Aqueous heat-insulation heat-preservation fireproof material and preparation method thereof

A technology of thermal insulation and fireproof coatings, applied in fireproof coatings, reflective/signal coatings, coatings, etc., can solve the problems of reduced heat transfer efficiency, unsatisfactory thermal insulation effect, unstable performance, etc., and achieve good thermal insulation effect , Energy-saving and heat preservation effect is remarkable, and the effect of improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

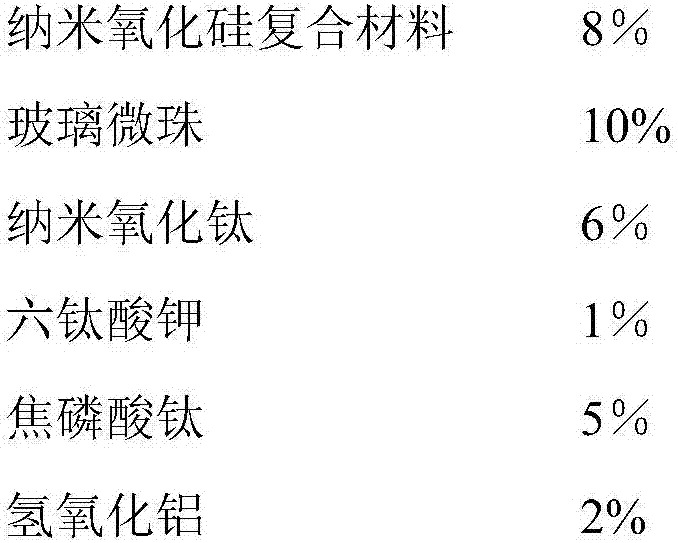

[0038] In this embodiment, a kind of water-based thermal insulation fireproof coating, its component and content are respectively as follows according to weight percentage:

[0039]

[0040]

[0041] Among them, the nano-silicon oxide composite material is a material composed of nano-silicon oxide powder with controllable structure and ultra-high specific surface area nano-silicon oxide cake in a ratio of 1:1 by weight. Among them, the nano-silica powder with controllable structure is an amorphous powder, and its specific surface area is not less than 700m 2 / g, porosity ≥ 70%, micropore diameter 3 / g, particle size 10-40nm. The specific surface area of ultra-high specific surface area nano-silica cake is not less than 1160m 2 / g, porosity ≥ 80%, micropore diameter 3 / g, particle size 5 ~ 10nm.

[0042] In this embodiment, the functional aids preferably include 0.5% dispersant, 0.5% wetting agent, 0.3% film-forming aid, 0.1% bactericide, 0.1% pH regulator, 0.05% leve...

Embodiment 2

[0046] In this embodiment, a kind of water-based thermal insulation fireproof coating, its component and content are respectively as follows according to weight percentage:

[0047]

[0048] Among them, the nano-silica composite material is a material composed of nano-silica powder with controllable structure and ultra-high specific surface area nano-silica cake at a weight percentage of 2:1. Among them, the nano-silica powder with controllable structure is an amorphous powder, and its specific surface area is not less than 700m 2 / g, porosity ≥ 70%, micropore diameter 3 / g, particle size 10-40nm. The specific surface area of ultra-high specific surface area nano-silica cake is not less than 1160m 2 / g, porosity ≥ 80%, micropore diameter 3 / g, particle size 5-10nm.

[0049] In this embodiment, the functional aids preferably include 0.5% of dispersant, 0.5% of wetting agent, 0.3% of film-forming aid, 0.1% of bactericide, 0.1% of pH regulator, 0.05% of leveling agent, and...

Embodiment 3

[0053] In this embodiment, a kind of water-based thermal insulation fireproof coating, its component and content are respectively as follows according to weight percentage:

[0054]

[0055] Among them, the nano-silica composite material is a material composed of nano-silica powder with controllable structure and ultra-high specific surface area nano-silica cake at a weight percentage of 3:1. Among them, the nano-silica powder with controllable structure is an amorphous powder, and its specific surface area is not less than 700m 2 / g, porosity ≥ 70%, micropore diameter 3 / g, particle size 10-40nm. The specific surface area of ultra-high specific surface area nano-silica cake is not less than 1160m 2 / g, porosity ≥ 80%, micropore diameter 3 / g, particle size 5-10nm.

[0056] In this embodiment, the functional aids preferably include 1.5% of dispersant, 1.5% of wetting agent, 0.3% of film-forming aid, 0.1% of bactericide, 0.1% of pH regulator, 0.05% of leveling agent, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com