Rotary kiln lining structure

A rotary kiln and inner lining technology, which is applied in the field of smelting equipment, can solve the problems of easy direct washing of the insulation layer, affecting the function of the rotary kiln, and the insulation layer is easy to fall off, so as to achieve energy saving, good heat preservation effect, and improved heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

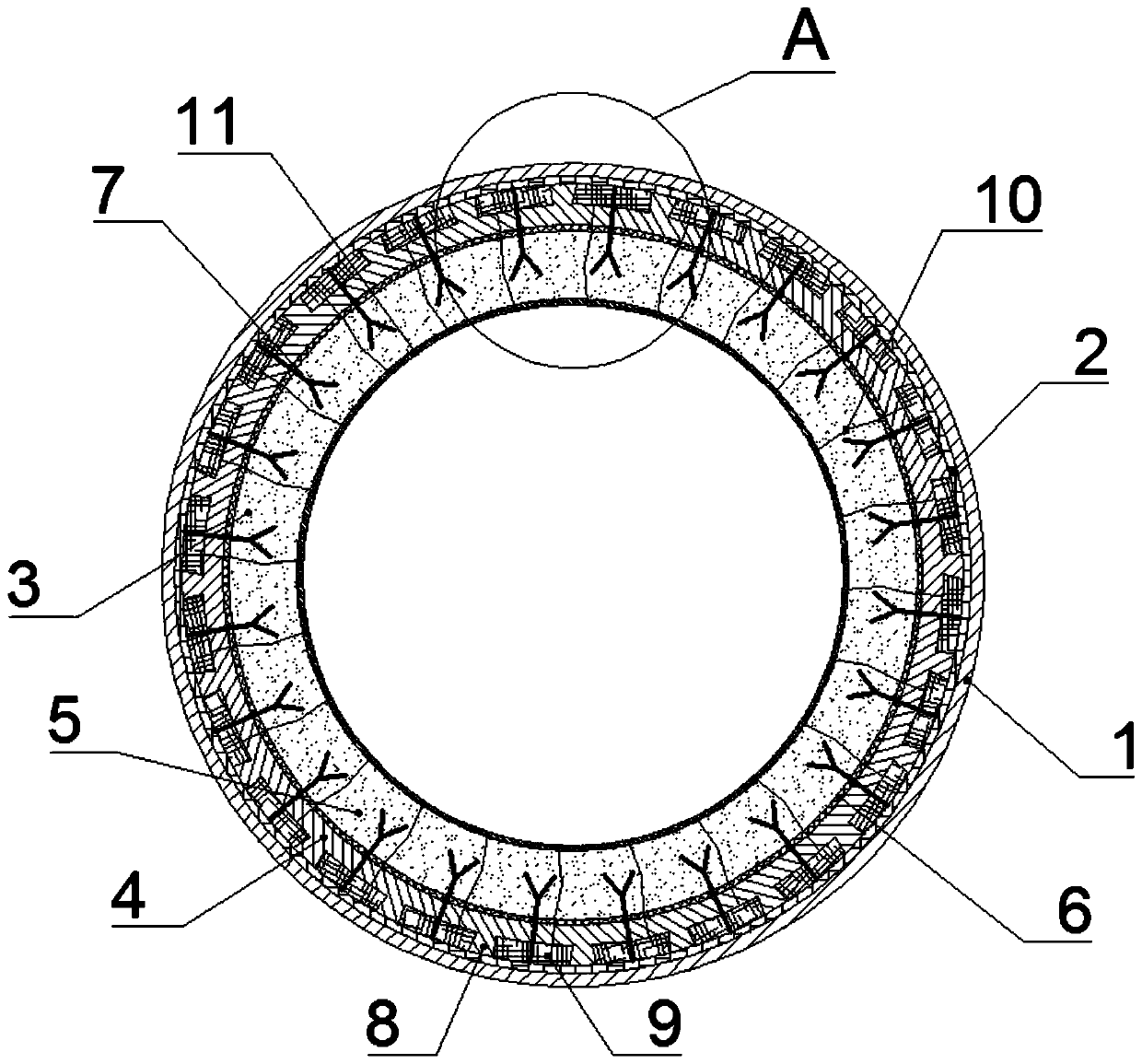

[0022] like figure 1 and figure 2 As shown, a rotary kiln lining structure, including a rotary kiln shell 1 and a lining, the inner wall of the rotary kiln shell 1 is covered with an insulating layer 2, the insulating layer 2 is a ceramic fiber board, and the insulating layer 2 is arranged on the rotary kiln shell 1 and lining.

