Preparation method of amido bond-linked covalent organic framework

A technology of covalent organic framework and amide bond, which is applied in the field of preparation of covalent organic framework, can solve the problems of complex and cumbersome operation steps, time-consuming, unfavorable scale-up production, etc., and achieve the effect of simple operation steps, avoiding procedures, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071]

[0072]

[0073] Covalent organic framework Ⅰ (30mg) and KHSO 5 (86 mg, 3 equiv.) was added to anhydrous N,N-dimethylformamide (2 ml), then 0.1 ml of glacial acetic acid was added, the nitrogen gas was quickly replaced several times, sealed, and stirred at 25°C for 5 hours. Filtration, filter cake with 10% Na 2 S 2 o 3 Washed with aqueous solution, water and tetrahydrofuran. Then the obtained solid was Soxhlet extracted with anhydrous methanol and THF for 5 hours, respectively, and dried under vacuum at 100°C for 2 hours to obtain a brown solid (30 mg, 90%).

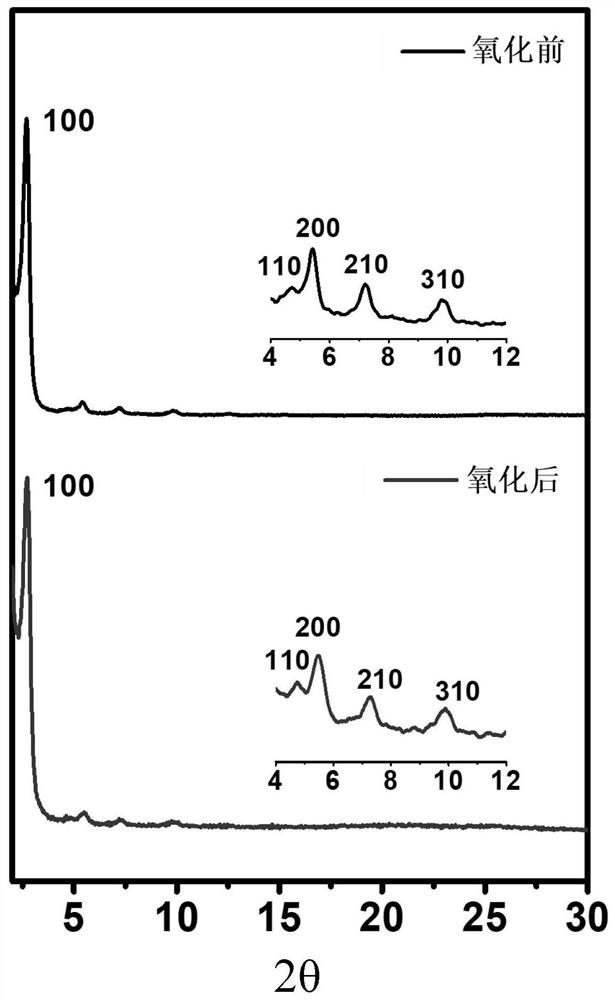

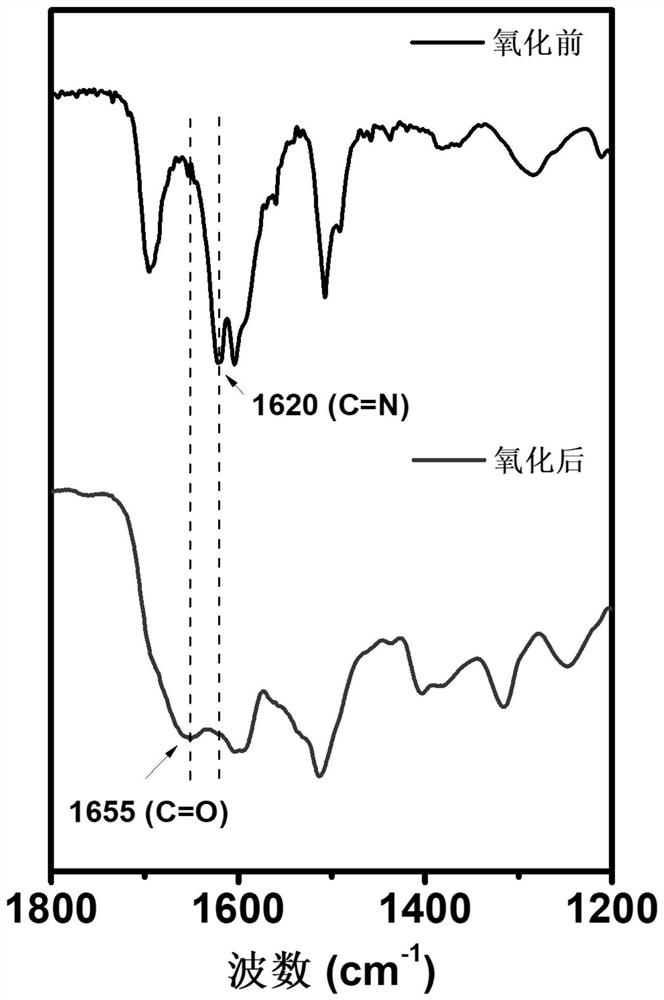

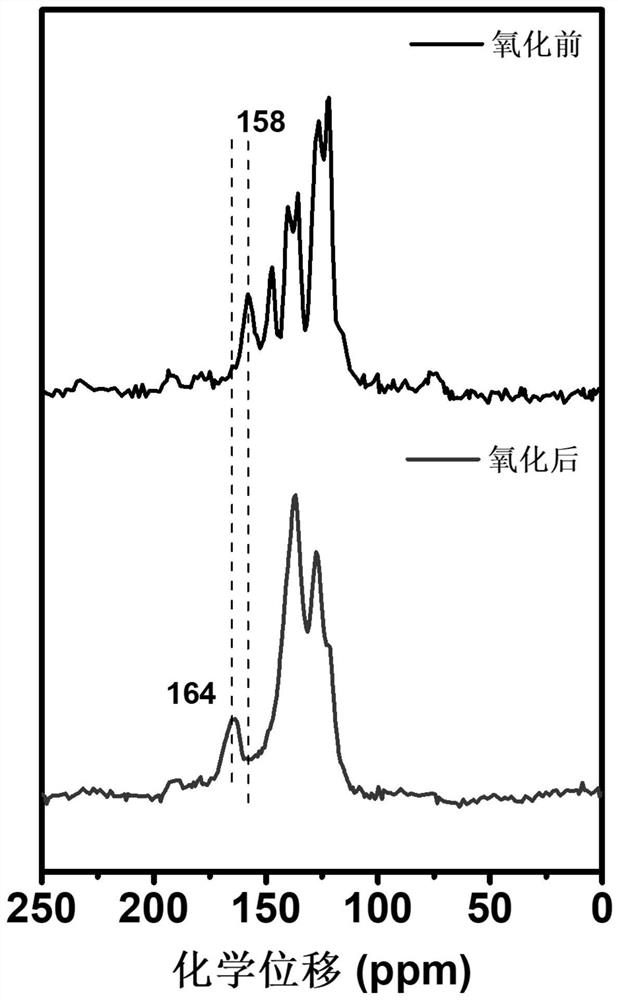

[0074] From figure 1 It can be seen that the powder X-ray diffraction peaks remain basically unchanged before and after oxidation, indicating that the amide bond-linked covalent organic framework obtained after oxidation has a crystal similar to its precursor (-C=N-linked covalent organic framework) structure. Among them, the diffraction peaks of covalent organic framework II at 2Theta=2.76°, 5.46°, a...

Embodiment 2

[0081]

[0082]

