Light steel composite plate assembled house

A composite board and house technology, applied in construction, building structure and other directions, can solve the problems of unreliable guarantee of house safety performance, high labor intensity of construction workers, unsatisfactory building energy saving, etc. Labor cost, excellent sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

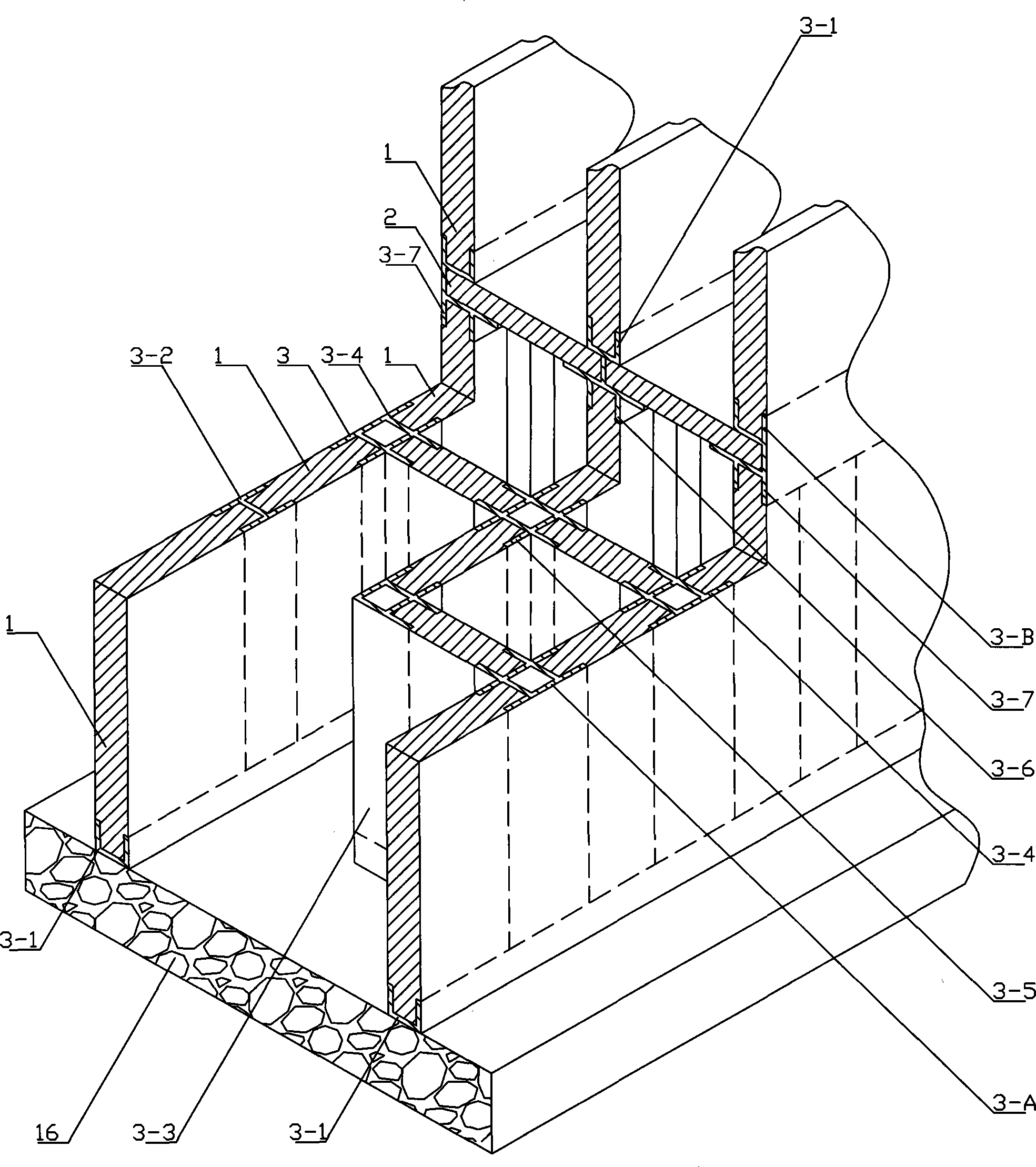

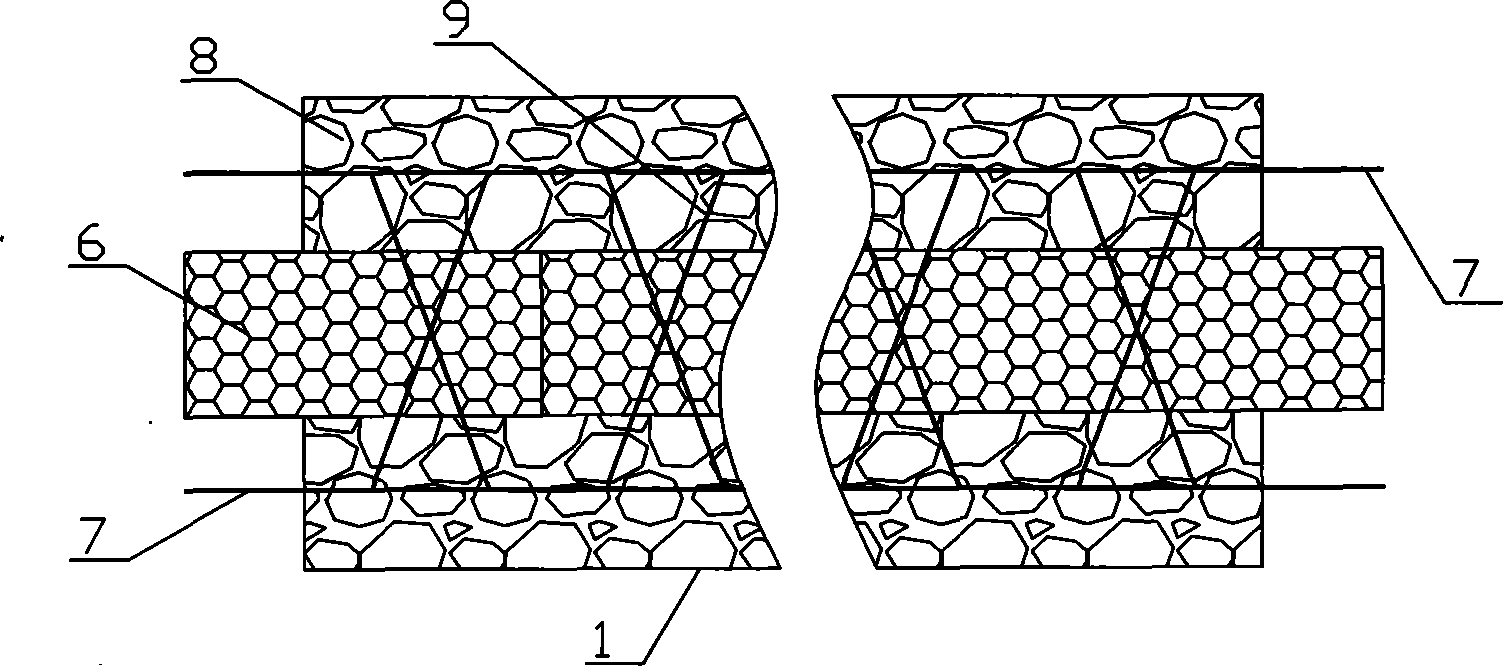

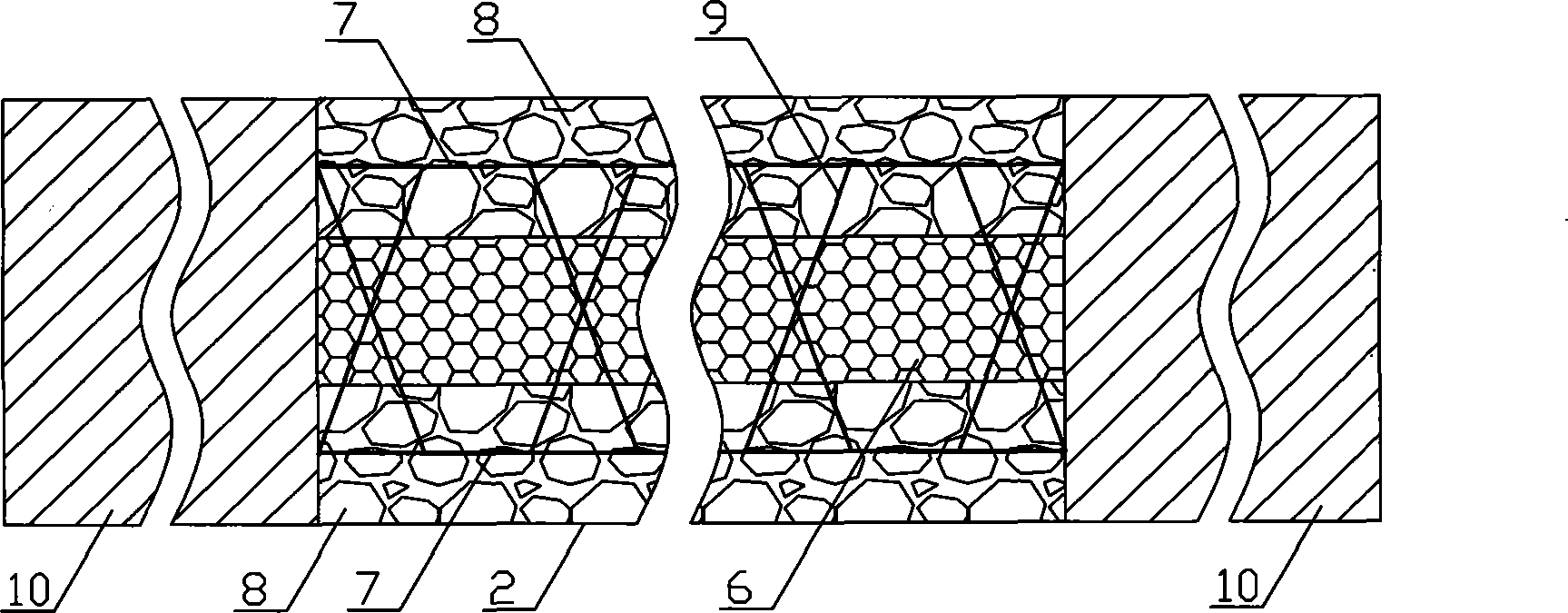

[0040] Specific implementation methods: such as figure 1 As shown, the light steel composite panel assembled house includes a house foundation 16, a wall panel 1, a floor slab 2 and a connection profile 3 with a groove 4, and a filling glue layer 5 is provided on the bottom surface of the groove 4 of the connection profile 3, and the connection Profile 3 includes foundation connection profile 3-1, wall panel connection profile 3-A and floor connection profile 3-B, wall panel connection profile 3-A includes butt connection profile 3-2, corner connection profile 3-3, and T-shaped connection Profile 3-4, cross-shaped connection profile 3-5, floor connection profile 3-B include interior wall and floor connection profile 3-6 and exterior wall and floor connection profile 3-7; foundation connection profile is fixed on the house foundation 16 3-1, the wall panel connection profile 3-A is vertically fixed on the foundation connection profile 3-1, the bottom of the wall panel 1 is plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com