Slag partition wall light building block producing method

A production method and technology of slag, applied in the field of light block production of slag partition walls, can solve the problems of labor-intensive, long construction period, unit volume weight of masonry, etc., reduce labor intensity, simple and fast production, and improve decoration speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: raw material formula: cinder ash: 25%, slag 25%, 425# cement 50% form dry mixture; Per ton of dry mixture is equipped with: polystyrene particle 2.5 cubic meters; Add water by 25%; Various additives 1.5% includes: hydroxypropyl methylcellulose 17: 1.5kg, dispersible latex powder 18: 0.4kg, early strength agent 19: 9.2kg, water reducing agent 20: 480ml, air-entraining agent 21: 800ml.

Embodiment 2

[0033] Embodiment 2: raw material formula: cinder ash: 25%, slag 30%, 425# cement 45% form dry mixture; Per ton of dry mixture is equipped with: polystyrene particle 2.3 cubic meters; Add water by 23%; Various additives 1.5% includes: hydroxypropyl methylcellulose 17: 1.5kg, dispersible latex powder 18: 0.4kg, early strength agent 19: 9.2kg, water reducing agent 20: 480ml, air-entraining agent 21: 800ml.

Embodiment 3

[0034] Embodiment 3: raw material formula: cinder ash: 30%, slag 20%, 425# cement 50% form dry mixture; Per ton of dry mixture is equipped with: polystyrene particle 2.4 cubic meters; Add water by 24%; Various additives 1.5% includes: hydroxypropyl methylcellulose 17: 1.5kg, dispersible latex powder 18: 0.4kg, early strength agent 19: 9.2kg, water reducing agent 20: 480ml, air-entraining agent 21: 800ml.

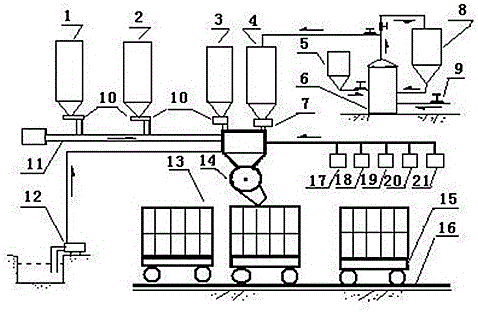

[0035] Referring to the accompanying drawings, the production system includes: the outlets of cinder ash bin 1, slag bin 2, and cement bin 3 are equipped with computer-controlled electronic scales 10 and docked with auger conveyor 11, auger conveyor 11 and mixer 14 feed end connections.

[0036] The outlet of the polystyrene raw material bin 5 is connected to the inlet of the polystyrene pellet extruder 6, the polystyrene pellet extruder 6 is connected with a steam pipe 9, and the outlet of the polystyrene primary extruder bin 8 is connected to the polystyrene pellet extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com