[0083] Covalent organic framework III (30mg) and KHSO 5 (48 mg, 2 equiv.) was added to anhydrous N,N-dimethylformamide (2 ml), then 0.1 ml of glacial acetic acid was added, the nitrogen gas was quickly replaced several times, sealed, and stirred at 25°C for 5 hours. Filtration, filter cake with 10% Na 2 S 2 o 3 Washed with aqueous solution, water and tetrahydrofuran. Then the obtained solid was Soxhlet extracted with anhydrous methanol and THF for 5 hours, respectively, and dried under vacuum at 100°C for 2 hours to obtain a brown solid (30 mg, 92%).

[0084] From Figure 5 It can be seen that the powder X-ray diffraction peaks remain basically unchanged before and after oxidation, indicating that the amide bond-linked covalent organic framework obtained after oxidation has a crystal structure similar to that of the precursor covalent organic framework. Among them, the diffraction peaks of covalent organic framework IV at 2Theta=3.76°, 5.38°, 7.49°...

Embodiment 3

[0089]

[0090] Covalent organic framework Ⅴ (40mg) and KHSO 5 (73 mg, 2 equiv.) was added to anhydrous N,N-dimethylformamide (2 ml), then 0.1 ml of glacial acetic acid was added, the nitrogen gas was quickly replaced several times, sealed, and stirred at 25°C for 5 hours. Filtration, filter cake with 10% Na 2 S 2 o 3 Washed with aqueous solution, water and tetrahydrofuran. The obtained solid was then Soxhlet extracted with anhydrous methanol and THF for 5 hours, and dried under vacuum at 100°C for 2 hours to obtain a brown solid (26 mg, 59%).

[0091] From Figure 9 It can be seen that the powder X-ray diffraction peaks remain basically unchanged before and after oxidation, indicating that the amide bond-linked covalent organic framework obtained after oxidation has a crystal structure similar to that of the precursor. Among them, the diffraction peaks of the covalent organic framework VI at 2Theta=5.12° and 10.29° correspond to the diffraction of (100) and (020) crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com