Patents

Literature

41results about How to "No yellowing phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

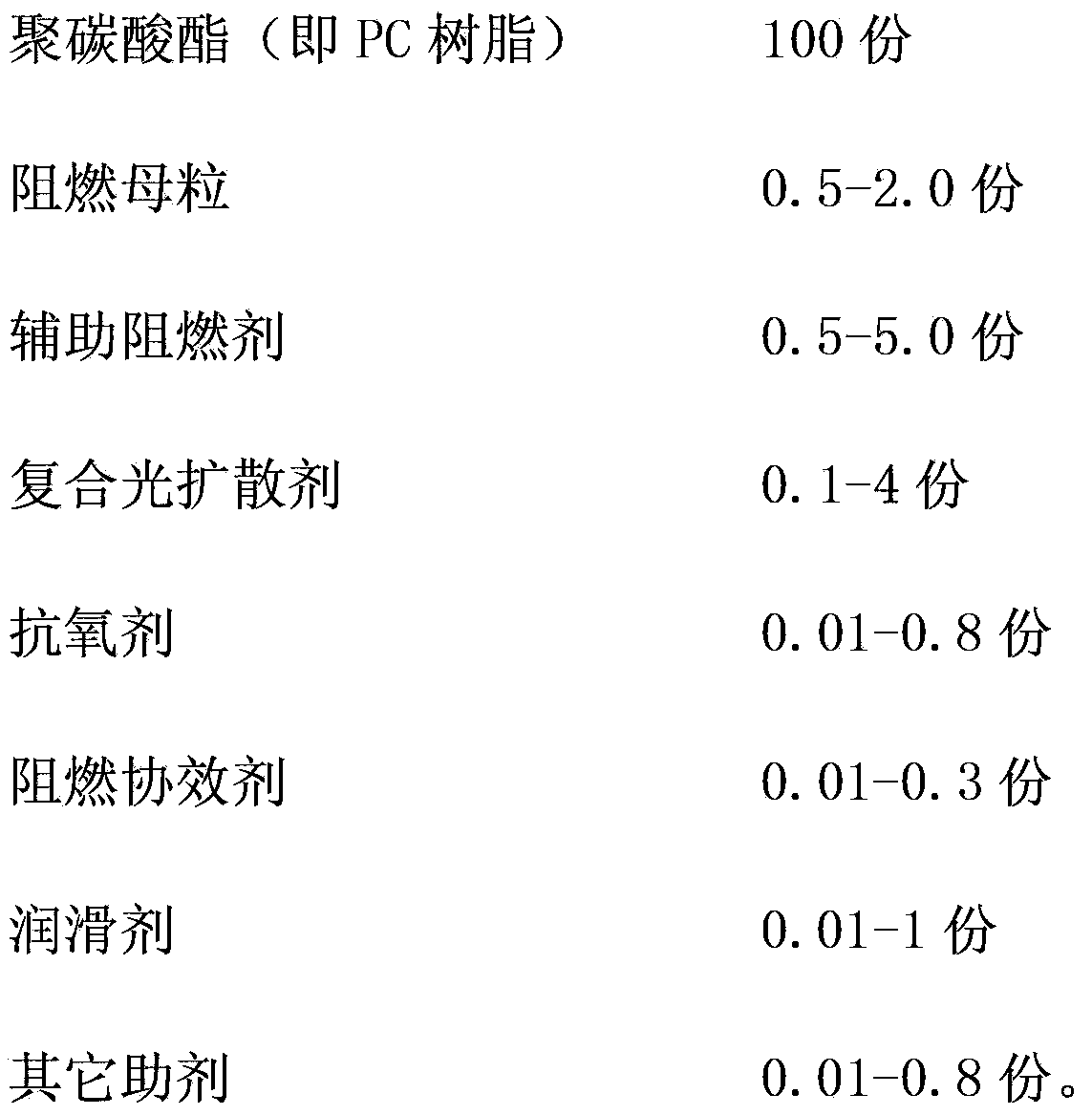

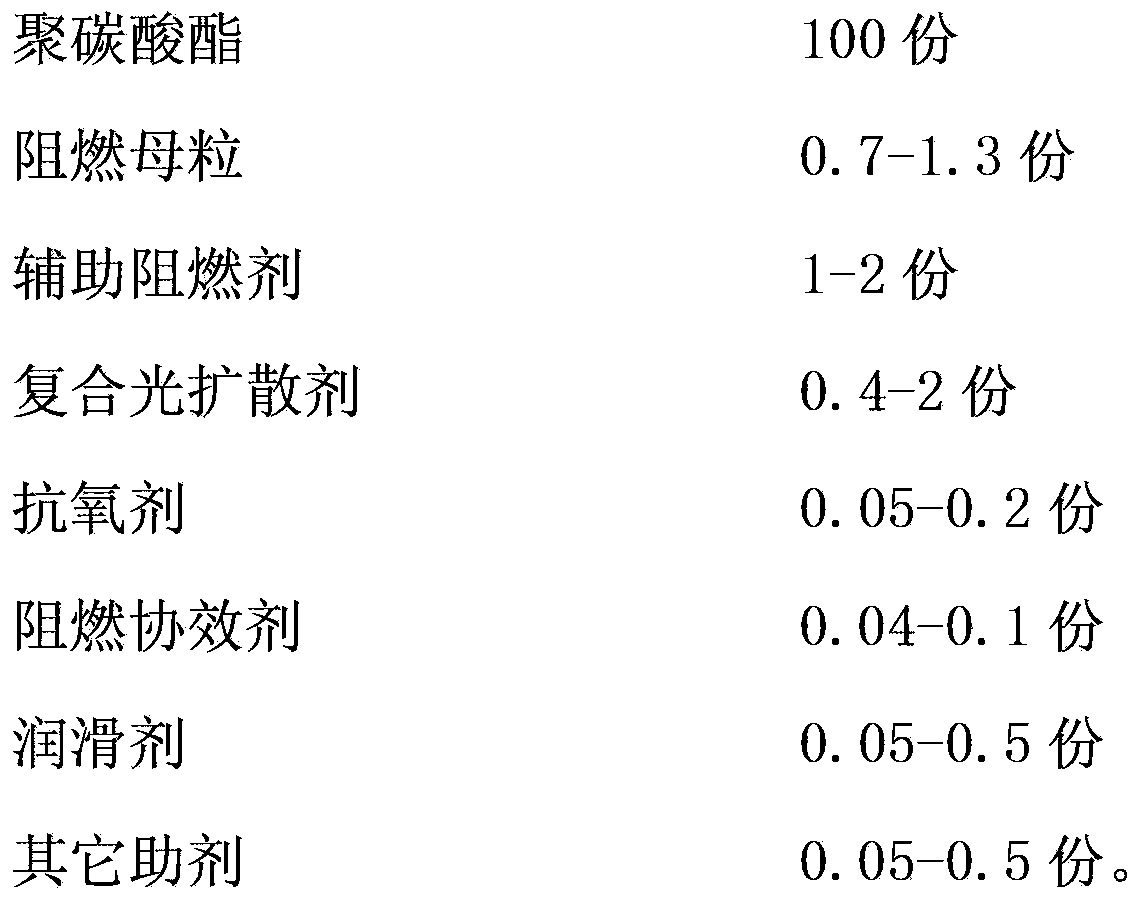

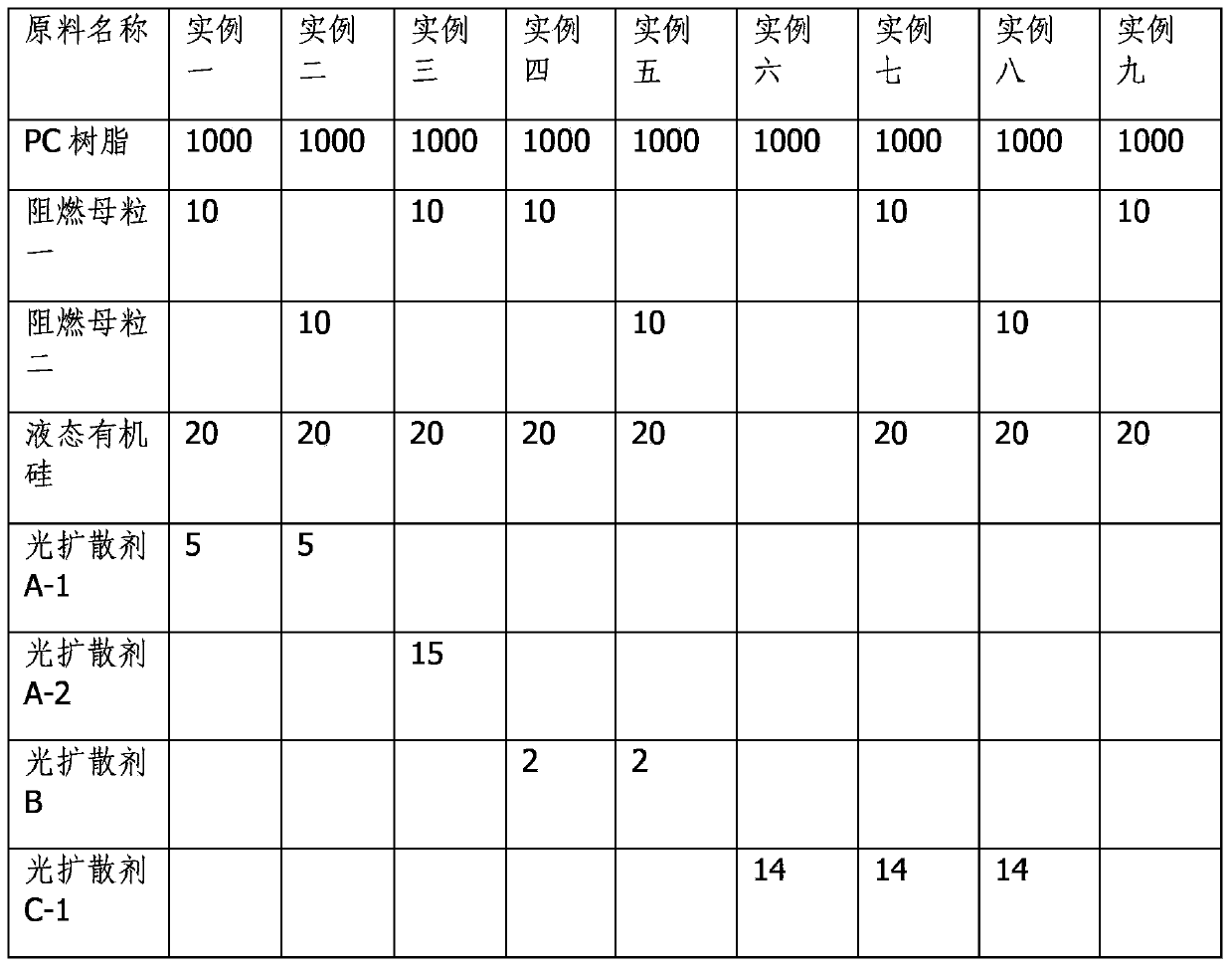

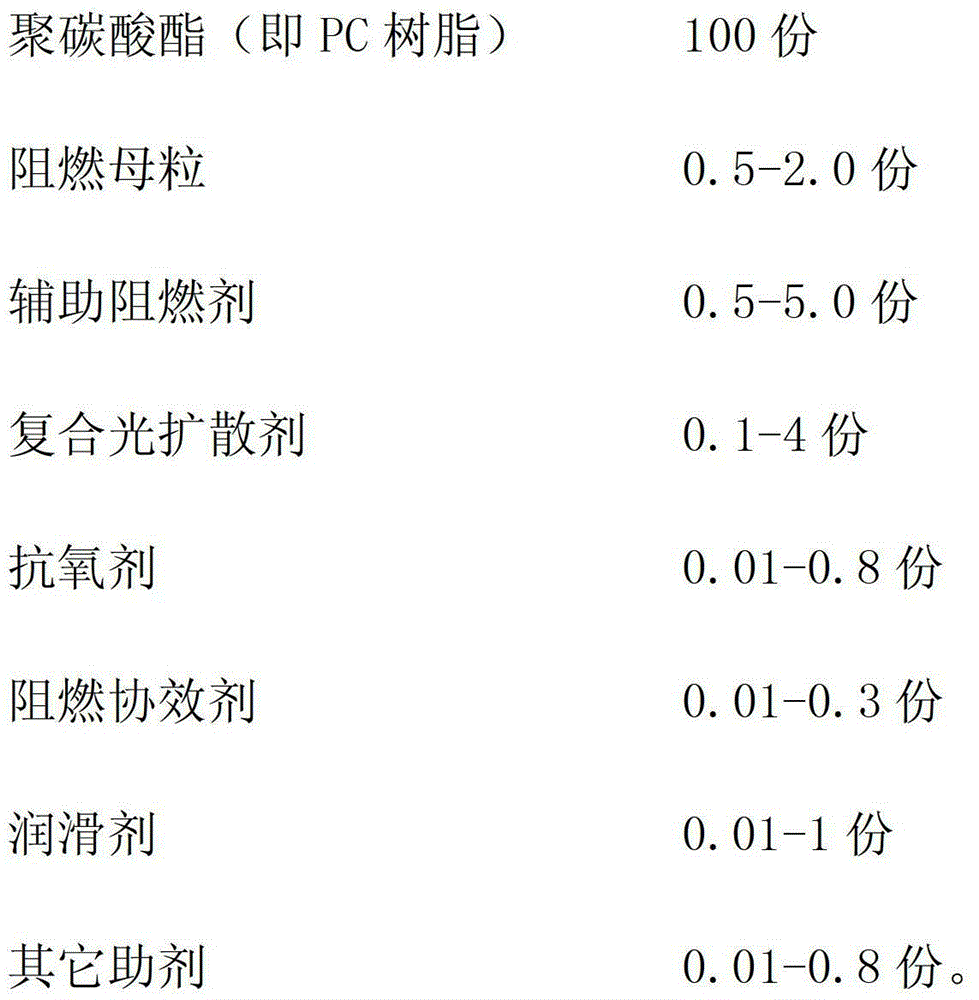

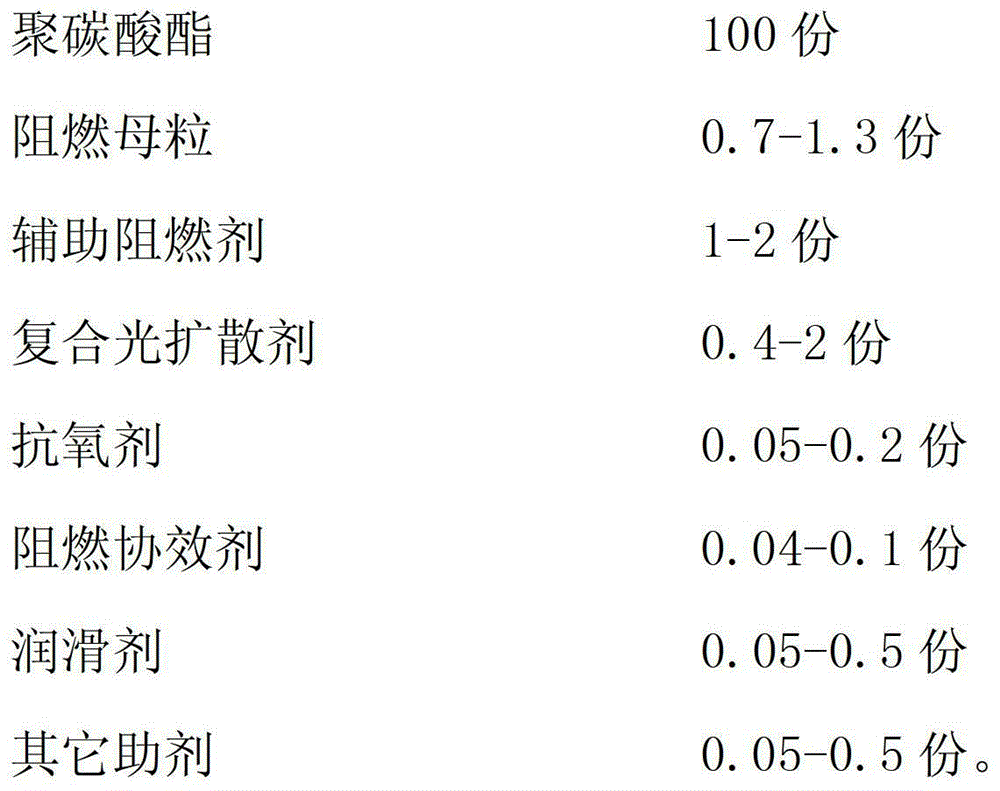

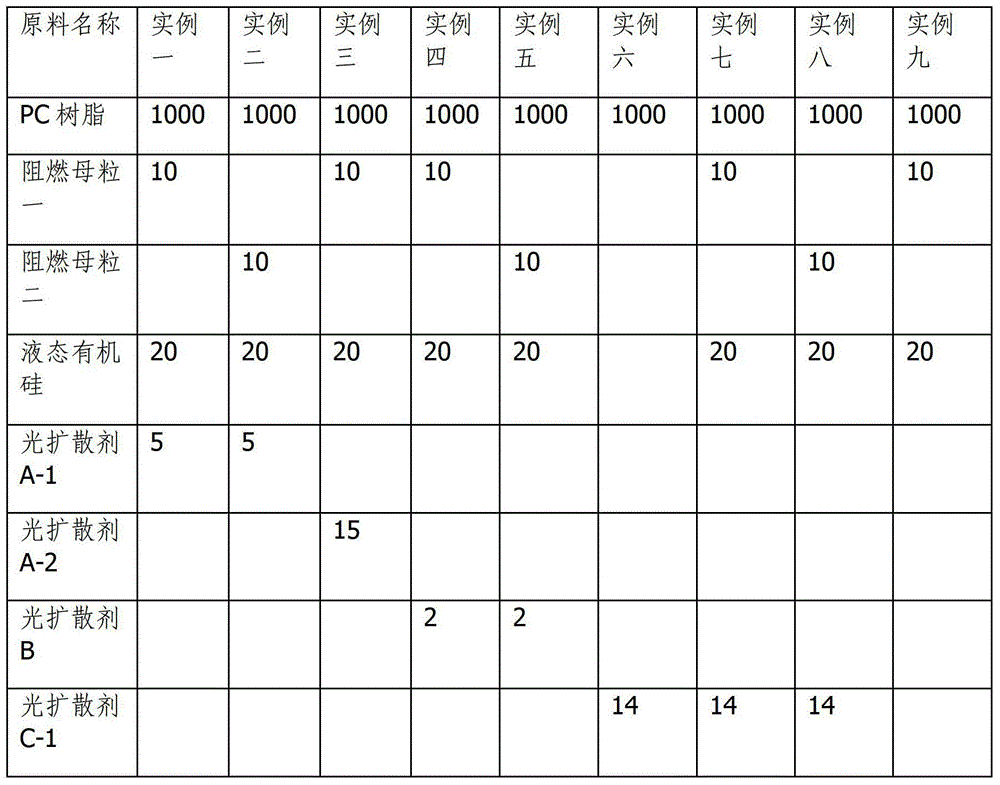

Polycarbonate material with excellent transparent light diffusion function and preparation method thereof

The invention discloses a PC (Polycarbonate) material with an excellent transparent light diffusion function and a preparation method thereof. The PC material is composed of polycarbonate, flame retardant masterbatch, an auxiliary flame retardant, a compound light diffuser, an antioxidant, a flame retardant synergist, a lubricant and other auxiliaries. The principle ingredient of the PC material is PC resin; the PC material is extruded by two steps, wherein the first step is to blend a sulfonate type major flame retardant and an organic silicon flame retardant with the PC resin by melting and granulate the mixture through extrusion by virtue of a twin-screw extruder so as to obtain the light diffusible flame retardant masterbatch, and the second step is to add the compound light diffuser, the flame retardant masterbatch, the antioxidant, the flame retardant synergist, the lubricant and other auxiliaries for further melting blending by taking PC as the major ingredient, and then extrude and granulate the mixture. The flame-retardant light diffusible PC material provided by the invention can be widely applied to an LED (Light-Emitting Diode) lamp, the backlight of a liquid crystal display, a transmission type screen, a decorative lighting billboard, an advertisement lamp box and the like in the lighting field.

Owner:NANTONG DONGFANG PLASTIC CO LTD

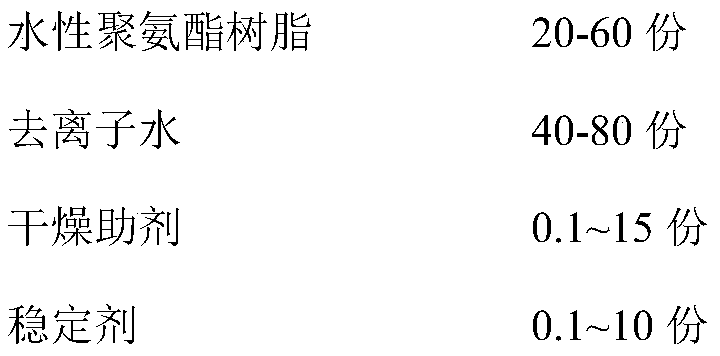

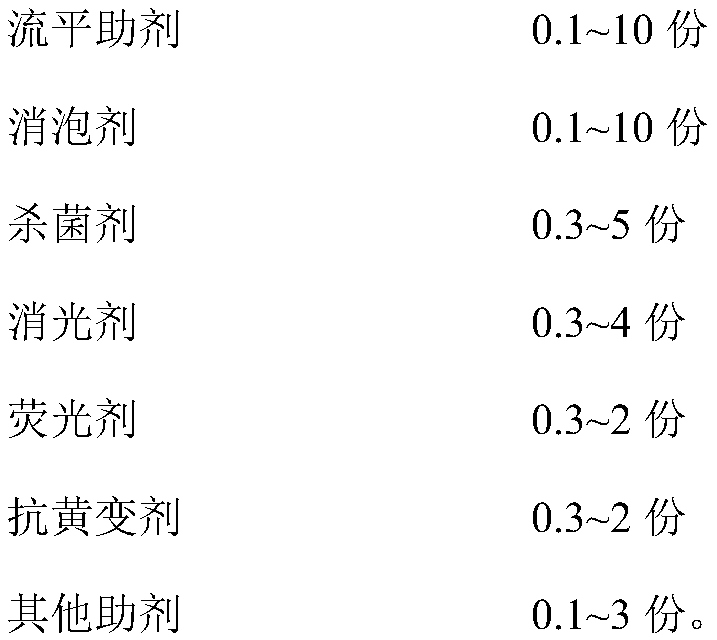

Preparation process for waterborne polyurethane emulsion

