Cloud manufacturing resource service optimization scheduling method based on fuzzy multi-objective optimization

A multi-objective optimization and resource service technology, applied in resources, manufacturing computing systems, data processing applications, etc., can solve problems such as inaccurate service quality evaluation, lack, lack of manufacturing tasks, product parts and processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

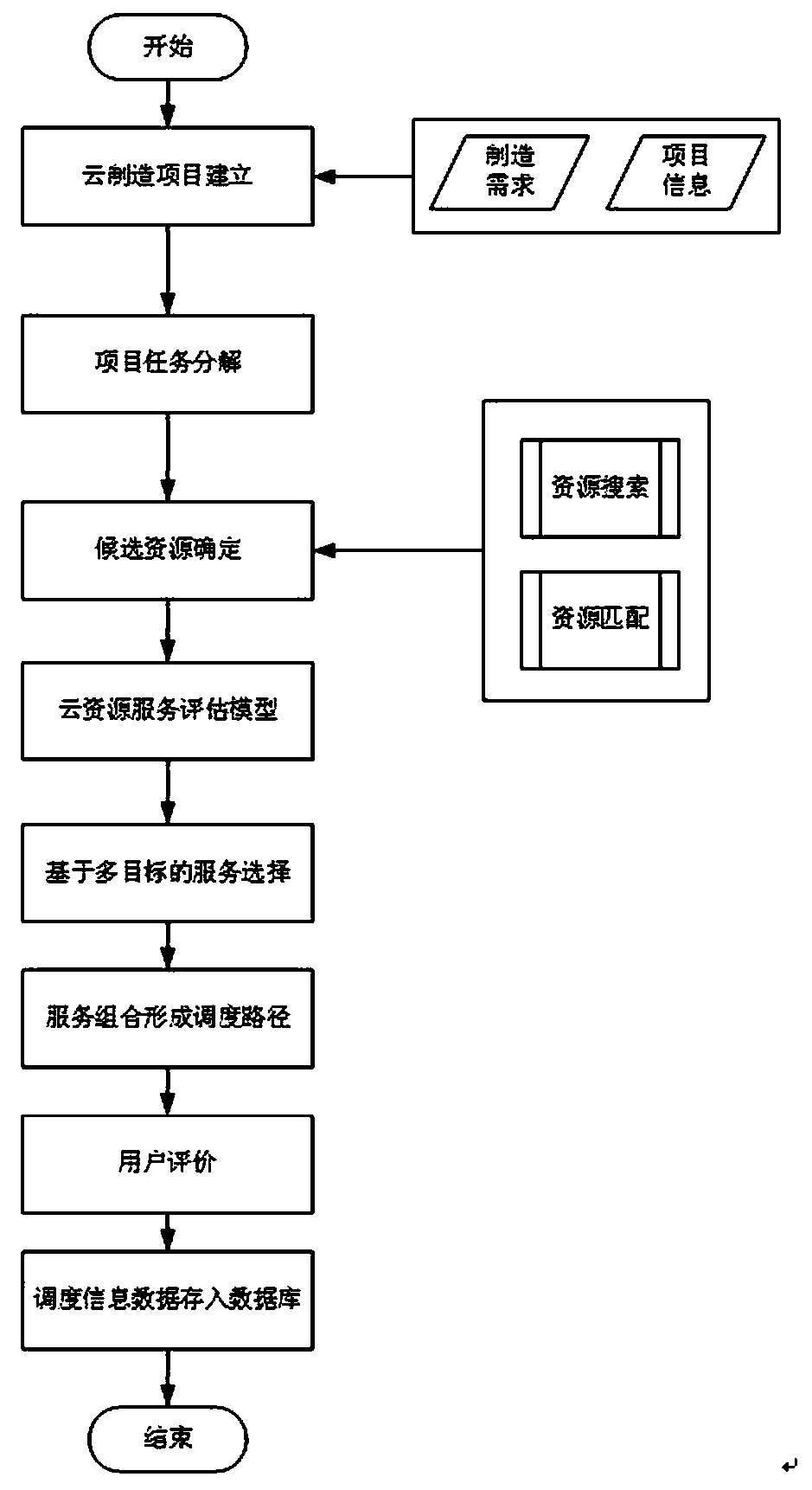

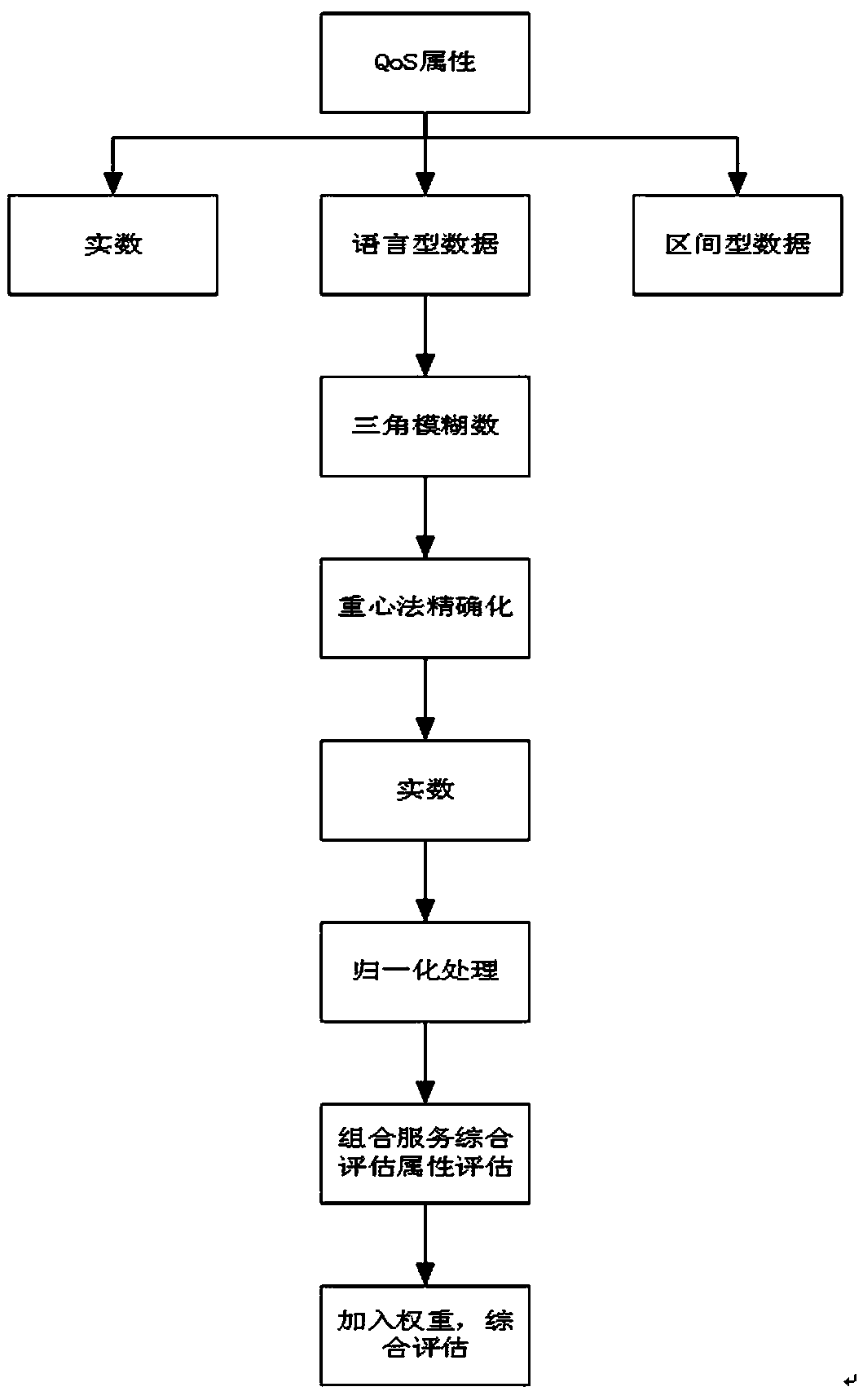

[0065] Attached below Figure 1-4 The technical scheme of the present invention is described in further detail:

[0066] This embodiment proposes a cloud manufacturing resource service optimization scheduling method based on fuzzy multi-objective optimization, including the following steps:

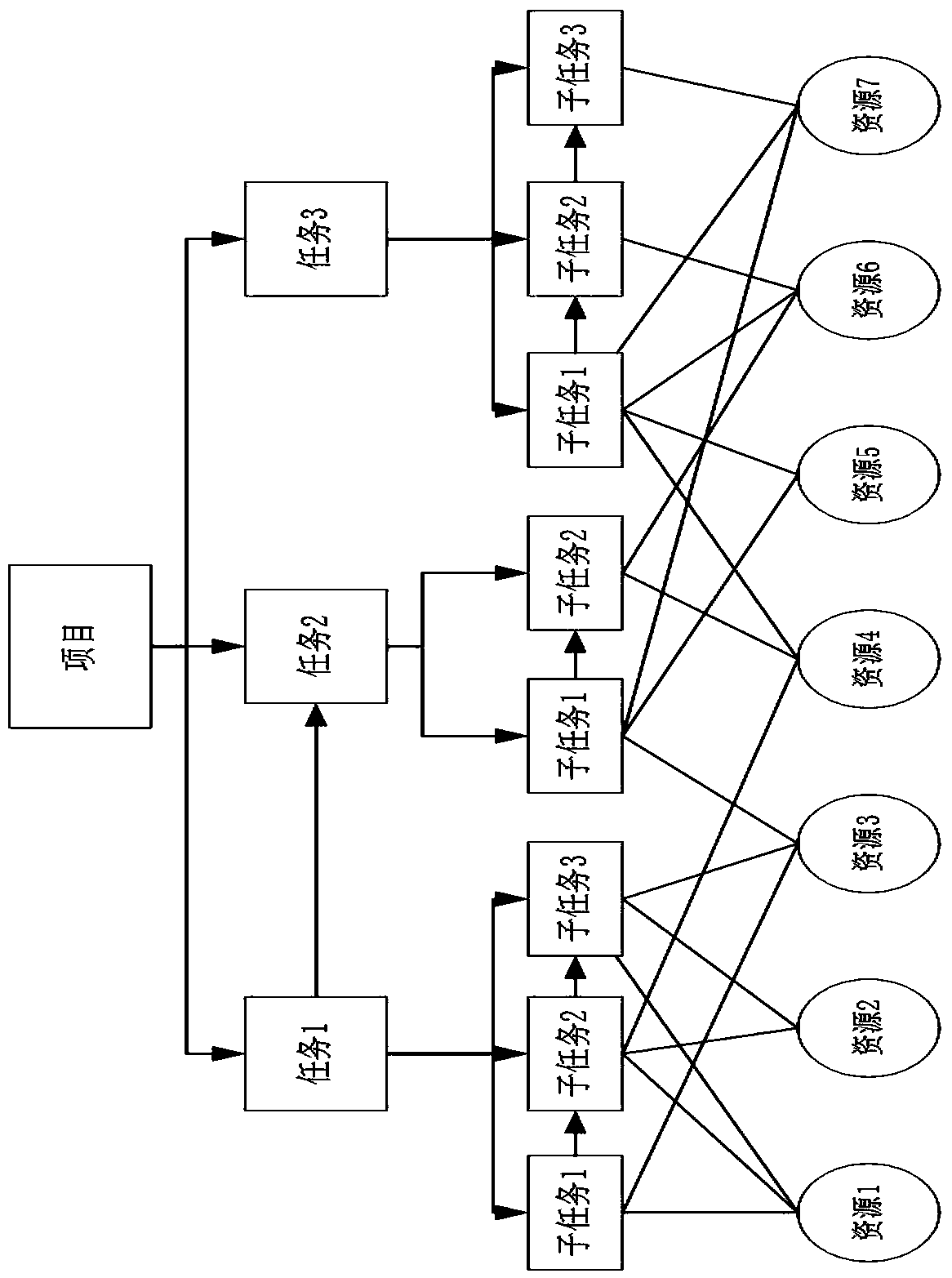

[0067] Step 1. The service demander puts forward the project requirements: the user puts forward the project task manufacturing requirements and project information according to his actual needs, and uploads them to the cloud manufacturing management platform; the project task consists of multiple stages, and each stage has multiple subtasks. Each subtask occupies one or more resource services, and one resource service may serve multiple subtasks, thus forming a complex product structure.

[0068] Step 2, project task decomposition: analyze the manufacturing process of complex products, perform task decomposition and modeling based on product structure, life cycle process and production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com