Machine tool equipment service capability modeling method in cloud manufacturing environment

A technology of service capability and modeling method, applied in the field of machine tool equipment service capability modeling under cloud manufacturing environment, can solve the problem of not supporting resource integration and sharing line operation and optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

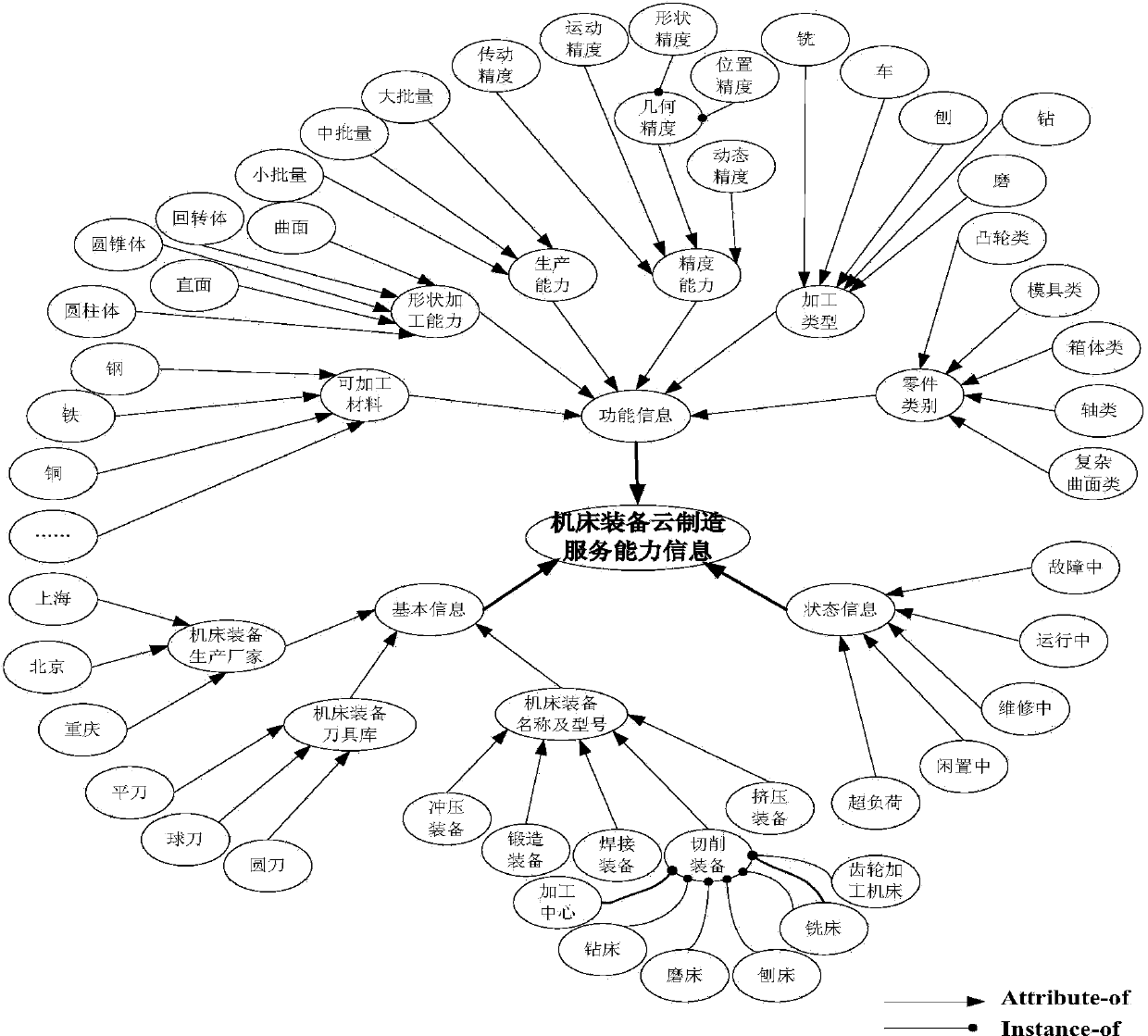

[0018] 1. Extract all kinds of information from machine tool equipment through the method of material information analysis and extraction, and define the concepts of these information, and then carry out logical induction and classification on the concept of machine tool equipment resource information, and obtain a complete machine tool equipment service capability resource information tree. Such as figure 1 shown. The specific implementation is as follows:

[0019]1) Analyze and extract various resource information of machine tool equipment: machine tool equipment can be represented by various information concepts describing its own essential information. For example, the manufacturer of a cutting and milling machine is Shanghai. The processing materials are steel and iron. It can process rotary bodies, straight surfaces and curved surfaces. It can process shaft and box parts in medium batches. It has excellent precision. The tool library generally uses flat knives. Status ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com