The invention provides a preparation process for a waterborne polyurethane emulsion. The preparation process comprises the following steps: a) subjecting carbon dioxide copolymer polyol, aliphatic diisocyanate and a hydrophilic chain extender to a reaction under the action of a catalyst so as to obtain a reaction product; b) reacting the reaction product obtained in the step a) with an epoxy silane coupling agent and a salt forming agent so as to obtain a performed polymer; and c) adding water into the performed polymer, carrying out emulsification and then reacting the emulsified performed polymer with an amine chain extender so as to obtain the waterborne polyurethane emulsion. The waterborne polyurethane emulsion prepared by using the preparation process has good resistance to water soaking and yellowing.

Owner:GUANGDONG UNIV OF TECH

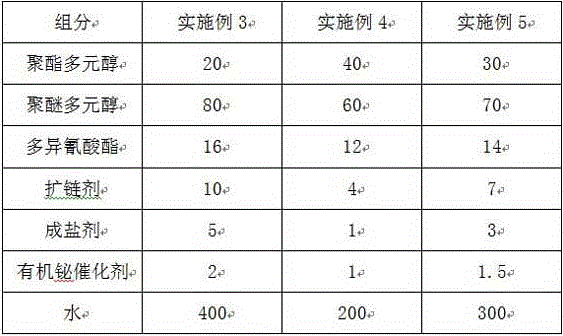

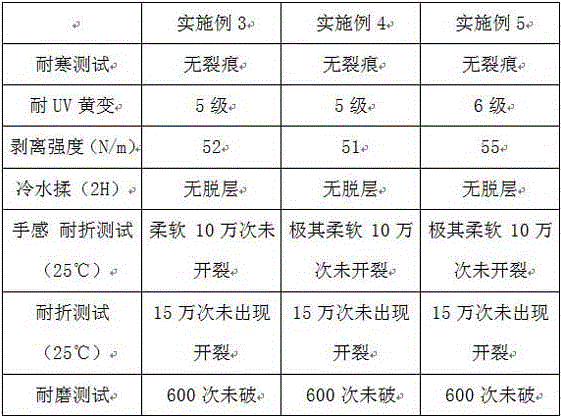

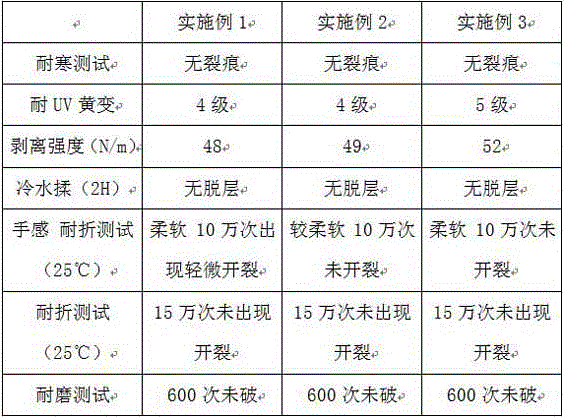

Waterborne polyurethane resin

The invention relates to waterborne polyurethane resin. The waterborne polyurethane resin comprises, by weight, 20-40 parts of polyester polyol, 60-80 parts of polyether polyol, 12-16 parts of polyisocyanate, 4-10 parts of chain extender, 1-5 parts of salt-forming agent, 1-2 parts of organic bismuth catalyst and 200-400 parts of water. The polyester polyol is formed by mixing polycaprolactone polyol and aliphatic polycarbonate, the polyether polyol is tetrafluorohydrazine-propylene oxide copolymer diol, and the chain extender is formed by mixing ethylene glycol and IPDA. The waterborne polyurethane resin has the advantages that the waterborne polyurethane resin can be resistant to cold by adjusting components in the formula and the ratio of the components, and when the waterborne polyurethane resin is used for clothing leather facing, a fitting layer is soft in hand feeling, high in peel strength and good water resistance.

