Production method for foam sandwich type wall panels

A production method and wallboard technology, which is applied in the production of foam sandwich wallboards and in the field of building materials, can solve the problems of high cost of building mechanics, unit volume weight of masonry, and large amount of steel, so as to achieve simple and fast production and low production cost. Low, weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0043] Use a 5mm ordinary calcium silicate decorative board as the panel, and the intermediate filling material is a hydraulic substance. The formula of the hydraulic substance is as follows: cinder ash 25%, perlite 35%, 425# cement 40% composed of dry mixes.

[0044] Each ton of dry mix is equipped with 2. 3m 3 polystyrene particles.

[0045] Add water 26%, and various additives at 1.5%.

[0046] The various additives described are calculated per ton of dry mix: 1.6kg of hydroxypropyl methylcellulose, 0.5kg of dispersible latex powder, 10.5kg of early strength agent, 500ml of water reducing agent, and 1200ml of air-entraining agent.

[0047] Perlite is crushed with a crusher, and the maximum particle size is required to be less than 15 mm; it is light in weight and has a certain strength, and it is used as aggregate to make the particle volume ratio reach an ideal ratio.

Embodiment 2

[0049] 4mm ordinary calcium silicate decorative board is used as the panel, and the intermediate filling material is a hydraulic substance. The formula of the hydraulic substance is: cinder ash 30%, perlite particles 25%, 425# cement 45% % composition of dry blends.

[0050] Each ton of dry mix is equipped with 2. 4m 3 polystyrene particles.

[0051] Add water 24%, and various additives at 1.8%.

[0052] The 1.5% of various additives are calculated per ton of dry mix: 1.7kg of hydroxypropyl methylcellulose, 0.7kg of dispersible latex powder, 11.5kg of early strength agent, 600ml of water reducing agent, and 1300ml of air-entraining agent.

[0053] Perlite 2 is crushed with a crusher, and the maximum particle size is required to be below 15 mm; it is light in weight and has a certain strength, and it is used as aggregate to make the particle volume ratio reach an ideal ratio.

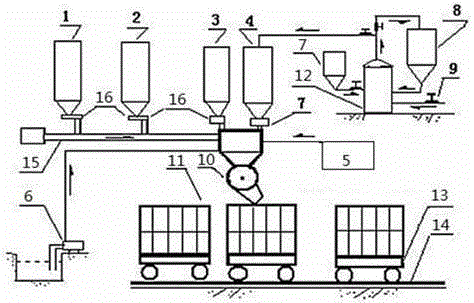

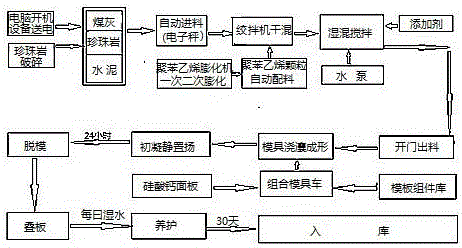

[0054] Referring to the accompanying drawings, the outlets of the fly ash silo 1, the perlite si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com