Autoclaved aerated concrete block

A technology of concrete block and autoclaved aeration, which is applied to building components, buildings, building structures, etc., can solve the problems of poor freeze-thaw resistance, high cost, unstable natural maintenance quality, etc., and can improve the thermal resistance value. , to ensure the effectiveness, the effect of reducing the shrinkage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A nano-building material greenness enhancer, the main components are 1 part of bentonite, 3 parts of bauxite, 1 part of diatomite, mixed with 0.3 parts of nano-coupling agent and then ground (the specific surface area is not less than 600m 2 / kg), the nano-coupling agent is compounded by nano-sodium silicate and aluminate at a ratio of 1:1 at room temperature, and is the modified activator of this enhancer.

Embodiment 2

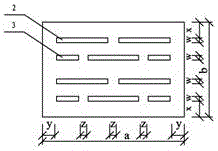

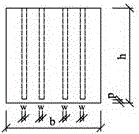

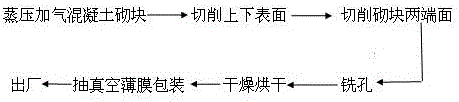

[0038] like figure 1 As shown, an autoclaved aerated concrete block has four rows of flat strip vertical blind holes downwards on the upper surface of the block, two middle blind holes are arranged side by side in the first row and the third row, and the second row and the fourth row are arranged side by side from left to right with short blind holes, middle blind holes and short blind holes. The hole width is 16-18 mm, and the distance between the bottom of the blind hole and the bottom plane of the block body is 10±0.5 mm; 2≤The number of blind holes in each row is ≤4, and the width of the thermal bridge between blind holes and blind holes is greater than 30 mm, the distance between two rows of blind holes is ≥30 mm and ≤60 mm; the side ribs at both ends of the block body along the length direction are not less than 30 mm, and the side ribs on both sides along the width direction are not less than 40 mm; autoclaved aerated concrete blocks The porosity of the core hole shall...

Embodiment 3

[0053] The similarities between this embodiment and Embodiment 2 will not be repeated, and the difference is that the distribution diagram of block blind holes in Embodiment 3 is shown in Figure 16 (Four rows of hole layout scheme 2), the indicators are as follows:

[0054] One of the dimensions of the block body is 597×240×237 mm, which is processed and formed in a fine machining center at one time by using the processing method of this scheme. There are 4 rows of blind holes on it. The blind hole type described in this plan is a rectangular hole with chamfers, and there are three types, which are divided into three types: long blind hole, medium blind hole and short blind hole. The hole lengths are 537 mm, 253 mm, 111 mm, hole width 16 mm; hole height 227 mm; hole-to-hole thermal bridge size width greater than 30 mm, distance between two rows of holes ≥ 30 mm and ≤ 60 mm; side ribs at both ends of the block body along the length direction are not less than 30 mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com