Owner:南通万顺化工科技有限公司

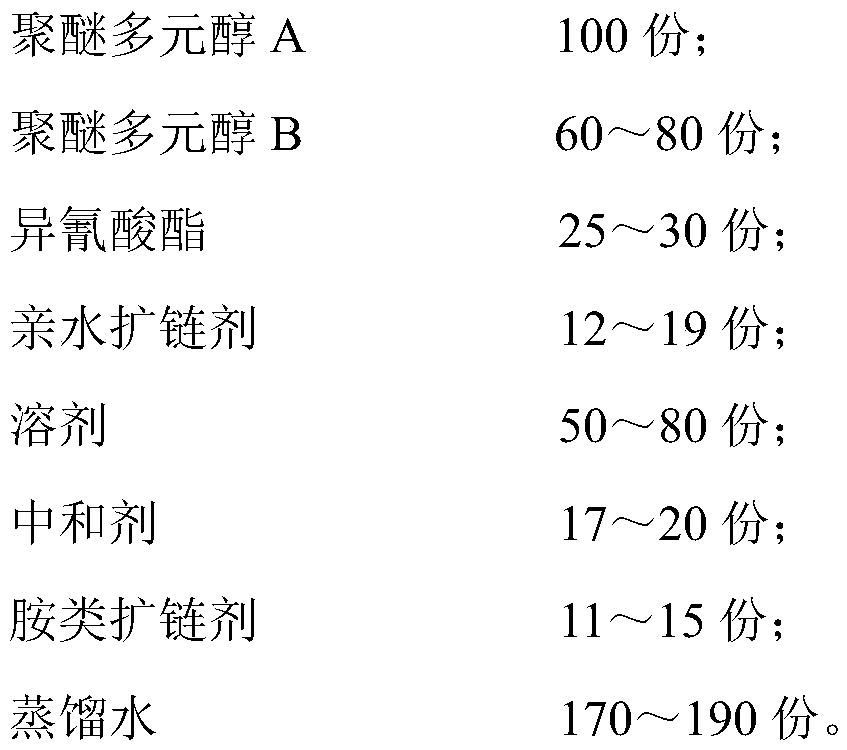

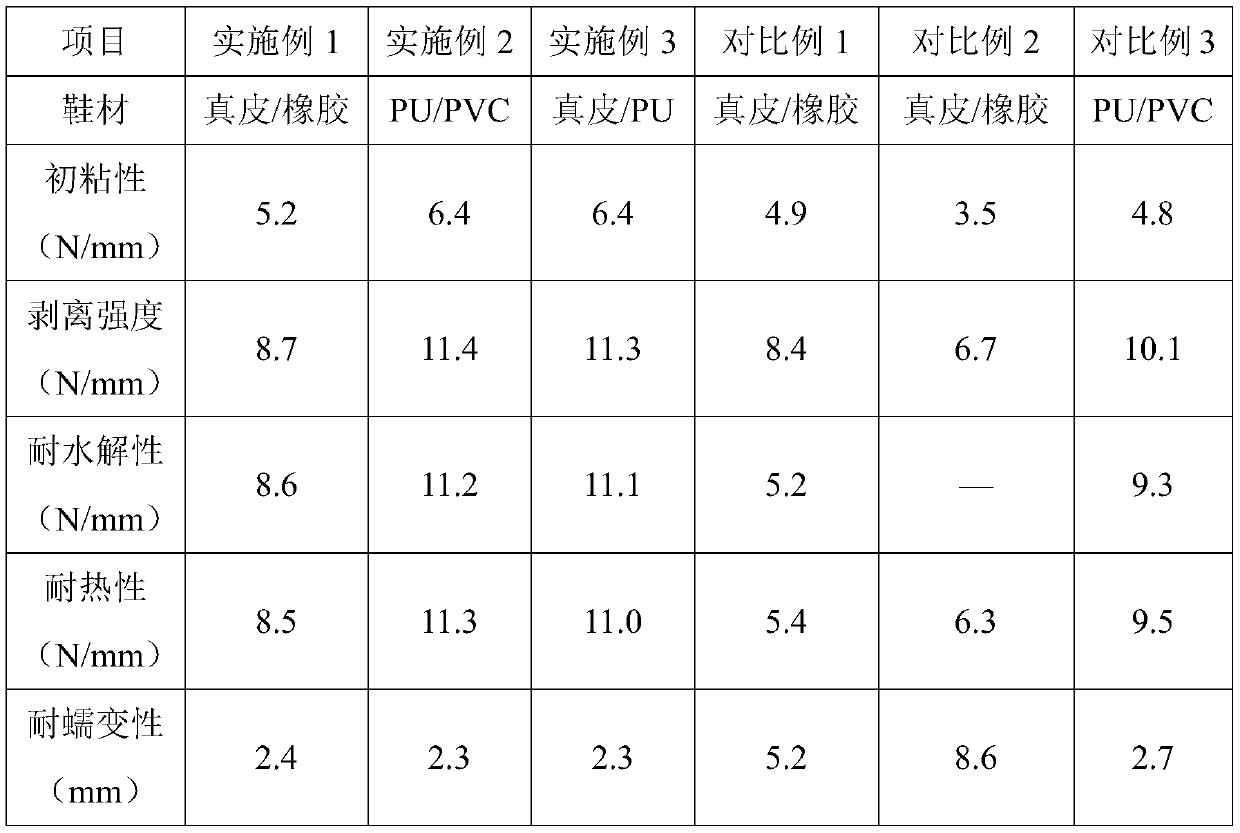

Waterborne polyurethane adhesive used for shoes and preparation method thereof

InactiveCN109705792AImprove water resistanceGood flexibility at low temperaturePolyureas/polyurethane adhesivesPolyurethane adhesiveGlycerol

The invention relates to the technical field of polyurethane adhesives, specifically to a waterborne polyurethane adhesive used for shoes and a preparation method thereof. The waterborne polyurethaneadhesive comprises the following raw materials by mass: 100 parts of polyether polyol A, 60 to 80 parts of polytetrahydrofuran diol, 25 to 30 parts of isocyanate, 12 to 19 parts of a hydrophilic chainextender, 50 to 80 parts of a solvent, 17 to 20 parts of a neutralizing agent, 11 to 15 parts of an amine chain extender and 170 to 190 parts of distilled water, wherein the polyether polyol A is polyether polyol which uses glycerin as a starting agent, uses epoxypropane for ring opening and oxirane for end termination, and has a functionality degree of 2.5 to 3.5 and a number average molecular weight of 4500 to 5500; and the isocyanate is 1,4-cyclohexane diisocyanate. The waterborne polyurethane adhesive provided by the invention has good initial strength and initial adhesion, high bonding strength and good heat resistance and water resistance in the process of use. The invention also provides a preparation method for the waterborne polyurethane adhesive.

Owner:耿佃勇

Anti-termite cable material and cable using same

InactiveCN103980605AWith anti-ultraviolet functionNo yellowing phenomenonPlastic/resin/waxes insulatorsInsulated cablesBifenthrinCorrosion resistant

The invention relates to the technical field of wires and cables and in particular relates to an anti-termite cable material. The cable material is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of ethylene-tetrafluoroethylene copolymer, 30-40 parts of propylene-tetrafluoroethylene copolymer, 12-18 parts of glass fibers, 2-4 parts of magnesium hydroxide, 2-4 parts of mica powder, 2-4 parts of carbon black or titanium dioxide, 1-3 parts of bifenthrin and 3-5 parts of methylbenzene. The invention further discloses a manufacturing method of the cable material. The cable material mainly has the beneficial effects of being outstanding in anti-termite and anti-mouse performance and excellent in anti-ultraviolet-aging performance, has the advantages of being high in electrical insulativity, relatively heat-resistant, relatively corrosion-resistant, relatively steam-resistant, relatively oil-resistant, relatively fire-resistant, relatively flame-retardant, relatively high in mechanical strength and the like, and is easy to manufacture; the production speed is relatively high and the thickness can be accurately controlled when the cable material is used for producing the wires and the cables.

