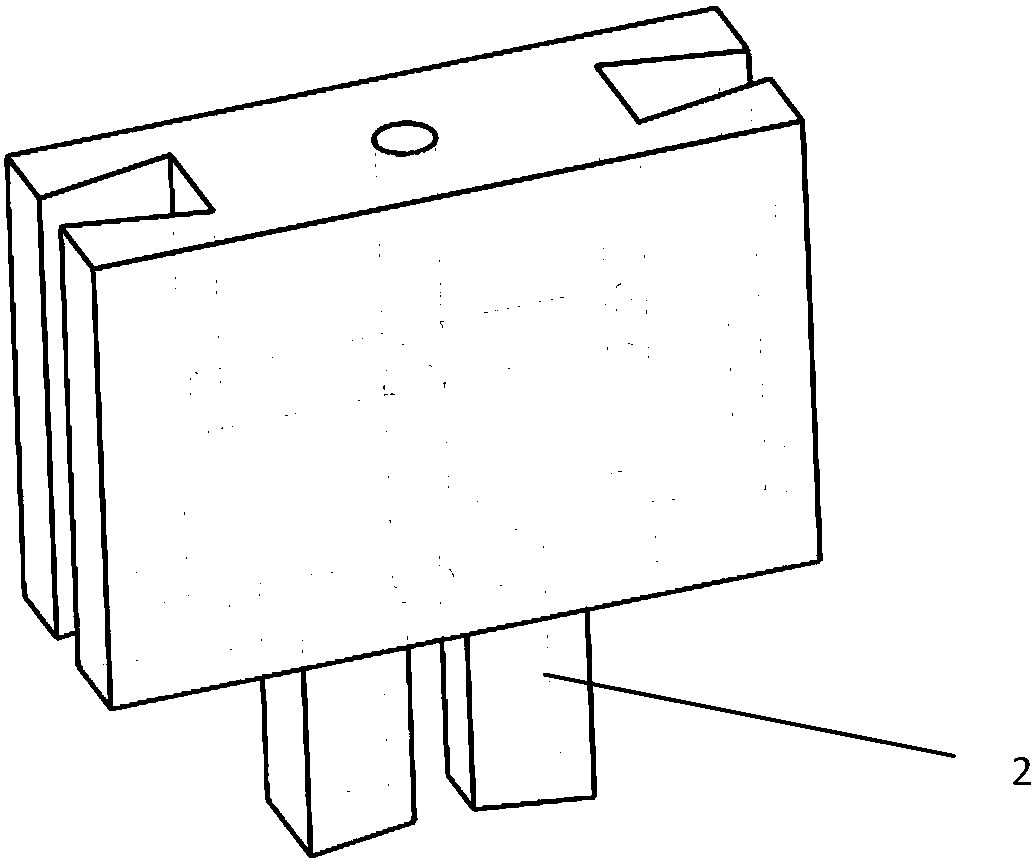

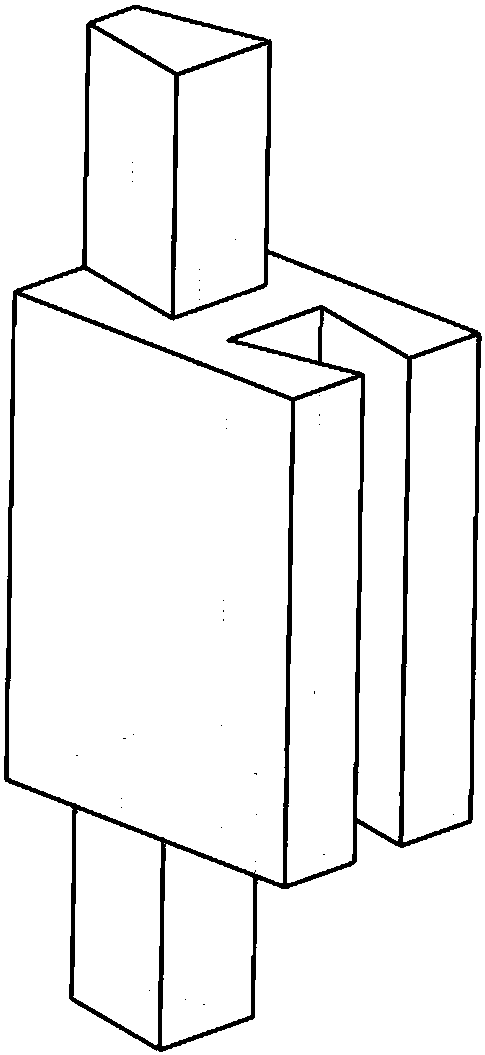

[0050] Such as Figure 1-9 As shown, a new type of infill wall suitable for green assembly mode and a new type of infill wall suitable for green assembly mode are mainly assembled from various components, including the lower bottom plate, the middle connecting plate, and the end connection Plate, L-shaped connecting plate and / or T-shaped connecting plate, upper cover plate, lower bottom plate, middle connecting plate and upper cover plate are connected up and down one by one; the end connecting plate is located at the open end of the filling wall, and both ends of the end connecting plate Connect the lower bottom plate and the upper cover plate respectively; the L-shaped connecting plate and / or T-shaped connecting plate are located at the closed end of the filling wall, and the two ends of the L-shaped connecting plate and / or T-shaped connecting plate are respectively connected to the lower bottom plate and the upper cover plate, The middle part of the L-shaped connecting plate...

Embodiment 2

[0057] A new type of infill wall suitable for green assembly mode. Based on the first embodiment, a further preferred solution is that there is more than one reserved hole in the middle of the middle connecting plate.

Embodiment 3

[0059] On the basis of a new type of infill wall suitable for green assembly modes in Examples 1 and 2, the thickness of the mortise is less than the width of the mortise by 0.1-0.2mm, the width of the mortise is 0.5-0.75mm larger than the length of the mortise, and the length of the mortise is longer than the mortise. The depth is less than 5-7.5mm and more than half the thickness of the mortise part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com