Patents

Literature

30results about How to "Avoid complex procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

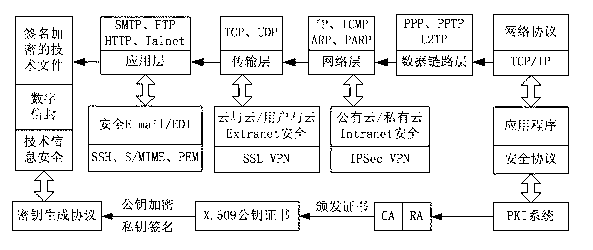

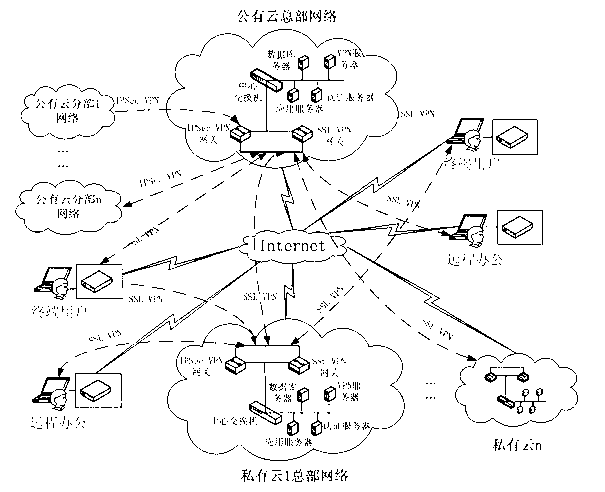

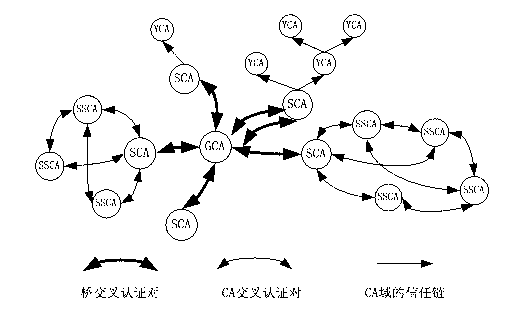

Information security management and control method under cloud manufacturing environment

InactiveCN102710605ASolve the problem of update and maintenanceAvoid complex proceduresPublic key for secure communicationUser identity/authority verificationConfidentialityPrivate network

The invention discloses an information security management and control method under a cloud manufacturing environment. On the basis of a network security protocol, a password technology and a public key infrastructure (PKI), comprehensive security guarantee is supplied to information interaction among cloud internal networks, between one cloud and another cloud, and between a user and each cloud by using implementation technologies and methods, such as a virtual private network (VPN) based on multiple layers of protocols, a digital envelope and a password algorithm; Intranet, Extranet and Internet of a cloud manufacturing system are covered; comprehensive management and control technical information files are stored and transmitted to each used loop; a session key (SK) which is randomly produced by using a key production protocol is used for symmetrically encrypting the technical information files; and a receiver public key obtained according to a PKI digital certificate asymmetrically encrypts the SK to form the digital envelope for protecting the technical information files and the SK. The information security management and control method has the characteristics of being high in confidentiality, high inefficiency, flexible in arrangement and the like and can be widely applied to the cloud manufacturing system and other network manufacturing systems.