Owner:STATE GRID CORP OF CHINA +1

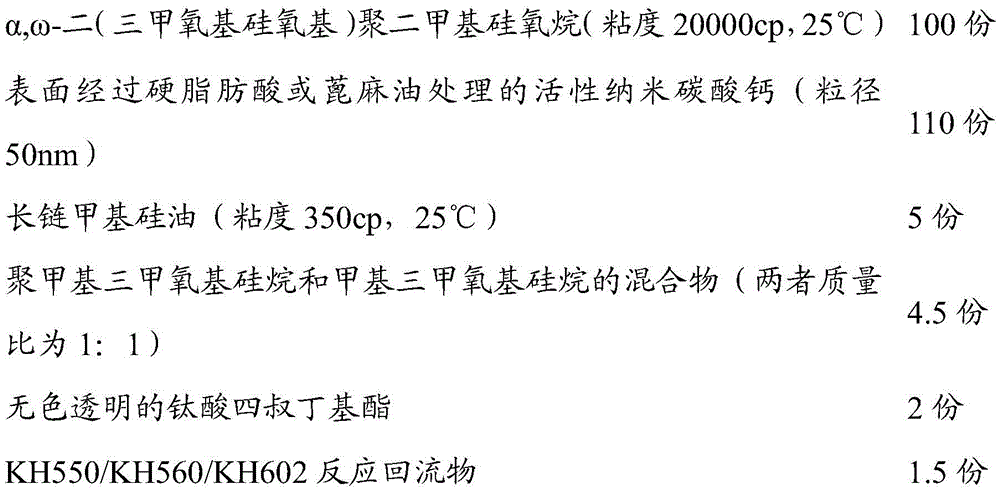

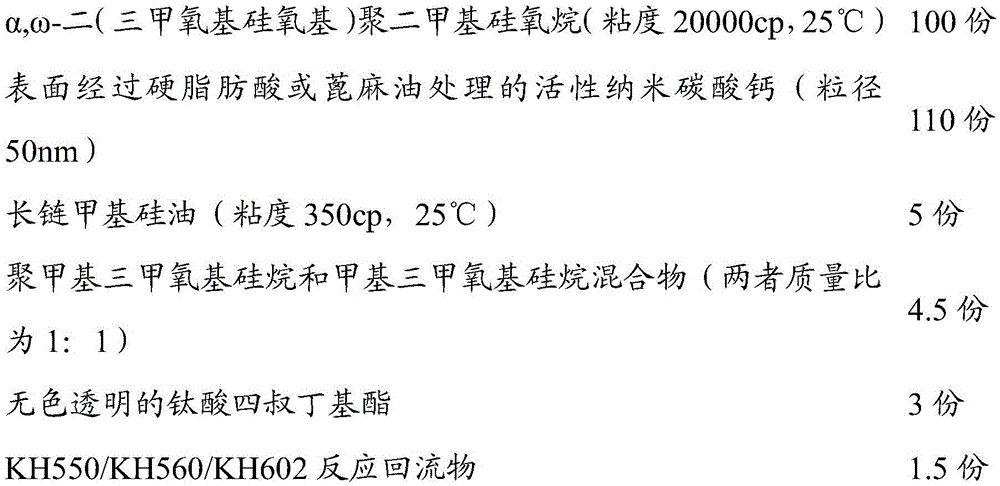

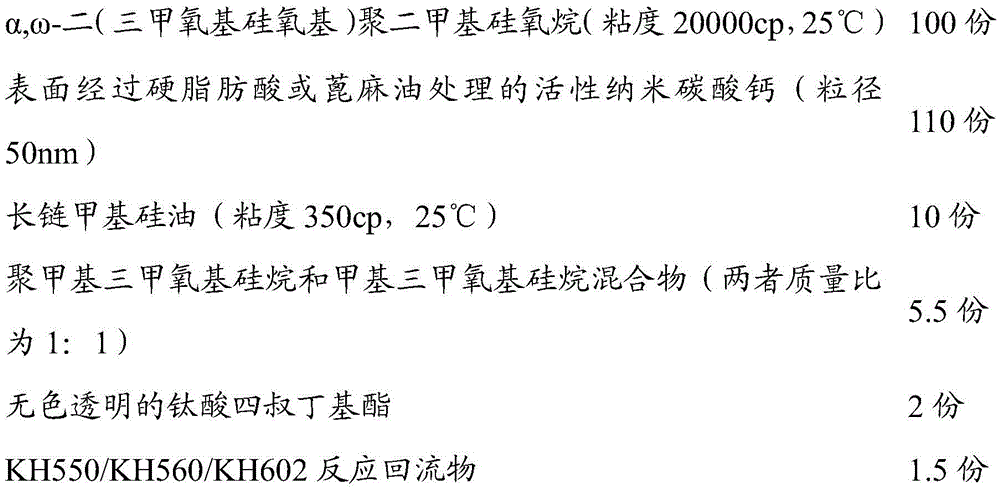

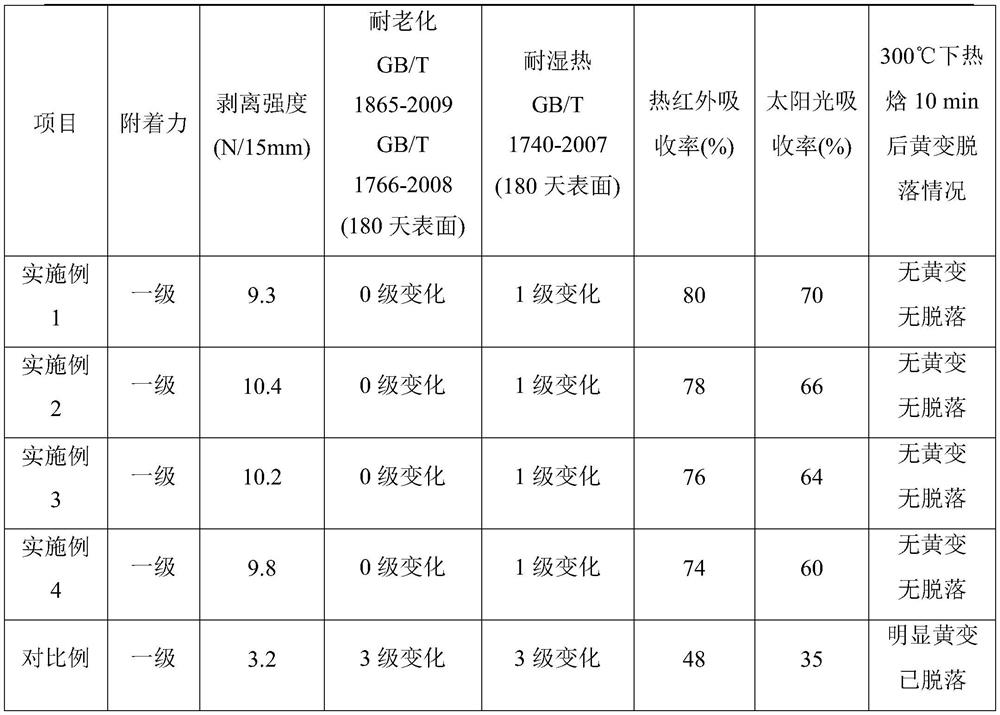

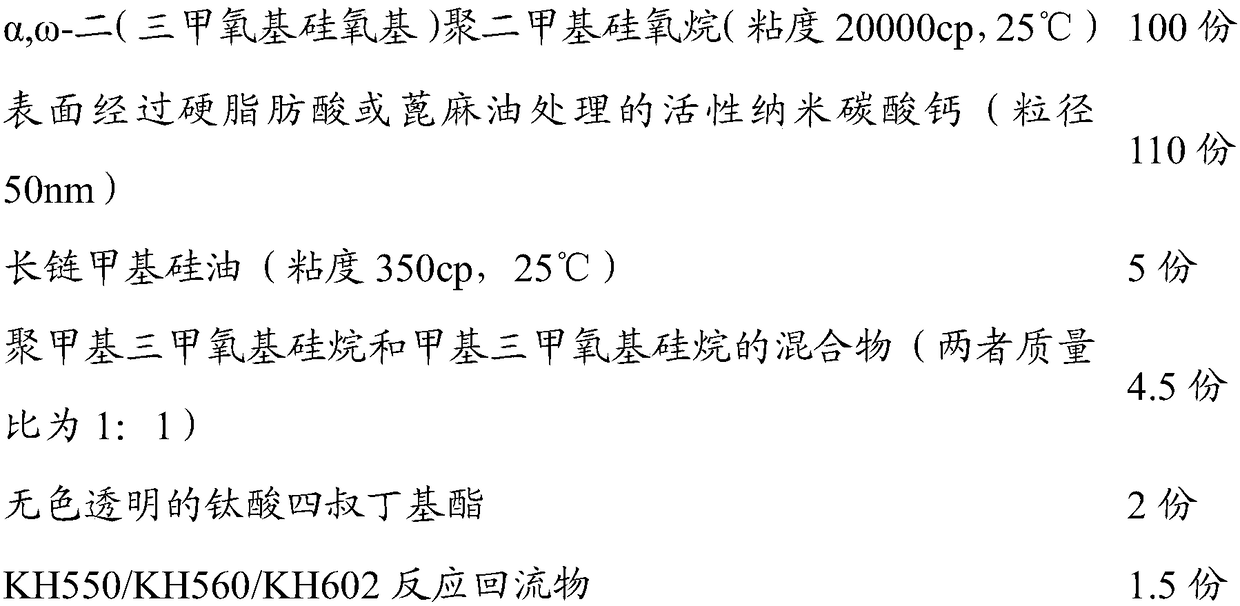

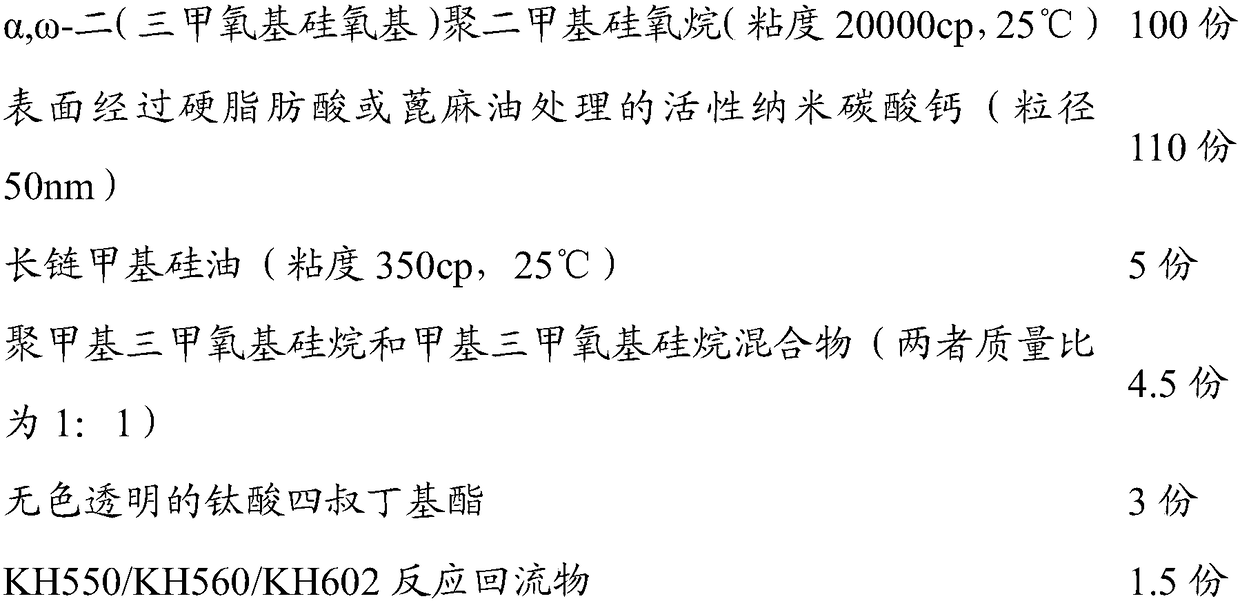

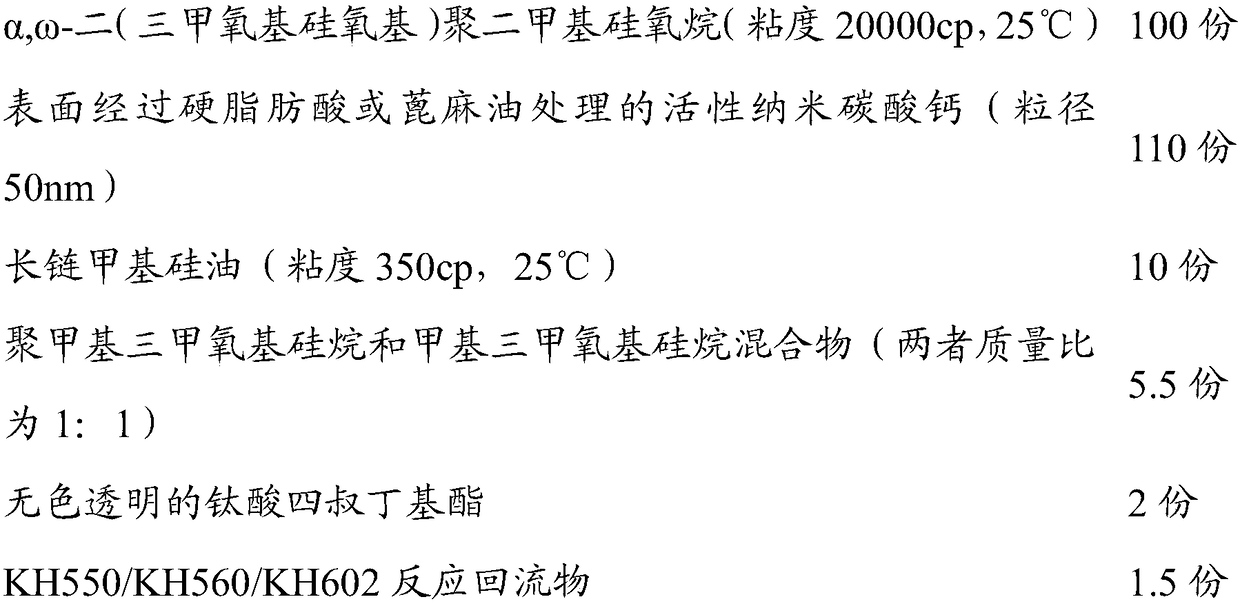

Single-component RTV (room temperature vulcanization) silicone sealing material for LED lamp and preparation method of single-component RTV silicone sealing material

ActiveCN105524590AGood adhesionLow resistance to yellowingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkLED lamp

The invention relates to a single-component RTV (room temperature vulcanization) silicone sealing material for an LED lamp and a preparation method of the single-component RTV silicone sealing material. The single-component RTV silicone sealing material comprises raw materials in parts by weight as follows: 100 parts of alpha, omega-bis(trimethoxysilyloxy) polydimethylsiloxane, 100-120 parts of reinforcing filler, 1-10 parts of a plasticizer, 3-7 parts of a cross-linking agent, 1-3 parts of a catalyst and 1-5 parts of an adhesion promoter. The single-component RTV silicone sealing material for the LED lamp has excellent adhesive property, high temperature and low temperature resistance, high temperature and high humidity resistance, yellowing resistance, low volatile matter content and no sulfur and halogen, and can provide a better adhesion solution for LED lamp assembly such as adhesive fixation of a PC (polycarbonate) bulb and a lamp holder and adhesive fixation of an LED light bar and a lamp tube.

