Aluminum alloy thermal-insulation and fire-resistant window

A fire-resistant window, aluminum alloy technology, applied in the direction of windows/doors, fire doors, window/door frames, etc., can solve the problems of poor fire-resistance integrity, melting of surface materials, low fire-resistance integrity, etc., to increase fire-resistance integrity, The effect of improving refractory integrity and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

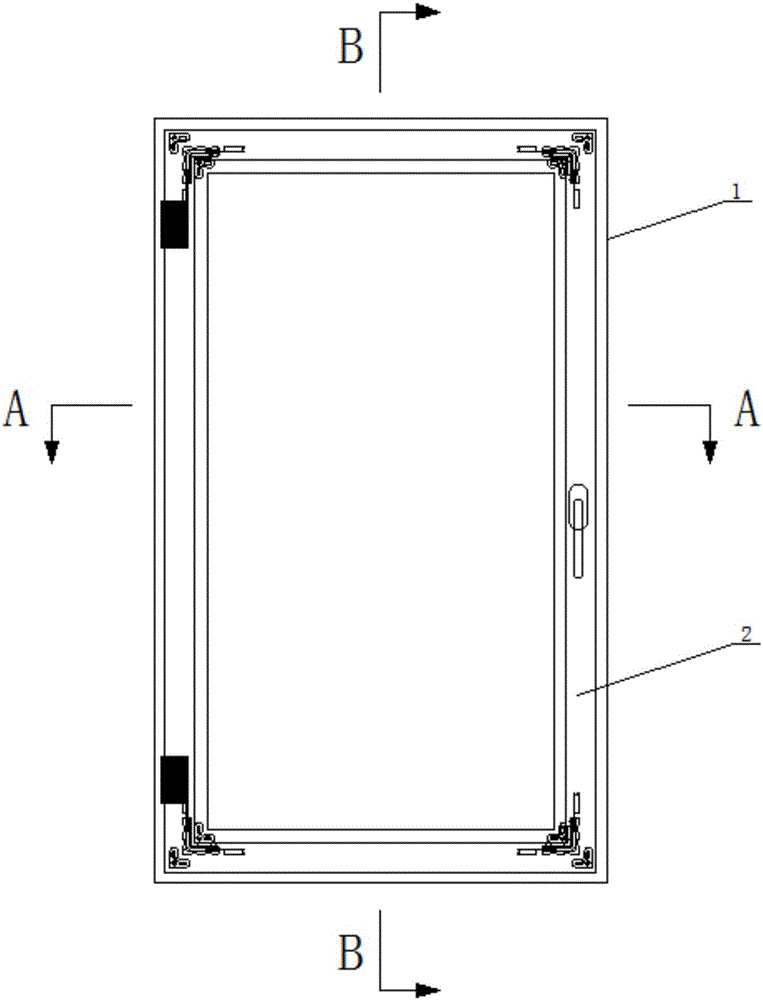

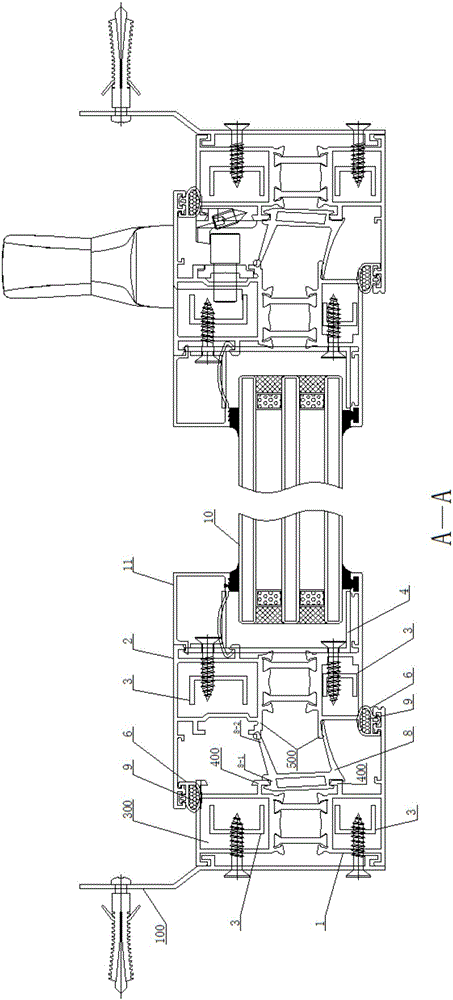

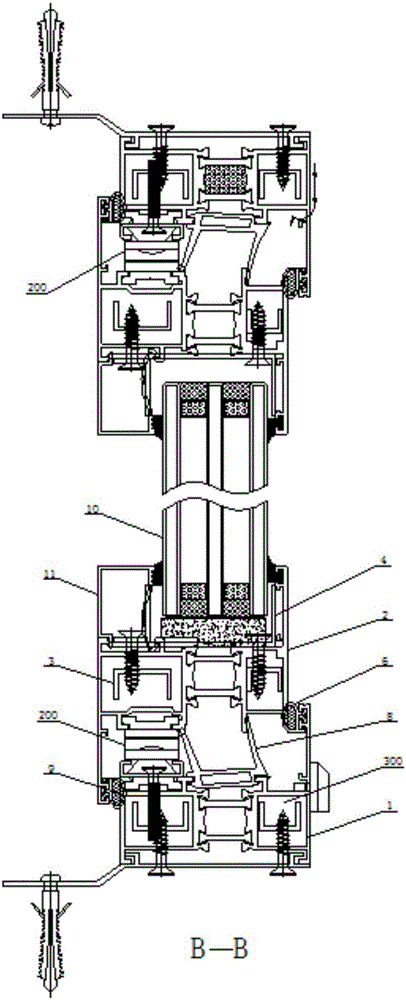

[0029] Embodiment 1: as Figure 1-3 and Figure 9-12 As shown, an aluminum alloy heat-insulating and fire-resistant window in this embodiment includes a window frame 1, a window sash 2, a reinforcing bracket 3 and a glass protective frame 4, and the window frame 1 is fixed and installed on the wall through a clip-type fixing member 100 One side of the window sash 2 is connected to the window frame 1 through a friction hinge 200, and a fireproof sealing strip 6 is provided at the lap joint between the other side and the window frame 1; the glass protective frame 4 is fixedly connected to the window sash 2 by screws , the window frame 1 and the window sash 2 are both formed with a hollow cavity 300, the reinforcing bracket 3 is arranged in the hollow cavity 300, and the hollow cavity 300 is filled with fire-resistant and heat-insulating filling materials. The friction hinge 200 is connected with the reinforcing bracket 3, and it is integrated with the reinforcing bracket 3 to e...

Embodiment 2

[0042] Embodiment 2: as Figure 4 to Figure 12 As shown, the difference between Embodiment 2 and Embodiment 1 lies in the addition of the middle stile 5, because when the size of the aluminum alloy heat-insulating and fire-resistant window is too large, it is not suitable for the entire window glass to be installed on the window sash, and the window needs to be installed at this time. Reasonable division is carried out so that the whole aluminum alloy heat-insulating and fire-resistant window includes not only the window sash but also the fixed glass; in order to cooperate with the entire rational design, the present invention also includes a middle pole 5 for fixing the glass and supporting the window frame 1. One side of the pole 5 is fixed with the glass protective frame 4 by screws, and the other side is connected with the lap joint of the window sash 2 by setting a fireproof sealing strip 6; a hollow cavity 300 is formed in the center pole 5, and the hollow cavity The bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com