In-situ testing machine for microcosmic performance of multi-load and multi-physical-field coupling material

A multi-physical field and material microscopic technology, which is applied in the direction of analyzing materials, testing material hardness, and using stable tension/pressure to test material strength, etc., to achieve the effect of high scientific significance, complete functions, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

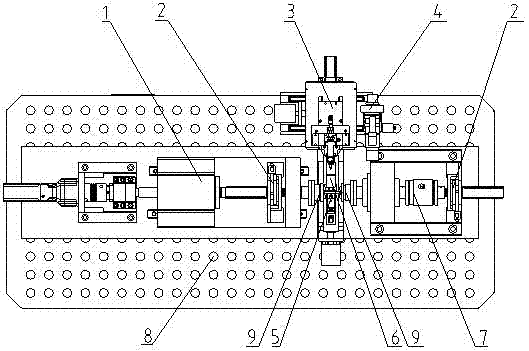

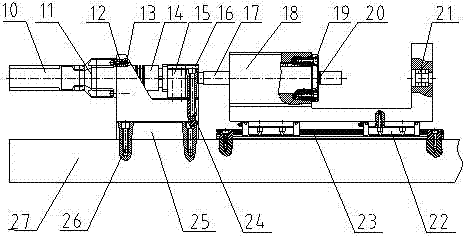

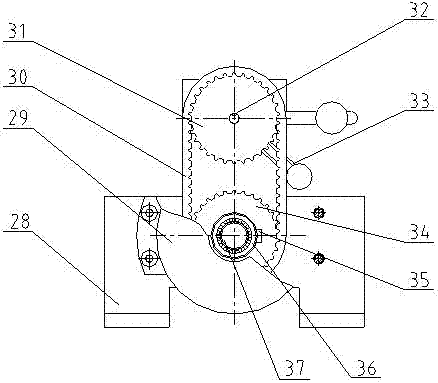

[0035] see Figure 1 to Figure 9As shown, the multi-load multi-physical field coupling material microscopic property in-situ testing machine of the present invention includes a tension / compression module 1, a torsion module 2, an indentation module 3, an in-situ observation module 4, a three-point bending module 5, a thermal Magnetic loading module 6, frame support module 8 and clamping module 9, the testing machine adopts a horizontal asymmetric structure arrangement as a whole, and pull / twist sensor 7 and pull torsion module sensor are arranged on one side; the indentation module 3 and in-situ The observation module 4 is integrated on the same lifting platform; the three-point bending module 5 and the thermal-magnetic loading module 6 are integrated on the same lifting platform; the tension / compression module 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com