Owner:GUANGZHOU BAIYUN CHEM IND

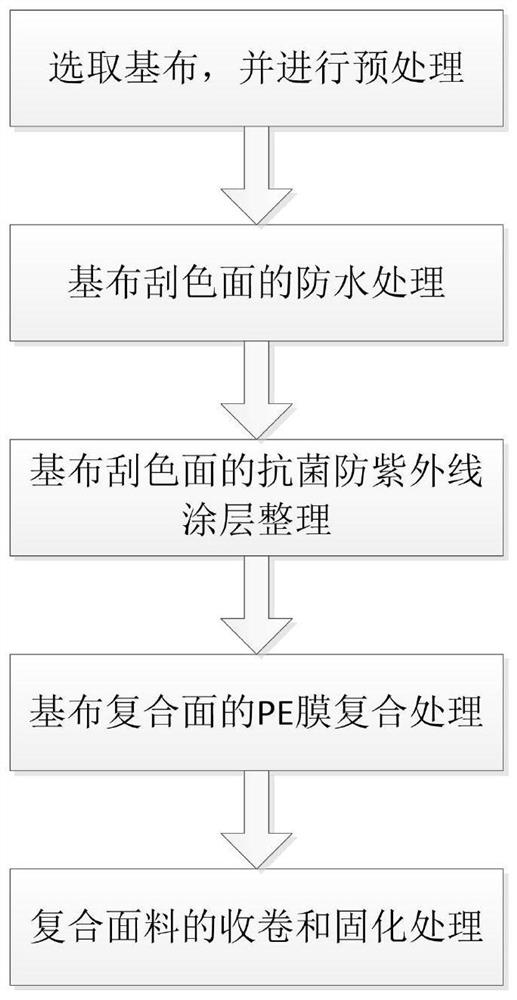

Method for improving yellowing resistance of antibacterial ultraviolet-proof composite curtain fabric

PendingCN114193866AAntibacterialFunctionalLamination ancillary operationsSynthetic resin layered productsPolymer scienceEngineering

The invention discloses a method for improving the yellowing resistance of an antibacterial and ultraviolet-proof composite curtain fabric. The method comprises the following steps: S1, selecting base cloth and performing pretreatment; s2, performing color scraping surface waterproof treatment on the color scraping surface of the base cloth; s3, preparing antibacterial and ultraviolet-proof color paste, blade-coating the color scraping surface of the base cloth with the antibacterial and ultraviolet-proof color paste, and then sequentially performing drying treatment and calendaring treatment on the color scraping surface; s4, bonding a PE film to the composite surface of the base cloth; s5, carrying out rolling and curing treatment on the compounded fabric to obtain a finished product of the antibacterial and ultraviolet-proof type composite curtain fabric. On the premise of ensuring that the composite curtain fabric has antibacterial and ultraviolet-proof properties, the yellowing resistance of the fabric is improved, the use requirement standard of customers is met, and the processing cost and the popularization difficulty of products are reduced.

Owner:CHANGZHOU TAILUN TEXTILE CO LTD

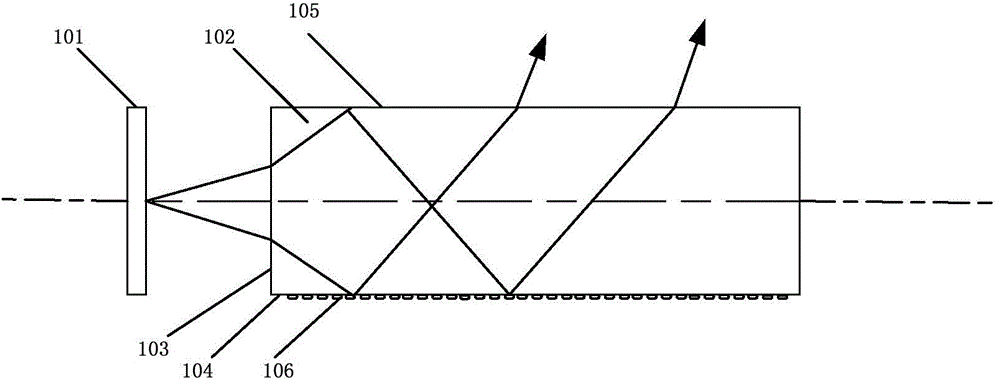

Backlight module and display device

ActiveCN104595804AImprove luminous efficiencyNo yellowing phenomenonMechanical apparatusPoint-like light sourceGamutLight guide

The invention discloses a backlight module and a display device. The backlight module comprises a blue light-emitting diode and a light guiding plate. The light guiding plate comprises a bottom face, a light emitting face opposite to the bottom face, and a light incidence face for the bottom face and the light emitting face to be connected. RG printing ink net points are evenly distributed on the outer side of the bottom face of the light guiding plate. Light emitted by the blue light-emitting diode passes the light incidence face and is mixed with RG printing ink in the RG printing ink net points to generate white light, and the white light is irradiated through the light emitting face of the light guiding plate. According to the technical scheme, the blue light emitted by the blue light-emitting diode is mixed with the RG printing ink arranged on the bottom face of the light guiding plate to reflect the high-gamut white light, and therefore the design cost for achieving the high-gamut white light is reduced; due to the fact that the blue light-emitting diode does not contain fluorescent powder, the light-emitting efficiency is high, and a display frame cannot become yellow.

Owner:QINGDAO GOERTEK

Ultraviolet-curable laminating adhesive and preparation method thereof

InactiveCN110283539AExcellent high-gloss packaging effectImprove qualityOrganic non-macromolecular adhesivePhotoinitiatorChemistry

The invention provides an ultraviolet-curable laminating adhesive and a preparation method thereof. The ultraviolet-curable laminating adhesive comprises, by mass, 20-35 parts of an polyurethane acrylate oligomer, 10-30 parts of a first ultraviolet curing monomer, 35-60 parts of a second ultraviolet curing monomer and 2-6 parts of a photoinitiator, wherein the glass transition temperature of the first ultraviolet curing monomer is 70-150 DEG C, and the glass transition temperature of the second ultraviolet curing monomer is -50-50 DEG C. The ultraviolet-curable laminating adhesive has the advantages of good transparency, strong caking property, high drying speed, and realization of high-quality high-light packaging at a low cost.

Owner:中山布瑞特环保油墨有限公司

High-pressure hydrogen peroxide bleaching method of soda pulp

The high-pressure hydrogen peroxide bleaching method for alkali pulp includes the following steps: using chelating agent to pretreat pulp, then respectively adding Na2SiO3, NaOH, MgSO4 and H2O2, thenusing medium concentration pulp pump to pump the pulp into the medium concentration pulp mixer, adding oxygen gas and steam into the medium concentration pulp mixer, adding oxygen gas and steam into medium concentration pulp mixer after the pulp is passed through the mixer, feeding the pulp into hydrogen peroxide bleaching tower, then feeding the pulp into pulp washing machine, then washing and cleaning. Said invention raise reaction pressure and reaction temp. for bleaching pulp, and greatly raises bleaching efficiency, and its waste water contains no chlorinated organics, and can be recovered by recovering procedure, so it implements the "zero discharge" of beaching waste water.

Owner:黄干强 +1

Water-based microfiber non-woven fabric capable of replacing leather

PendingCN110607694AGood surface feelGood antifouling and antibacterial performanceStain/soil resistant fibresBiochemical fibre treatmentEmulsionWoven fabric

The invention relates to a water-based microfiber non-woven fabric capable of replacing leather. The water-based microfiber non-woven fabric capable of replacing leather comprises a microfiber non-woven fabric, a bottom layer covering the microfiber non-woven fabric and a surface layer covering the bottom layer. The water-based microfiber non-woven fabric capable of replacing leather consists of the following raw materials in parts by weight: 100 parts of aqueous polyurethane emulsion, 35-38 parts of dimethylformamide, 30-40 parts of polymer particles, 20-150 parts of deionized water, 0.1-2.0parts of a cell regulator and 0.2-0.8 part of an antifouling additive. Compared with the prior art, the water-based microfiber non-woven fabric capable of replacing the leather has good surface touchfeeling and antifouling antibacterial performance; the characteristics of fullness, softness and high leather feel of the water-based microfiber non-woven fabric are realized; and the prepared water-based microfiber non-woven fabric capable of replacing the leather has a relatively fine cell structure.

Owner:晋江全亿无纺布有限责任公司

Polyurethane resin

InactiveCN101381447BNo yellowing phenomenonGuaranteed softnessFibre treatmentAnti freezingOrganic solvent

The invention relates to polyurethane resin, which consists of the following components in weight percentage: 4 to 5 percent of polyethylene glycol adipate, 11 to 13 percent of polytetrahydrofuran glycol, 0.4 to 0.6 percent of ethylene glycol, 1.8 to 1.9 percent of isophorone diamine, 6 to 8 percent of isophorone diisocyanate, 0.08 to 0.1 percent of antioxidant and 73 to 80 percent of organic solvent. The polyurethane resin is applied to produce instep leather of top-grade travel shoes and has good ultraviolet ray yellow stain resistant performance; and under the sunlight, the leather color can be kept unchanged for a long time, and no yellow stain occurs; meanwhile, the polyurethane resin also has good anti freezing property, and no crack generates when the polyurethane resin is used at low temperature for a long time.

Owner:XUCHUAN CHEM KUNSHAN

Polycarbonate material with good transparent light diffusion function and preparation method thereof

The invention discloses a PC (Polycarbonate) material with an excellent transparent light diffusion function and a preparation method thereof. The PC material is composed of polycarbonate, flame retardant masterbatch, an auxiliary flame retardant, a compound light diffuser, an antioxidant, a flame retardant synergist, a lubricant and other auxiliaries. The principle ingredient of the PC material is PC resin; the PC material is extruded by two steps, wherein the first step is to blend a sulfonate type major flame retardant and an organic silicon flame retardant with the PC resin by melting and granulate the mixture through extrusion by virtue of a twin-screw extruder so as to obtain the light diffusible flame retardant masterbatch, and the second step is to add the compound light diffuser, the flame retardant masterbatch, the antioxidant, the flame retardant synergist, the lubricant and other auxiliaries for further melting blending by taking PC as the major ingredient, and then extrude and granulate the mixture. The flame-retardant light diffusible PC material provided by the invention can be widely applied to an LED (Light-Emitting Diode) lamp, the backlight of a liquid crystal display, a transmission type screen, a decorative lighting billboard, an advertisement lamp box and the like in the lighting field.

Owner:NANTONG DONGFANG PLASTIC CO LTD

Polyurethane film with high wear resistance and preparation method of polyurethane film

The invention relates to the technical field of wear-resistant films, in particular to a polyurethane film with high wear resistance. The polyurethane film is prepared from isophorone diisocyanate, polyethylene glycol, ethylene glycol, trimethylolpropane, a titanate coupling agent, a nonionic surfactant, a defoaming agent, a pH regulator, a flame retardant, a filling agent and the balance of deionized water. The invention also discloses a preparation method of the polyurethane film with high wear resistance. The method comprises preparation steps as follows: S1, weighing and proportioning; S2,stirring and mixing; S3, plastification; S4, calendaring molding; S5, modified pretreatment; and S6, plasma modification. The polyurethane film and the preparation method have the benefits as follows: the formula is scientific and reasonable, the surface of the plasma modified film is uniform and compact, the wear resistance and adhesion of the film are substantially improved, the process is simple, the cost of raw materials is low, and large-scale application can be realized.

Owner:HUBEI UNIV OF ARTS & SCI

Orchid-extract-containing softener

InactiveCN106894235ASoft and fluffy effectGood stabilityBiochemical fibre treatmentGrip property fibresChemistryEssence oil

The composition and mass percentage of the softening agent containing orchid extract of the present invention are 18%-35% of chlorohydrocarbyl functional group silane, 2%-8% of orchid extract, and 5%-8% of dialkyl dimethyl quaternary ammonium salt. %, hibiscus essential oil 11% to 15%, plant essence 2% to 3.5%, ether 12% to 15%, calcium halide 2% to 8% and deionized water 48% to 58%. The chlorohydrocarbyl functional group silane is chloropropyltrimethoxysilane. The hibiscus essential oil is imidazoline hibiscus essential oil. The calcium halide is calcium chloride. A softener containing orchid extract of the present invention has good soft and fluffy effect after disinfection and washing; low use concentration does not damage fabrics; good stability does not damage skin; low cost and no pollution to the environment; especially for common harmful microorganisms The pathogenic bacteria have a strong killing effect, and the fabric is guaranteed to be free of bacteria after washing; the fabric has good antistatic and re-wetting properties, and there is no damage to yellowing.