Owner:CHONGQING UNIV

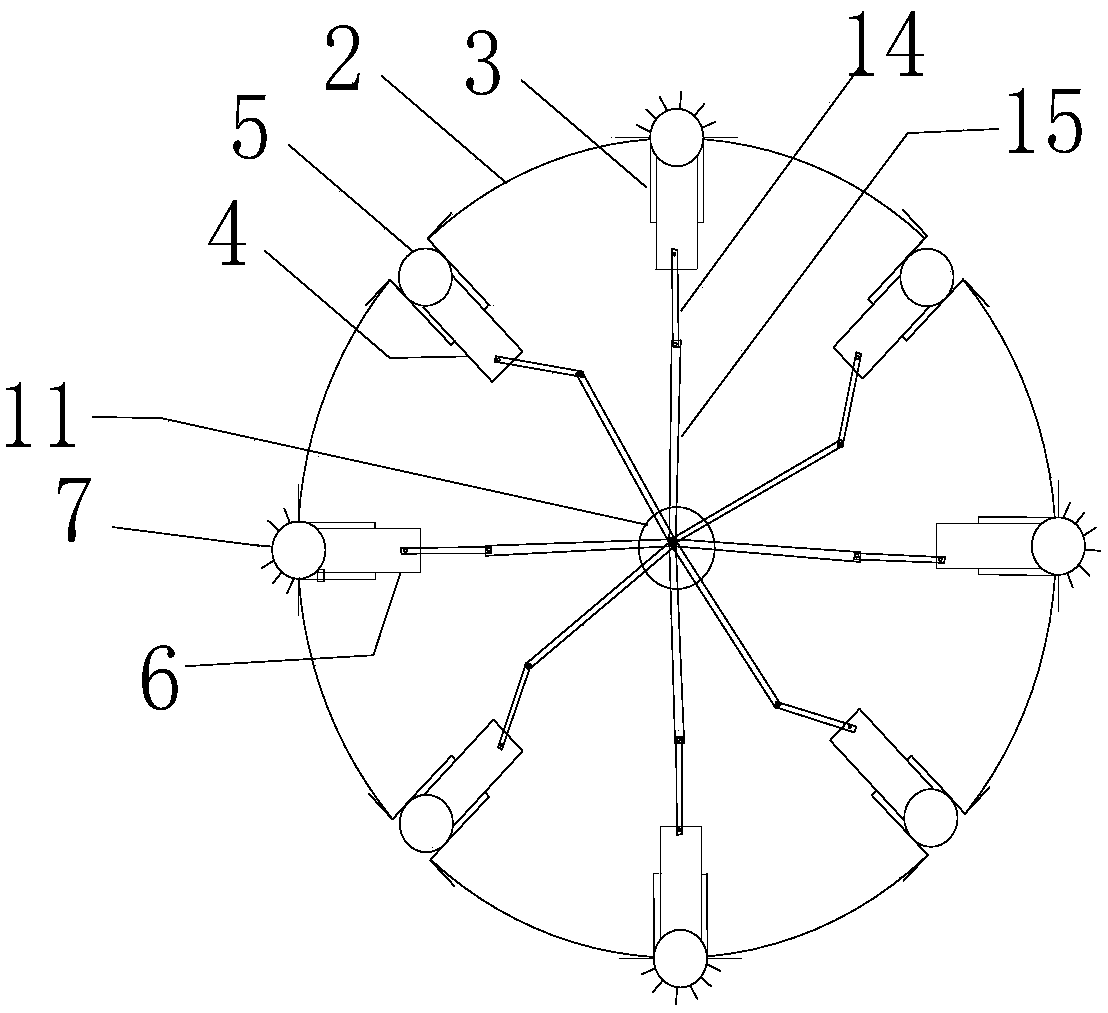

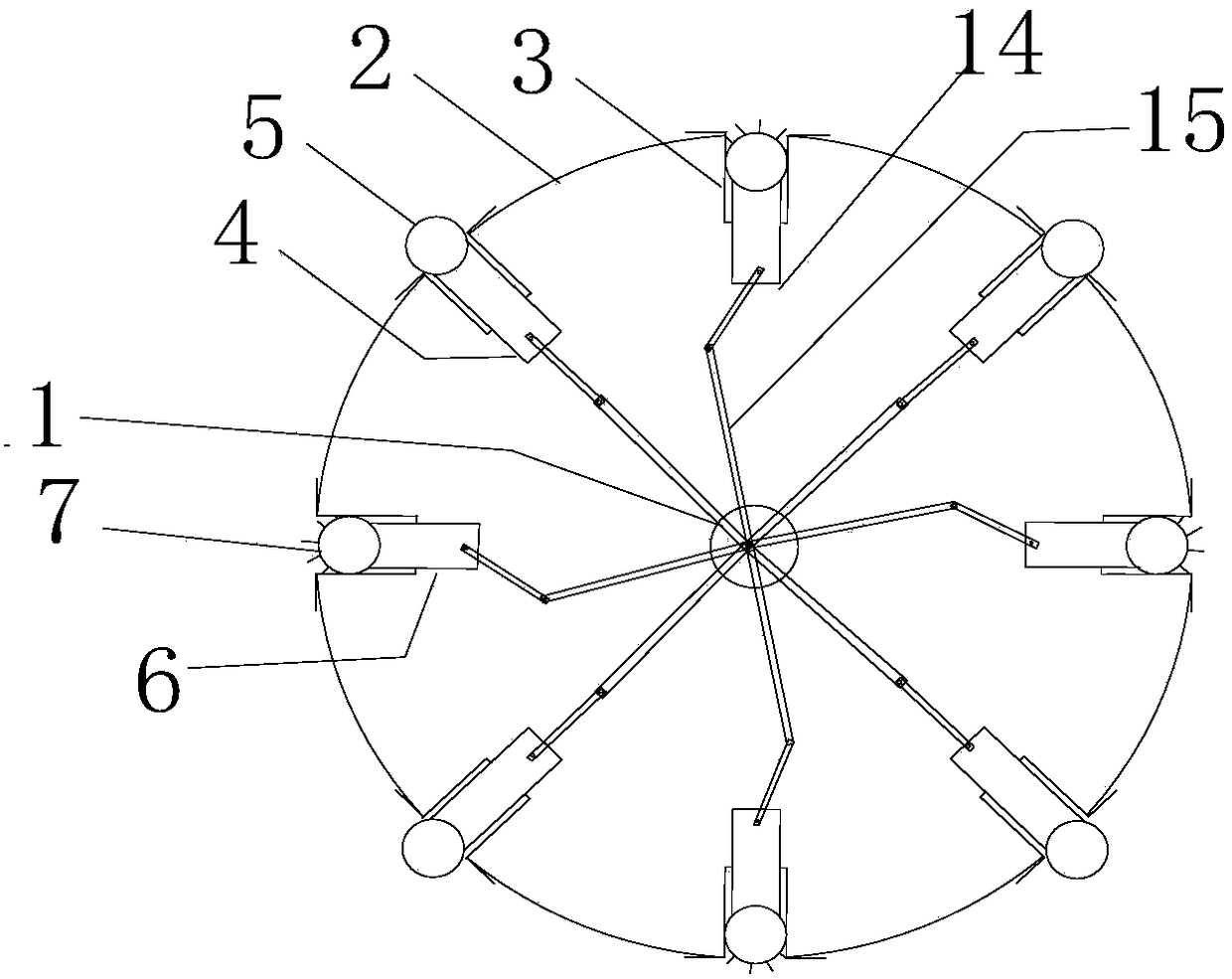

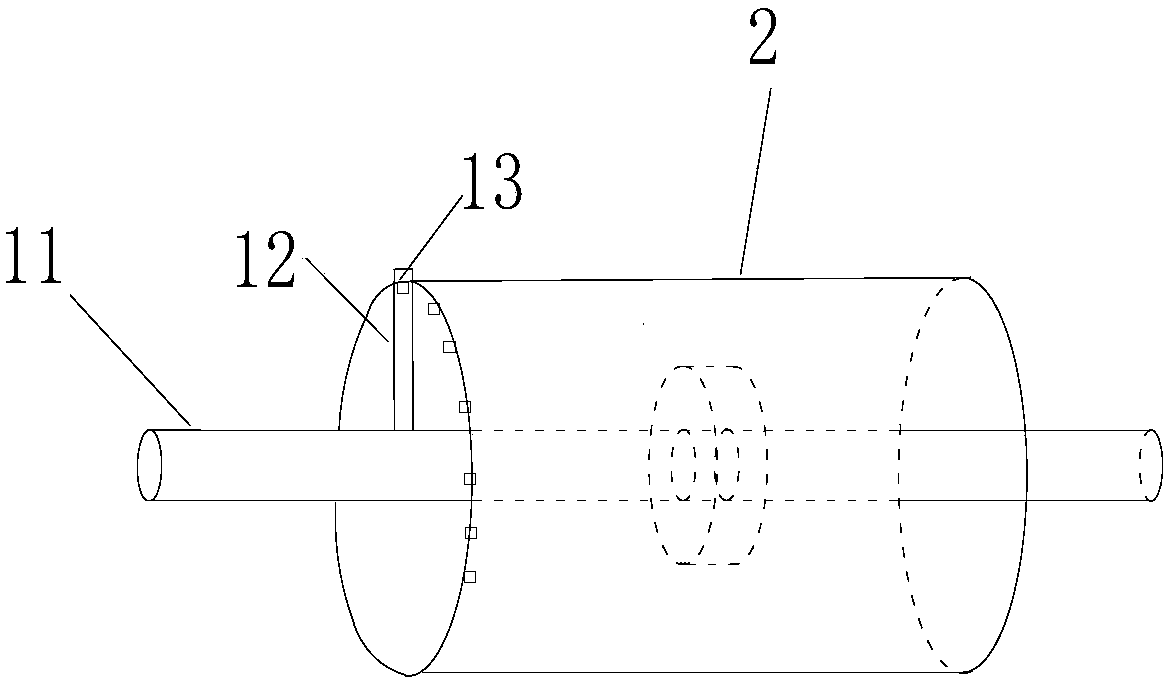

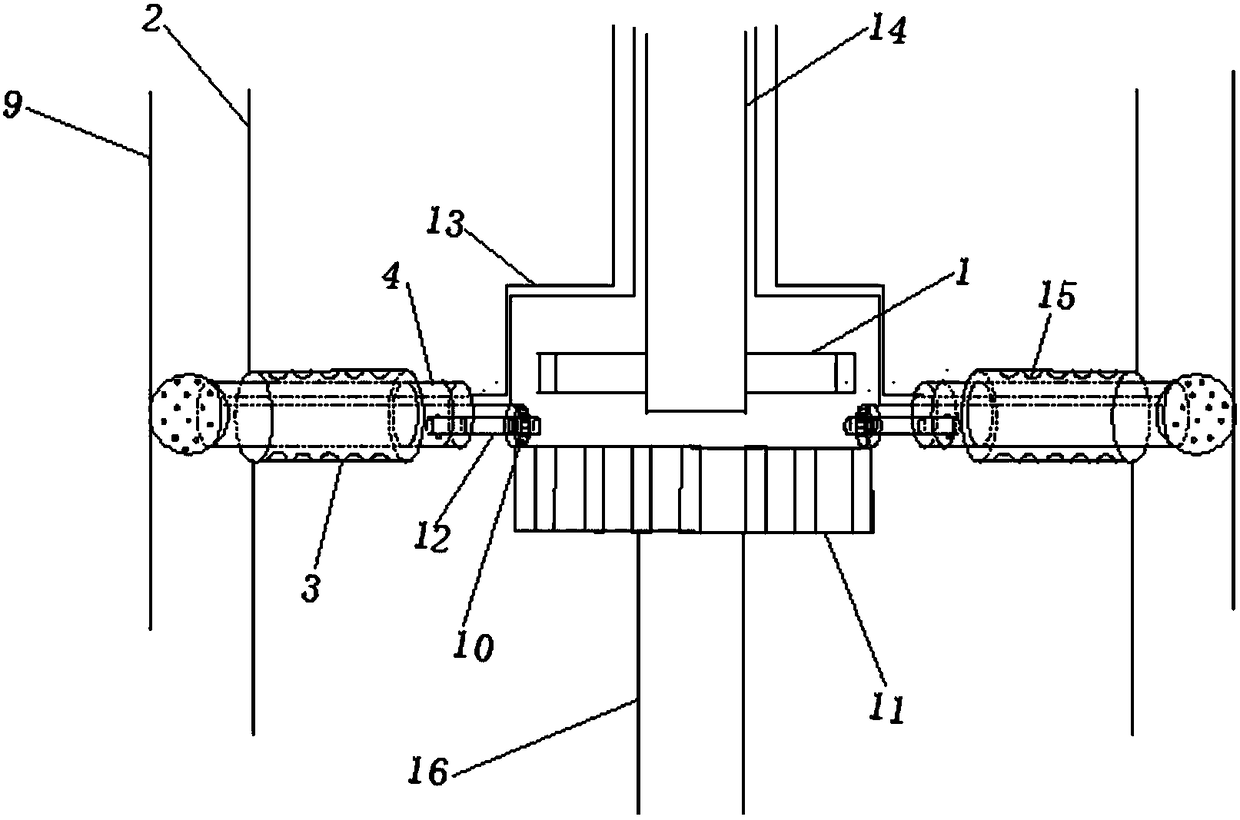

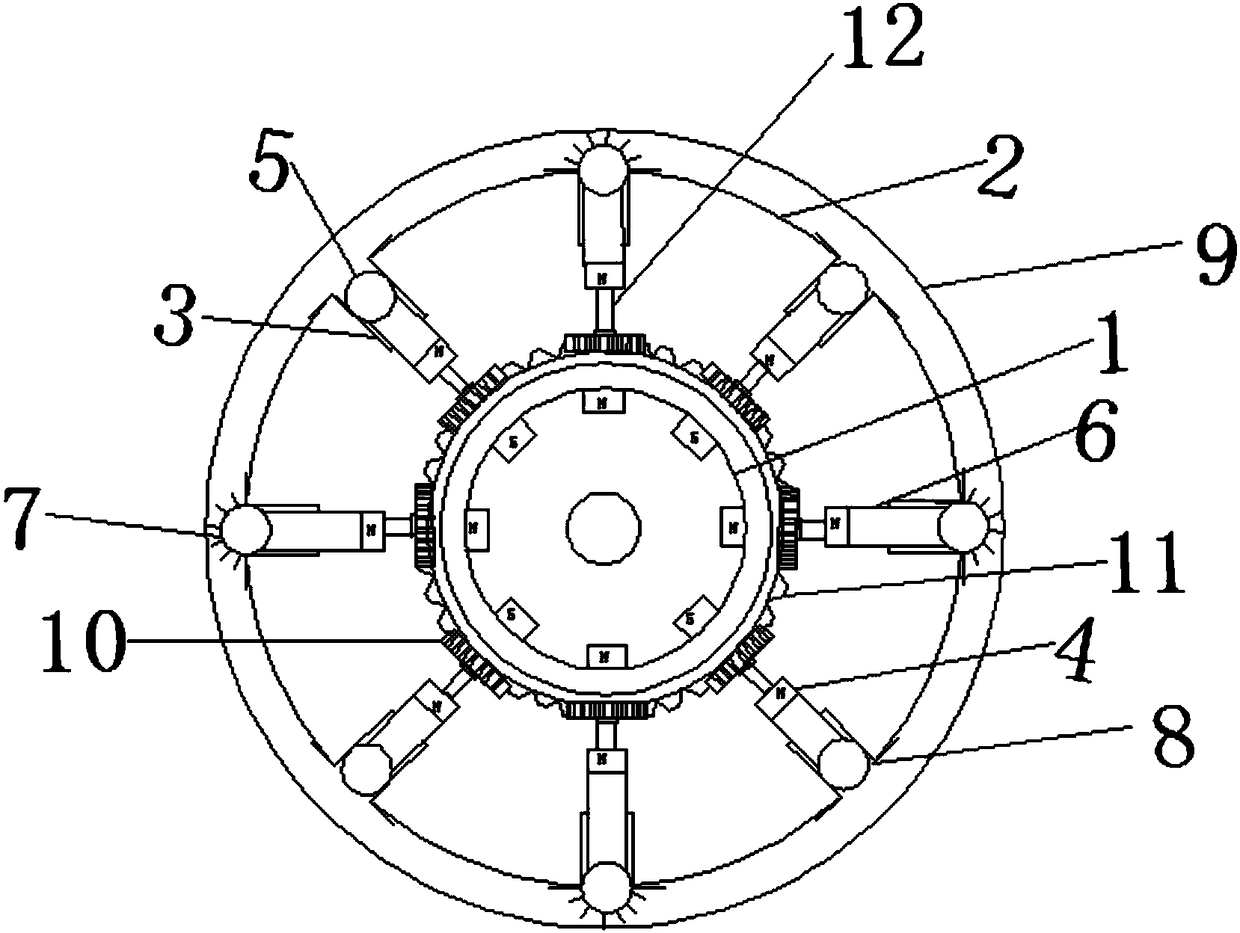

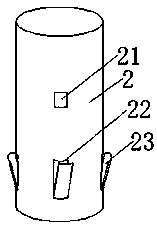

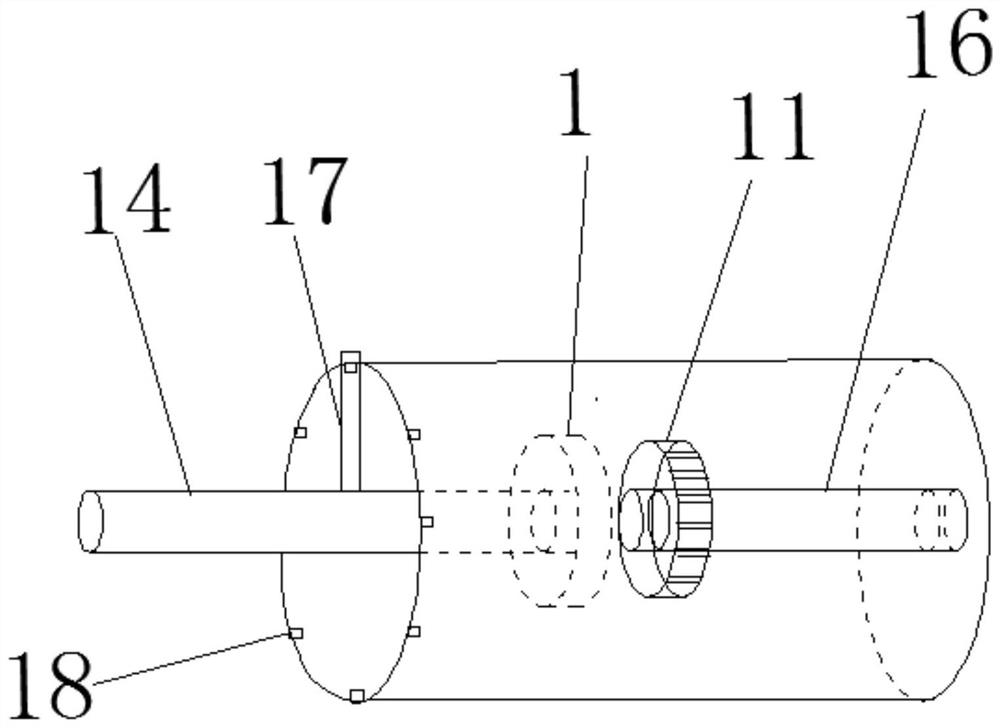

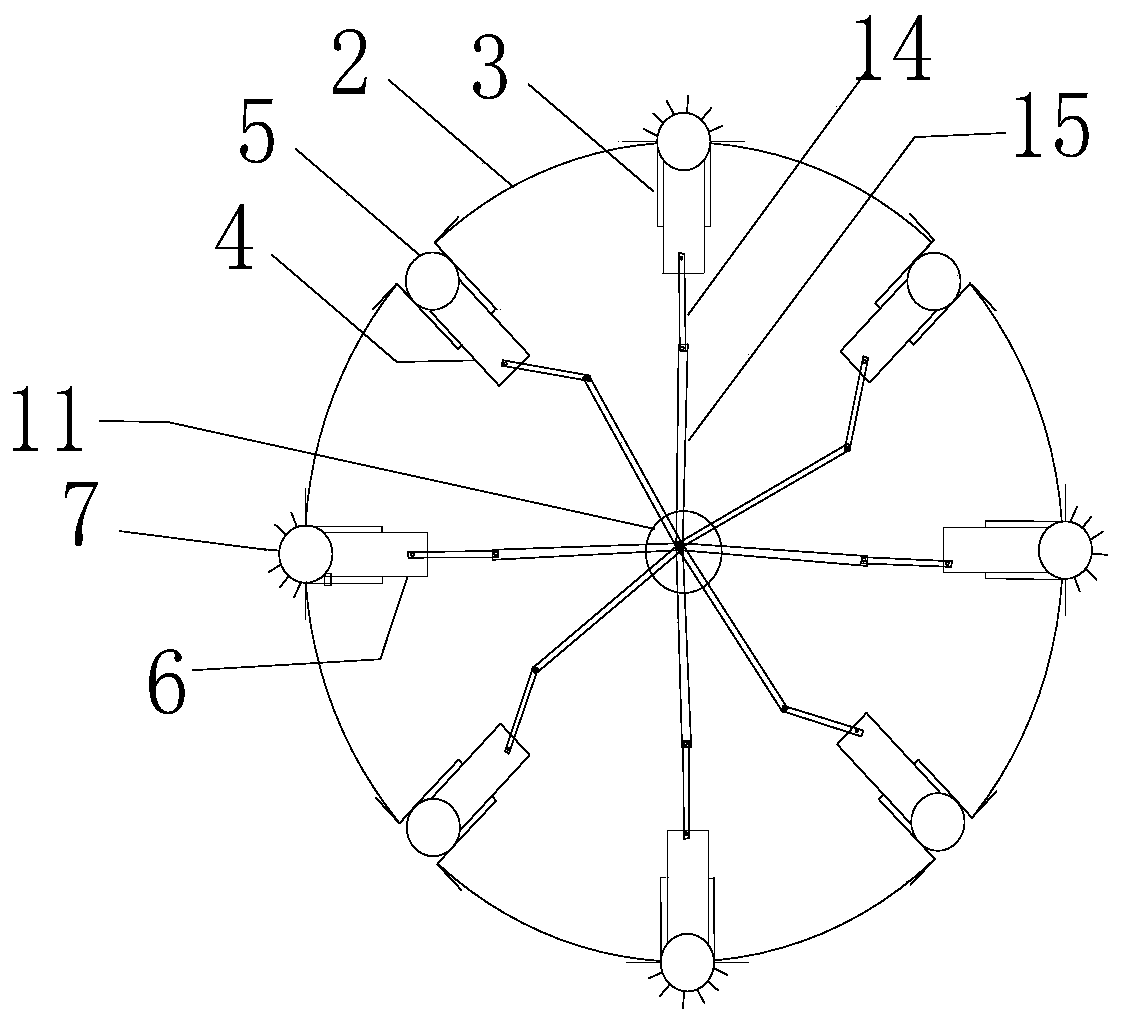

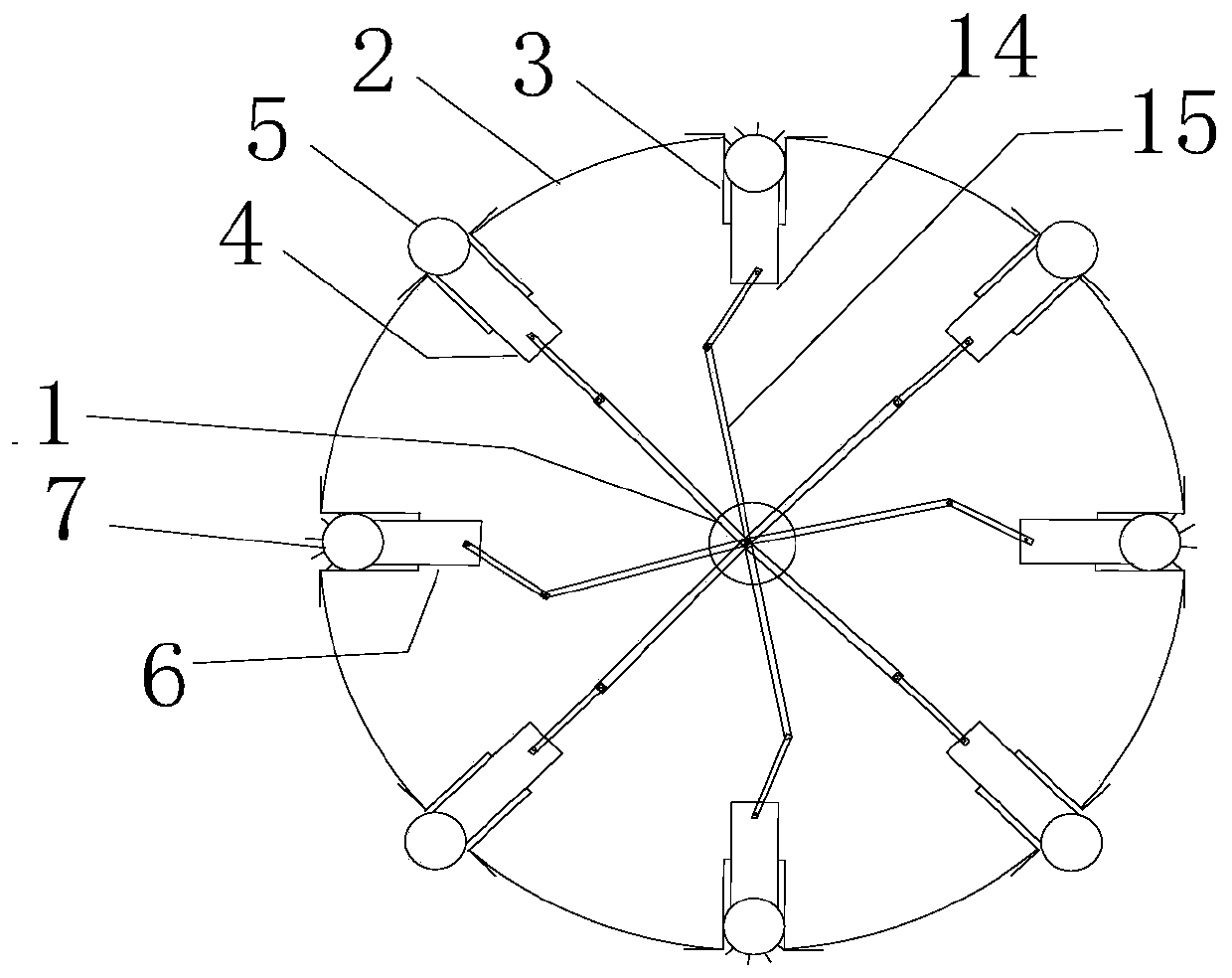

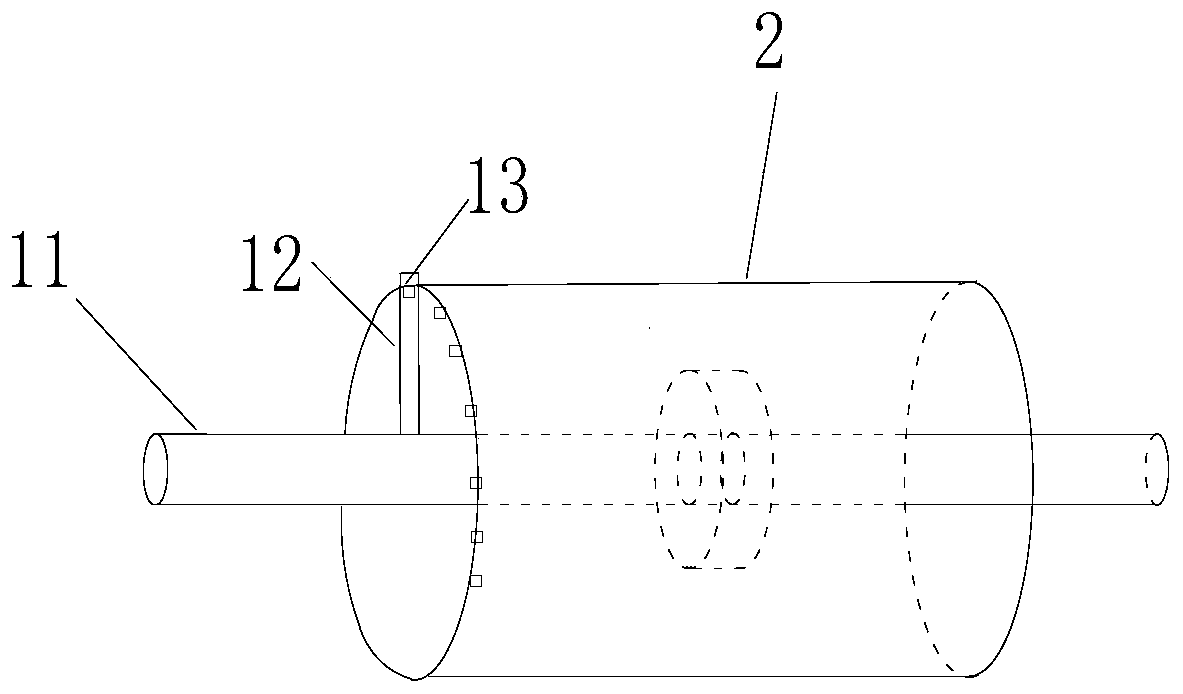

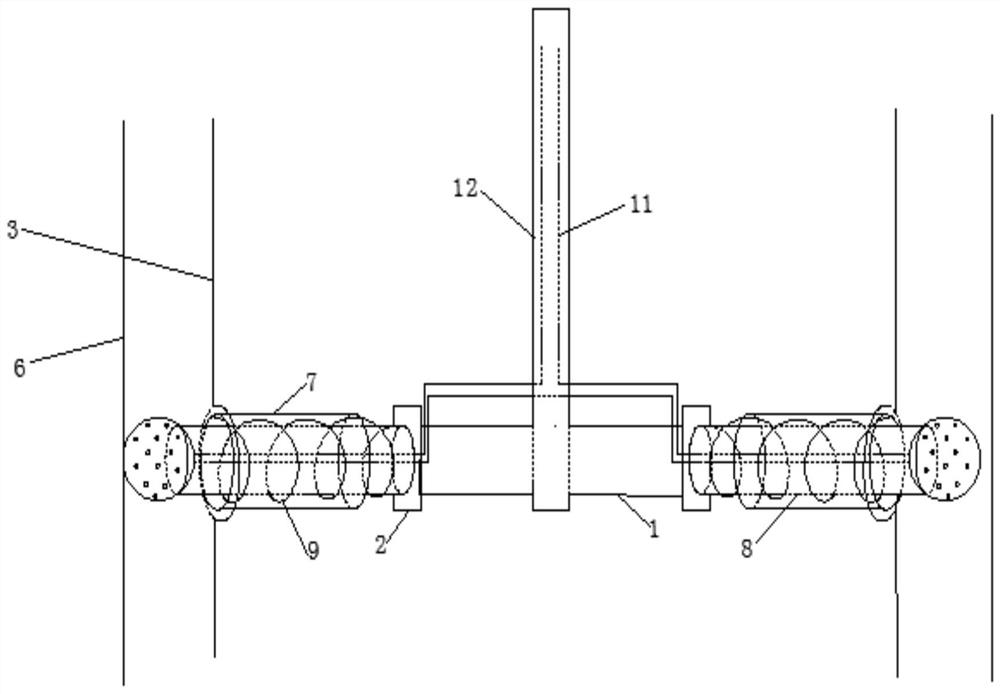

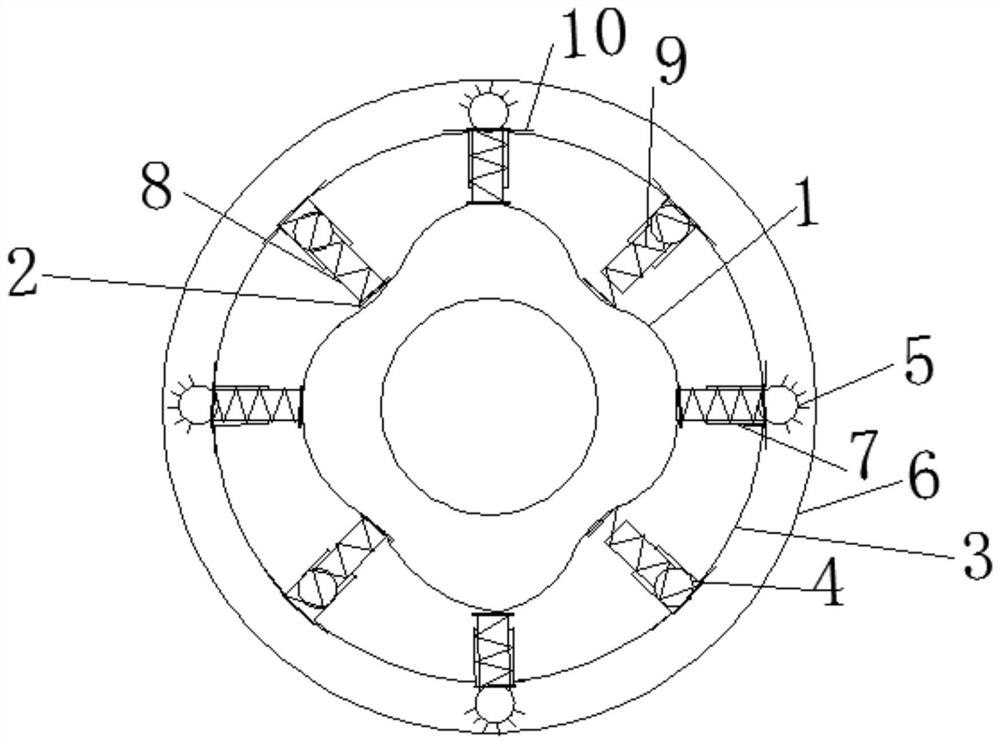

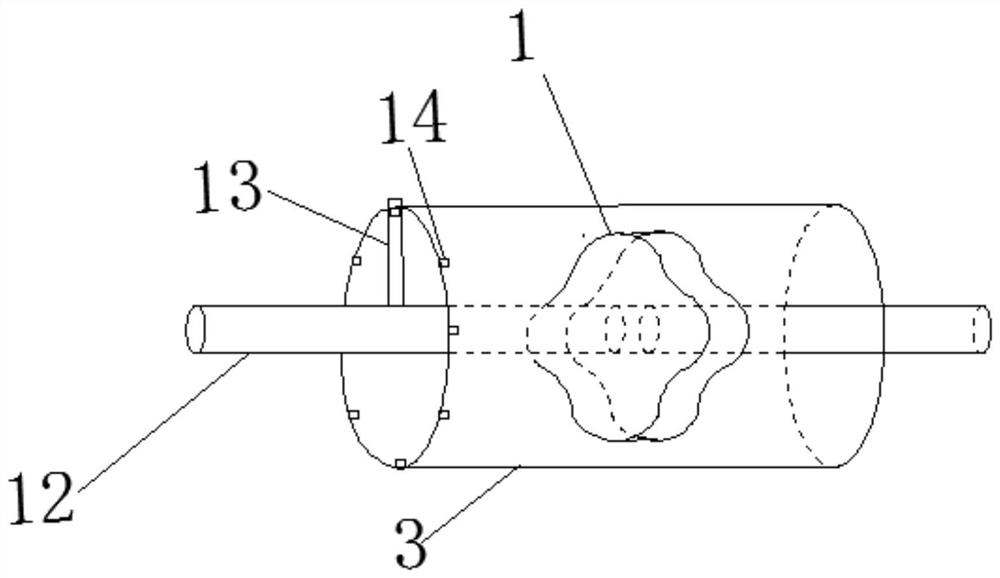

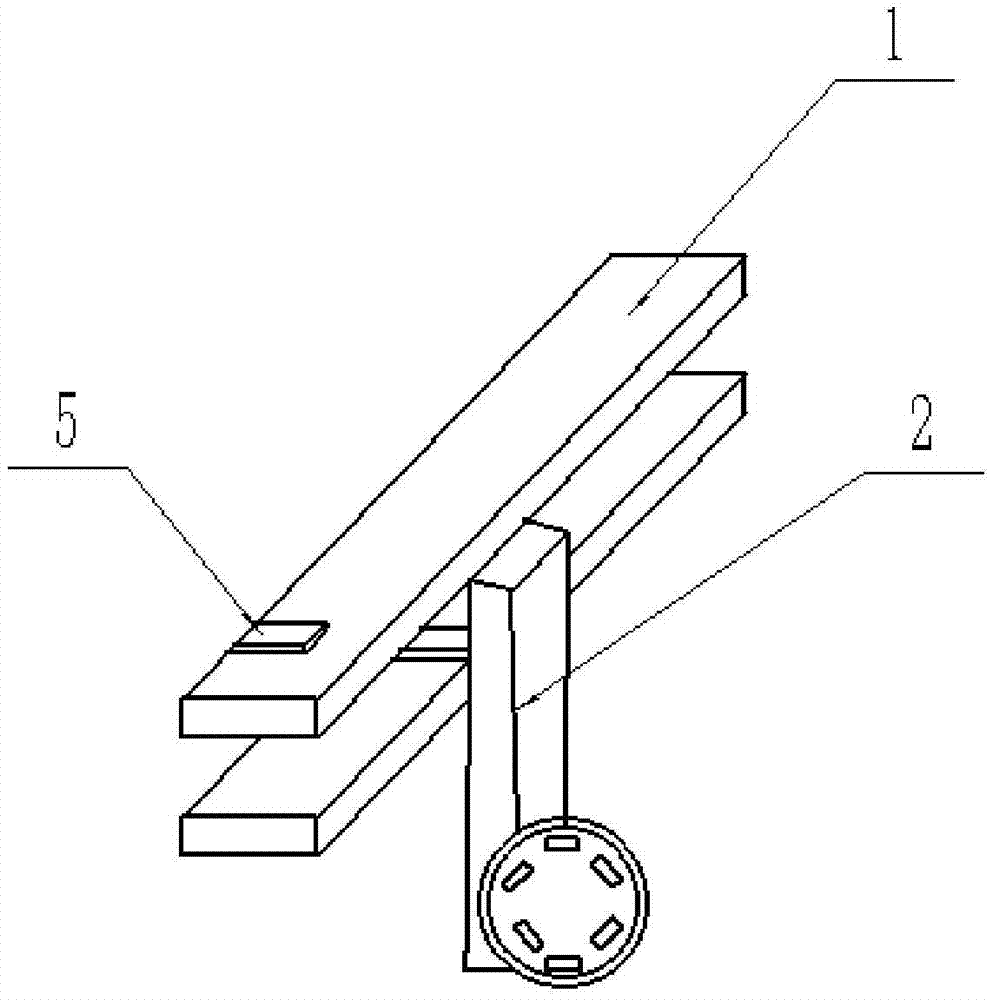

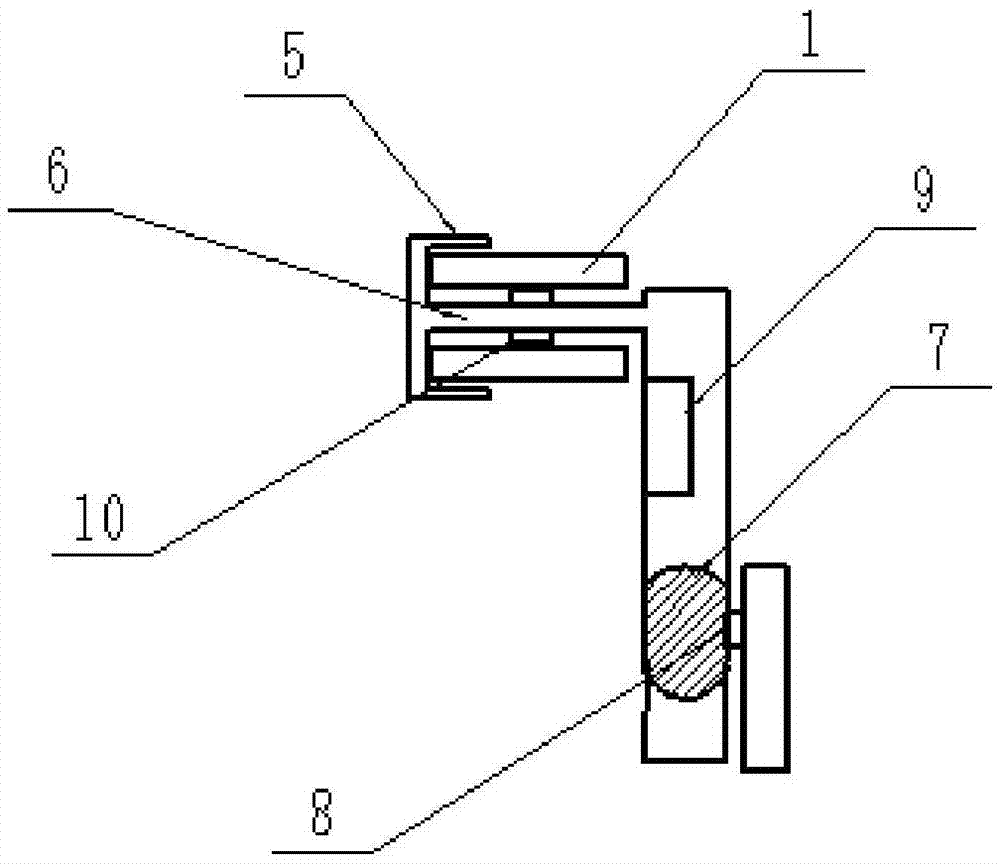

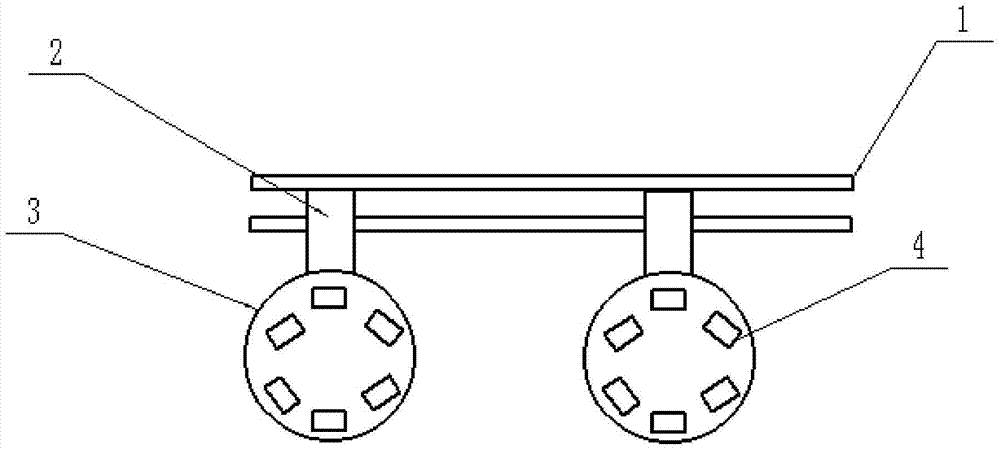

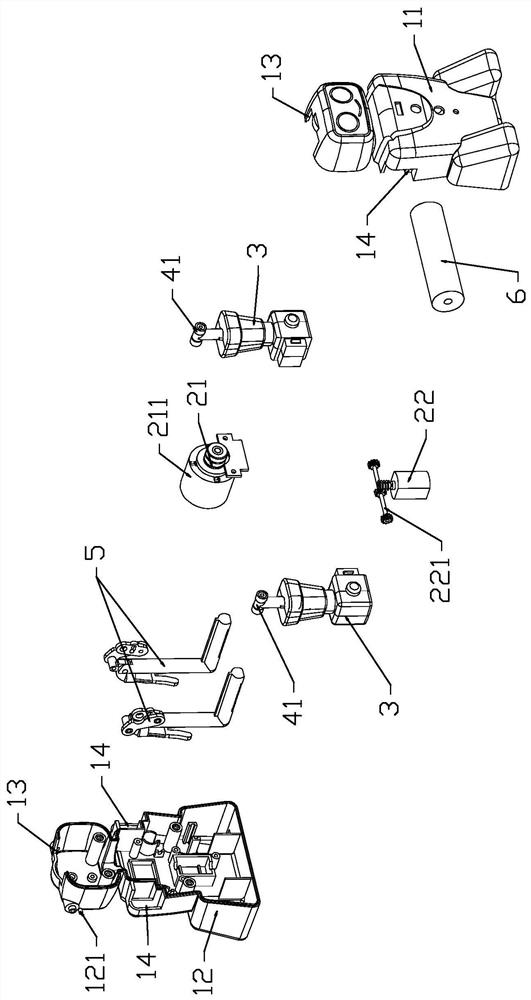

Pipeline inner wall cleaning device

ActiveCN108453101AImprove versatilityImprove effective useHollow article cleaningDrive shaftWater spray

The invention discloses a pipeline inner wall cleaning device. The pipeline inner wall cleaning device comprises an adjusting disc, a rotating disc, a pipe inner wall, holes, guiding pipes, rotating rods, a hard hairbrush device, a soft hairbrush device, a driving shaft, a water inlet pipe, water spray mouths, the pipe inner wall, a connection rod and a locking groove. According to the pipeline inner wall cleaning device, by means of the manner that a hard hairbrush and a soft hairbrush perform cleaning in sequence, all kinds of dirt can be thoroughly removed at a time with more pertinence, various cleaning processes are finished on one cleaning structure, cleaning is performed thoroughly and completely, and complex procedures of the routine cleaning process are avoided, operation workingprocedures are saved, the whole pipeline inner wall cleaning device is simple in structure and convenient to use, the cleaning process is convenient to operate utilizing the cleaning structure, by means of the arrangements of a switching blocking rod and a plurality of clamping grooves, switching of the extension length of the hairbrushes can be realized, the fact that the suitable and thorough cleaning method and cleaning sequence are selected more freely can be realized according to actual pipelines and different types of media inside the pipelines, and the universality of the cleaning device is improved.

