Method for preparing micro magnetic carrier, micro magnetic carrier and active sludge immobilization method

A technology of activated sludge and carrier, which is applied in the direction of inorganic material magnetism, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of weak adsorption performance, inability to fix and catalyze, loss of efficacy, etc., and achieve transformation and enhance, improve processing efficiency and effect, and efficiently remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

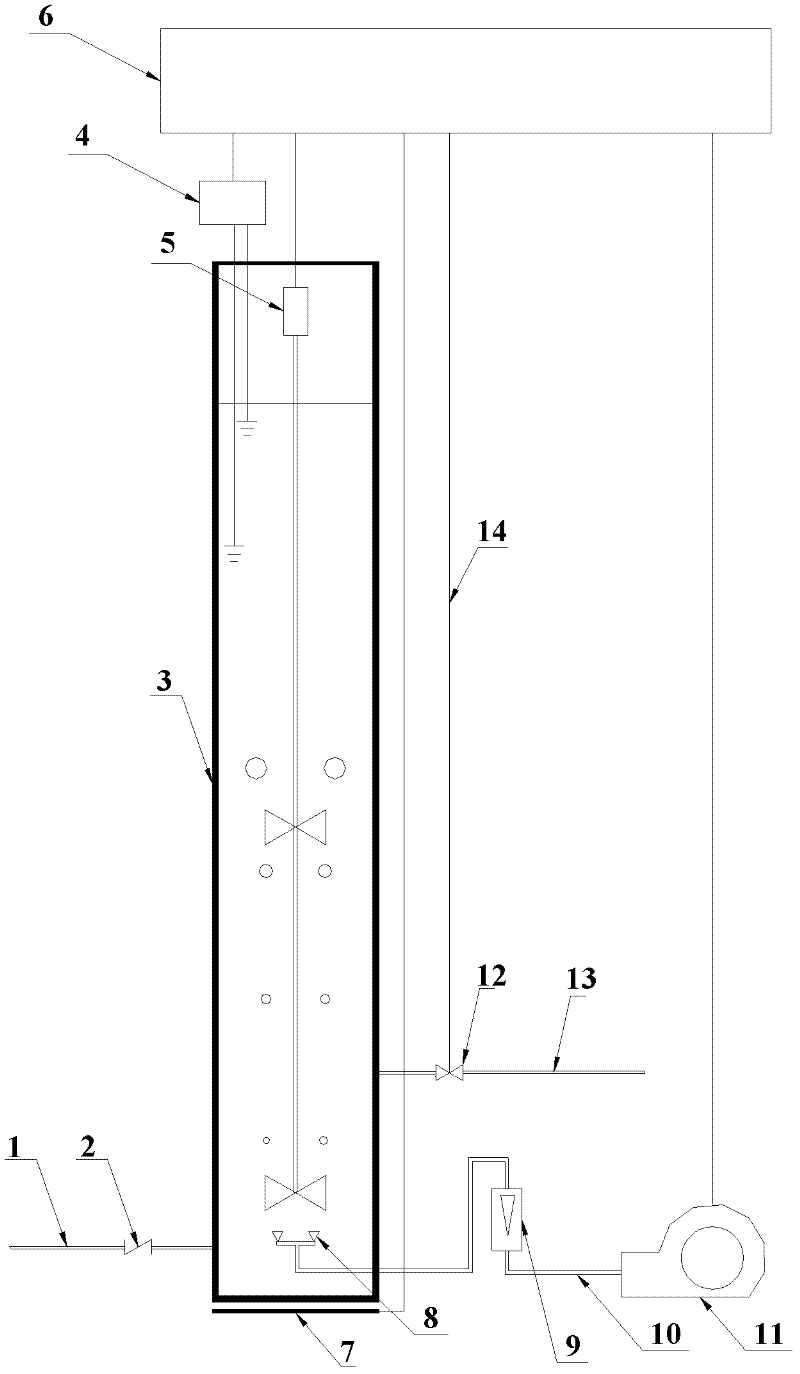

[0030] Provide a kind of preparation method of micromagnetic carrier in this example, it is characterized in that comprising the following steps:

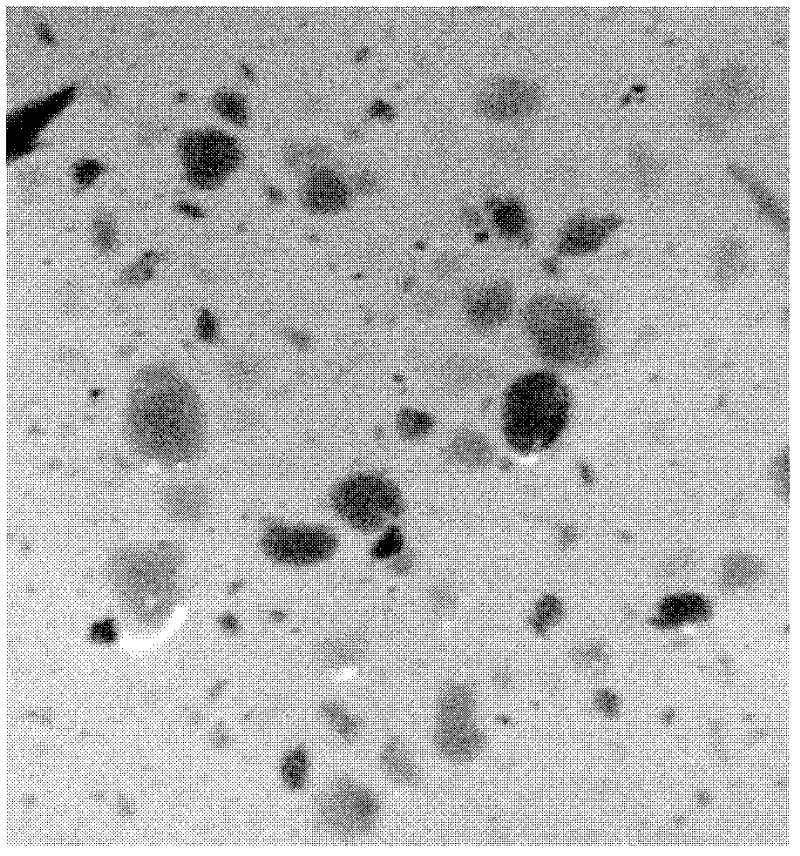

[0031] (1) In the container of the polyvinyl alcohol solution of 10% in the splendid attire 500mL mass concentration, the particle diameter is the magnetic Fe of 90-110nm 3 o 4 The particles are added to the polyvinyl alcohol solution according to the mass volume ratio of 20g / L, that is, 10g, and are evenly distributed by ultrasonic oscillation. The ultrasonic power is 200W and the time is 30min;

[0032] (2) At a solution temperature of 85° C., stir for 30 minutes with a stirrer at a speed of 1000 r / min;

[0033] (3) In the solution of step (2), add successively the glutaraldehyde solution that the mass concentration of 1% namely 5mL is 25% by volume ratio, the analytical pure concentrated hydrochloric acid that volume ratio is 1.5% namely 7.5mL, volume ratio is 0.5 %, that is, 2.5mL of sodium alginate solution with a mass conce...

Embodiment 2

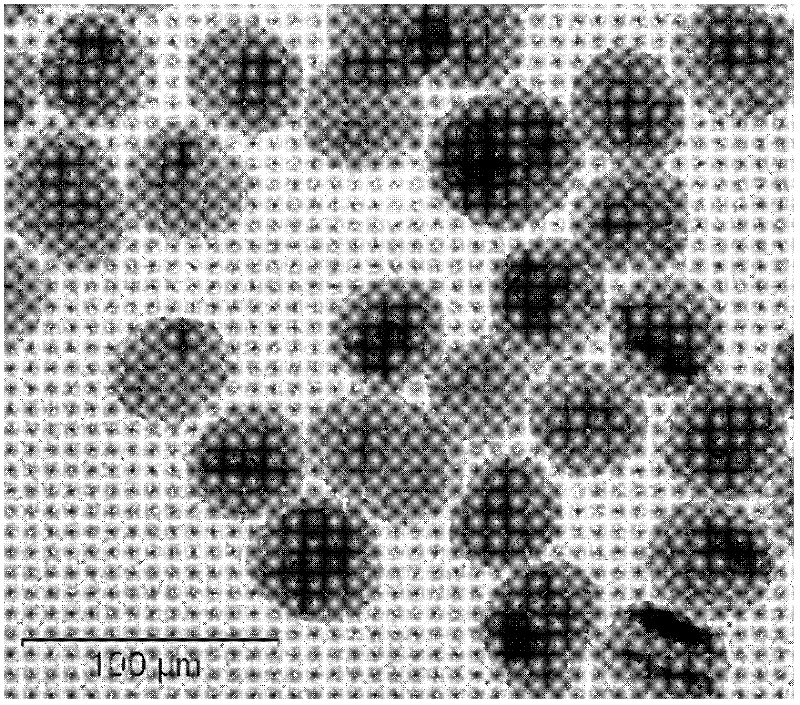

[0036]The preparation method of the micromagnetic carrier in this example, its preparation step just changes the step (1) in embodiment 1, particle diameter is the magnetic Fe of 90-110nm 3 o 4 The microparticles are added into the polyvinyl alcohol solution with a mass concentration of 15% according to the mass-volume ratio of 30g / L, that is, 15g; in step (2), at a solution temperature of 90° C. Rotating speed, stir 50min; In step (3), add the glutaraldehyde solution that volume ratio is 1.5%, namely 7.5mL mass concentration is 25%, add the sodium alginate that volume ratio is 1.5%, namely 7.5mL mass concentration is 2% solution, reacted for 1h; in step (4), successively use analytical pure acetone, mass concentration to be 70% ethanol and distilled water to clean respectively 18min, 20min, 20min, obtain the magnetic Fe 3 o 4 The particle is a granular micro-magnetic carrier with a particle diameter of 100-150 μm coated with a porous polyvinyl alcohol layer on the surface o...

Embodiment 3

[0039] The preparation method of the micromagnetic carrier in this example, its preparation step just changes embodiment 1 step (1), and particle diameter is the magnetic Fe of 90-110nm 3 o 4 The microparticles are added into the polyvinyl alcohol solution with a mass concentration of 20% according to the mass-volume ratio of 50g / L, that is, 25g; in step (2), at a solution temperature of 95° C. Rotating speed, stir 40min; In step (3), add the glutaraldehyde solution that volume ratio is 2%, namely 10mL mass concentration is 25%, adding volume ratio is 2%, namely 10mL mass concentration is the sodium alginate solution of 2%, Reaction 1.5h; In step (4), successively with analysis pure acetone, mass concentration is the ethanol of 70% and distilled water respectively cleaning 20min, 16min, 16min to obtain with magnetic Fe 3 o 4 The particle is a granular micro-magnetic carrier with a particle diameter of 200-250 μm coated with a porous polyvinyl alcohol layer on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com