Owner:QINGDAO XINYIFA IND & TRADE

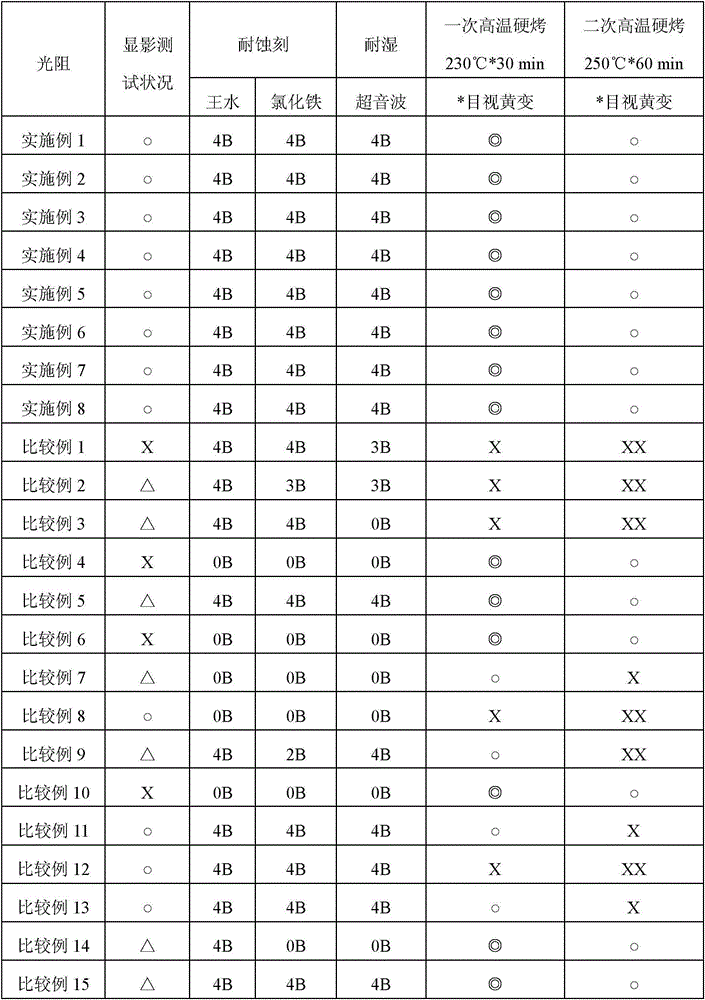

White light sensitivity resin composition and purpose thereof

InactiveCN104062847AMeet the needs of anti-yellowingMoisture resistantPhotomechanical apparatusInput/output processes for data processingTransmittanceKetone

Provided is a white light sensitivity resin composition comprising alkali soluble resin, polymeric composition, photoinitiator, white pigment, and solvents, wherein the photoinitiator is formed by 2,4,6-trimethylbenzoyldiphenylphosphine oxide and 1-hydroxyl-cyclohexyl-phenyl-ketone. The white light sensitivity resin composition has characteristics of not turning yellow in high-temperature baking (about 250 DEG C) and being graphical. The invention also provides the purpose of the above white light sensitivity resin composition, the composition is used in touch panels and for forming a shielding layer at the periphery of a transmittance substrate.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

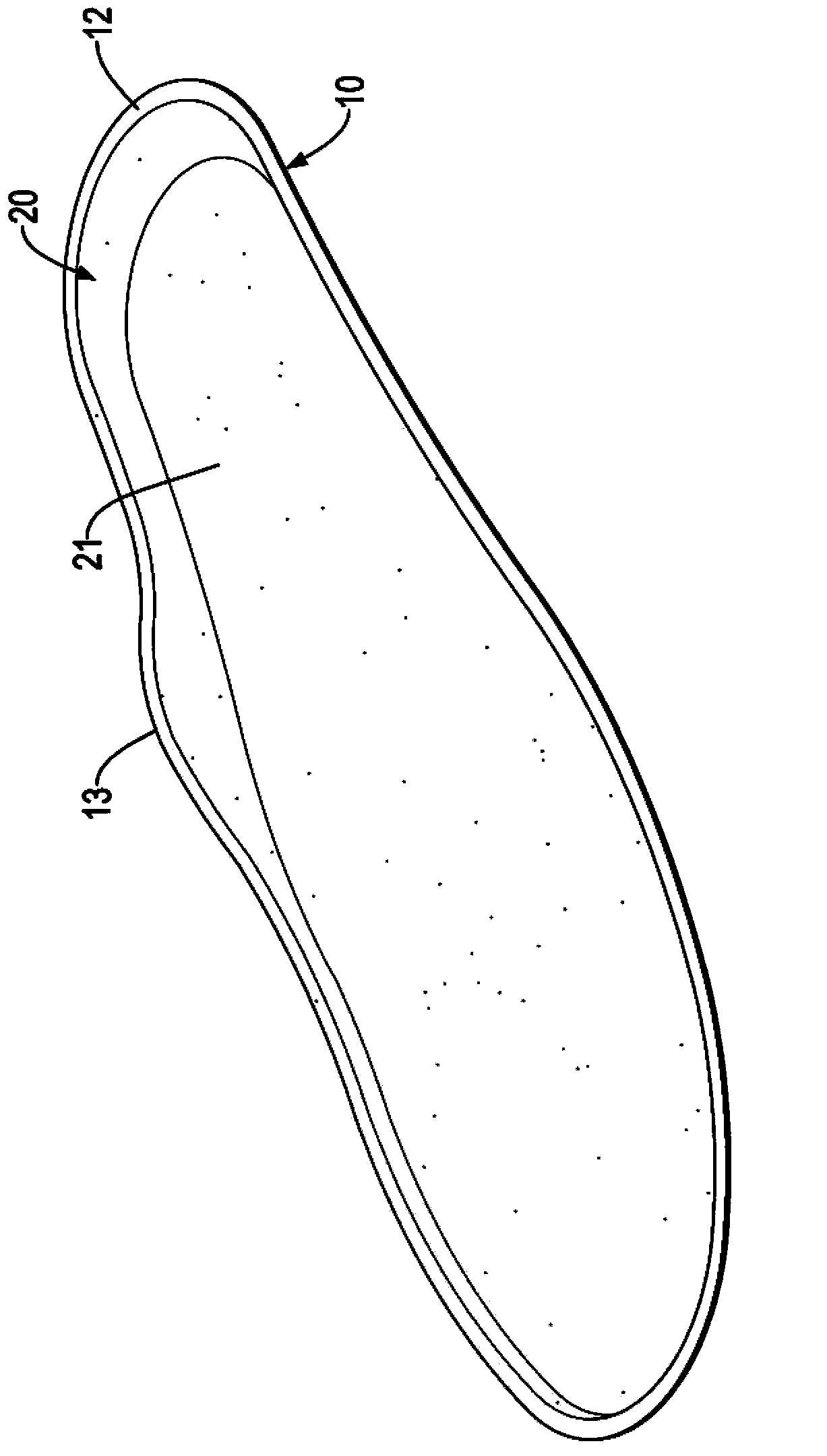

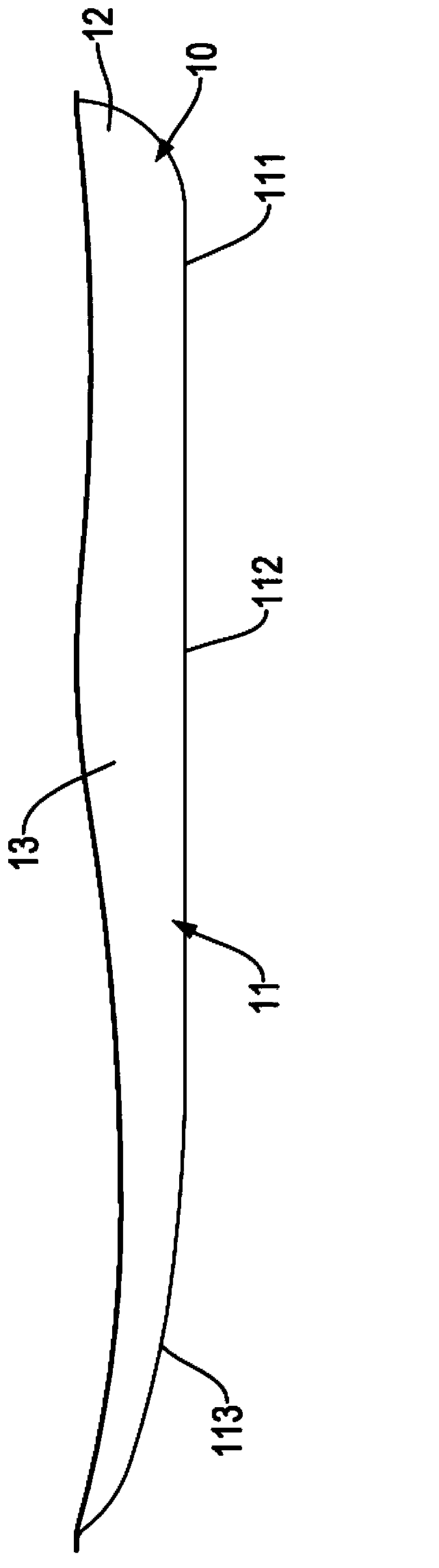

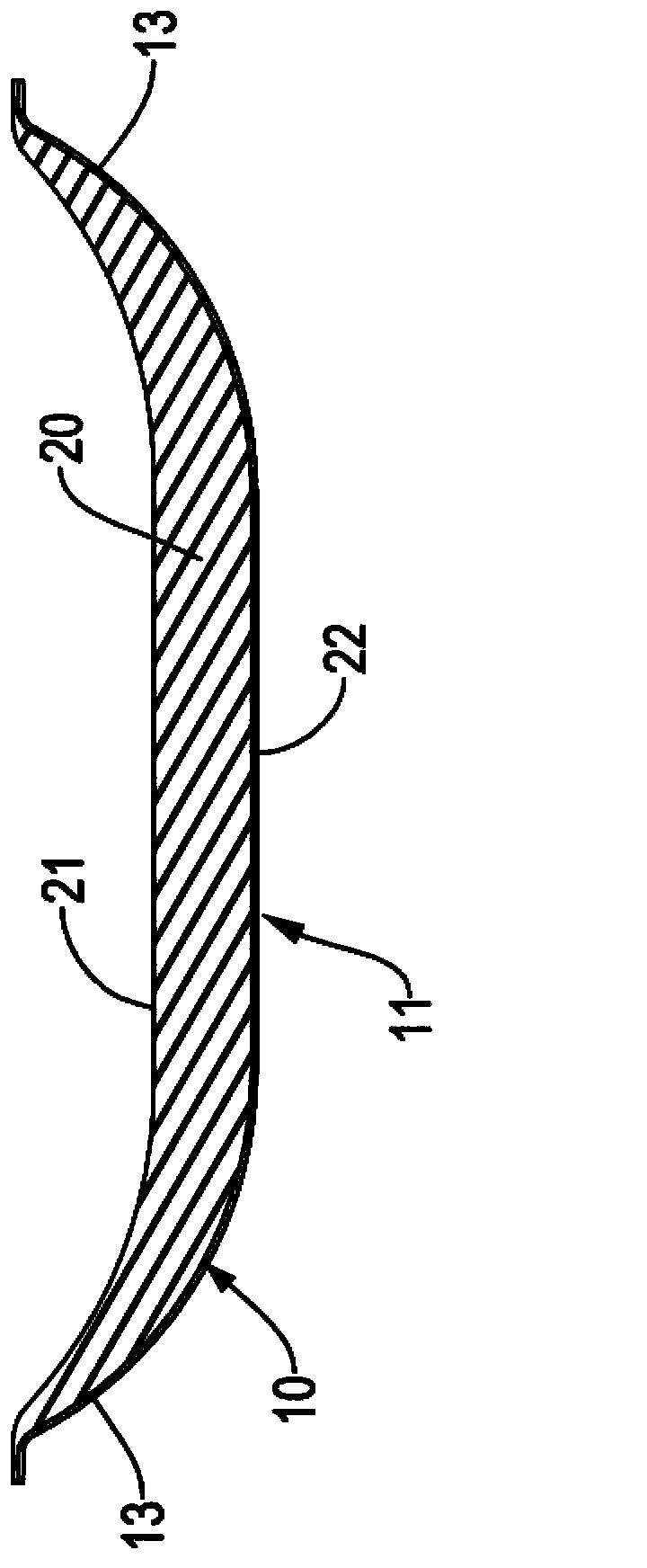

Insole and preparation method thereof

InactiveCN103829458AAvoid deformationExtended service lifeInsolesDomestic footwearHardnessEngineering

The invention relates to an insole. The insole comprises a hard case. The hard case comprises an insole body, a fixing portion and a soft insole body. The insole body is provided with a foot rear portion, a foot middle portion and a foot front portion, wherein the foot rear portion, the foot middle portion and the foot front portion are sequentially connected and are respectively provided with inner side surfaces and outer side surfaces opposite to the inner side surfaces. The fixing portion protrudes and extends to the periphery of the foot rear portion of the insole body and is provided with an inner side surface and an outer side surface opposite to the inner side surface. The soft insole body is provided with a top surface and a bottom surface opposite to the top surface, wherein the bottom surface is attached to all portions of the insole body and the inner side surface of the fixing portion. The hardness of the hard case is larger than that of the soft insole body. The hard case and the soft insole body are integrally formed by heating spray-bonded non-woven fabric. The invention provides a method for preparing the insole. The method comprises the steps of providing the spray-bonded non-woven fabric; providing a mold, wherein the mold corresponds to the insole in shape and is provided with a heating surface; placing the spray-bonded non-woven fabric into the mold and attaching the spray-bonded non-woven fabric to the heating surface; and enabling the heating surface of the mold to be warmed until the temperature is between 160 to 200 DEG C.