Owner:大庆乾斯晨石油科技开发有限公司

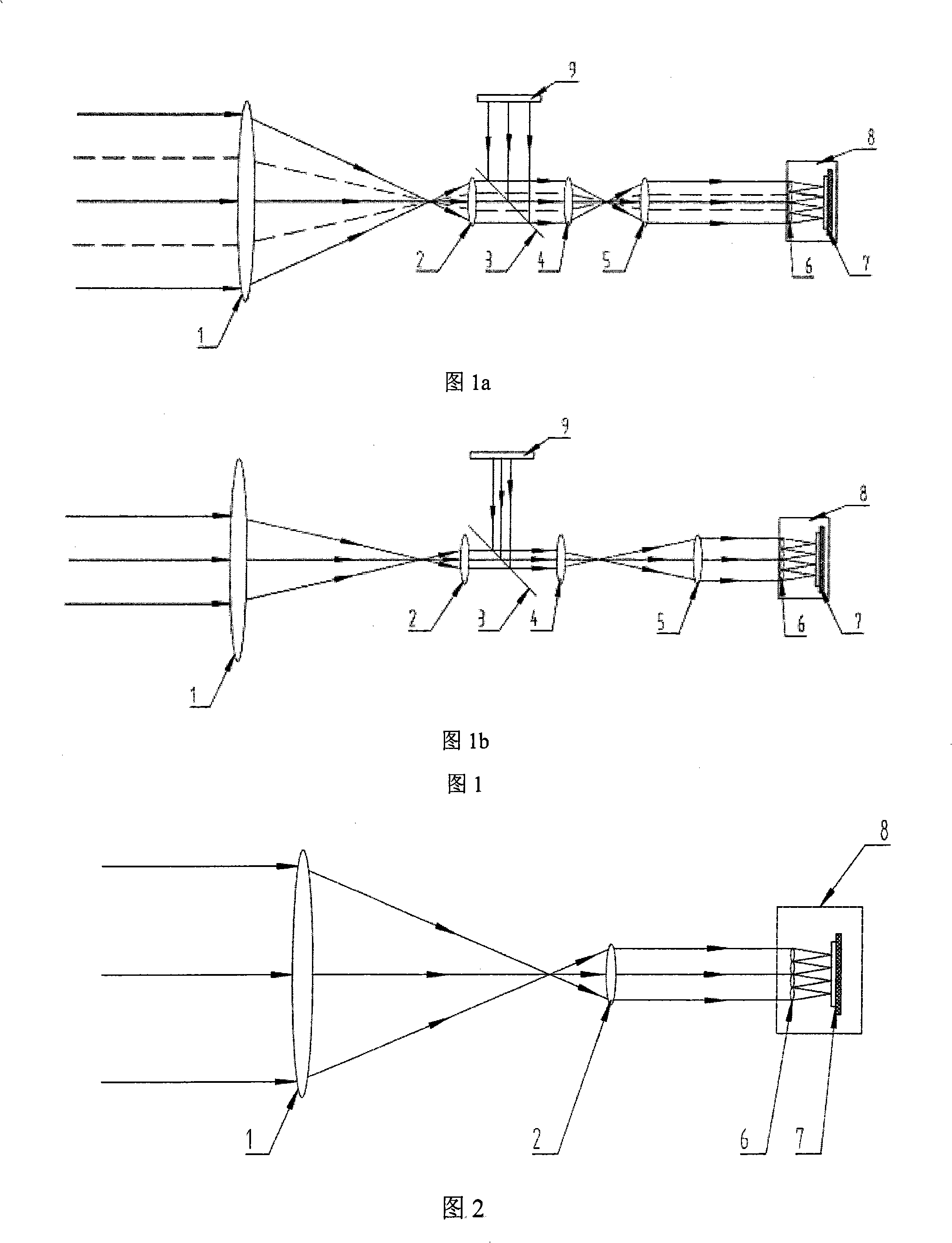

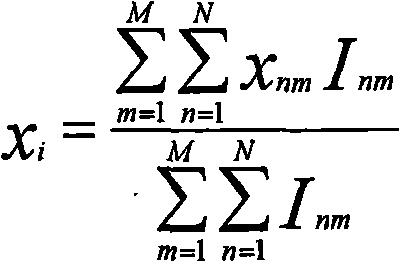

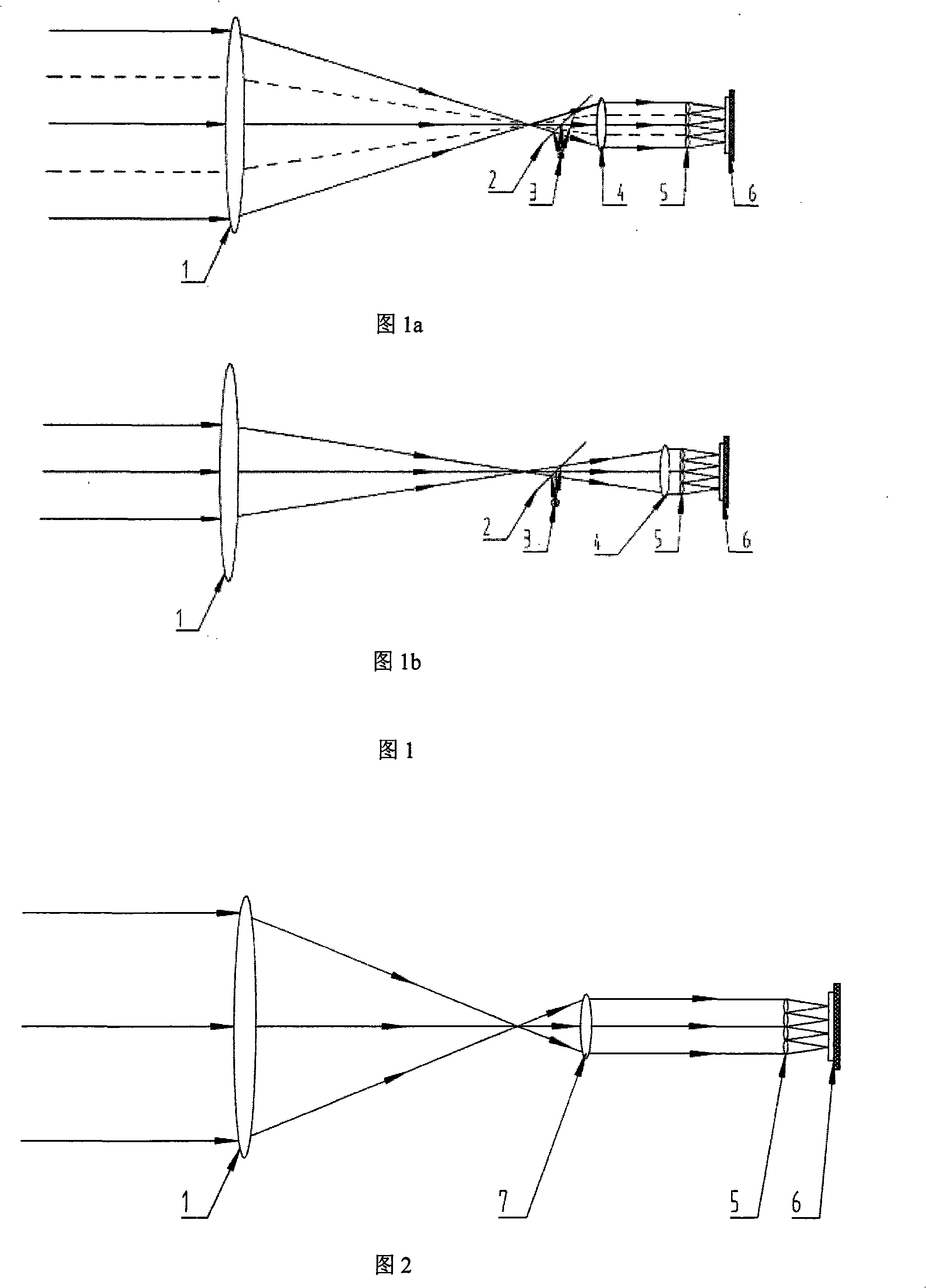

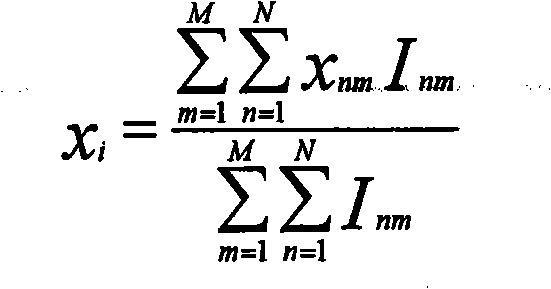

Continuous zooming Hartmann sensor utilizing parallel light source for calibration

InactiveCN101285713AAvoid complex proceduresOptical measurementsTesting optical propertiesLight pipeLight beam

The invention relates to a continuous zooming Hartmann sensor by utilizing parallel light source calibration. The invention is characterized in that: a transition light pipe system which can change the beam condensing rate is arranged on the back of a beam contraction system of the prior Hartmann sensor and in the front of a microlens array; a light source system is arranged between the beam contraction system and the transition light pipe system; through adjusting a zoom lens foci in the transition light pipe system, incident beams in different apertures are output to the microlens array by the same emergent aperture; therefore, the beams in different incident apertures can sample by the same spatial sampling frequency. The continuous zooming Hartmann sensor enlarges the application range of the Hartmann sensor to the field of measuring the continuously-changed beam apertures and has the same spatial sampling frequency for different incident apertures, thereby measuring the beams with different apertures on the premise of not reducing measurement precision and increasing the universality of the Hartmann sensor in order that one Hartmann sensor can be used for different apertures and save use cost.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Continuous zooming Hartmann sensor utilizing point light source for calibration

InactiveCN101285714AAvoid complex proceduresOptical measurementsTesting optical propertiesLight beamMicro lens array

The invention relates to a continuous zooming Hartmann sensor by utilizing pointolite calibration. The invention is characterized in that: the Hartmann sensor makes two changes on the basis of the prior Hartmann sensor: firstly, after the beam contraction, a lens is changed into a lens set which can continuously zoom; secondly, a light source system is arranged in the middle of a beam contraction system; through adjusting a foci of the lens after beam contraction, the incident beams in different apertures are output to a microlens array by the same emergent aperture; therefore, the beams in different incident apertures can sample by the same spatial sampling frequency. The continuous zooming Hartmann sensor enlarges the application range of the Hartmann sensor to the field of measuring the continuously-changed beam apertures and has the same spatial sampling frequency for different incident apertures, thereby measuring the beams with different apertures on the premise of not reducing measurement precision and increasing the universality of the Hartmann sensor in order that one Hartmann sensor can be used for different apertures and save use cost.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

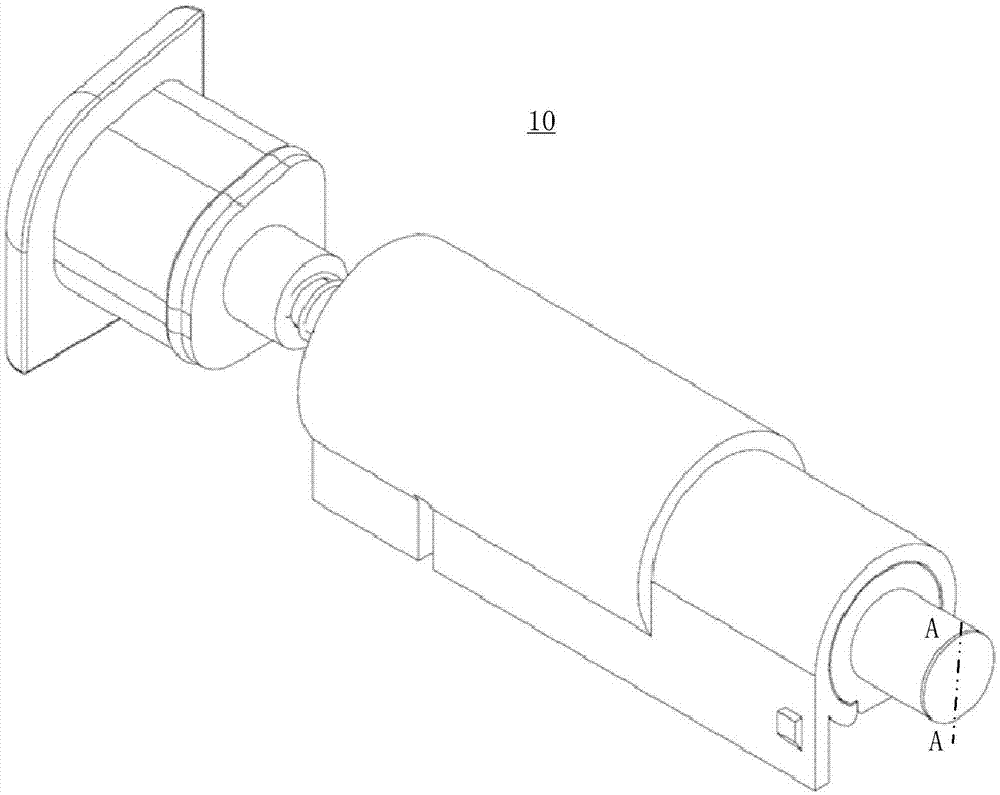

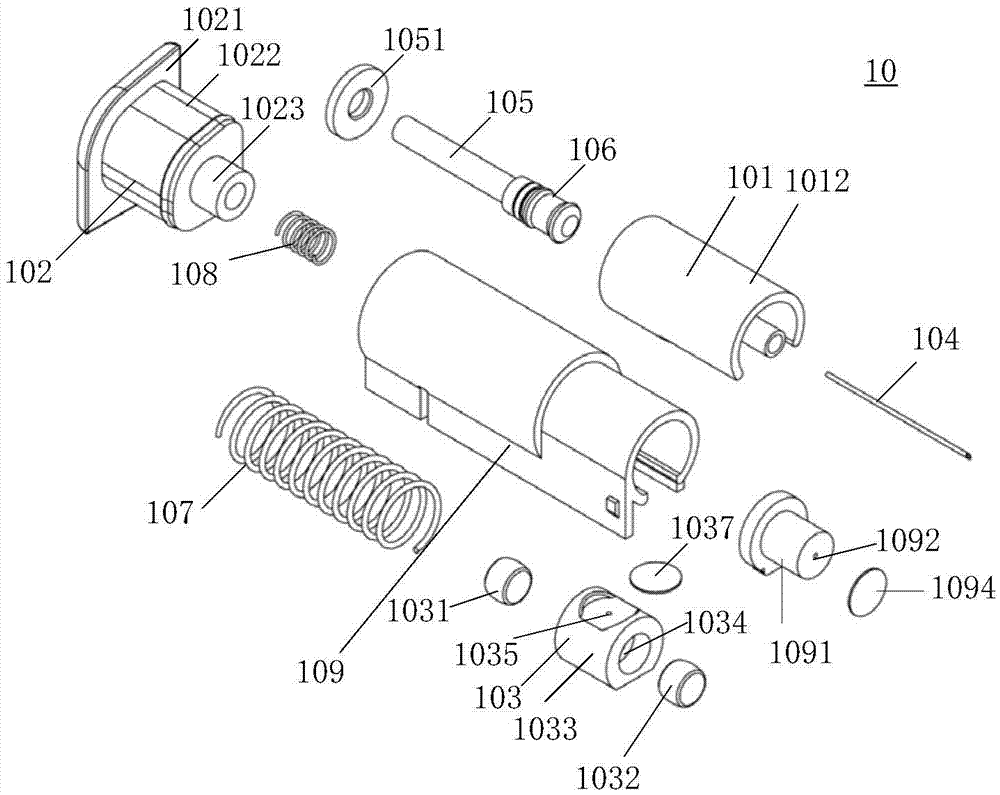

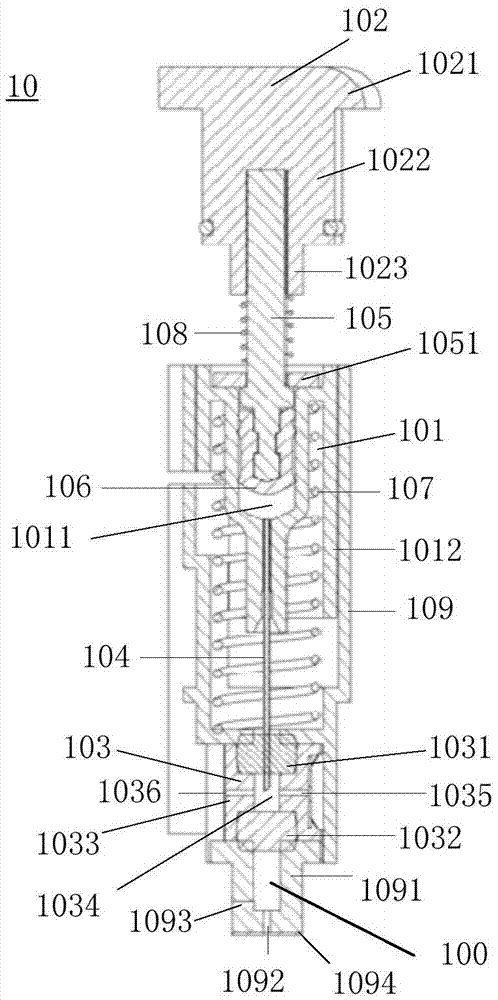

Fluid infusion device for dosing patient

InactiveCN106902420AAvoid complex procedures for setting infusion volumeAvoid complex proceduresAutomatic syringesMedical devicesFluid infusionBiomedical engineering

The invention provides a fluid infusion device for dosing a patient. The fluid infusion device comprises an injection mechanism, a fluid output channel, a connecting portion and a hollow puncture component. The hollow puncture component and the injection mechanism are fixedly connected, and the hollow portion is communicated with a liquid storage cavity of the injection mechanism. The hollow puncture component is configured to penetrate through a supply cavity of the connecting component under push of the injection mechanism, stretch into a fluid output channel so that a piston inside the liquid storage cavity can drive fluid inside the liquid storage cavity to the fluid output channel, and return to the supply cavity under dragging of the injection mechanism so that the supply cavity and the liquid storage cavity can be communicated so as to guide fluid inside the supply cavity into the liquid storage cavity. According to the fluid injection device, the process of setting the infusion amount during each injection can be omitted, and process for setting the infusion amount is simplified.

