Insole and preparation method thereof

A technology for insoles and soft pads, which is applied in the field of insole preparation, can solve the problems of airtightness, watertightness, and lack of shaping ability, and achieve the effects of good moisture permeability, good air permeability, and good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

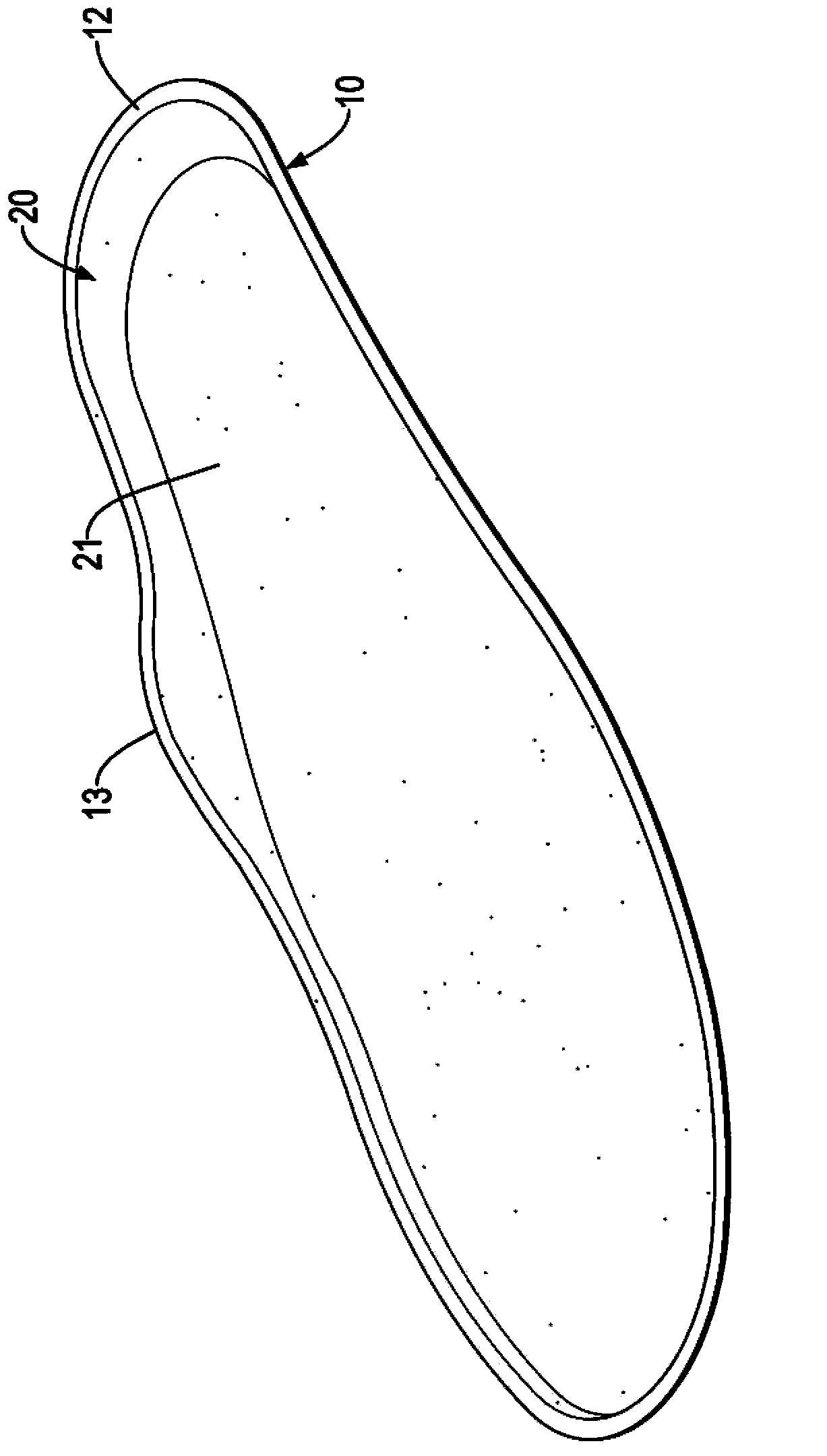

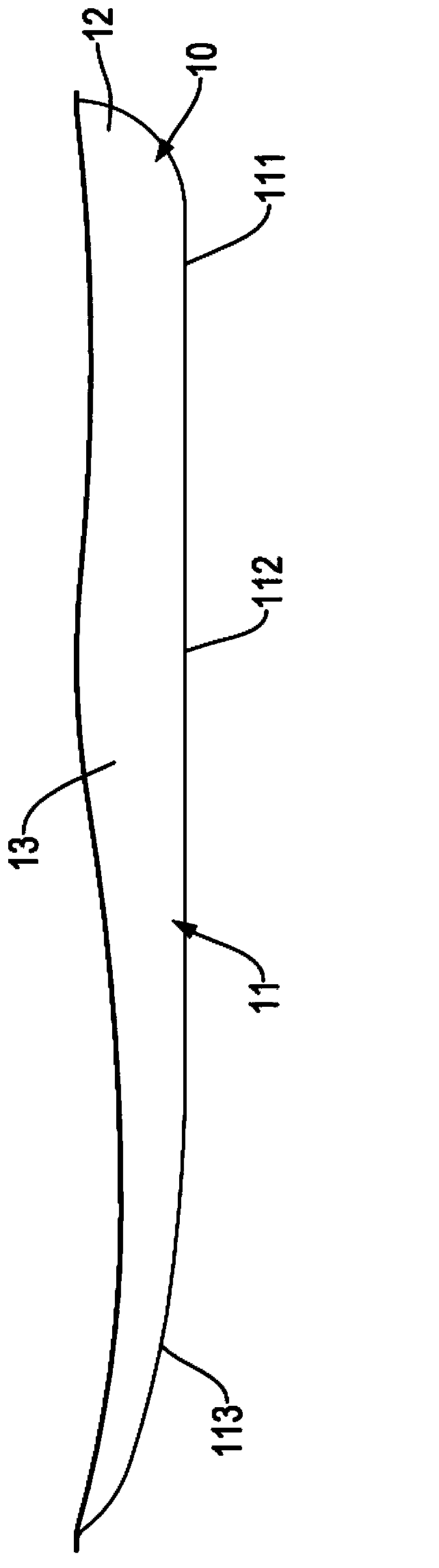

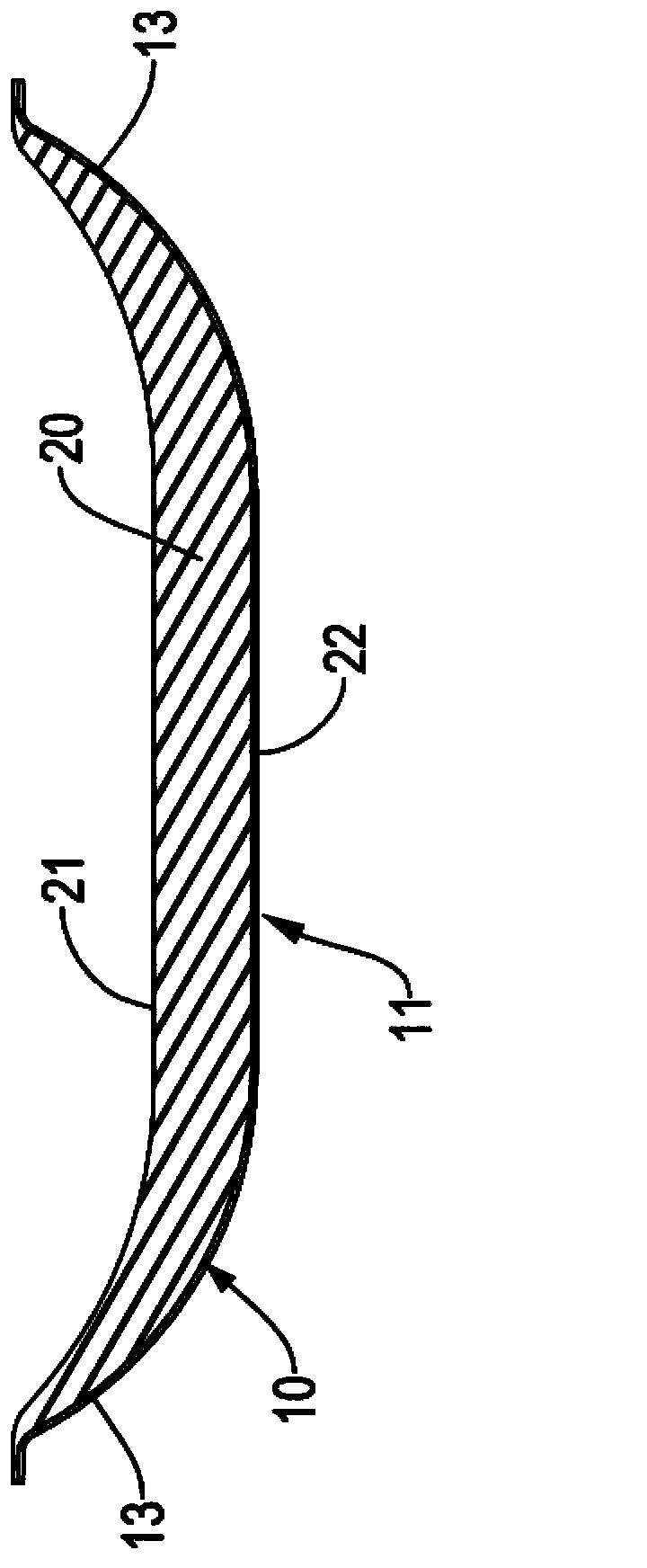

[0060] see Figures 1 to 3 As shown, the insole of this embodiment has a hard shell 10 and a soft cushion body 20 connected with the hard shell 10 .

[0061] The aforementioned hard case 10 has a pad body 11 , a fixing portion 12 connected to the pad body 11 , and a support portion 13 connected to the pad body 11 and the fixing portion 12 . The pad body 11 has a rear part 111, a middle part 112, and a front part 