Owner:林国彬

Special binder of reflecting material and production thereof

InactiveCN100338165CImprove adhesionImprove aging resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

A special binder for reflecting material and its production are disclosed. It is characterized by taking polyester polylol, solvent, isocyanate, coupler, catalyst and antiager as raw materials to prepare A component, taking isocyanate, low-molecular polylol and solvent as raw materials to prepare B component, and mixing A with B to obtain the binder. It achieves low cost, simple process, excellent binding and ageing-resistant performances.

Owner:NANTONG GAOMENG NEW MATERIAL

A kind of water-based polyurethane three-proof paint for circuit board anticorrosion

ActiveCN107573831BFree from corrosionImprove insulation performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEngineeringMechanical engineering

Owner:YIK SHING TAT INDUSTRIALCO LTD

Anti-termite cable material, anti-termite cable using same and anti-termite optical cable

InactiveCN105419079AStable heat resistanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesElectric cablesBifenthrin

Owner:沈群华

Softening agent containing honeysuckle extract

InactiveCN106917270AGuaranteed to be sterileImprove anti-static effectBiochemical fibre treatmentLight resistant fibresSilanesGanoderma lucidum

The invention relates to a softening agent containing a honeysuckle extract, wherein the components comprise, by mass, 23-40% of chlorohydrocarbyl functional group silane, 3-6% of a ganoderma lucidum extract, 5-8% of plant essence, 11-15% of a fructus arctii extract, 2-3.5% of sodium alginate, 10-15% of a ginkgo extract, 3-6% of a wild chrysanthemum extract, and 40-61% of deionized water, the chlorohydrocarbyl functional group silane is chloropropyltrimethoxysilane, the fructus arctii extract is an imidazoline fructus arctii extract, and the wild chrysanthemum extract is calcium chloride. According to the present invention, the softening agent has advantages of good softening and fluffiness effect after disinfection and washing, low use concentration, no damage on fabrics, good stability, no damage on skin, low cost and no environment pollution, can strongly kill common harmful microorganisms, especially pathogenic bacteria, and can ensure that the fabric does not contain bacterial and has characteristics of good static electricity resistance, good re-mixing wetting property, no damage and no yellowing after the washing.

Owner:QINGDAO XINYIFA IND & TRADE

Deep-sea-seaweed-active-element-containing softener

InactiveCN106894236AImprove anti-static effectNo yellowing phenomenonFibre treatmentDiphenyl etherSilanes

The invention relates to a deep-sea-seaweed-active-element-containing softener which is composed of the following components in percentage by mass: 20-31% of chloroalkyl functional group silane, 3-6% of deep-sea seaweed active element, 5-8% of bis alkyl dimethyl quaternary ammonium salt, 11-15% of methyl sulfate, 2-3.5% of stearic acid, 10-18% of trichlorohydroxy diphenyl ether, 3-6% of calcium halide and 40-61% of deionized water. The chloroalkyl functional group silane is chloropropyltrimethoxysilane. The methyl sulfate is methyl imidazolinylsulfate. The calcium halide is calcium chloride. The fabric has favorable soft and fluffy effects after being disinfected and washed by the deep-sea-seaweed-active-element-containing softener. The softener has low use concentration, and does not damage the fabric. The softener has high stability, and does not hurt the skin. The softener has the advantages of low cost price and no environmental pollution. The softener has strong killing actions on common harmful microbes and especially pathogenic bacteria, and ensures that the fabric is free of bacteria after being washed. The fabric has favorable antistatic property and favorable rewettability, and does not have the phenomenon of damage or yellowing.

Owner:QINGDAO XINYIFA IND & TRADE

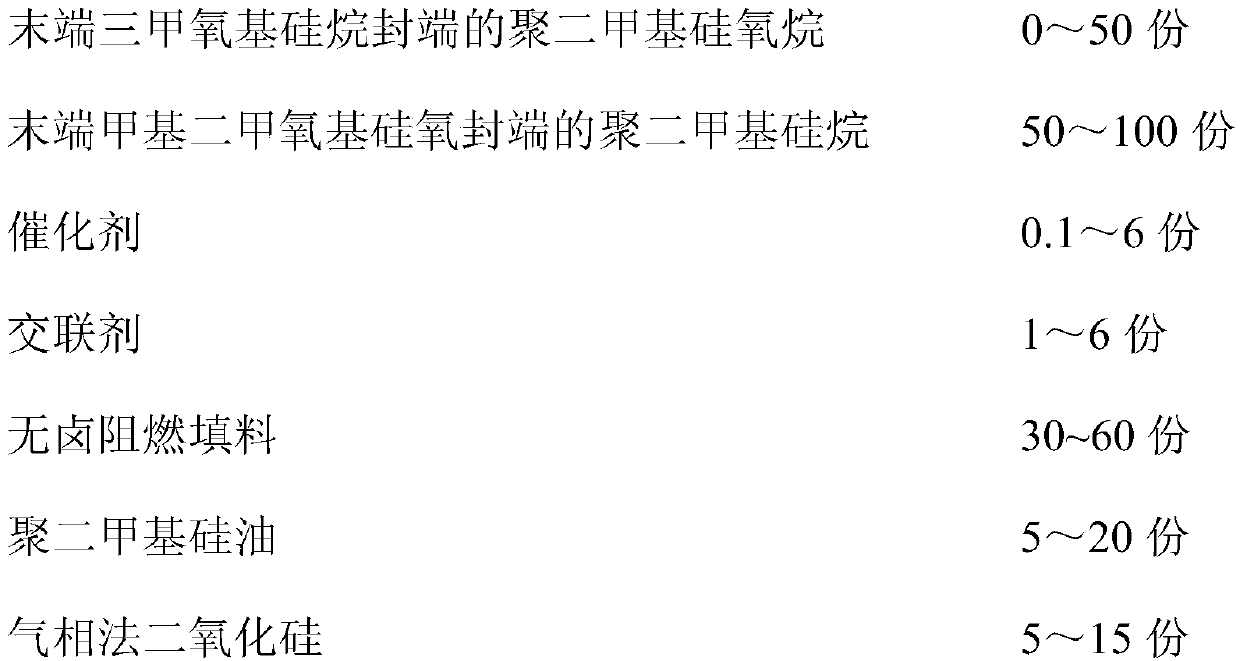

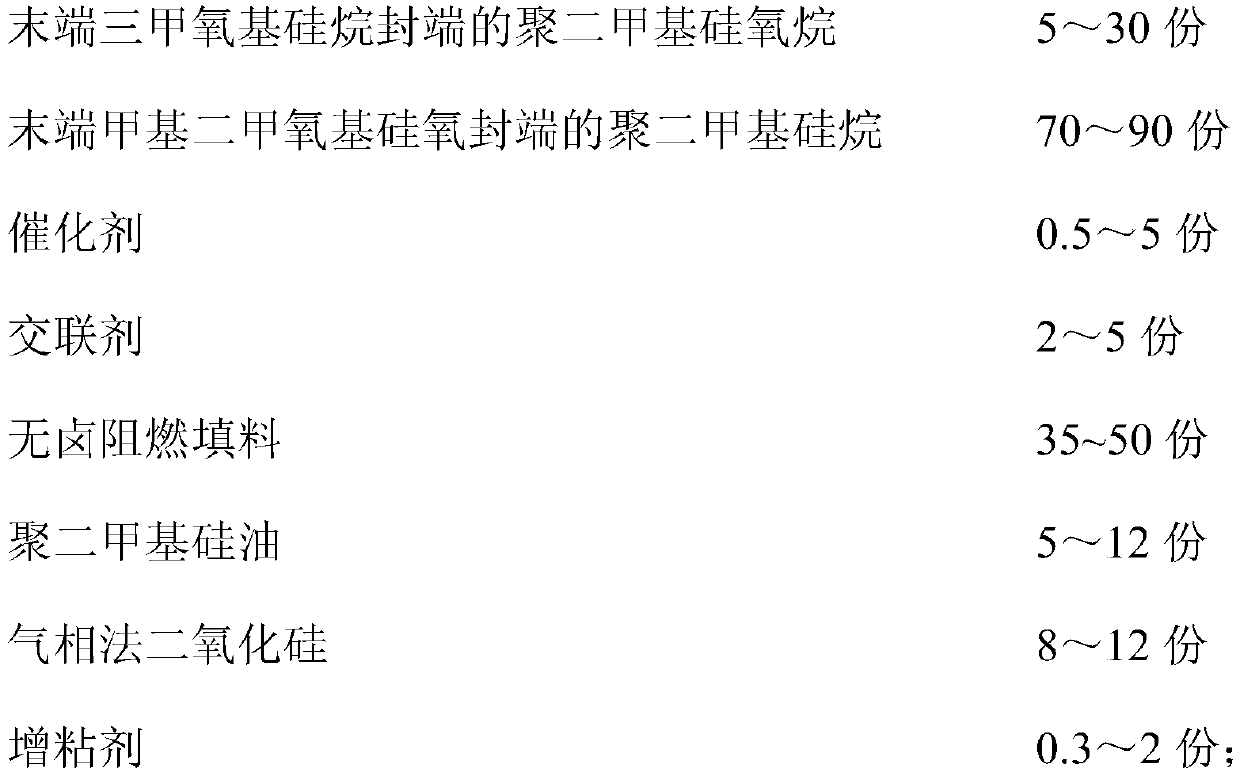

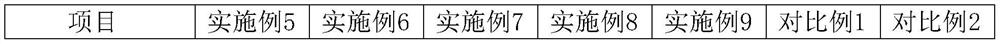

One-component titanate halogen-free flame-retardant silicone sealant

ActiveCN105585998BGood compatibilityImprove flame retardant performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesGas phase

The invention provides a single-component titanate halogen-free flame-retardant organic silicone sealant. The organic silicone sealant is mainly prepared from, by weight, 0-50 (not including 0) parts of polydimethylsiloxane with the end capped with trimethoxy silane, 50-100 parts of polydimethylsilane with the end capped with methyl dimethoxy silica, 0.1-6 parts of catalyst, 1-6 parts of cross-linking agent, 30-60 parts of halogen-free flame-retardant filler, 5-20 parts of polydimethicone, 5-15 parts of gas phase method silicon dioxide and 0.1-3 parts of tackifier. The organic silicone sealant has excellent adhesive properties, yellowing resistance and storage stability, can be cured quickly, has good flame retardance with the flame-retardant rating reaching UL94-V0 and also has the advantage of being free of pollution during production; the shear strength is larger than or equal to 3.5 Mpa, and when the organic silicone sealant is stored at the temperature of 25 DEG C or below, the product guarantee period can be as long as 13 months; the organic silicone sealant can be widely applied to bonding of components of electronic and electric devices.

Owner:兆舜科技(广东)有限公司

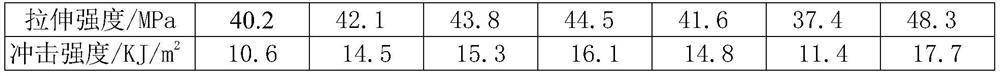

A kind of preparation method of high antibacterial activity and anti-yellowing antibacterial agent, plastic plate and locker

The invention relates to a method for preparing an antibacterial agent with high antibacterial activity and anti-yellowing. The antibacterial agent for door and cabinet plates is modified silver-loaded graphene oxide modified by maleic anhydride, or / and made of graphite oxide Nano-silver-metal oxide is loaded with nano-silver-metal oxide to form composite antibacterial agent, and the modified composite antibacterial agent that forms through maleic anhydride modification comprises the steps: step 1, maleic anhydride is dissolved in DMF solvent completely, then continue Add xylene and stir to dissolve all components; step 2, add silver-loaded graphene oxide or / and composite antibacterial agent to the solution in step 1, and react at 40°C-50°C for 5-6h under stirring conditions, Then suction filtration treatment to obtain the antibacterial agent filter residue; step 3, the filter residue is fully washed, and then placed in an oven at 86°C-90°C to dry, to obtain modified silver-loaded graphene oxide modified by maleic anhydride or / and Modified compound antibacterial agent.

Owner:德红柜智能科技(厦门)有限公司

A composition and treatment method for treating mink fur oxidative dyeing wastewater

ActiveCN105502750BFast chemical reactionShort processing cycleWater treatment compoundsWater contaminantsFiltrationSulfate

The invention provides a composition for treating marten oxidation dyeing wastewater and a treatment method. The composition is prepared from, by weight, 1-10 parts of ferrous sulfate, 5-50 parts of hydrogen peroxide, 10-50 parts of flocculant, 1-10 parts of oxidation decoloring agent and 1-5 parts of COD remover. The treatment method comprises the steps that ferrous sulfate and hydrogen peroxide are added to wastewater to be treated according to the formula, and an oxidation reaction is conducted; the flocculant is added to be reacted till sediments are not generated; the oxidation decoloring agent is added to be reacted, the sediments are removed through filtration, and the COD remover is added to be reacted finally. By means of the composition for treating the marten oxidation dyeing wastewater and the treatment method, the effects of reducing the cost, decoloring permanently, shortening a treatment cycle and the like can be achieved.

