Preparation method of mechanically-wrapped tobacco-coated cigar wrapper

A cigar wrapper and tobacco technology, which is applied in the field of machine-wrapped tobacco-coated cigar wrapper preparation, can solve the problems of poor combustibility, low quality, thick branches, etc., reduce tar and other harmful components, and increase static burning rate , The effect of reducing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

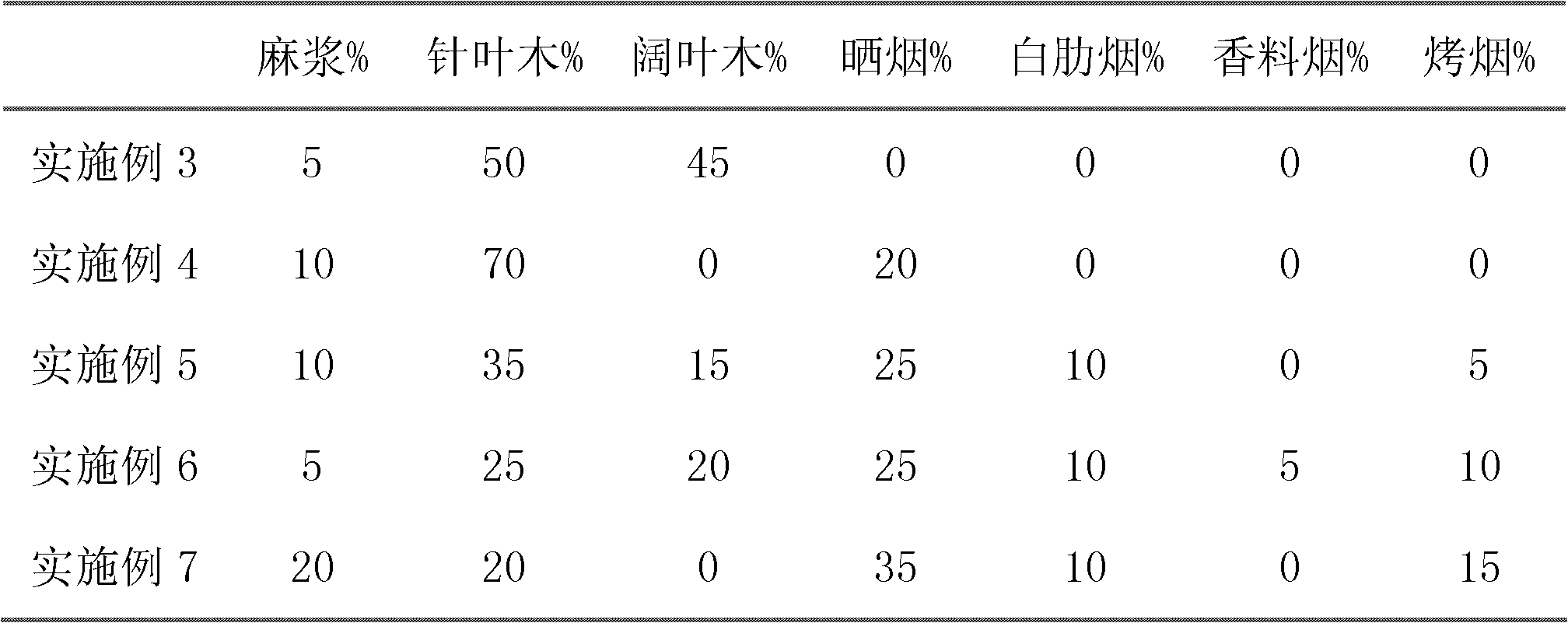

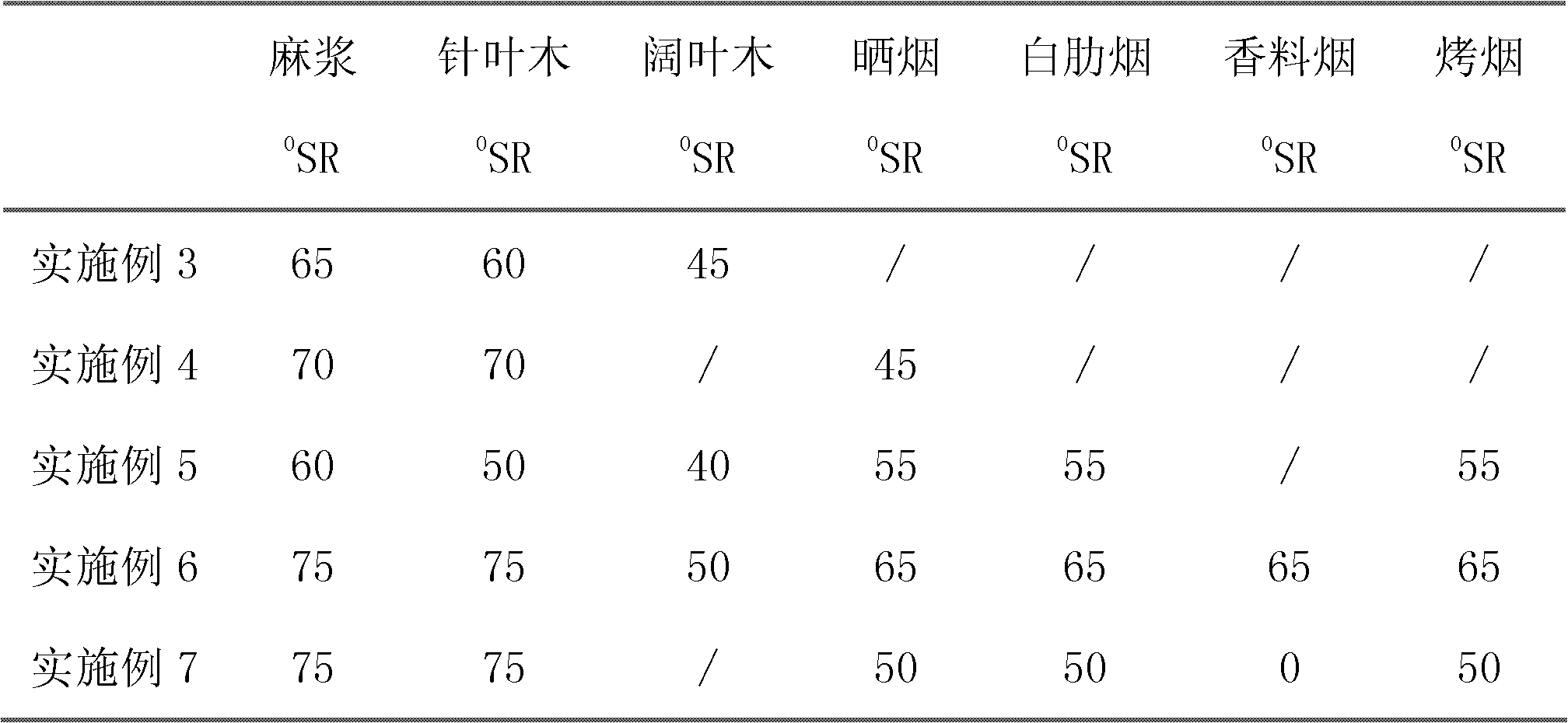

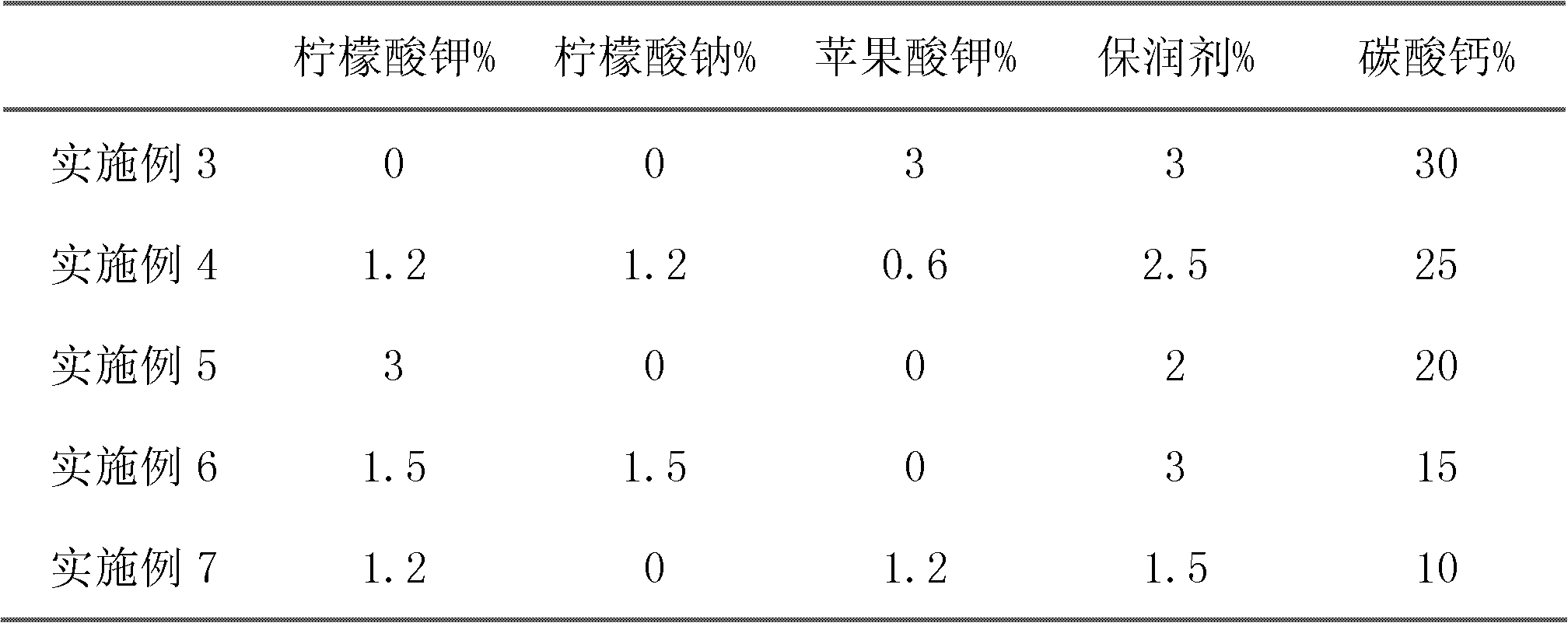

Examples

Embodiment 1

[0019] The present invention comprises the following steps:

[0020] (1) Add hot water 4-6 times the total weight of tobacco raw materials to the tobacco raw material burley tobacco, oriental tobacco, sun-cured tobacco, flue-cured tobacco fragments or tobacco stems, and perform separate or mixed extraction;