Owner:MEDTRONIC INC

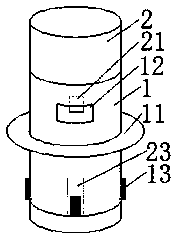

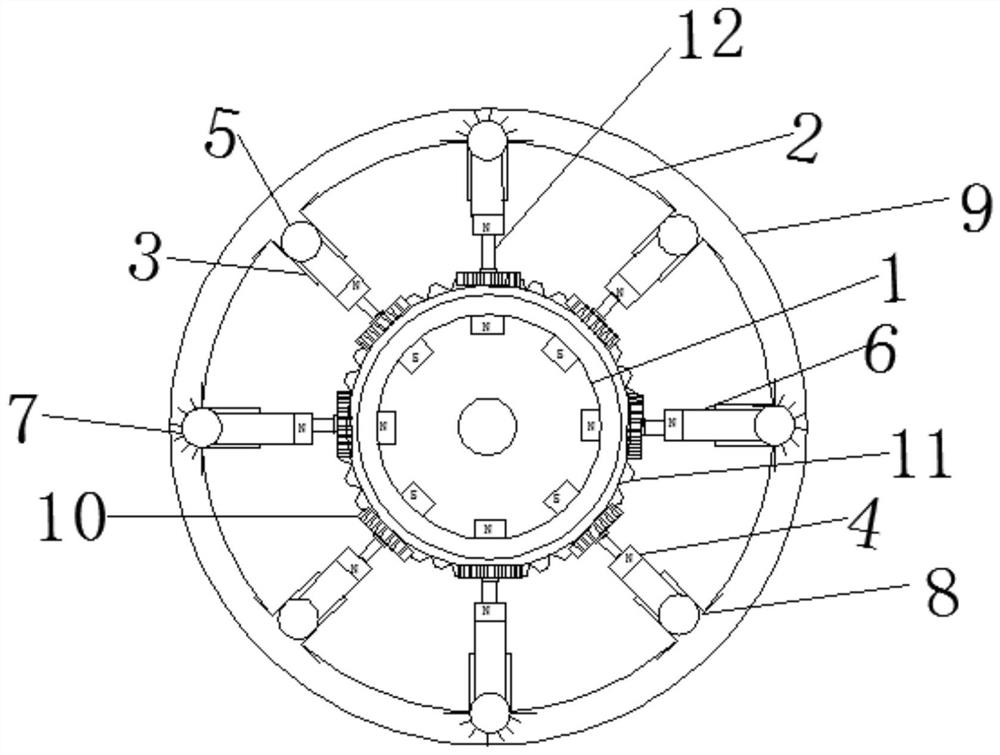

Pipeline inner wall washing device with self-cleaning function

ActiveCN108580457AClean up thoroughlyRealize free switchingHollow article cleaningDrive shaftEngineering

The invention discloses a pipeline inner wall washing device with a self-cleaning function. The pipeline inner wall washing device comprises an adjusting disc, a rotary disc, a pipe inner wall, holes,guide pipes, magnetic blocks, a hard brush device, a soft brush device, driving shafts, a water inflow pipe, water injection nozzles, a pipe inner wall, connecting rods and locking grooves. Various kinds of dirt can be more pertinently and completely cleaned away at a time in the manner of sequential washing of hard brushes and soft brushes, washing brush heads of the washing device do not need to be specially taken out, simplicity and convenience are achieved, the clean brush heads stretch out in the next conversion process after the brush heads are self-cleaned, new washing is carried out,thus, the problem that the brush heads with dirt are poor in washing effect after being used for a long time can be avoided, and more convenient self-washing of the brush heads is also achieved whilethe washing effect is enhanced.

Owner:LUAN XIANGCHUAN TECH CO LTD

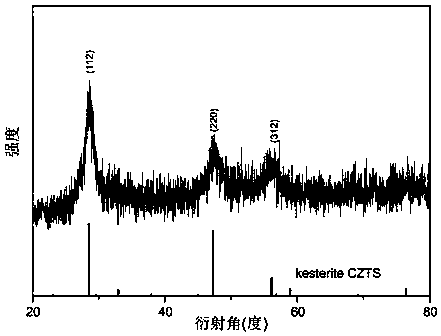

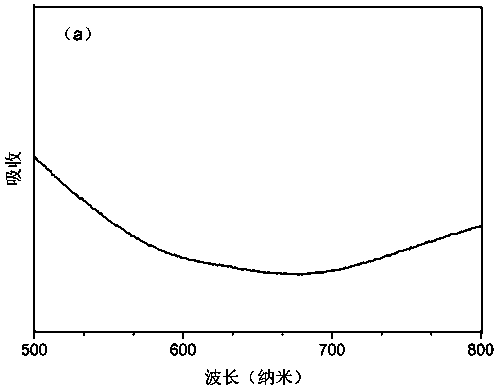

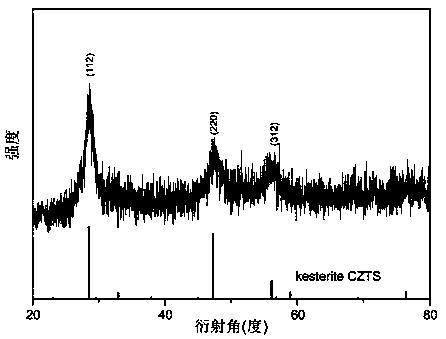

Preparation method of copper-zinc-tin-sulfur film

ActiveCN108550642ASimple processThe reaction device is simpleSemiconductor devicesChemistryFilm material

The invention relates to a preparation method of a copper-zinc-tin-sulfide film, and belongs to the technical field of functional film materials. According to the invention, a copper source, a zinc source, a tin source and a sulfur source are added into an organic solvent, wherein the molar ratio of the copper source, the zinc source, the tin source and the sulfur source is (1-2) (1-2): (1-2): (4-10). The organic solvent is stirred and subjected to ultrasonic treatment, and then a precursor solution is obtained. The ultrasonic cleaning and drying process of an FTO conductive glass or a siliconwafer in the vacuum state is carried out. The precursor solution is coated on the FTO conductive glass or the silicon wafer through the spin-coating process. Meanwhile, the FTO conductive glass or the silicon wafer is dried in the vacuum state for 6-10 hours at the temperature of 60-90 DEG C. After that, the spin-coating process of the precursor solution is repeated for 3-6 times, and a CZTS filmprecursor is obtained after carrying out the vacuum drying operation. The annealing treatment is performed on the CZTS film precursor. Finally, the microwave optimization treatment is performed on the CZTS film precursor after being subjected to the annealing treatment, and then a CZTS film is obtained. The method is simple in process, simple in reaction device, high in reaction speed, low in cost and good in film forming quality.

Owner:KUNMING UNIV OF SCI & TECH

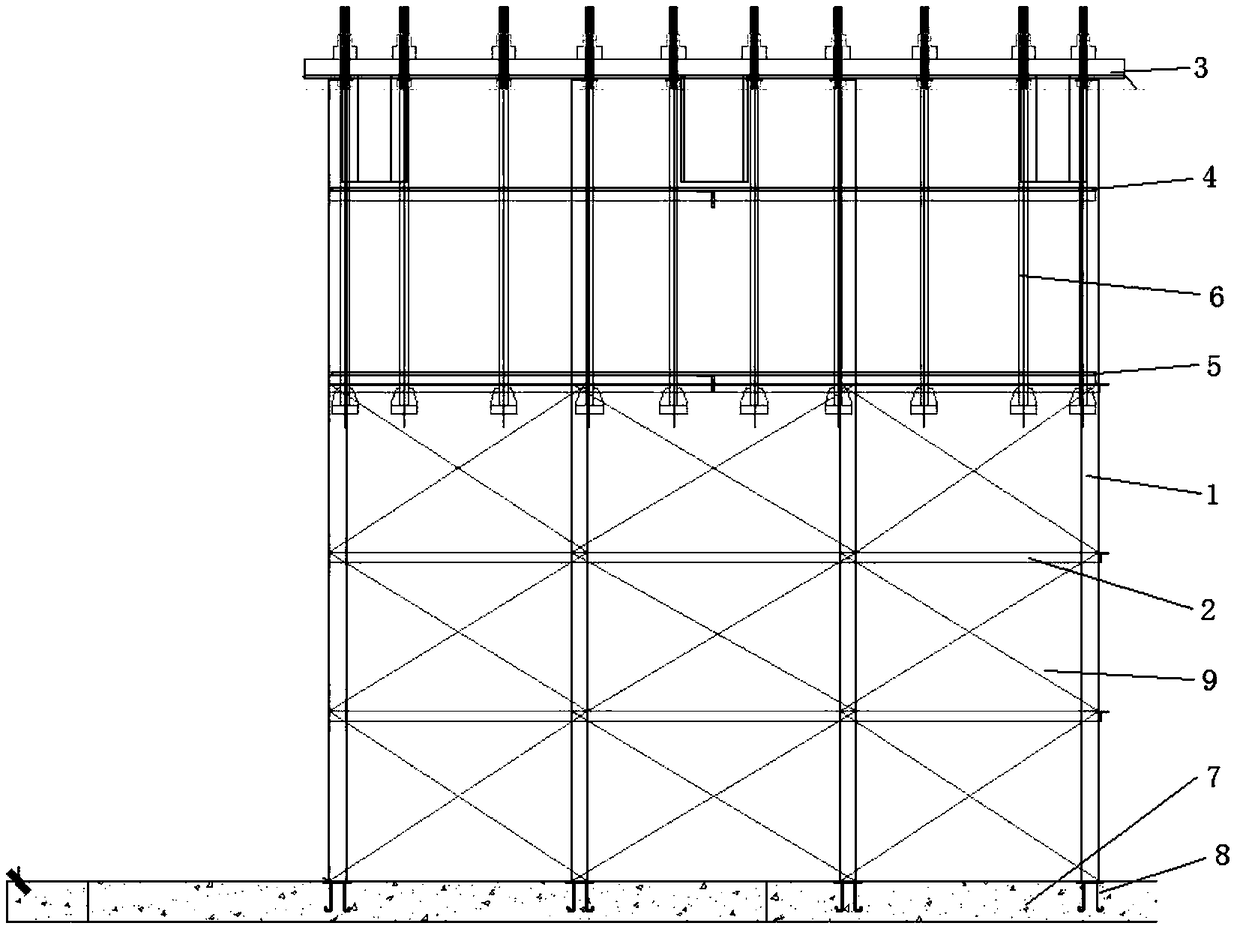

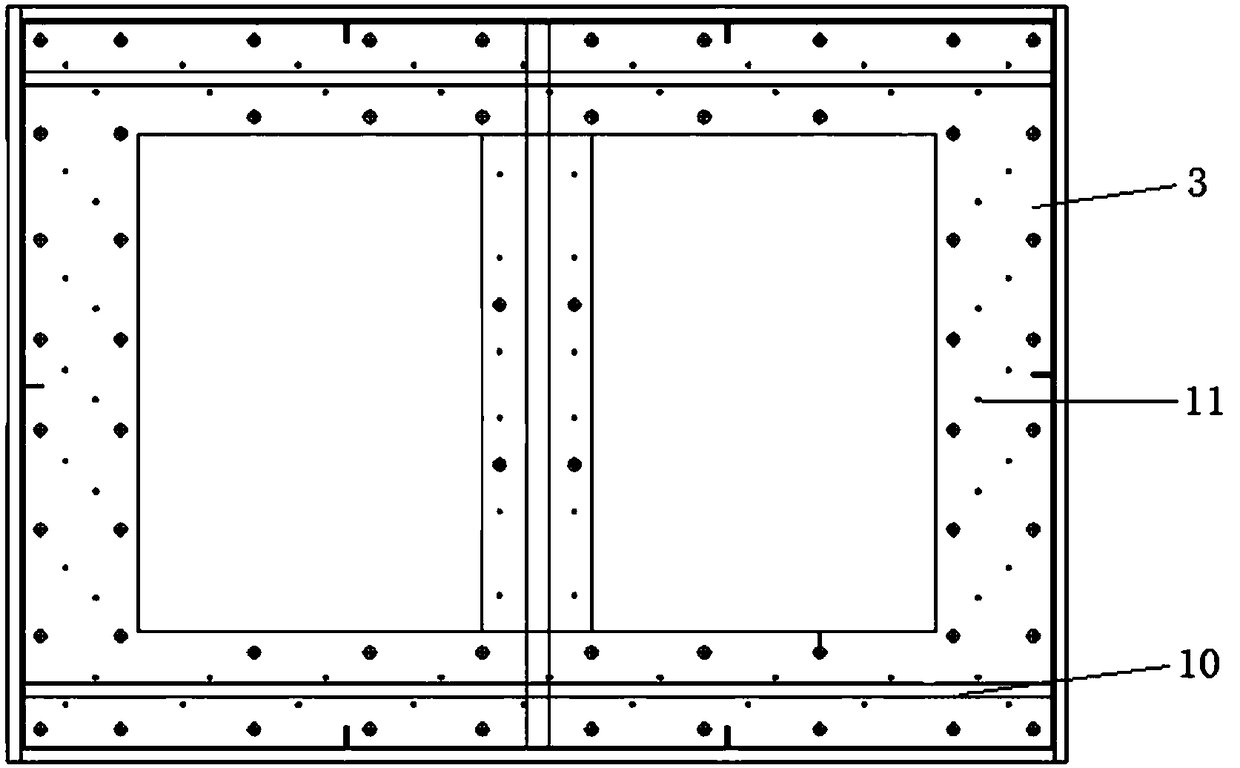

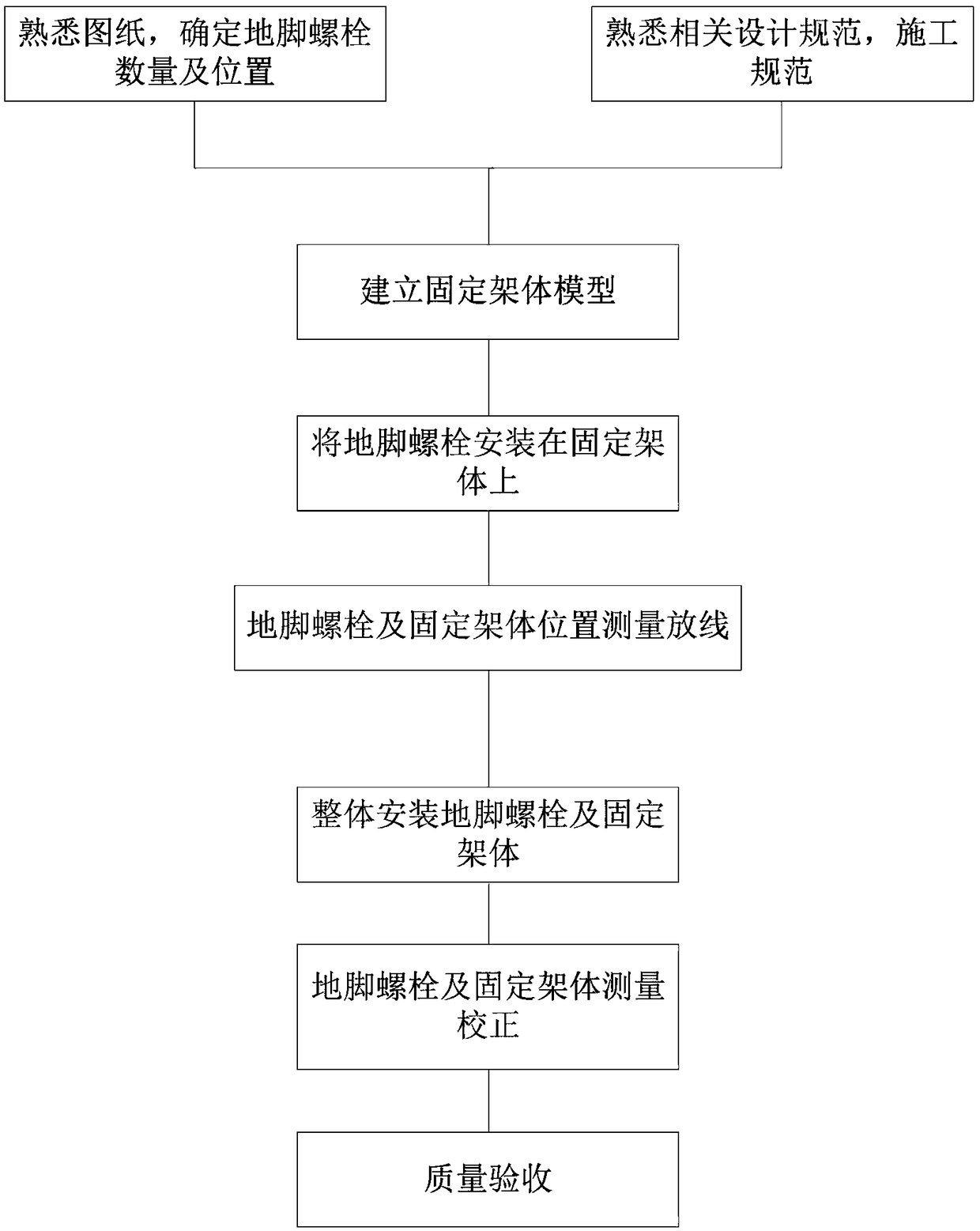

Fixing frame body for positioning anchor bolt group and construction method therefor

PendingCN109137963AAvoid complex proceduresEasy constructionFoundation engineeringCushionFixed frame

The invention discloses a fixing frame body for positioning an anchor bolt group, which comprises a frame which is formed by a plurality of upright columns and cross bars in a surrounding manner and which is vertically connected. The top of the frame is provided with an annular panel, and the middle part of the frame is provided with a first positioning plate and a second positioning plate parallel to the annular panel in a spaced manner; the annular panel is provided with a plurality of bolt mounting holes at intervals, and anchor bolts sequentially pass through the second positioning plate,the first positioning plate, and the bolt positioning holes in the annular panel and are matched with nuts; and the lower ends of the upright columns are connected with pre-buried plates pre-buried ina base cushion of a steel structure giant column. The invention also discloses a construction method for pre-burying the anchor bolt group. The invention has the beneficial effects that the fixing frame body is designed, the anchor bolts are accurately mounted on the fixing frame body, the fixing frame body and the anchor bolts are integrally formed, and finally the overall correction is carriedout by adjusting the positions of the fixing frame body and the steel structure giant column to realize the pre-buried precision of the anchor bolts; the method is simple to construct; and the positioning accuracy of the anchor bolts is higher.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Technological method for recovering lead from copper smelting smoke dust

InactiveCN107815555AEmission reductionReduce wastePhotography auxillary processesProcess efficiency improvementElectrolysisResource utilization

The invention discloses a technological method for recovering lead from copper smelting smoke dust. According to the adopted main technological procedure, the copper smelting smoke dust is sequentially subjected to water-slurrying leaching, blast furnace smelting, lead alloy fire refining, lead alloy electrolysis and alkaline fusion lead extracting, and finally, a lead ingot is prepared. Accordingto the technology, the waste copper smelting smoke dust is adopted as a raw material, and the advantage of increasing of the resource utilization rate is achieved; in the smelting process, a circulating system is adopted, resource comprehensive utilization is achieved, and the resource is saved; and through an alkaline fusion lead extracting method, the complex procedure of subsequent treatment of a traditional method is omitted, the extracting cost is reduced, and the lead extracting efficiency is improved.

Owner:安徽省恒伟铋业有限公司

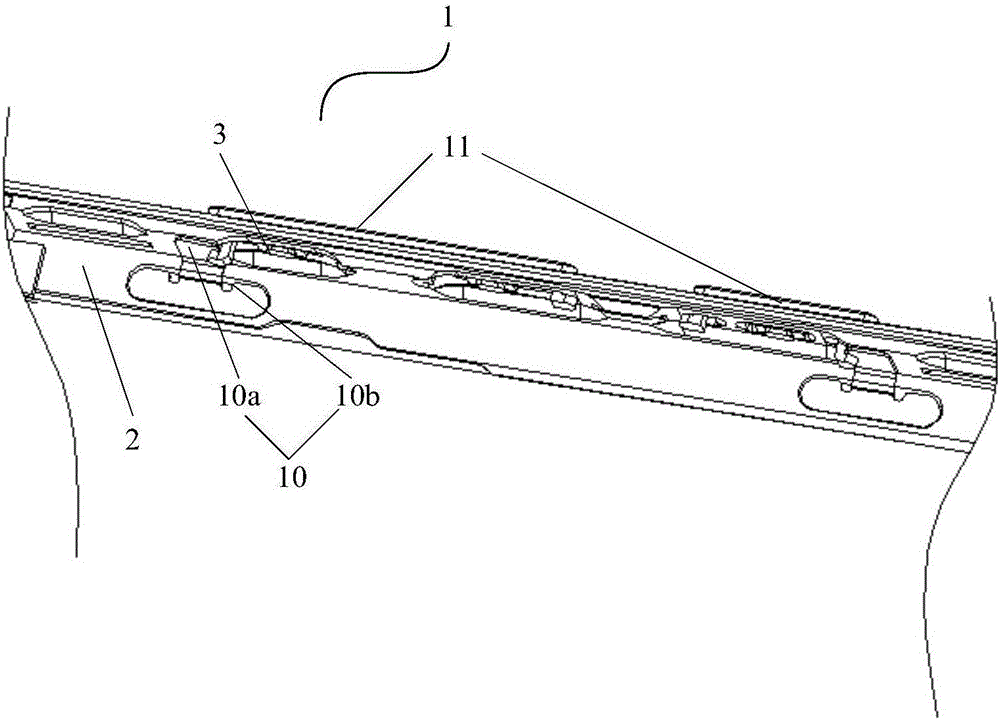

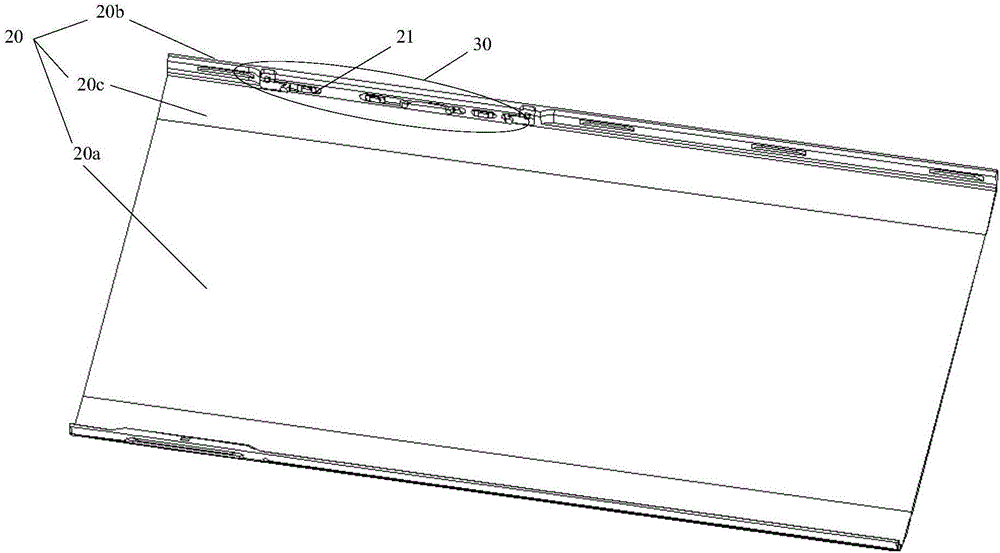

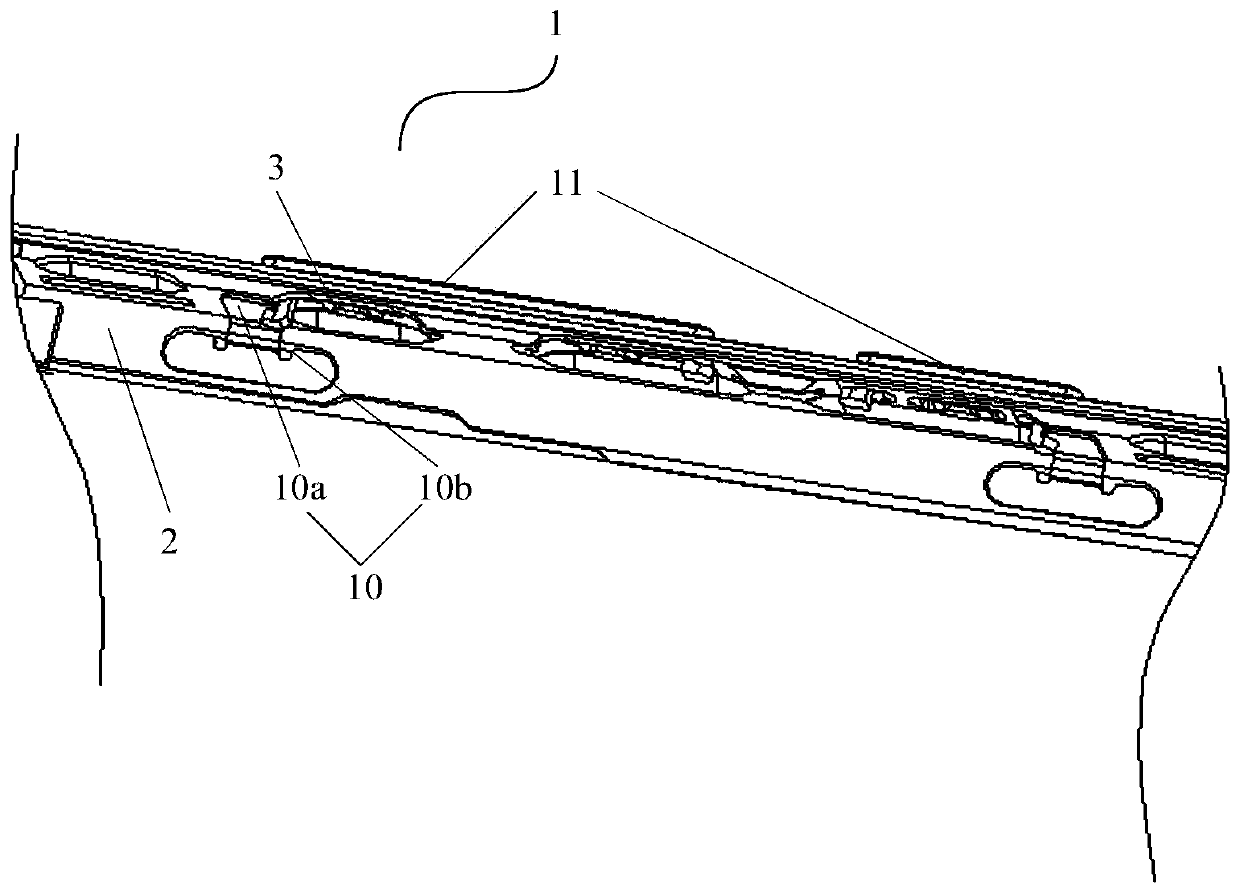

Side button fixing structure and mobile terminal

ActiveCN106531513AAvoid complex proceduresReduce manufacturing costElectric switchesEngineeringKey pressing

The invention provides a side button fixing structure and a mobile terminal. The mobile terminal comprises a shell. The side wall of the shell is provided with installing holes. The side button fixing structure comprises side buttons and limiting members. The side buttons are installed on the side wall of the shell through the installing holes. Each limiting member comprises a fixing part and a limiting part. The fixing part is fixed on the side wall of the shell. The first end of the limiting part is connected with the fixing part. The second end of the limiting part extends along the internal side of the side wall of the shell and is connected with the side buttons in a limiting manner. Therefore, the limiting members are directly fixed on the side wall of the shell without considering the radian size of the transition shell part of the back surface of the shell and the side wall of the shell so that complex processing procedures of the shell can be avoided and manufacturing cost can be saved.