Owner:北京泛博清洁技术研究院有限公司

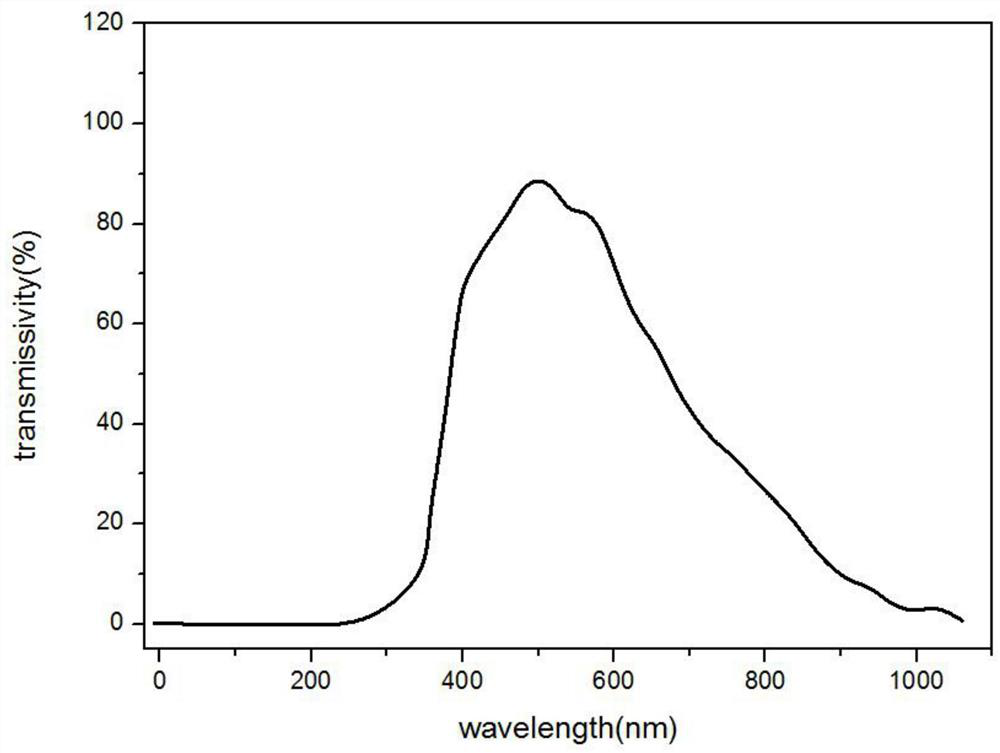

A kind of preparation method of PET-based heat-absorbing film

ActiveCN112011078BGood film formingIncrease stickinessRadiation-absorbing paintsPolymer sciencePolyvinyl alcohol

A method for preparing a PET-based heat-absorbing film. The heat-absorbing film includes a polymer film and a modified PET film that are closely bonded by thermal compression. The specific steps of the preparation method are as follows: (1) modification of the PET film; (2) ) Preparation of polymer film (a) Add polyvinyl alcohol solution, maleic anhydride and initiator to the reaction kettle, add styrene, tackifier and near-infrared absorber after dissolving, stir and react in nitrogen atmosphere to obtain film preparation solution , and dry to obtain the film preparation material; (b) dissolve the film preparation material in the casting film solution to form a coating solution, apply the coating solution on the substrate and dry to form a polymer film; use a polymer film layer to replace the traditional The adhesive base layer improves the temperature resistance and weather resistance of the polymer film layer, has good thermal stability and flexibility, and can maintain a high adhesive force at a higher temperature without falling off; in the polymer film preparation material The near-infrared absorber is added to make the polymer film have the functions of heat preservation, heat insulation and ultraviolet protection, which enriches the functions of the polymer film.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

One-component RTV silicone sealing material for LED lamp and preparation method thereof

ActiveCN105524590BGood adhesionLow resistance to yellowingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkPolycarbonate

The invention relates to a single-component RTV (room temperature vulcanization) silicone sealing material for an LED lamp and a preparation method of the single-component RTV silicone sealing material. The single-component RTV silicone sealing material comprises raw materials in parts by weight as follows: 100 parts of alpha, omega-bis(trimethoxysilyloxy) polydimethylsiloxane, 100-120 parts of reinforcing filler, 1-10 parts of a plasticizer, 3-7 parts of a cross-linking agent, 1-3 parts of a catalyst and 1-5 parts of an adhesion promoter. The single-component RTV silicone sealing material for the LED lamp has excellent adhesive property, high temperature and low temperature resistance, high temperature and high humidity resistance, yellowing resistance, low volatile matter content and no sulfur and halogen, and can provide a better adhesion solution for LED lamp assembly such as adhesive fixation of a PC (polycarbonate) bulb and a lamp holder and adhesive fixation of an LED light bar and a lamp tube.

Owner:GUANGZHOU BAIYUN CHEM IND

Softening agent containing peony root bark extract

InactiveCN106917287AImprove anti-static effectNo yellowing phenomenonGrip property fibresSilanesRhizome

The invention relates to a softening agent containing a peony root bark extract, wherein the components comprise, by mass, 12-36% of chlorohydrocarbyl functional group silane, 2.5-4.5% of a peony root bark extract, 5-8% of orange powder, 2-3.5% of plant care essential oil, 10-15% of a common yam rhizome plant extract, 2.5-4.5% of ethanol, and 30-65% of deionized water, the chlorohydrocarbyl functional group silane is chloropropyltrimethoxysilane, and the ethanol is calcium chloride. According to the present invention, the softening agent has advantages of good softening and fluffiness effect after disinfection and washing, low use concentration, no damage on fabrics, good stability, no damage on skin, low cost and no environment pollution, can strongly kill common harmful microorganisms, especially pathogenic bacteria, and can ensure that the fabric does not contain bacterial and has characteristics of good static electricity resistance, good re-mixing wetting property, no damage and no yellowing after the washing.

Owner:QINGDAO XINYIFA IND & TRADE

Softening agent containing sanguisorba officinalis l extract

InactiveCN106917280AImprove anti-static effectGood rewettingLight resistant fibresGrip property fibresIsoflavonesPollution

The invention relates to a softening agent containing a sanguisorba officinalis l extract, wherein the components comprise, by mass, 20-31% of cyclocarya paliurus, 3-6% of a sanguisorba officinalis l extract, 5-8% of soybean isoflavone, 13-18% of natural essence, 2-3.5% of an epimedium extract, 10-18% of trichlorohydroxydiphenyl ether, 3-6% of Brazil essential oil, and 40-55% of deionized water, the cyclocarya paliurus is chloropropyltrimethoxysilane, the natural essence is imidazoline natural essence, and the Brazil essential oil is calcium chloride. According to the present invention, the softening agent has advantages of good softening and fluffiness effect after disinfection and washing, low use concentration, no damage on fabrics, good stability, no damage on skin, low cost and no environment pollution, can strongly kill common harmful microorganisms, especially pathogenic bacteria, and can ensure that the fabric does not contain bacterial and has characteristics of good static electricity resistance, good re-mixing wetting property, no damage and no yellowing after the washing.

Owner:QINGDAO XINYIFA IND & TRADE

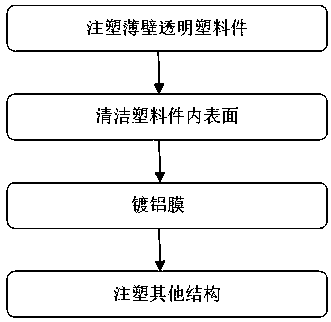

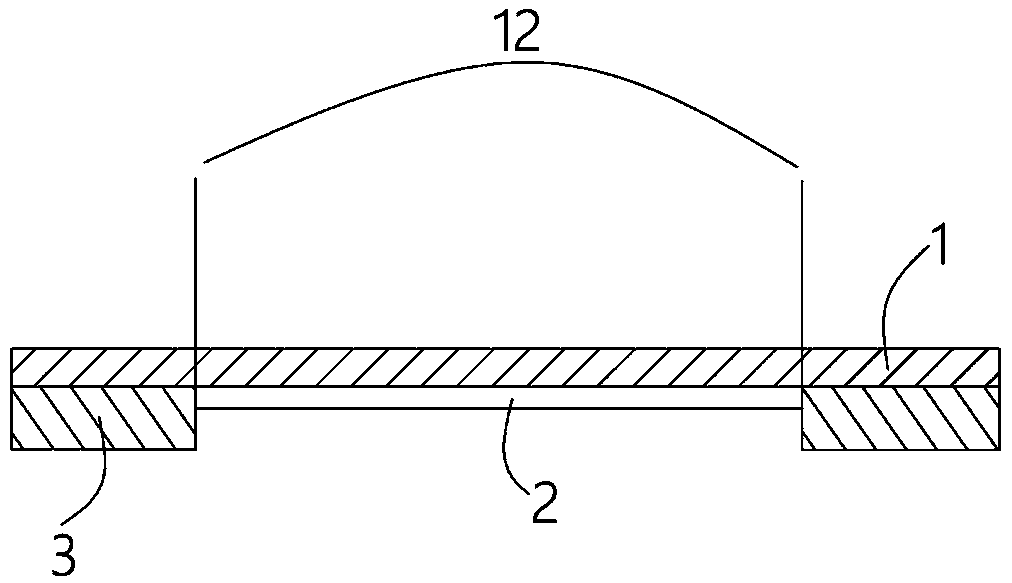

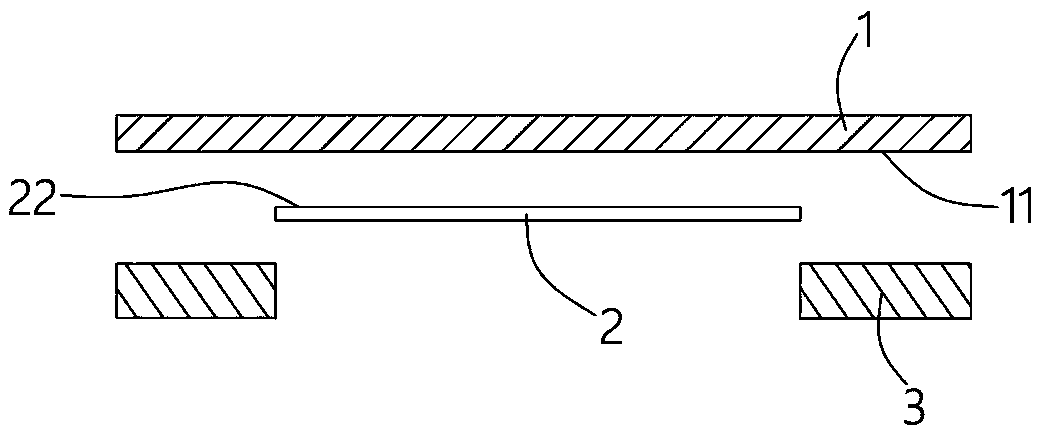

Vehicle lamp plastic part machining process with reflecting surface and vehicle lamp plastic part

PendingCN110757723AGuaranteed Optical PerformanceDoes not affect reflectivityVehicle headlampsLighting and heating apparatusMachining processMechanical engineering

The invention belongs to the technical field of vehicle lamp manufacturing, and discloses a vehicle lamp plastic part machining process with a reflecting surface and a vehicle lamp plastic part. The machining process comprises the following steps that firstly, a first injection transparent plastic part is taken as a reflecting surface carrier; based on the light transmission characteristic of thetransparent plastic part, the reflecting surface carrier is taken as a substrate of the coating, an aluminum film is plated on the back surface of the reflecting surface carrier, the surface, facing the reflecting surface carrier, of the aluminum film is a front surface, and the front surface of the aluminum film is a light reflecting surface; and the reflecting surface carrier coated with the aluminum film on the back side is used as a base body, and other structures are injected on the back surface for two times or multiple times to form the target coated vehicle lamp plastic part. Accordingto the vehicle lamp plastic part machining process, the corrosion resistance and the anti-aging performance of the coating layer of the vehicle lamp plastic part can be further improved, defects suchas collision or pollution are not likely to be caused in the vehicle lamp assembly process, the effect of protecting the metal film is effectively achieved, the corrosion resistance of the aluminum film is enhanced, the procedure is reduced, and the cost is reduced.

Owner:ZHEJIANG TIANCHONG VEHICLE LAMP GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com