113 connected in sequence, and the rear part 111, the middle part 112 and the front part 113 respectively have a medial surface and a The outer side of the side. The fixing portion 12 protrudes from the periphery of the rear portion 111 of the pad body 11 , and the fixing portion 12 has an inner surface and an outer surface opposite to the inner surface. The support portion 13 protrudes from the periphery of the midfoot portion 112 and the forefoot portion 113 of the pad body 11 and is connected to the fixing portion 12. The support portion 13 has an inner surface an...

Embodiment 2

[0064] see Figure 4 As shown, the insole of this embodiment is roughly as described in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that in this embodiment, the mid-foot portion 112 of the pad body 11 is arched toward the direction of the cushion body 20, so as to correspond to the arched arch in the center of the sole of the human body, so it fits The position of the cushion body 20 corresponding to the midfoot portion 112 on the inner surfaces of the rear foot portion 111 , the midfoot portion 112 , the forefoot portion 113 , the fixing portion 12 and the support portion 13 is also toward the cushion body 20 . The direction of the top surface 21 is arched.

Embodiment 3

[0066] see Figure 5 As shown, the insole of this embodiment is roughly as described in Embodiment 2, and will not be repeated here. The difference between this embodiment and Embodiment 2 lies in that the insole in this embodiment further has a fabric layer 30 which is attached to the top surface 21 of the cushion body 20 to serve as a layer in contact with the sole of the foot. Specifically, the fabric layer 30 is bristle cloth, but not limited thereto.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com