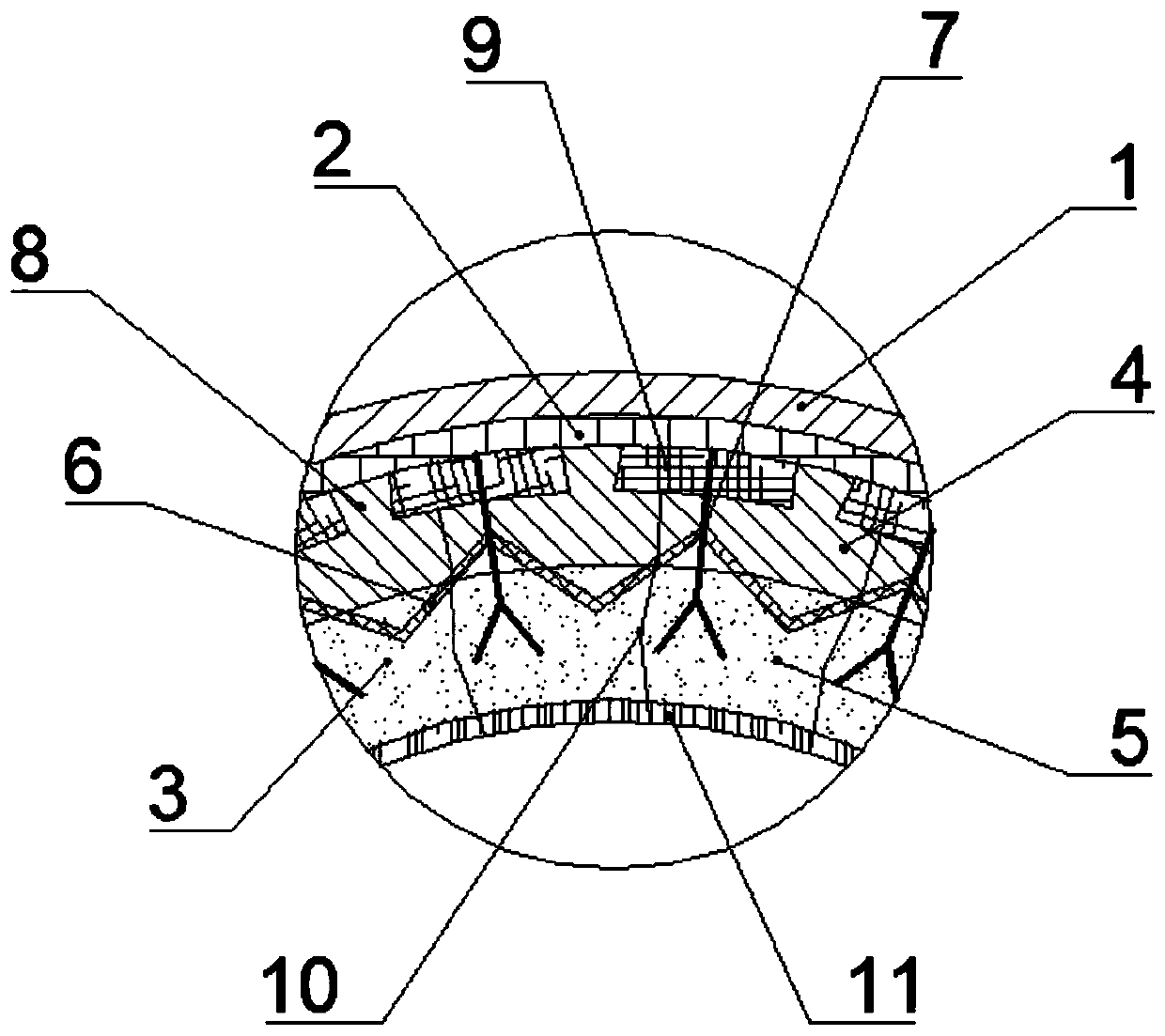

[0023] The lining is made of refractory bricks 3 surrounded by piles. The refractory bricks 3 include a heat-insulating layer 4, a refractory fiber layer 6 and a refractory layer 5 distributed in sequence. The refractory fiber layer 6 runs through the heat-insulating layer 4 and the refractory layer 5. The refractory fiber layer Layer 6 can be a grid-shaped carbon fiber layer. In order to improve the wear resistance of the inner lining and prolong the service life of the inner lining, the inner surface of the refractory layer 5 is also provided with a fire-resistant and wear-resistant layer 11 . The refractory layer 5, the refractory fiber layer 6 ...

Embodiment 2

[0026] like image 3 As shown, the refractory brick 3 includes a heat insulation layer 4, a refractory fiber layer 6 and a refractory layer 5 arranged in sequence, the refractory fiber layer 6 is arranged in the refractory layer 5, and the refractory fiber layer 6 can be a grid-shaped carbon fiber layer. In order to improve the wear resistance of the inner lining and prolong the service life of the inner lining, the inner surface of the refractory layer 5 is provided with a refractory and wear-resistant layer 11 . The shape, positional relationship and used materials of other structures of the rotary kiln lining structure in this embodiment are consistent with those in Embodiment 1.

