Method for combining water atomization and oil emulsion used for turbine oil fire-extinguishing and device thereof

An oil emulsification and turbine oil technology, applied in fire protection equipment, fire rescue and other directions, can solve problems such as incompetence, achieve ideal effects, novel and scientific fire extinguishing mechanism, and reduce personal injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The combination of the present invention and the existing fire truck can not only be used for fire extinguishing of viscous oils such as turbine oil, but also can be used for general fire fighting, and one vehicle can be used for both purposes.

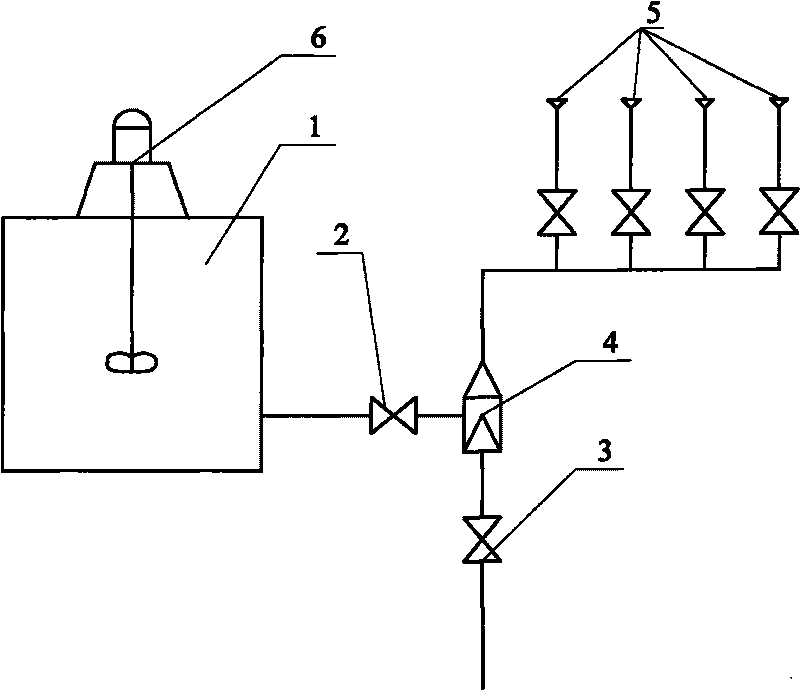

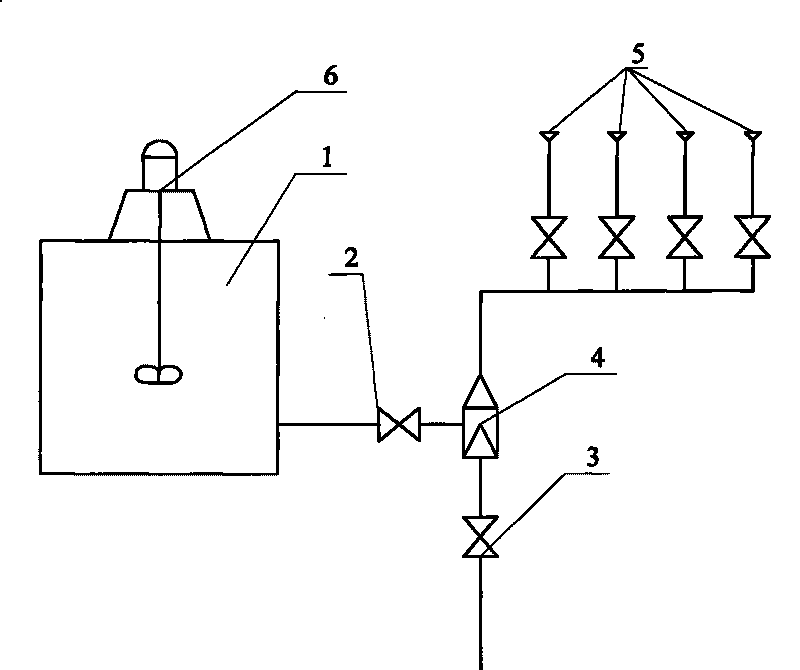

[0025] 1. Set the special fire-fighting liquid storage tank 1 on the fire truck, and the electric agitator 6 is installed in the liquid storage tank 1 . Connect the liquid outlet of the liquid storage tank 1 to the liquid inlet of the adjustable injector 4 through the valve 2 through the pipeline, the water inlet of the injector 4 is connected to the water source of the fire truck through the valve 3 through the pipeline, and the mixed liquid outlet of the injector 4 is Four straight column sprinklers 5 are connected in parallel through fire hoses.

[0026] 2. The raw materials with the following weight ratio: 20% triethanolamine oleate, 15% potassium oleate soap, 10% zinc naphthenate, and 55% desalted water are p...

Embodiment 2

[0028] Embodiment 2: The present invention is combined with the turbine oil system to realize the fire extinguishing of the turbine oil system.

[0029] 1. Set the special fire-fighting liquid storage tank 1 and the fire-fighting water storage device at a position far away from the turbine oil system, and the liquid storage tank 1 is equipped with an electric agitator 6 . The centrifugal atomizing nozzle 5 can be fixed above the point where the turbine oil lubricating oil system is easy to catch fire; the liquid outlet of the liquid storage tank 1 is connected to the liquid inlet of the adjustable injector 4 through the valve 2 through the pipeline, and the injector The water inlet of 4 is connected with the fire-fighting water storage device through the valve 3 through the pipeline, and the mixed solution outlet of the injector 4 is connected with 4 centrifugal atomizing nozzles 5 in parallel through the pipeline. Porous tubes can be arranged above the oil surface in the oil ...

Embodiment 3

[0033] Embodiment 3 is basically the same as Embodiment 1, and the difference is by the raw material of following weight ratio: 20% of sulfonated oil, 10% of triethanolamine, 10% of oleic acid, 60% of demineralized water are formulated into oil emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com