Electromagnetic thermal desorption remediation method and device used for remediating contaminated sites

A repair method, thermal desorption technology, applied in the field of contaminated site repair, can solve the problems of insufficient cost and application convenience, high installation and disassembly costs, complex equipment and other problems, and achieve accurate and efficient thermal desorption, high power consumption cost, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

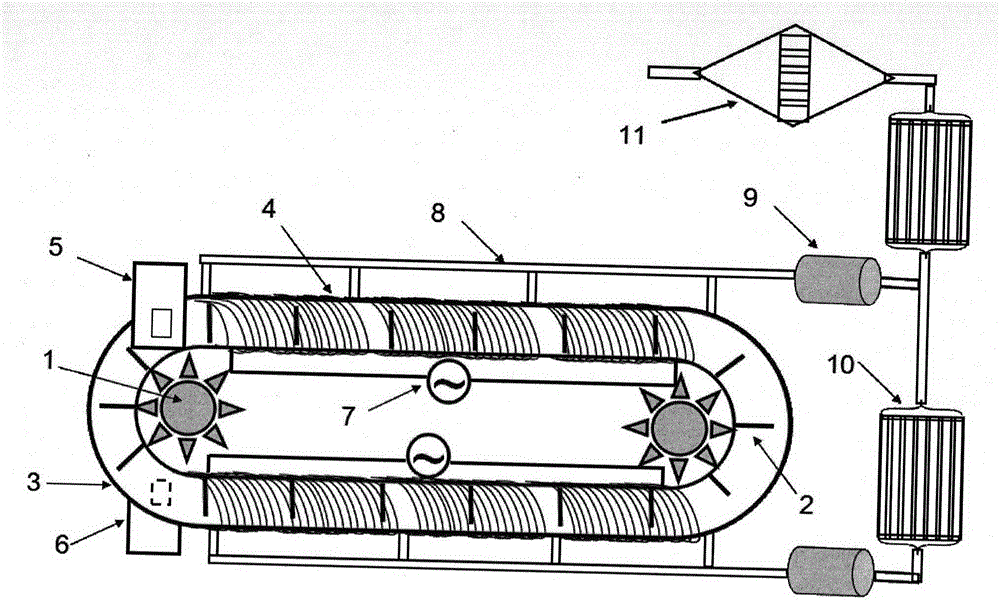

[0035] The structure of an embodiment of the present invention is shown as figure 2 Shown is a top view of the device. The electromagnetic thermal desorption device is a track-type hinged scraper device, which is equipped with a scraper stirring device. The distance between the scrapers is 5cm. The scraper blades are fixed on the hinge, and the scraper is driven by the drive wheels at both ends to reciprocate through the hinge. The driving wheel is connected with the frequency conversion motor and the reducer. The drive power of the frequency conversion motor is 3kW, and the speed is adjustable. The polluted soil is transported in the raceway-shaped tank. The diameter of the driving wheel is 500mm, and the distance between the centers of the two wheels is 3000mm. It is made of stainless steel, with built-in stainless steel hinges and porous scrapers. The electromagnetic induction coil is controlled by an electromagnetic controller. There are 2 sets of electromagnetic heating...

specific Embodiment 2

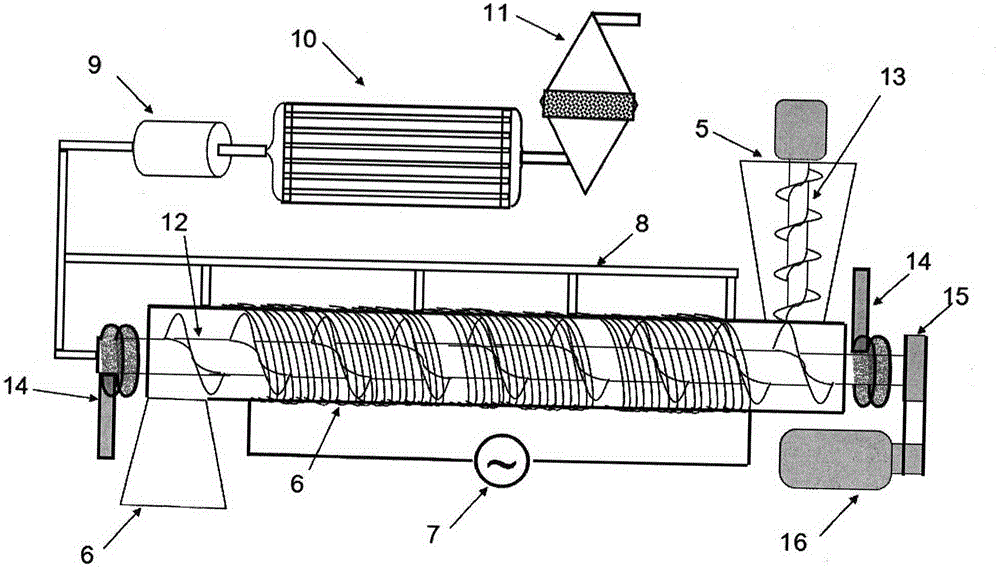

[0039] The structure of another embodiment of the present invention is shown as image 3 Shown is a side view of the device. The electromagnetic thermal desorption device is a cylindrical spiral stirring device, and the main shaft of the stirring screw is installed inside, the pitch is 8cm, and the diameter is 200mm. The spiral blade is fixed on the main shaft. It is connected with the frequency conversion motor 16 and the connecting shaft 15 of the reducer, wherein the drive power of the frequency conversion motor 16 is 3kW, the speed is adjustable, and the speed adjustment range is 0.1-20 rpm; the cross section of the tank body of the spiral thermal desorption device is circular, the diameter The diameter is 220mm, so that the polluted soil is transported in the cylindrical tank. The length of the spiral thermal desorption tank is 5000mm. It is made of stainless steel. Asbestos insulation material is laid outside the tank, and the electromagnetic induction coil is wound. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com