Continuous zooming Hartmann sensor utilizing parallel light source for calibration

A parallel light source and sensor technology, which is applied in the transmission of sensing components, instruments, optics, etc. by optical devices, can solve the problems that the Hartmann measurement accuracy is greatly affected, and the technical indicators of the Hartmann sensor cannot meet the design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

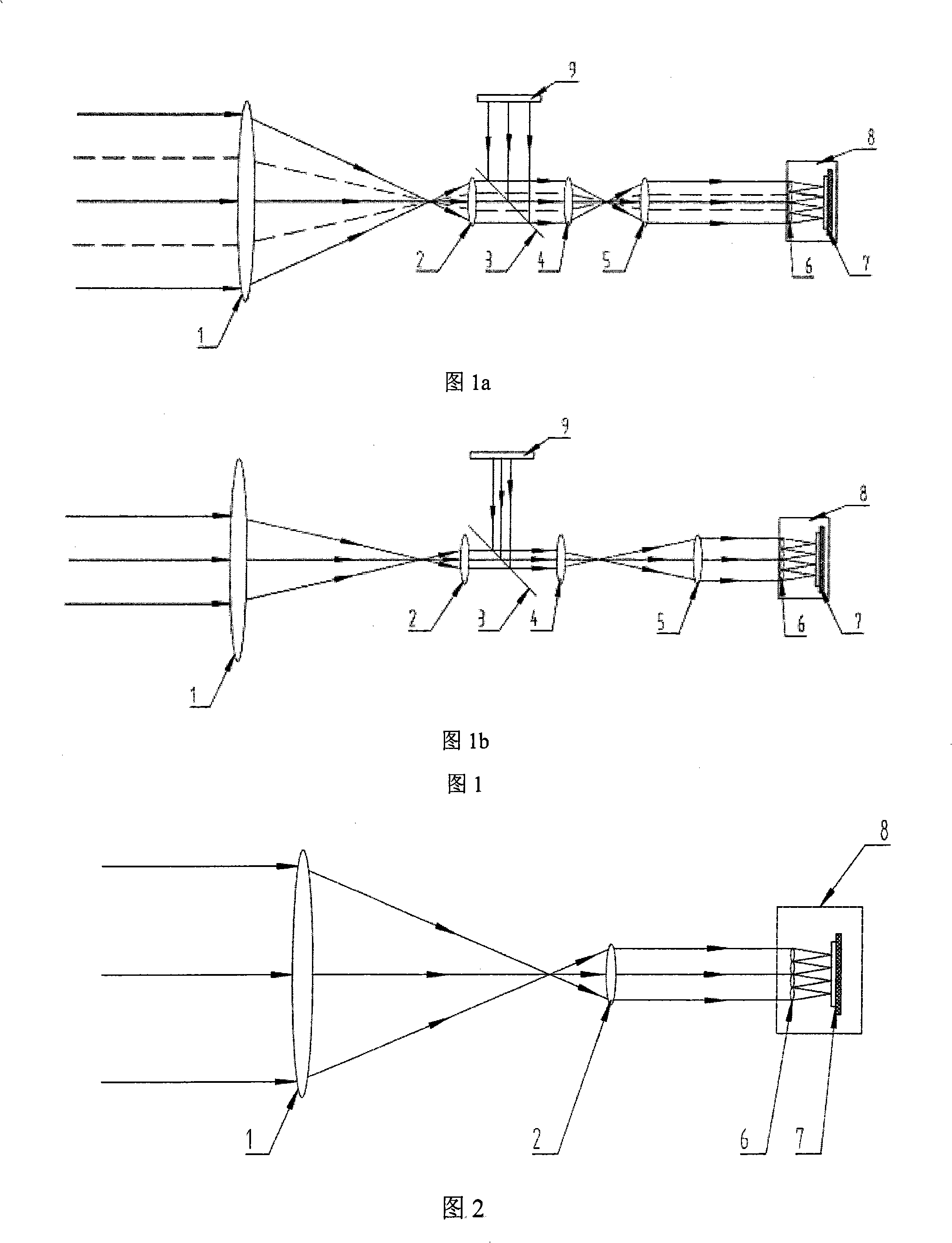

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] As shown in Figure 2, a common adaptive optics Hartmann wavefront sensor mainly includes a beam shrinking system composed of a before shrinking lens 1 and a shrinking lens 2, a microlens array 6, a photodetector 7, and a wavefront processing machine (the wave front processing machine is not shown in the figure), it uses the microlens array 6 to divide the incident signal wave front into sub-apertures, and the optical signal in each sub-aperture is focused on the subsequent photodetector 7, and the Calculate the position of the center of mass based on the energy distribution of the target surface;

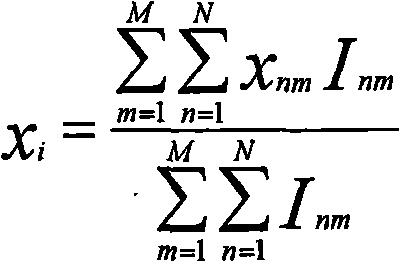

[0021] The Hartmann wavefront sensor mainly calculates the spot position (x i ,y i ), to detect the wavefront error information of the full aperture:

[0022] x i = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com