Owner:VIVO MOBILE COMM CO LTD

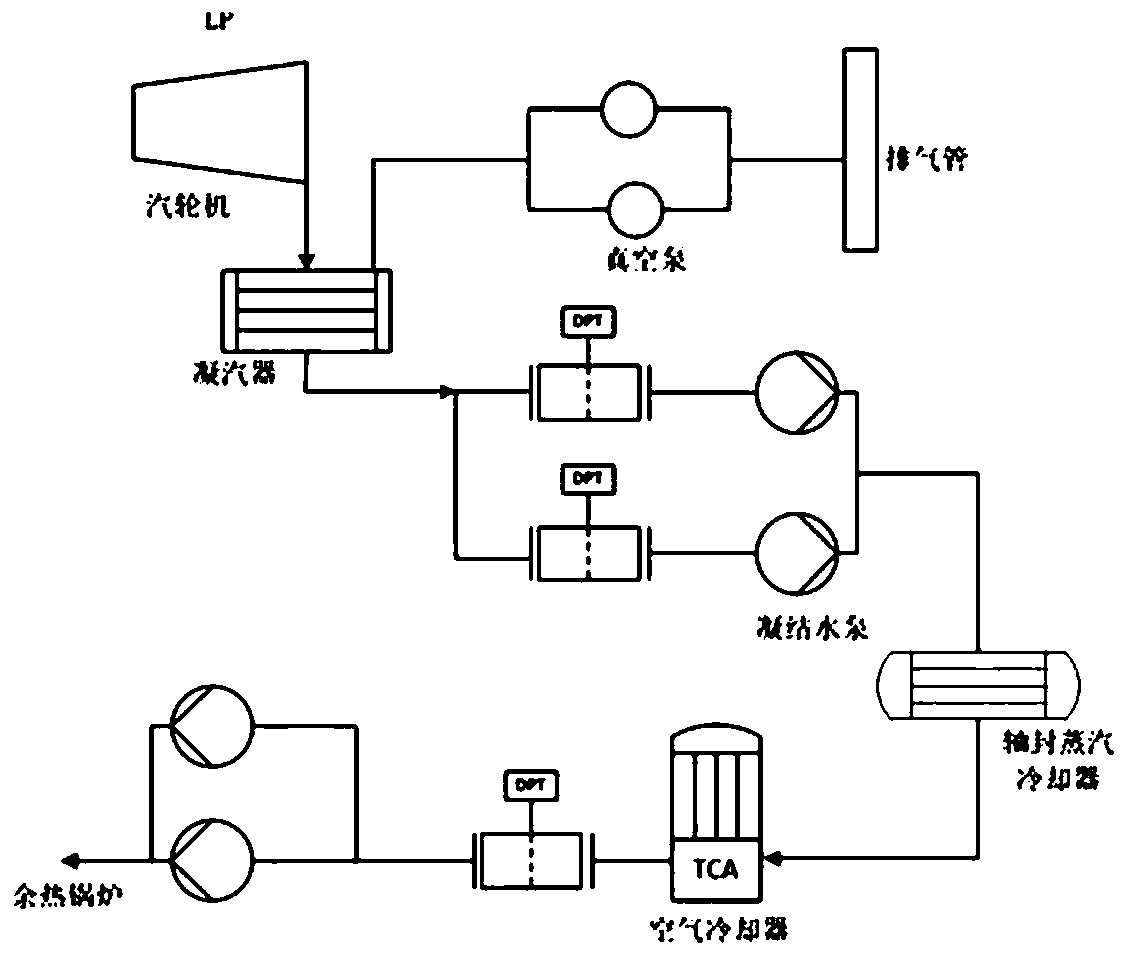

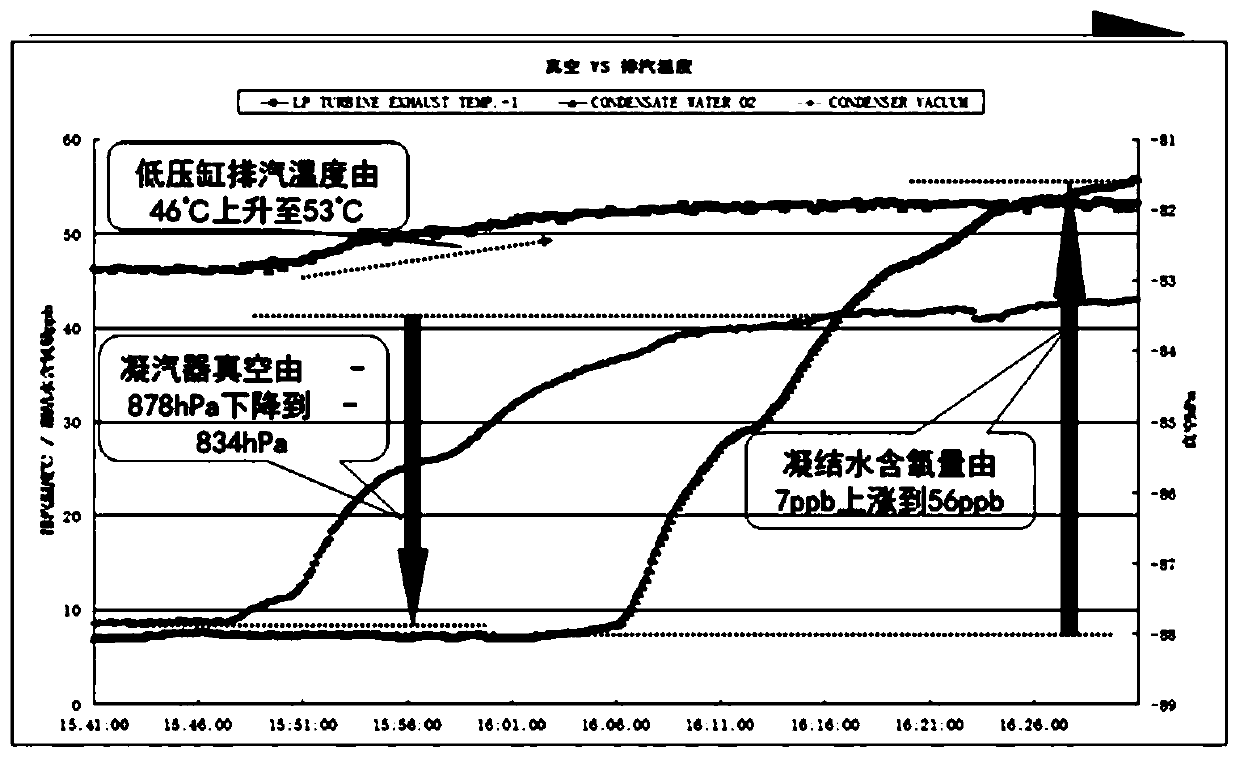

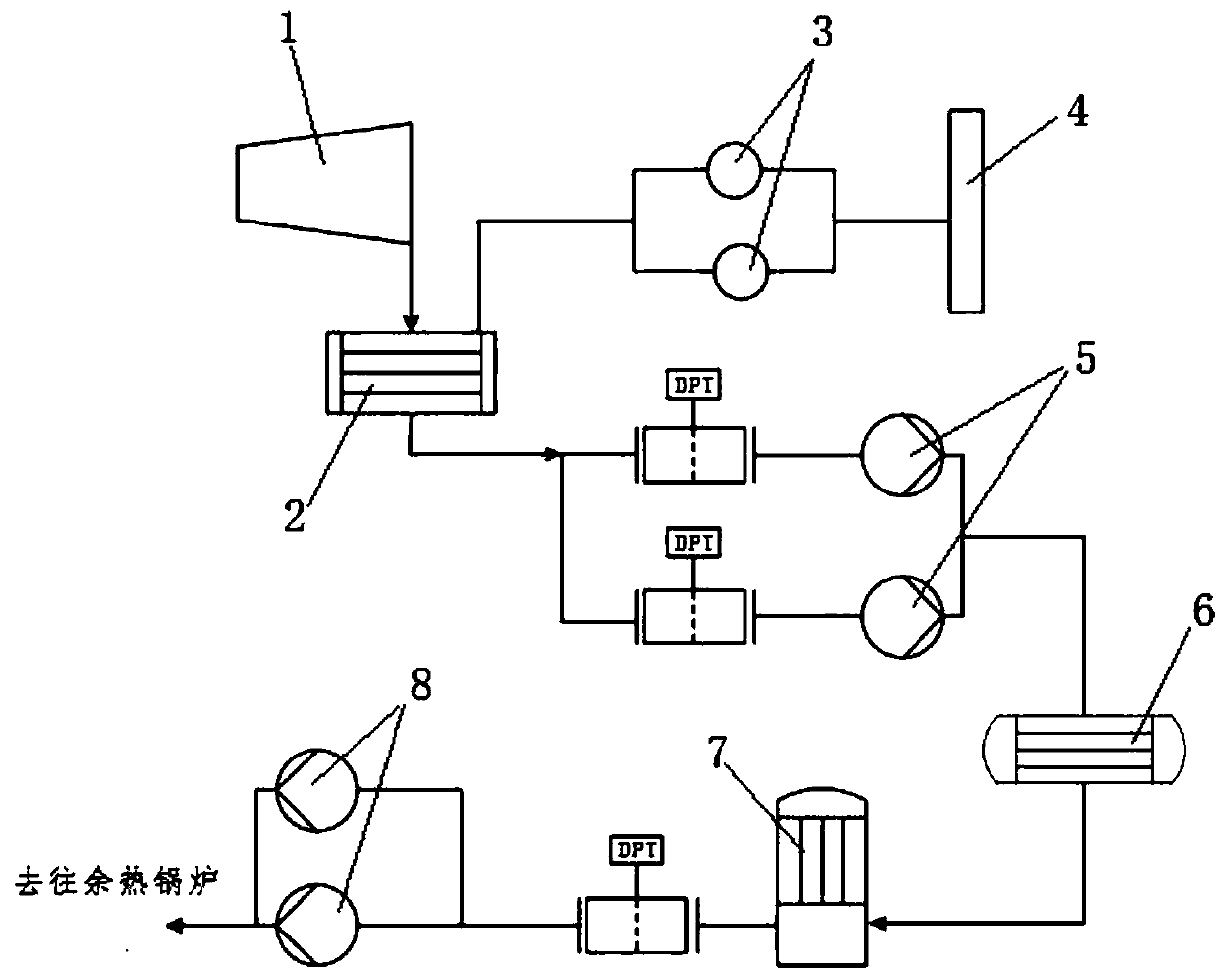

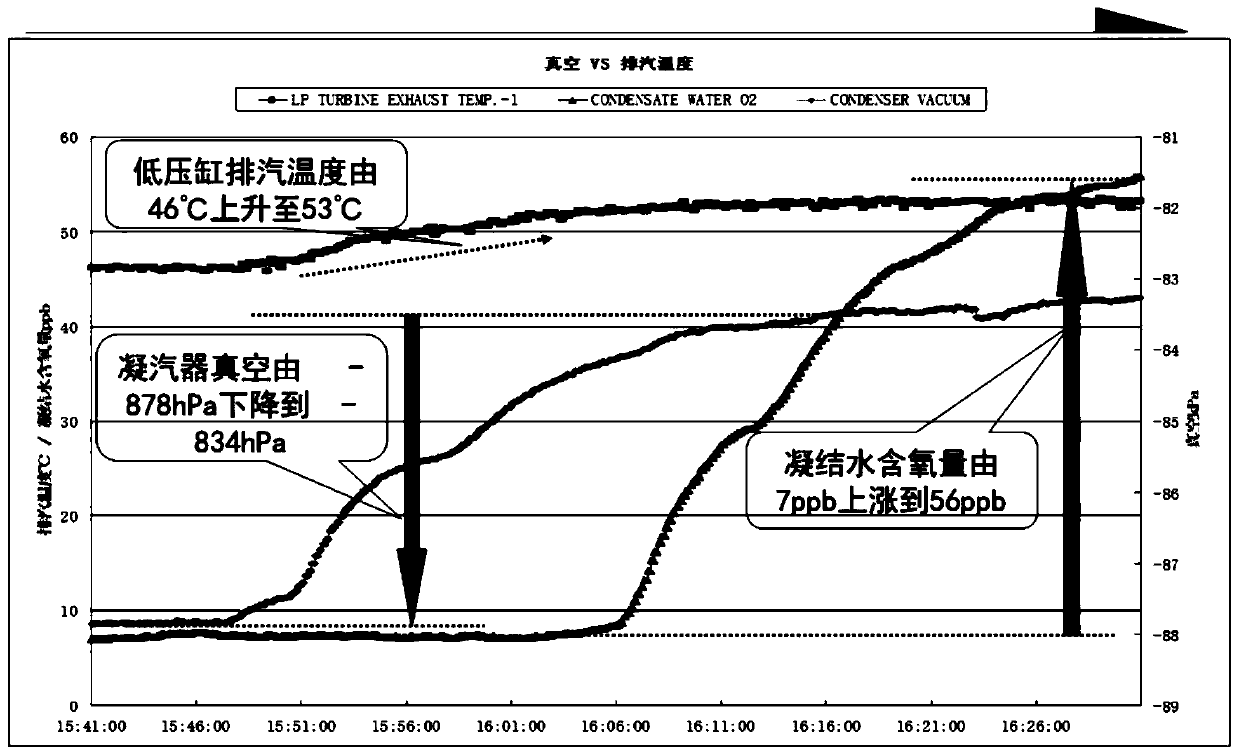

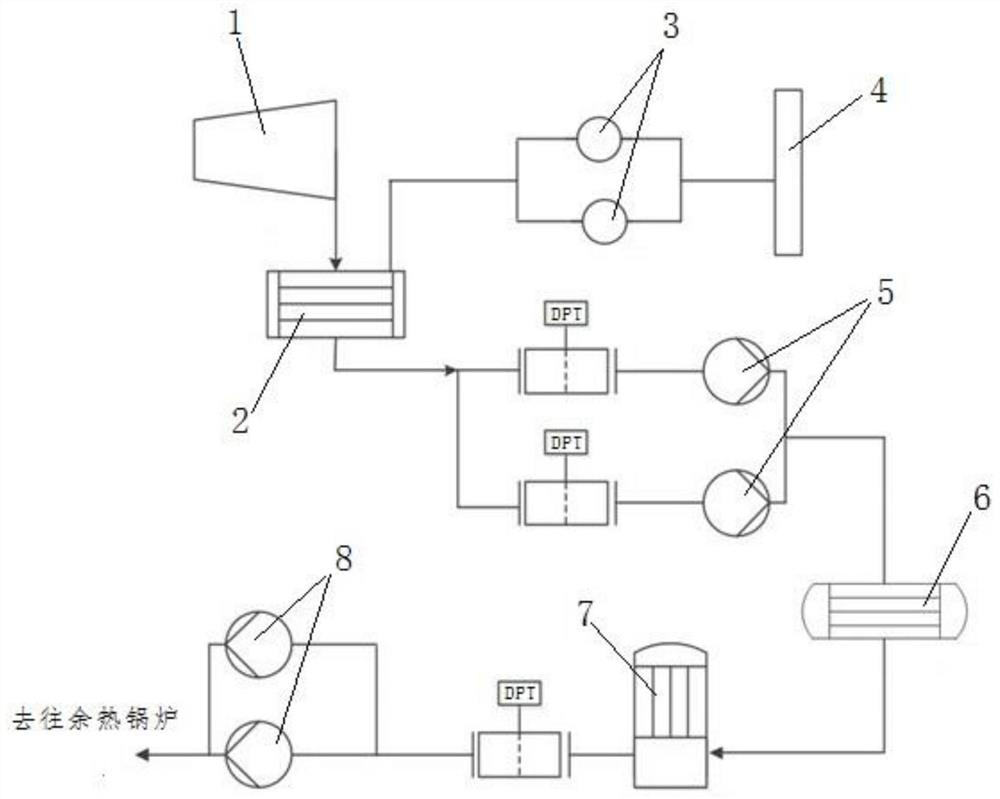

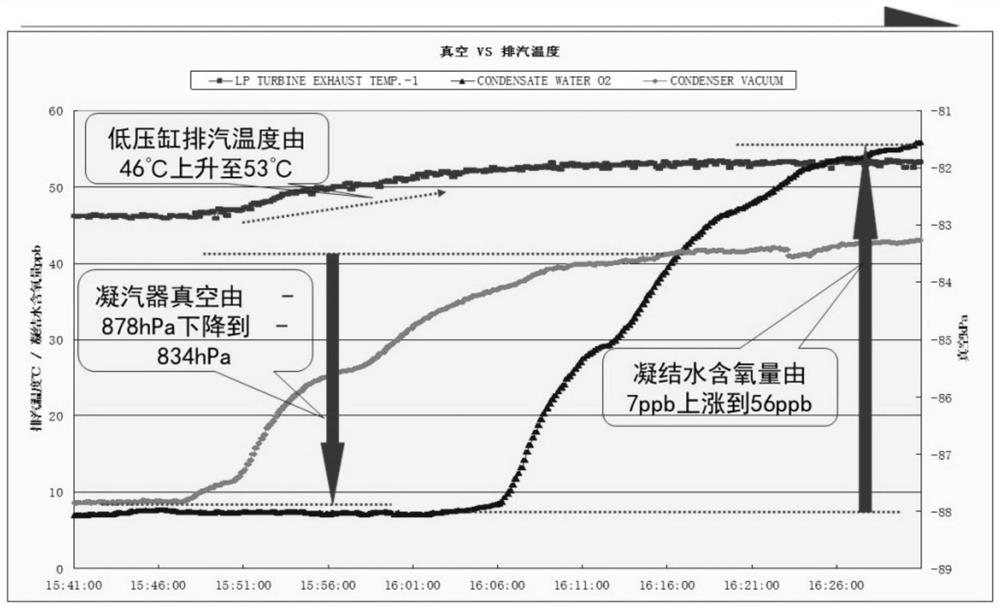

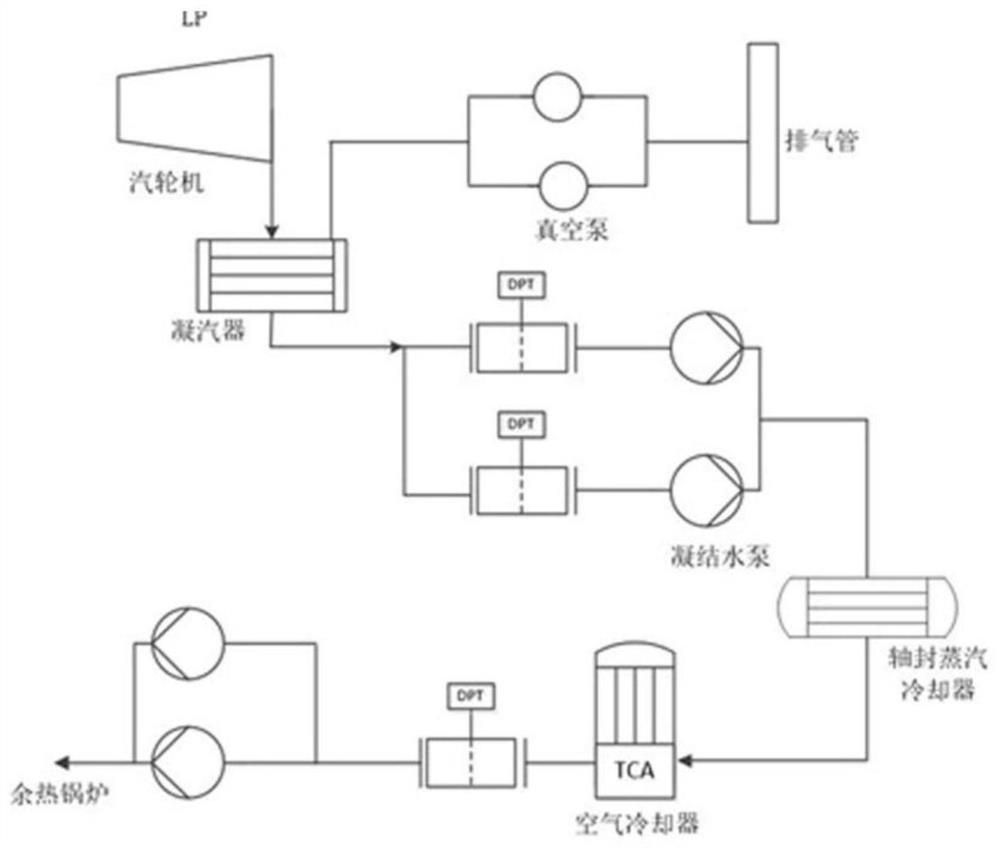

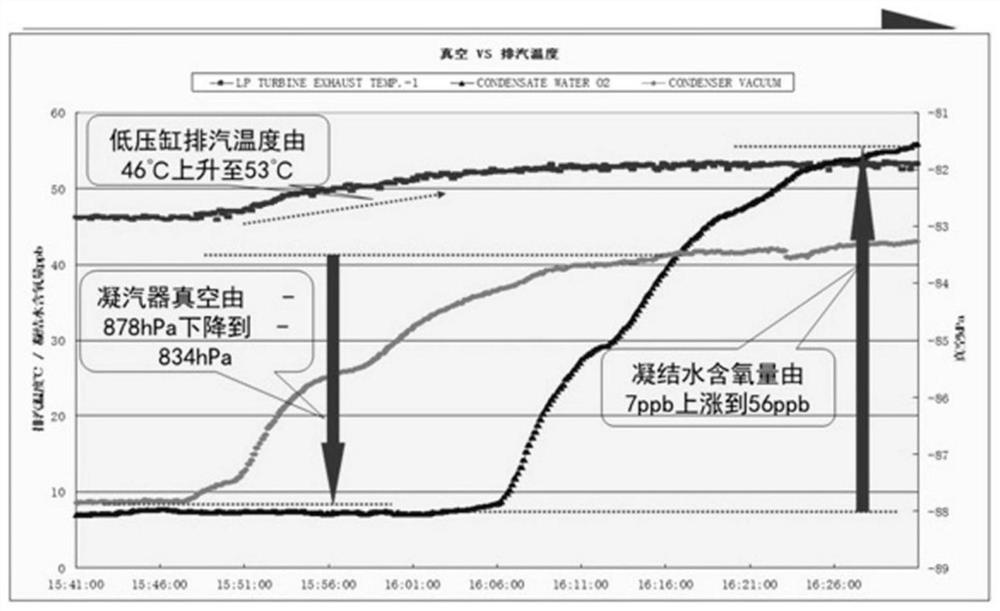

Method for rapidly checking leakage of cooler of air cooling system of gas turbine