[0021] (2), the above extracts are concentrated to 23 ± 0.5 ° Bé alone or mixed to make tobacco extract;

[0022] (3), in above-mentioned tobacco extractum, add the combustion aid of 2% of tobacco extract weight, the humectant of 2%;

[0023] (4), after above-mentioned tobacco raw material is extruded, mix beating to 50 ° of SR with refiner, obtain tobacco slurry;

[0024] (5), the added commercial wood pulp fiber is mixed and beaten to 55 ° SR, obtains added fiber slurry;

[0025] (6), above-mentioned tobacco slurry is mixed in the fiber slurry of adding, wherein the blending amount of tobacco raw material is 1.5 times of adding fiber raw material weight;

[0026] (7)...

Embodiment 2

[0031] The present invention comprises the following steps:

[0032] (1) Add hot water 6 times its weight to the sun-cured tobacco and tobacco stems for extraction; the water temperature is controlled at 45±5°C during extraction, and the extraction lasts for 50 minutes.

[0033] (2), the above extract is concentrated to 23 ± 0.5 ° B é, made of tobacco extract;

[0034] (3), in above-mentioned tobacco extractum, add the combustion aid of 2% of tobacco extract weight, the humectant of 1%;

[0035] (4), after above-mentioned tobacco raw material is extruded, mix beating to 65 ° SR with refiner, obtain tobacco slurry;

[0036] (5), adding commercial wood pulp coniferous wood and hemp pulp fiber mixed beating to 75 ° SR, broad-leaved wood beating to 45 ° SR separately, after mixing, obtain additional fiber slurry;

[0037] (6), the above-mentioned tobacco slurry is mixed in the added fiber slurry, and the blending amount of tobacco raw material is 1 times of the weight of added f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com