Embodiment 3

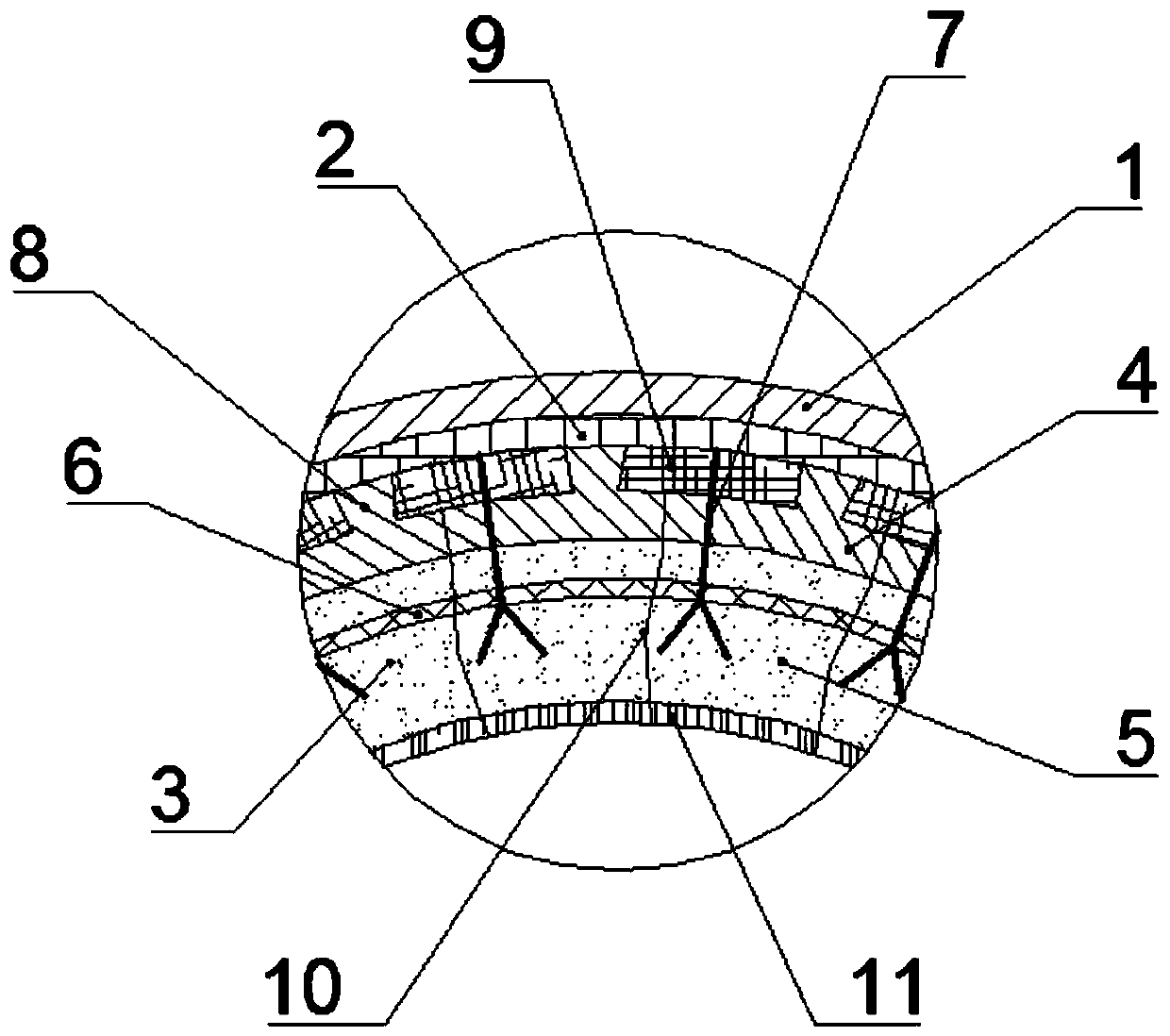

[0028] like Figure 4 As shown, the refractory brick 3 includes a heat insulation layer 4, a refractory fiber layer 6 and a refractory layer 5 arranged in sequence. The refractory fiber layer 6 is arranged between the refractory layer 5 and the heat insulation layer 4. carbon fiber layer. In order to improve the wear resistance of the inner lining and prolong the service life of the inner lining, the inner surface of the refractory layer 5 is provided with a refractory and wear-resistant layer 11 . The shape, positional relationship and used materials of other structures of the rotary kiln lining structure in this embodiment are consistent with those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com