ActiveCN110455460ASafe and stable operationEnsure safe and stable operationFluid-tightness measurement using fluid/vacuumTime efficientAir cooling system

The invention belongs to the technical field of monitoring of a gas and steam combined cycle power generation system, and particularly relates to a method for rapidly checking leakage of a cooler of an air cooling system of a gas turbine. The method is characterized by comprising the following steps: (1) normally operating a vacuum pump to obtain DD1, DT1 and VD1; (2) operating two vacuum pumps toobtain DD2, DT2 and VD2; (3) applying a load to a unit to obtain DD3, DT3 and VD3; and (4) rapidly judging a leakage position from a condenser to a TCA cooler. According to the method, safe and stable operation of the gas and steam combined cycle power generation system is monitored and maintained; and when the condenser is reduced in vacuum and increased in dissolved oxygen content of condensedwater, whether a heat exchange pipe leakage problem exists at the TCA cooler or not is rapidly judged, so that the complicated program for checking the leakage is avoided, the time is shortened, and safe and stable operation is guaranteed.

Owner:UNIV OF SCI & TECH LIAONING

Rapid leak detection method for TCA cooler of gas turbine air cooling system

ActiveCN110441011ASafe and stable operationAvoid complex procedures for leak detectionMeasurement of fluid loss/gain rateEngineeringAir cooling system

The invention relates to a rapid leak detection method for a TCA cooler of a gas turbine air cooling system, and the method comprises the following steps of 1) operating a vacuum pump to obtain a condensed water oxygen dissolved amount DD1 at the outlet of a condenser, a condensed water dissolved oxygen amount DT1 at the outlet of the TCA cooler, and a vacuum degree VD1 of the condenser; 2) operating two vacuum pumps at the same time to obtain a condensed water oxygen dissolved amount DD2 at the outlet of the condenser, a condensed water dissolved oxygen amount DT2 at the outlet of the TCA cooler, and a vacuum degree VD2 of the condenser; 3) increasing or decreasing the load of the unit to obtain a condensed water oxygen dissolved amount DD3 at the outlet of the condenser, a condensed water dissolved oxygen amount DT3 at the outlet of the TCA cooler, and a vacuum degree VD3 of the condenser; and 4) quickly judging the leak position between the condenser and the TCA cooler when the vacuum degree of the condenser or the condensed water dissolved oxygen amount is higher than a set normal threshold, and further performing leak detection on the TCA cooler.

Owner:UNIV OF SCI & TECH LIAONING

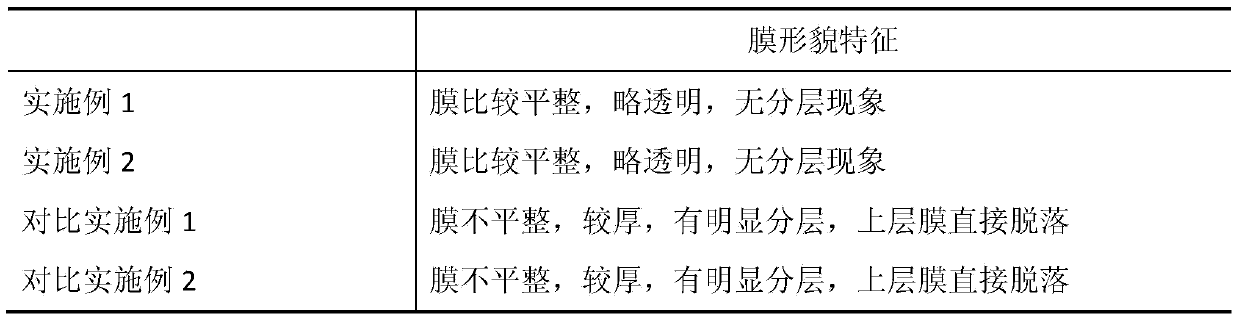

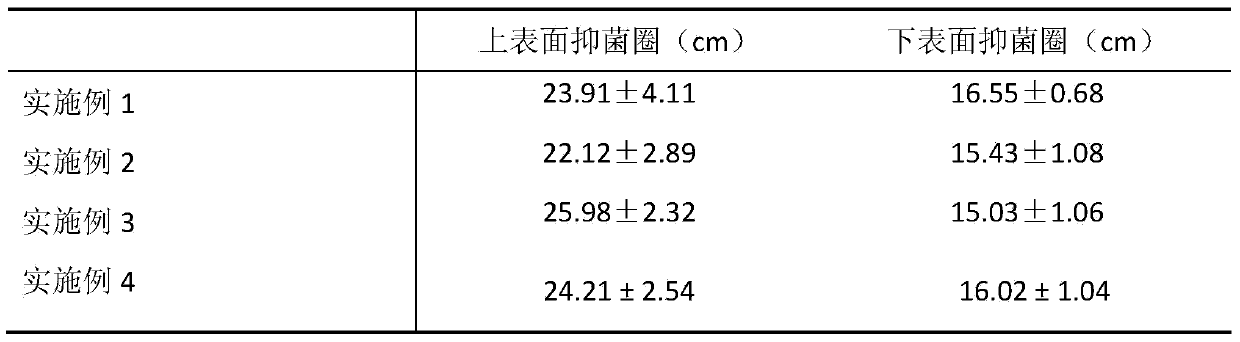

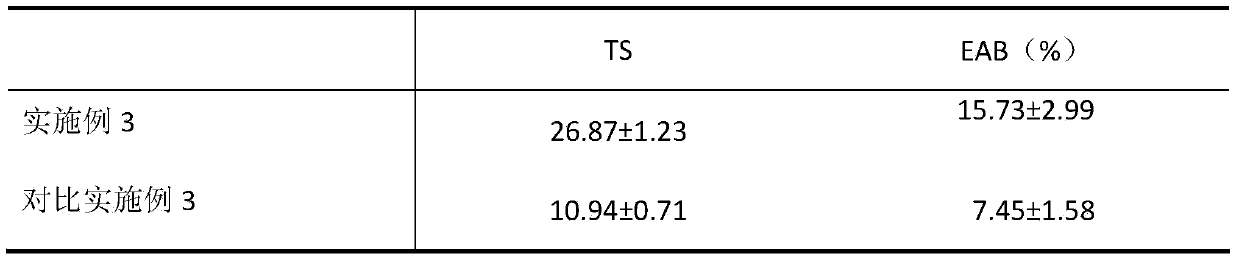

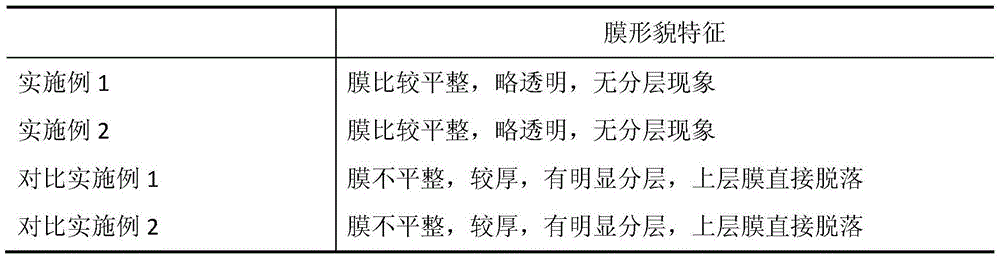

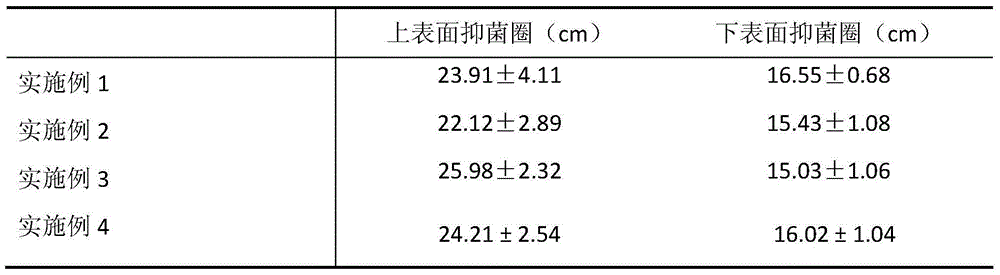

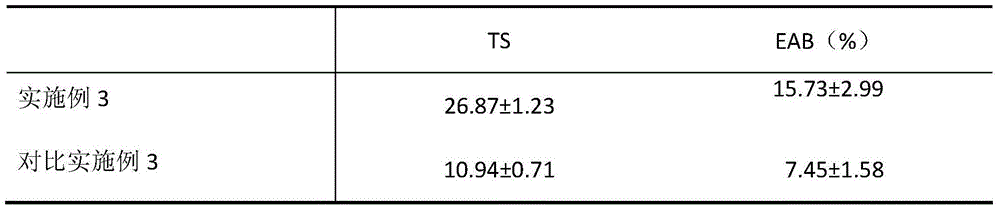

Multilayer directional controlled release antibacterial film and preparation method and application thereof

InactiveCN103434229AImproved oxygen and water resistanceAvoid complex proceduresFlexible coversWrappersBi layerChemistry

The invention discloses a multilayer directional controlled release antibacterial film and a preparation method and an application thereof. The method comprises the following steps: 1) preparing a PLA (poly lactic acid) solution; 2) adding glycerol and inverting film to obtain a PLA film; 3) dissolving zein into an ethanol aqueous solution; 4) adding catechin into the solution in the step 3); 5) bumping the mixed solution in the step 4) in boiling water; 6) coating the mixed solution obtained in the step 5) on the PLA film obtained in the step 2) through a coating machine to obtain a double-layer film; 7) preparing a carrageenan aqueous solution; 8) preparing a zein solution; 9) adding the carrageenan aqueous solution into the solution obtained in the step 8); 10) adding antibacterial substance); and 11) coating the mixed solution obtained in the step 10) on the double-layer film obtained in the step 5) through a coating method. The multilayer directional controlled release antibacterial film disclosed by the invention has good mechanical properties, and the water resistance and oxygen resistance performance are improved significantly.

Owner:SOUTH CHINA UNIV OF TECH

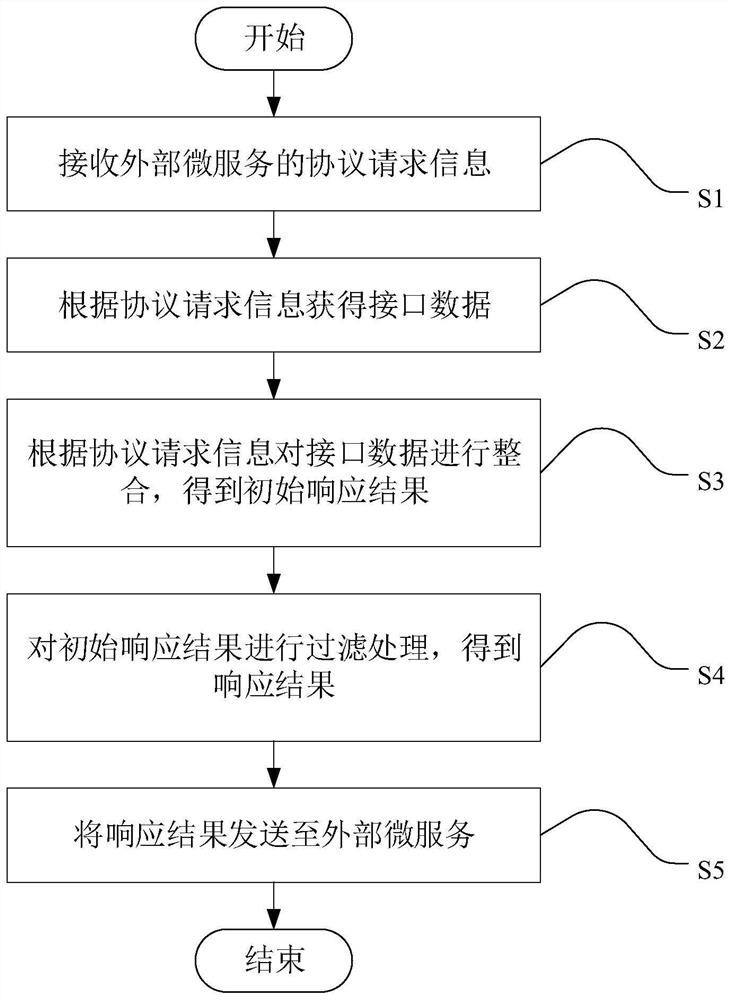

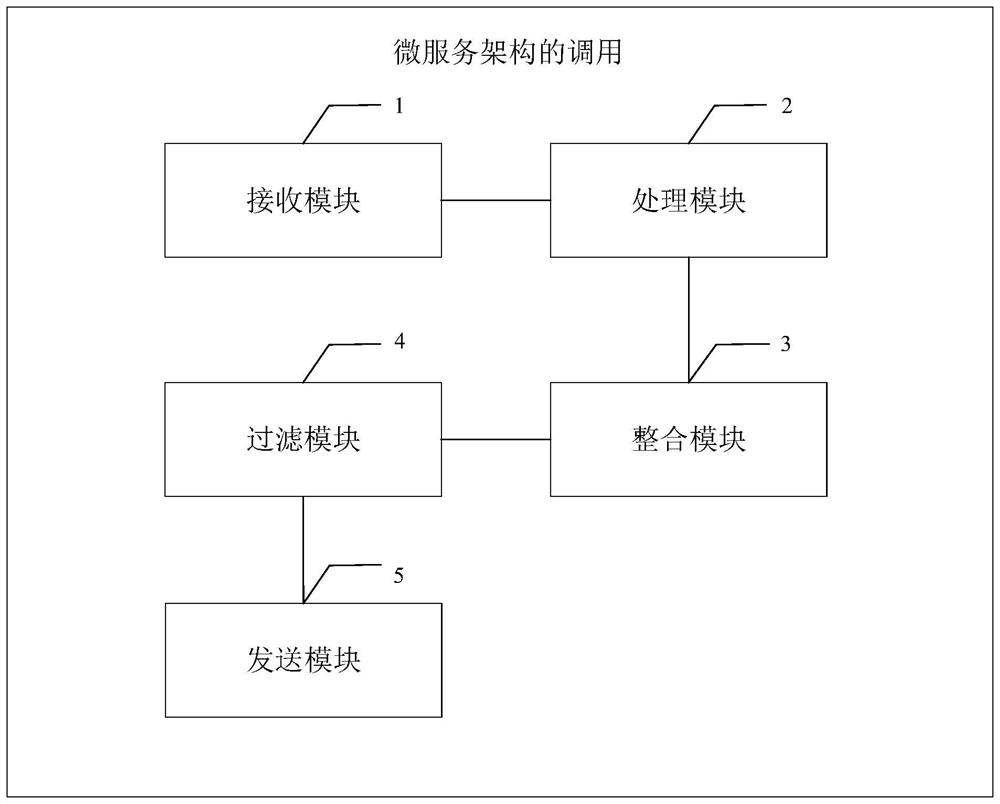

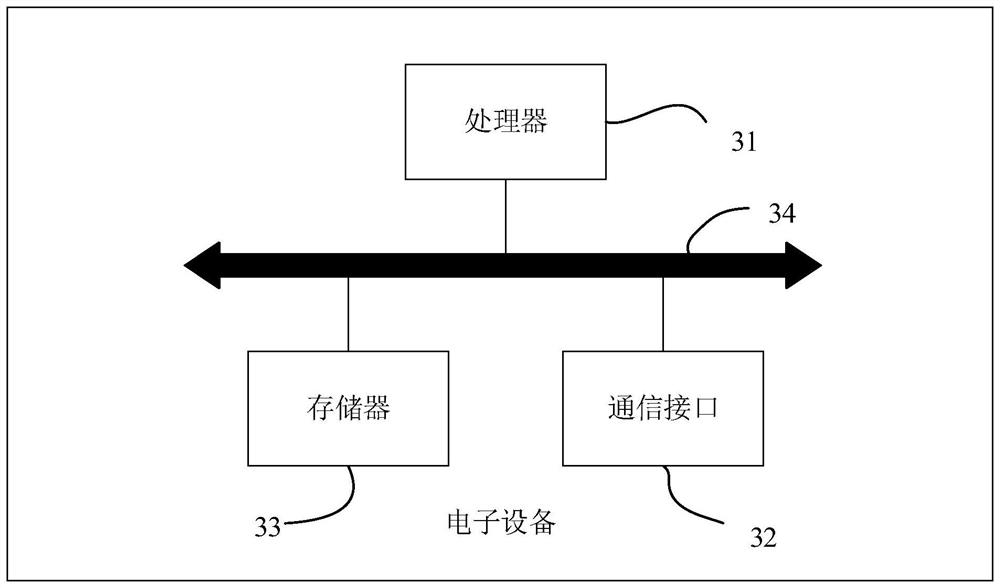

Microservice architecture calling method and device, electronic equipment and storage medium

PendingCN114238178ASimple callReduce maintenance costsElectric digital data processingSoftware engineeringMicroservices

The embodiment of the invention provides a micro-service architecture calling method and device, electronic equipment and a storage medium, and the method comprises the steps: receiving protocol request information of an external micro-service; obtaining interface data according to the protocol request information; integrating the interface data according to the protocol request information to obtain an initial response result; filtering the initial response result to obtain a response result; and sending a response result to the external micro-service. By implementing the embodiment of the invention, a plurality of interfaces with single functions can be freely combined together for calling, so that the calling of multiple interfaces is simplified, and the maintenance cost is reduced.

Owner:LINKDOC TECH BEIJING CO LTD

Method of manufacturing tribute pork rotund food

InactiveCN101133863AAvoid complex proceduresEasy to eatFungi medical ingredientsFish material medical ingredientsMonosodium glutamatePhosphate

The present invention relates to a preparation method of pork ball. Said preparation method includes the following steps: (1), cleaning fresh pork, freezing, slicing, pulverizing and pressing to obtain pork mince; (2), adding compound phosphate, water-soluble antioxidant, thickening agent, cinnamon bark powder, nutmeg powder, clove powder, star anise oil, licorice powder, salt, sugar and monosodium glutamate, quickly-stirring them for 3min; (3), adding lentinus edodes powder and ear shell powder, stirring them to obtain paste-like material; (4), utilizing ball-forming machine to make the above-mentioned pork paste into pork balls, steaming said pork balls and making them be cooked, natural cooling; and (5), vacuum packaging and checking so as to obtain the invented product.

Owner:TIANJIN CHINESE & BRITISH NANOMETER TECH DEV

Umbrella-type jaw cyst plug

The invention belongs to the technical field of auxiliary appliances for oral medicine cyst fenestration therapy and particularly relates to an umbrella-type jaw cyst plug. The jaw cyst plug comprisesan inner cannula and an external cannula, wherein an annular clamping plate extends outwards from the cross section is arranged on the periphery of the outer cannula, an external groove is formed inthe part, located on the upper side of the annular clamping plate, of the external cannula, and multiple bulges are uniformly arranged at the bottom of the outer side of the external cannula; an internal groove is formed in the internal cannula, multiple vertical holes are dug in the lower position of the internal cannula, and a movable piece with the bottom connected with the internal cannula isformed; a cyst plug cap is rotationally connected with the top of the internal cannula. Compared with the prior art, the cyst plug has the advantages as follows: a complex procedure of reproduction after jaw cyst fenestration is avoided, and the jaw cyst plug can reduce foreign body sensation, is standardized, cannot be damaged easily and comprise parts easy to replace as compared with manually produced cyst plugs. The jaw cyst plug is reasonable in structural design, convenient to operate and suitable to be worn simultaneously in surgery. The jaw cyst plug is deeper than manually produced cyst plugs and can realize smooth drainage more easily.

