Production technology for partition bricks

A production process and technology for partition wall bricks, which are used in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of high force in building mechanics, heavy unit volume of masonry, and large amount of steel, and achieve simple production. Fast, low production cost, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

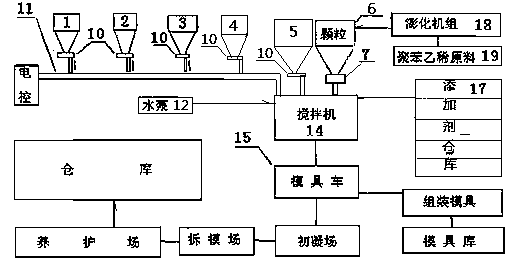

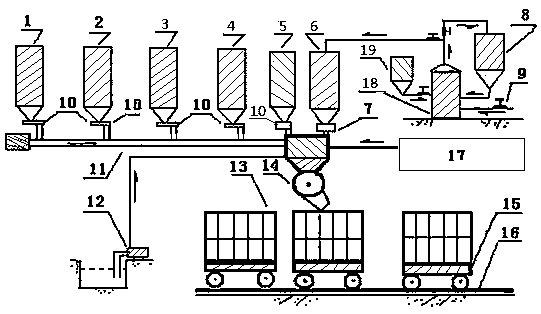

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0043] Referring to the accompanying drawings, the outlets of the lime slag bin 1, the fluidized furnace slag bin 2, the lime bin 3, the fine sand bin 4, and the cement bin 5 are all equipped with a computer-controlled electronic scale 10 and docked with the auger conveyor 11, and the auger conveys Machine 11 is connected to the feed end of mixer 14 .

[0044] The outlet of the polystyrene raw material bin 19 is connected with the inlet of the polystyrene pellet extruder 18, the polystyrene pellet extruder 18 is connected with a high-pressure steam pipe 9, and the outlet of the polystyrene primary expansion bin 8 is connected with the polystyrene pellet extruder The inlet of machine 18 is connected, the outlet of polystyrene pellet extruder 18 is connected with the inlet of polystyrene pellet silo 6 and the inlet of polystyrene primary expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com