Owner:刘畅

A pipeline inner wall cleaning device with self-cleaning function

Owner:LUAN XIANGCHUAN TECH CO LTD

A method for quick leak detection of TCA cooler in gas turbine air cooling system

ActiveCN110441011BSafe and stable operationAvoid complex procedures for leak detectionMeasurement of fluid loss/gain rateEnvironmental engineeringAir cooling system

The invention relates to a method for quickly checking for leaks in a gas turbine air cooling system TCA cooler, comprising: 1) running a vacuum pump to obtain the condensed water dissolved oxygen amount DD1 at the outlet of the condenser, the condensed water dissolved oxygen amount DT1 at the outlet of the TCA cooler, and the condensed water dissolved oxygen amount DT1 at the outlet of the condenser; Condenser vacuum VD1; 2) Two vacuum pumps run at the same time to obtain condensate dissolved oxygen DD2 at the outlet of the condenser, condensate dissolved oxygen DT2 at the outlet of the TCA cooler, and condenser vacuum VD2; 3) Increase or decrease the unit Load, obtain the condensed water dissolved oxygen amount DD3 at the condenser outlet, the condensed water dissolved oxygen amount DT3 at the TCA cooler outlet, and the condenser system vacuum degree VD3; 4) When the condenser vacuum degree or condensed water dissolved oxygen amount is higher than the set value When setting the normal threshold, quickly judge the leakage position between the condenser and the TCA cooler, and further check the leak of the TCA cooler.

Owner:UNIV OF SCI & TECH LIAONING

A kind of multi-layer directional controlled-release antibacterial film and its preparation method and application

InactiveCN103434229BGood antibacterial effectImprove featuresFlexible coversWrappersControlled releaseCarrageenan

The invention discloses a multilayer directional controlled release antibacterial film and a preparation method and an application thereof. The method comprises the following steps: 1) preparing a PLA (poly lactic acid) solution; 2) adding glycerol and inverting film to obtain a PLA film; 3) dissolving zein into an ethanol aqueous solution; 4) adding catechin into the solution in the step 3); 5) bumping the mixed solution in the step 4) in boiling water; 6) coating the mixed solution obtained in the step 5) on the PLA film obtained in the step 2) through a coating machine to obtain a double-layer film; 7) preparing a carrageenan aqueous solution; 8) preparing a zein solution; 9) adding the carrageenan aqueous solution into the solution obtained in the step 8); 10) adding antibacterial substance); and 11) coating the mixed solution obtained in the step 10) on the double-layer film obtained in the step 5) through a coating method. The multilayer directional controlled release antibacterial film disclosed by the invention has good mechanical properties, and the water resistance and oxygen resistance performance are improved significantly.

Owner:SOUTH CHINA UNIV OF TECH

A device for cleaning the inner wall of a pipe

ActiveCN108453101BClean up thoroughlyImprove versatilityHollow article cleaningEngineeringWater spray

Owner:大庆信海越石油科技开发有限公司

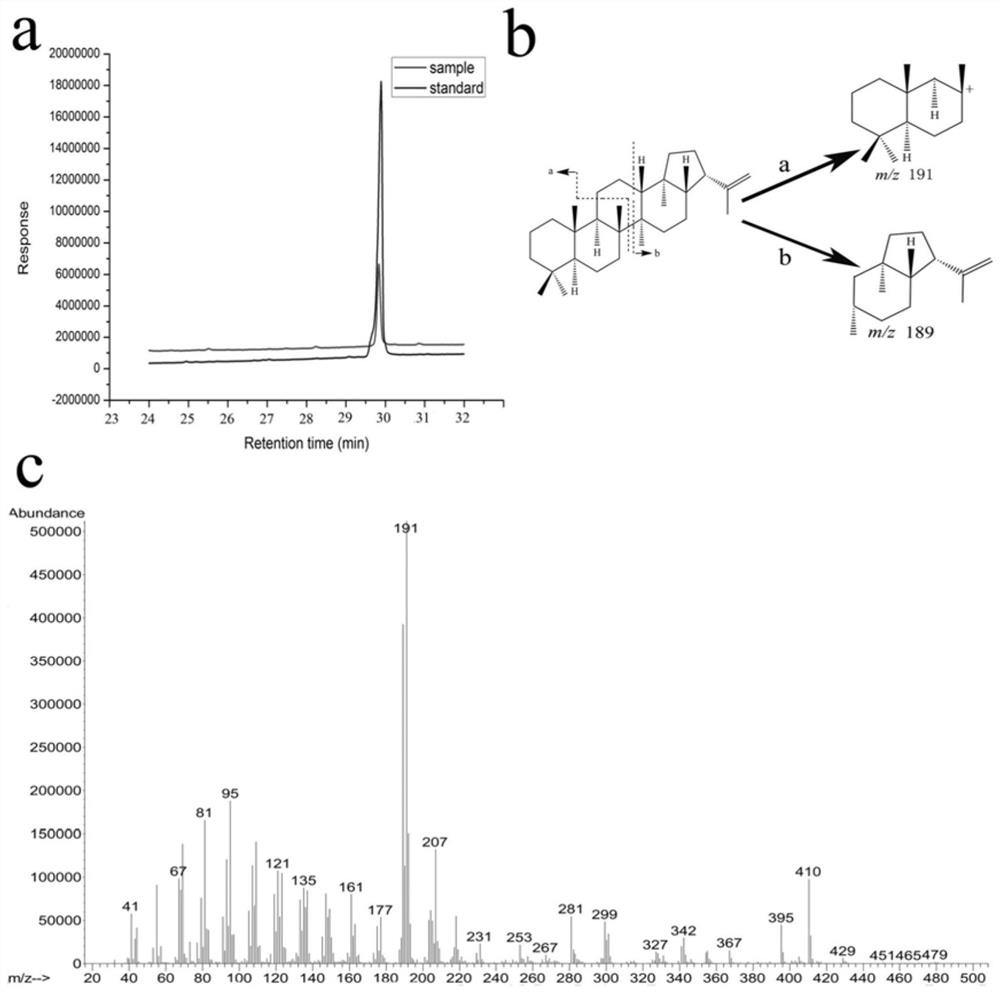

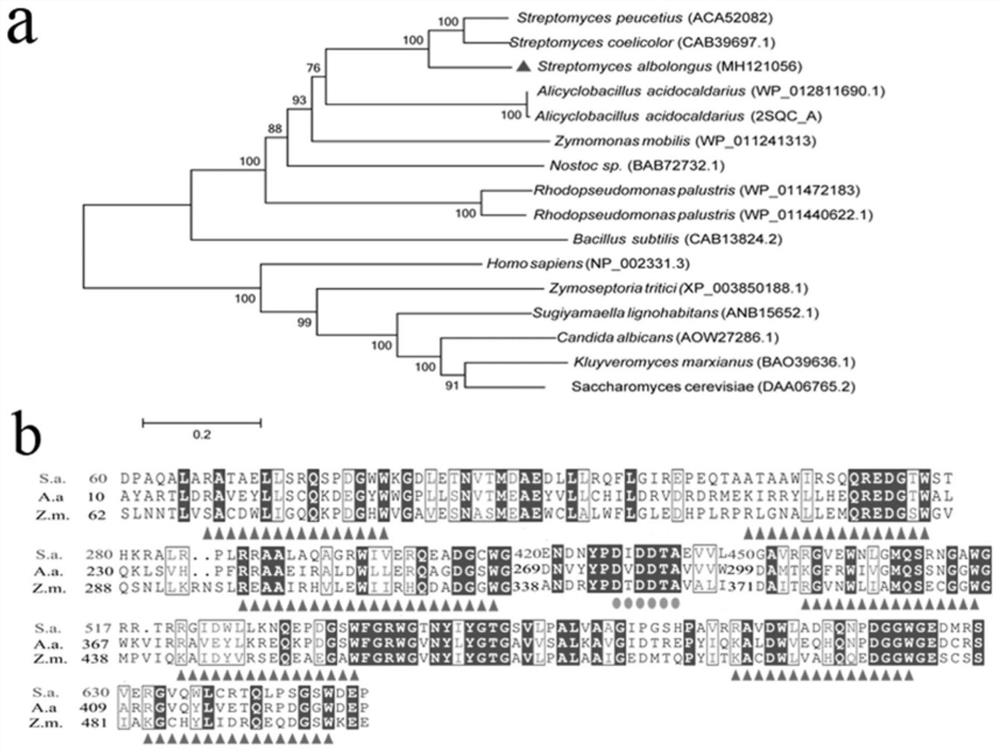

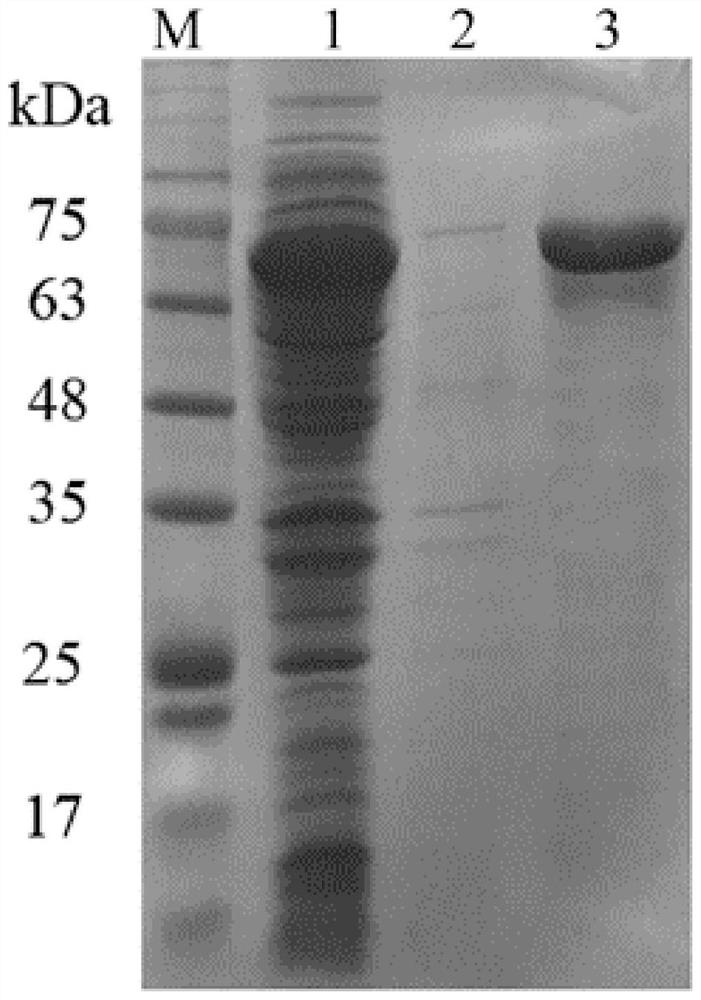

A novel squalene Hopaene cyclase and its application

Owner:OCEAN UNIV OF CHINA

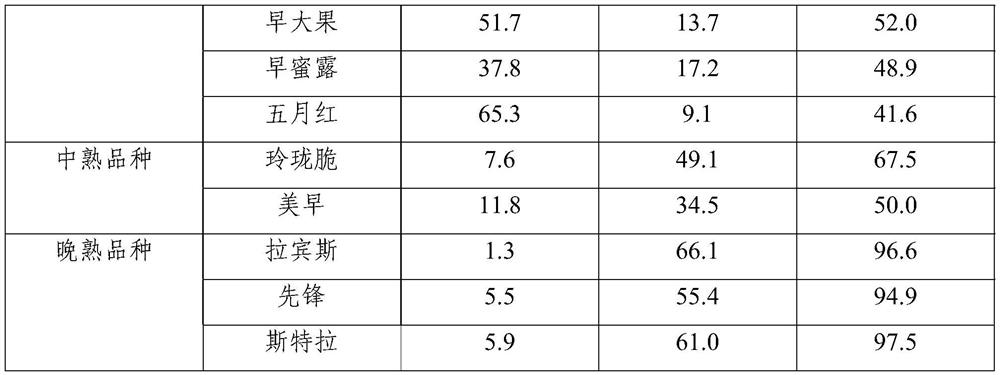

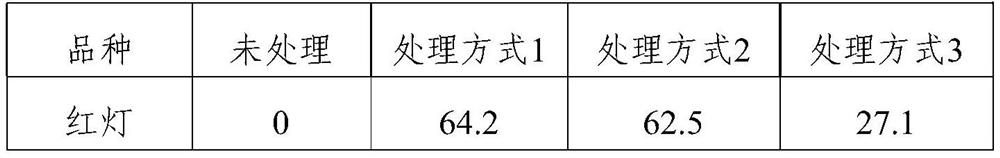

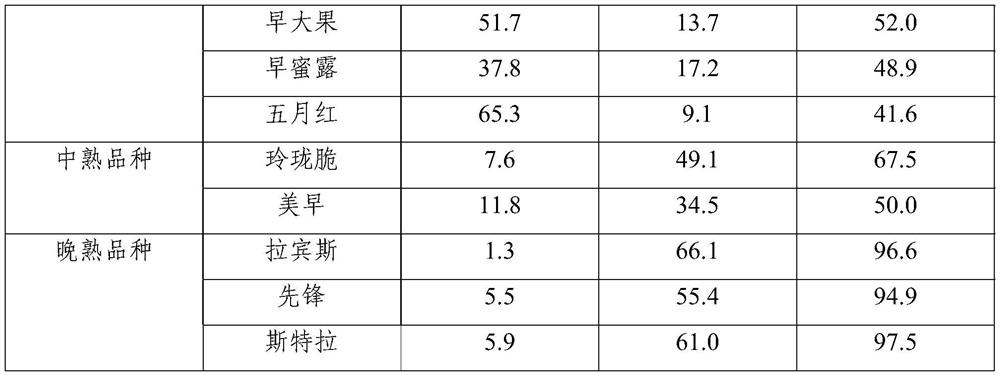

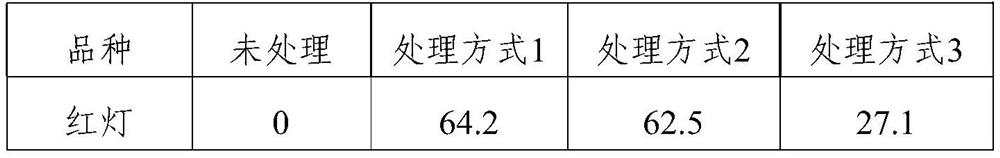

Seed treatment method for early-maturing sweet cherry variety and method for planting seedlings in that year

ActiveCN111972074AImprove germinationSuppress negative effectsSeed and root treatmentGrowth substratesCulture fluidCulture mediums

The invention belongs to the technical field of seed treatment and seedling cultivation, and particularly relates to a seed treatment method for an early-maturing sweet cherry variety and a method forplanting seedlings in that year. The seed treatment method for sweet cherries comprises the following step of treating seed embryos in a liquid culture manner, wherein liquid culture conditions are as follows: under a sealed condition, culture is performed for 5-7 days at the temperature of 2-6 DEG C; and a culture solution comprises the following components: an agar-free MS culture medium, 1.0 mg / L of 6-BA and 0.2 mg / L of IAA. The method is simple, efficient and suitable for large-group treatment, the germination rate of seeds of the early-maturing sweet cherry variety and the obtaining rateof offspring can be remarkably increased, and the method has higher practical value and is beneficial to application and popularization in breeding units; and meanwhile, the seed germination rate ofmedium and late maturing varieties of the sweet cherries can also be obviously improved by the method.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

A seed treatment method of a sweet cherry early-maturing variety and a method for seedling formation in the year of sowing

ActiveCN111972074BImprove germination rateIncrease acquisition rateSeed and root treatmentGrowth substratesCulture fluidSeed treatment

The invention belongs to the technical field of seed treatment and seedling cultivation, and in particular relates to a seed treatment method of an early-maturing sweet cherry variety and a method for seedling formation in the same year of sowing. The method for treating sweet cherry seeds adopts a liquid culture method to treat seed embryos; wherein the liquid culture conditions are: under sealed conditions, culture at a temperature of 2 to 6°C for 5 to 7 days; the composition of the culture solution is: not containing Agar MS medium, supplemented with 6‑BA1.0mg / L and IAA0.2mg / L. The method described in the present invention is simple, efficient and suitable for large population treatment, can significantly improve the germination rate of sweet cherry early-maturing varieties seeds and the acquisition rate of offspring, has greater practical value, and is conducive to popularization and use in breeding units; at the same time, the method The method can also significantly improve the seed germination rate of middle and late maturing varieties of sweet cherries.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

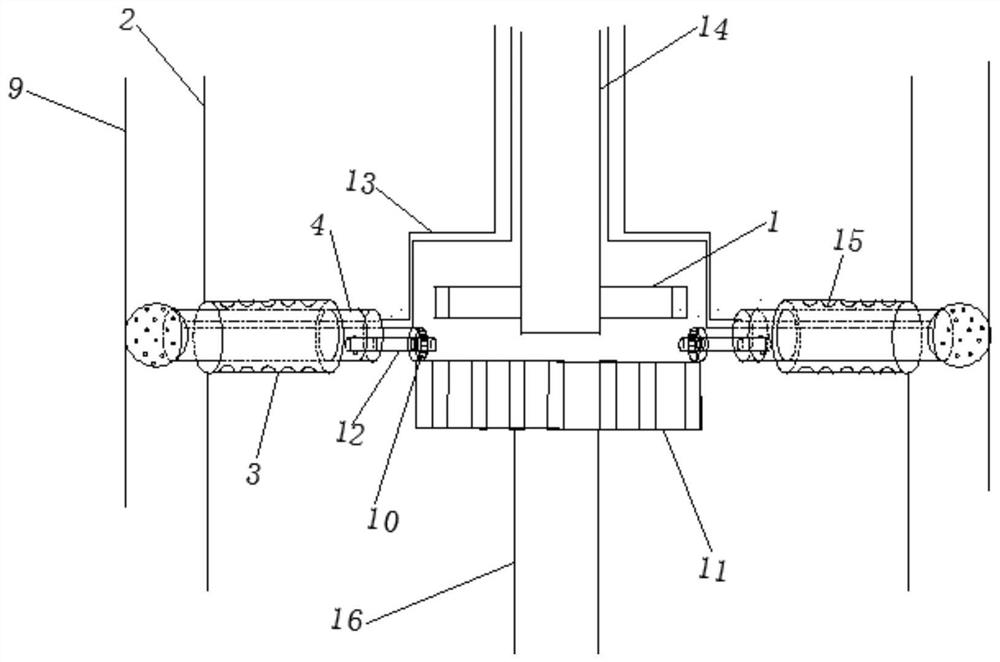

Pipeline inner wall cleaning device

ActiveCN108746095BClean up thoroughlyAchieve scaleHollow article cleaningDrive shaftStructural engineering

The invention discloses a pipeline inner wall cleaning device. The device comprises a driving shaft, an adjusting disc, rotating pipes, pipe inner walls, holes, guide pipes, hard brush devices, soft brush devices, springs, a water inlet pipe, a water spraying port, a connecting rod and a locking groove. According to the pipeline inner wall cleaning device, the springs sleeve brush rods, stretchingand retracting of the soft and hard brush rods are achieved through protruding and recessed arc-shaped rotating disk structures, the rotating angle of a shaft is adjusted, the clamping connection oflimiting grooves in different positions is adopted in combination at the same time so that brushes can be applied to cleaning of pipes with different pipe diameters, the universality of the cleaning device is improved, the cost problem caused by producing cleaning devices matched with pipelines with different pipe diameters is solved, the production cost is saved, and suitable and thorough cleaning methods and cleaning sequences can be more freely selected according to different types of the actual pipelines and the media in the pipes.

Owner:徐州驰泽环保科技有限公司

A kind of preparation method of copper-zinc-tin-sulfur film

ActiveCN108550642BThe reaction device is simpleShort reaction timeSemiconductor devicesSulfideFilm material

The invention relates to a preparation method of a copper-zinc-tin-sulfide film, and belongs to the technical field of functional film materials. According to the invention, a copper source, a zinc source, a tin source and a sulfur source are added into an organic solvent, wherein the molar ratio of the copper source, the zinc source, the tin source and the sulfur source is (1-2) (1-2): (1-2): (4-10). The organic solvent is stirred and subjected to ultrasonic treatment, and then a precursor solution is obtained. The ultrasonic cleaning and drying process of an FTO conductive glass or a siliconwafer in the vacuum state is carried out. The precursor solution is coated on the FTO conductive glass or the silicon wafer through the spin-coating process. Meanwhile, the FTO conductive glass or the silicon wafer is dried in the vacuum state for 6-10 hours at the temperature of 60-90 DEG C. After that, the spin-coating process of the precursor solution is repeated for 3-6 times, and a CZTS filmprecursor is obtained after carrying out the vacuum drying operation. The annealing treatment is performed on the CZTS film precursor. Finally, the microwave optimization treatment is performed on the CZTS film precursor after being subjected to the annealing treatment, and then a CZTS film is obtained. The method is simple in process, simple in reaction device, high in reaction speed, low in cost and good in film forming quality.

Owner:KUNMING UNIV OF SCI & TECH

Perforating device

The invention provides a punching device, which includes two sliding frames, the two sliding frames are parallel to each other; a horizontal sliding guide rail is arranged between the two sliding frames, and two sliding limit grooves are arranged at one end of the horizontal sliding rail. The two sliding frames are respectively located in the two sliding limit grooves, the other end of the transverse sliding rail is fixed with a longitudinal sliding rail, and the longitudinal sliding rail and the sliding frame are perpendicular to each other; a fixed plate is installed on the longitudinal sliding rail. The advantages and positive effects of the present invention are: due to the adoption of the above-mentioned technical scheme, the equipment can carry out various types of equipment drilling when punching plastics in automobiles, without changing equipment, and is suitable for assembly line operations while avoiding complicated operations. The program, the process of punching the car plastic is simple, and solves the cost of enterprise expenses, and at the same time, the structure is simple, easy to operate, and has no danger.

Owner:TIANJIN HAOFENGYUAN TOOL & DIE TECH DEV CO LTD

A side button fixing structure and mobile terminal

ActiveCN106531513BAvoid complex proceduresReduce manufacturing costElectric switchesKey pressingMechanical engineering

Owner:VIVO MOBILE COMM CO LTD

Method for Rapid Leak Detection of Cooler in Air Cooling System of Gas Turbine

ActiveCN110455460BSafe and stable operationGuaranteed uptimeFluid-tightness measurement using fluid/vacuumProcess engineeringAir cooling system

The invention belongs to the technical field of gas-steam combined cycle power generation system monitoring, and in particular relates to a method for quickly checking for leaks in a gas turbine air cooling system cooler, which is characterized in that it includes the following steps: (1) normal operation of a vacuum pump, respectively obtaining DD 1 、DT 1 and VD 1 ; (2) two vacuum pumps are running, respectively get DD 2 、DT 2 and VD 2 ; (3) unit load, get DD respectively 3 、DT 3 and VD 3 ; (4) Quickly judge the leakage position from the condenser to the TCA cooler. The invention can monitor and maintain the safe and stable operation of the gas-steam combined cycle power generation system. When the vacuum of the condenser decreases and the dissolved oxygen of the condensed water increases, it can quickly judge whether there is leakage of the heat exchange tube at the TCA cooler. Problems, avoid complex procedures for leak detection, save time, and ensure safe and stable operation.

Owner:UNIV OF SCI & TECH LIAONING

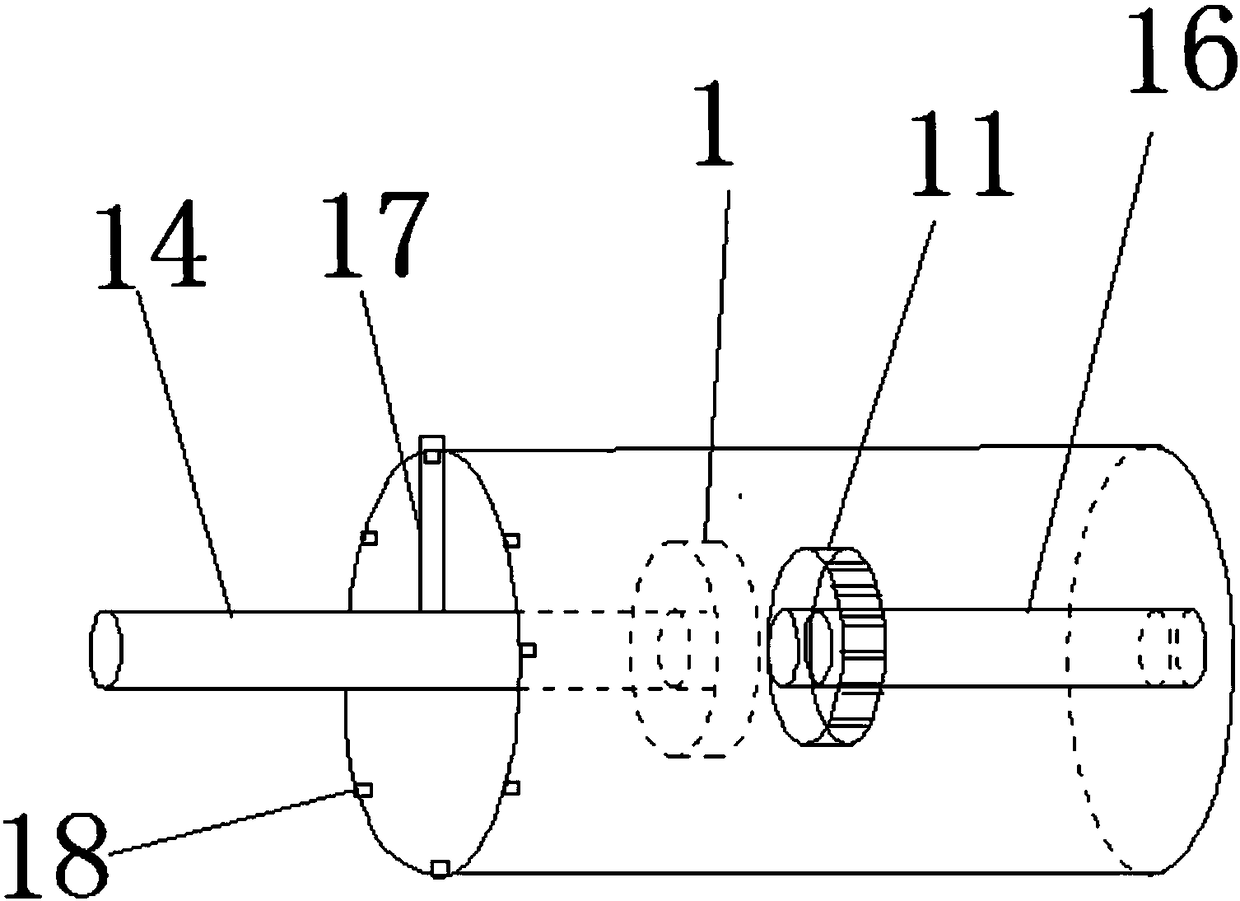

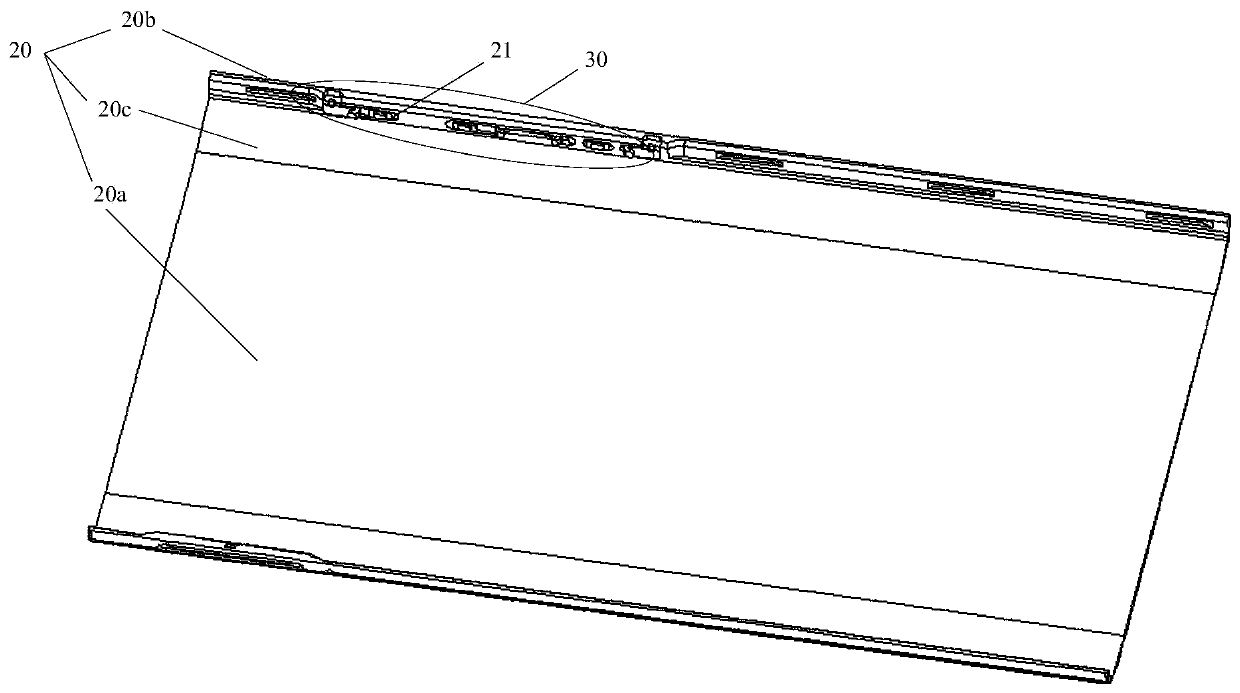

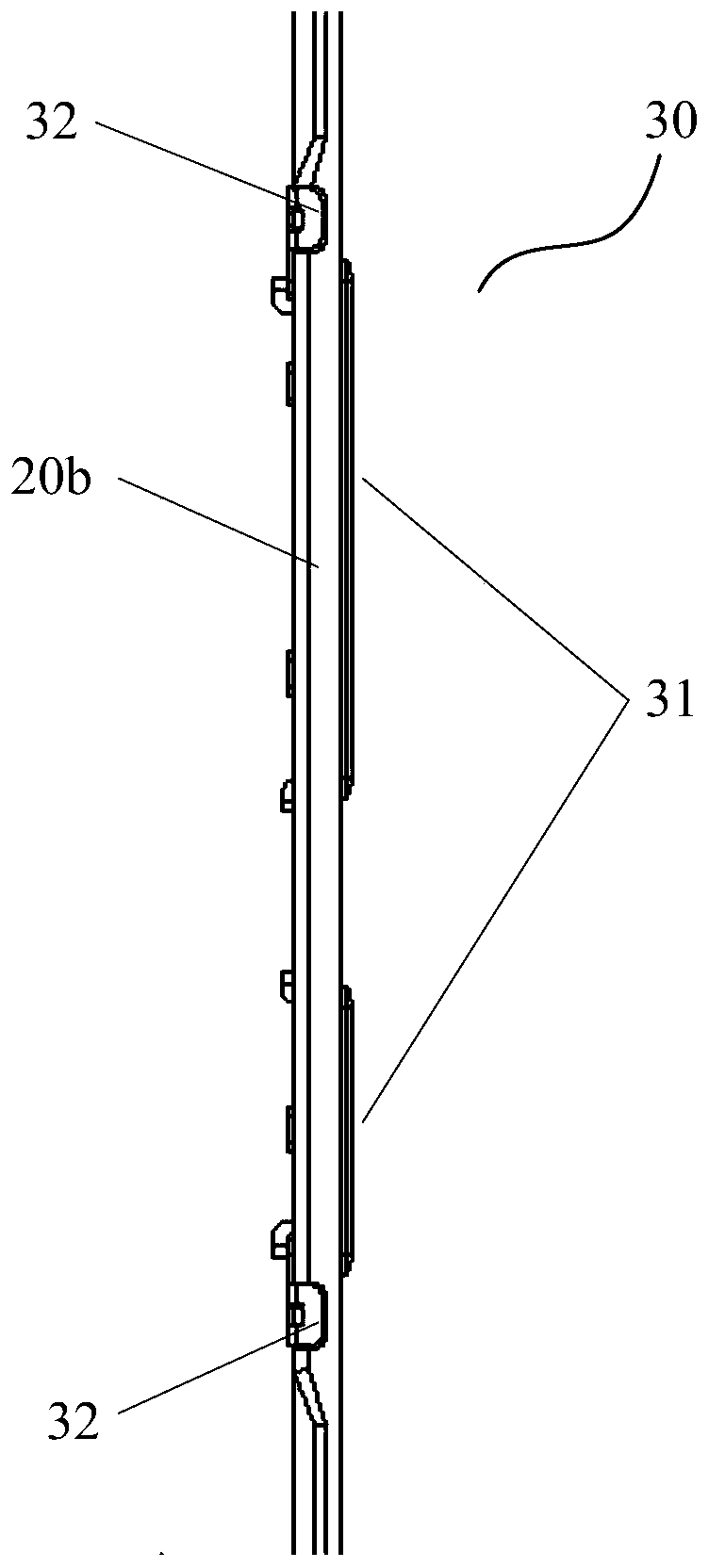

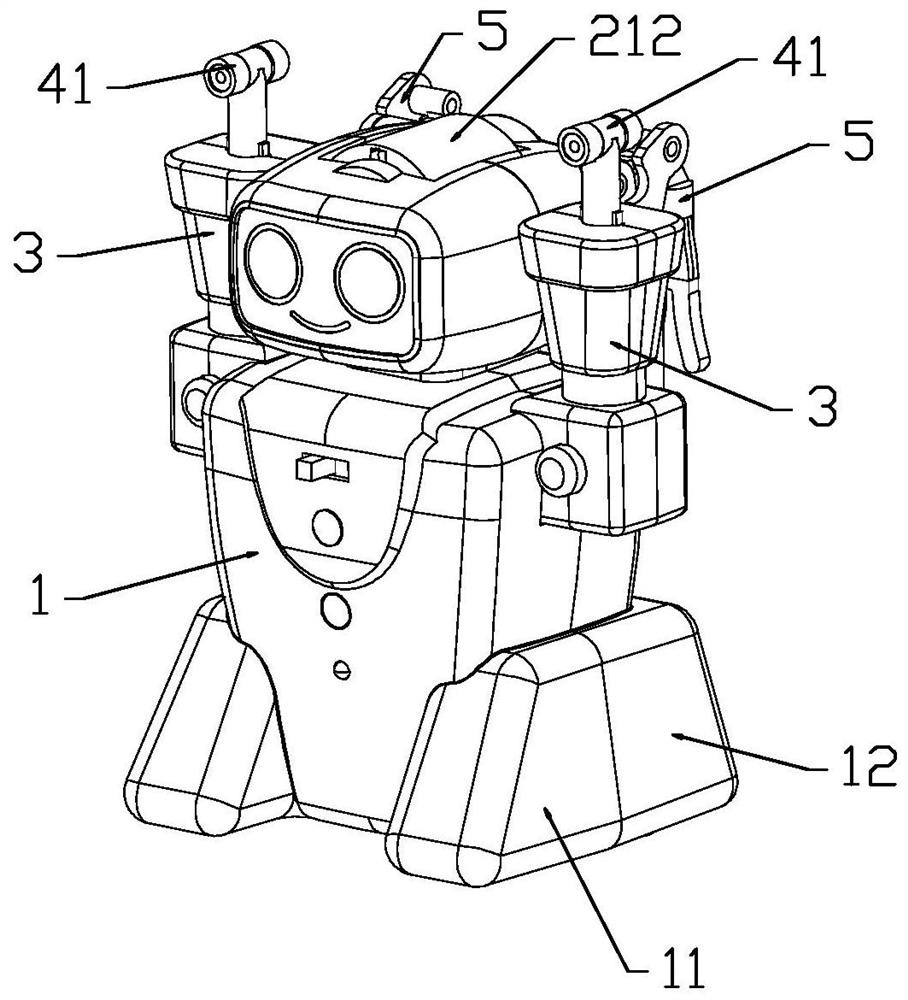

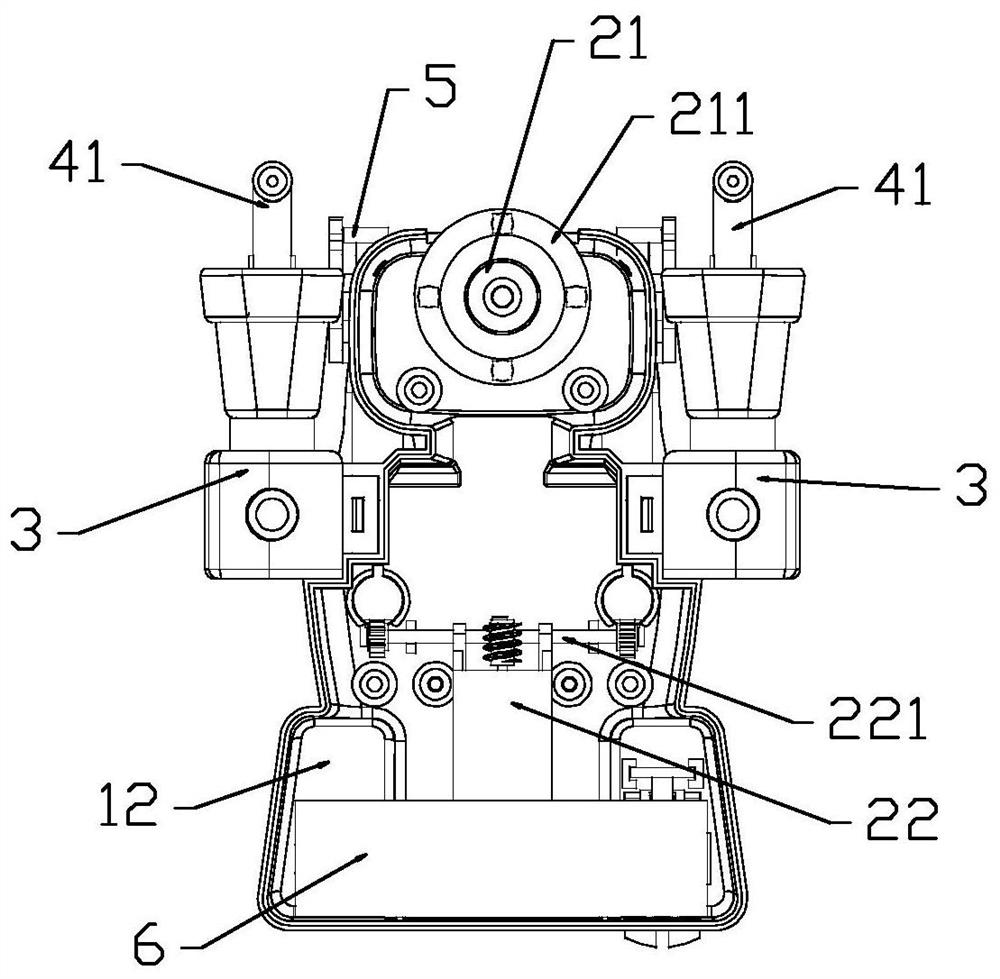

Intelligent curtain robot

PendingCN113142957AAlleviate burdensome problemsRealize the opening and closing effectCurtain accessoriesDrive wheelSimulation

The invention relates to the technical field of household articles, in particular to an intelligent curtain robot which comprises a body, hanging arms are arranged on the left side and the right side of the body, hanging pieces are arranged at the tops of the hanging arms, a first transmission system and a second transmission system are arranged in the body, and the first transmission system comprises a first driving piece which is in transmission connection with a driving wheel; the driving wheel is arranged at the top of the cavity; the second transmission system comprises a second driving part, the second driving part is in transmission connection with a telescopic arm through a transmission part, the telescopic arm is arranged on the rear side of the body, a swing arm is pivoted to the top of the telescopic arm, and a power element and a control element are further arranged in the body. According to the intelligent curtain robot, the problems that an existing charging type automatic opening and closing curtain driving structure is large in occupied space, large in weight and troublesome to control are solved.

Owner:福建花之恋饰品有限责任公司

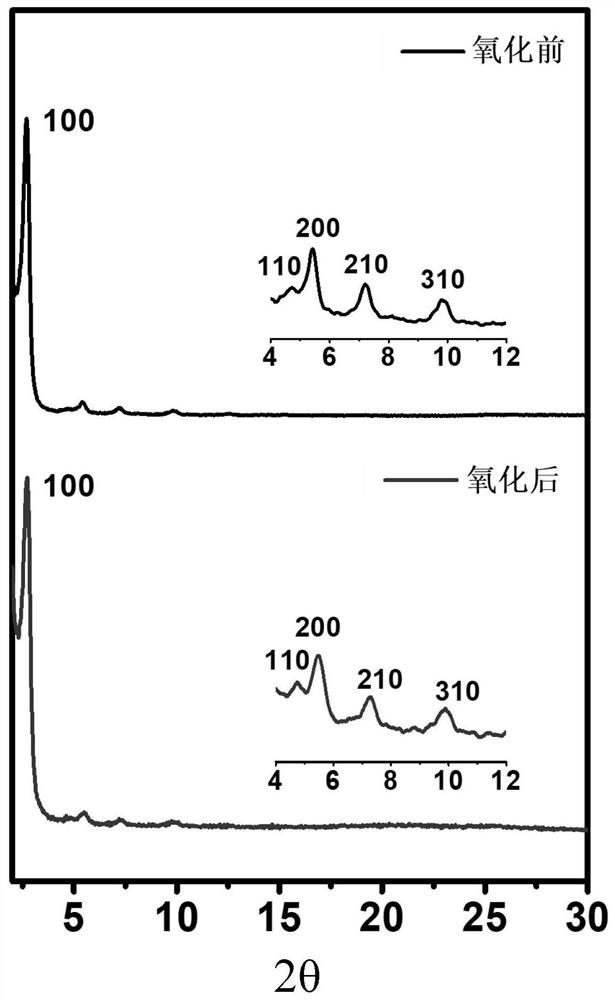

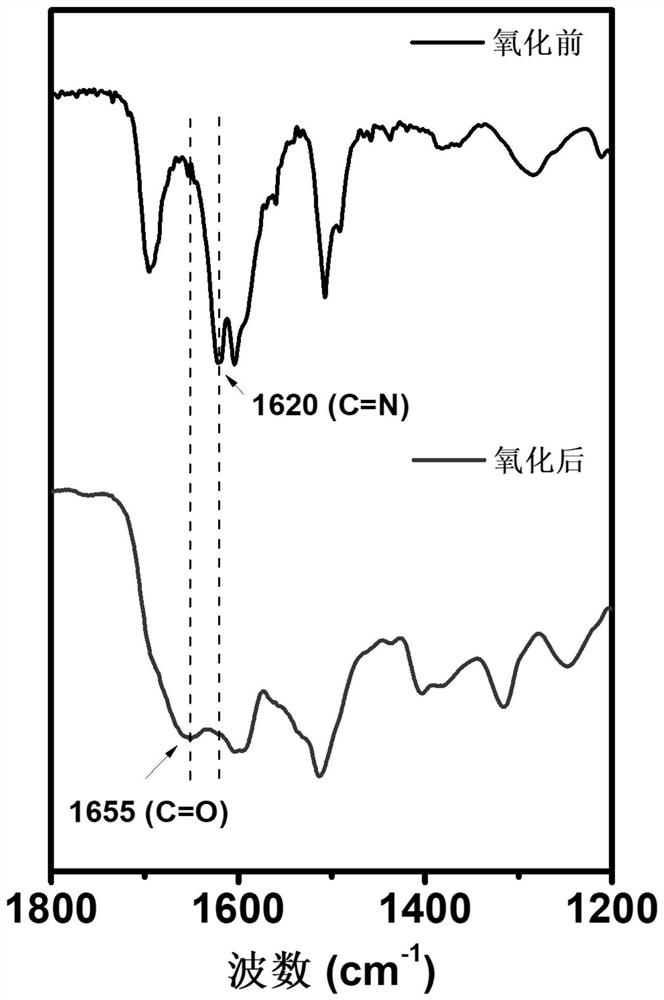

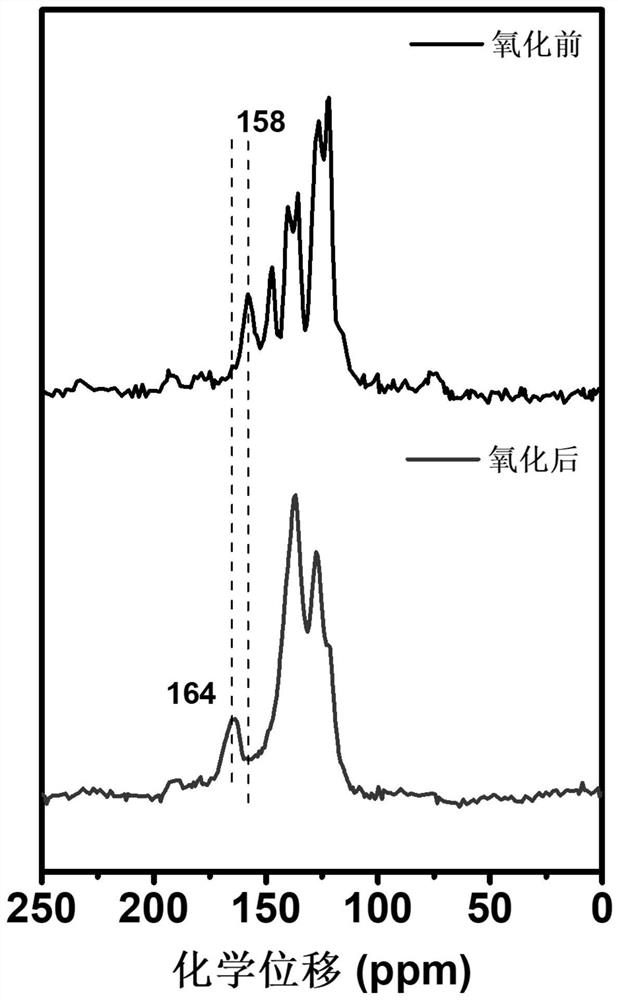

Preparation method of amido bond-linked covalent organic framework

The invention discloses a preparation method of an amido bond-linked covalent organic framework, which comprises the following step: in a solvent, carrying out oxidation reaction on an imine bond-linked covalent organic framework under the action of-HSO5 to obtain the amido bond-linked covalent organic framework. The preparation method disclosed by the invention has one or more advantages of high efficiency, universality and capability of realizing amplified preparation.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com