One-component RTV silicone sealing material for LED lamp and preparation method thereof

A technology of LED lamps and vulcanized silicone, applied in the directions of adhesive additives, non-polymer adhesive additives, polymer adhesive additives, etc. problems such as decline, to achieve the effect of excellent yellowing resistance, excellent adhesion, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

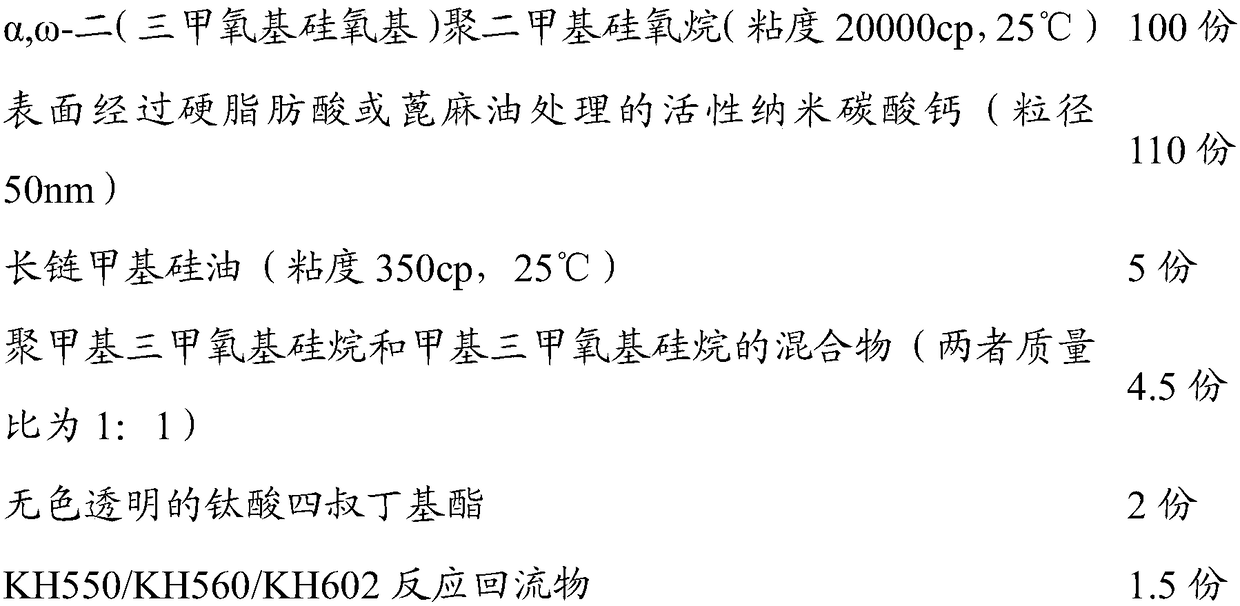

Embodiment 1

[0034] A one-component room temperature vulcanizing silicone sealant for LED lamps, the raw materials of which are composed of:

[0035]

[0036] The preparation method of the above-mentioned one-component room temperature vulcanizing silicone sealant for LED lamps in this embodiment, the steps are as follows:

[0037] Add the α,ω-bis(trimethoxysiloxy)polydimethylsiloxane and the active nano-calcium carbonate whose surface has been treated with hard fatty acid or castor oil into the kneader. Stir for 2 hours under the condition of vacuum degree of -0.095MPa, remove the moisture in the raw material under high temperature vacuum, and cool to room temperature to obtain a base material with uniform appearance;

[0038] Add the prepared base material, long-chain methyl silicone oil, and a mixture of polymethyltrimethoxysilane and methyltrimethoxysilane to the planetary machine, stir and react for 0.5h under nitrogen protection, and then add colorless and transparent titanic acid...

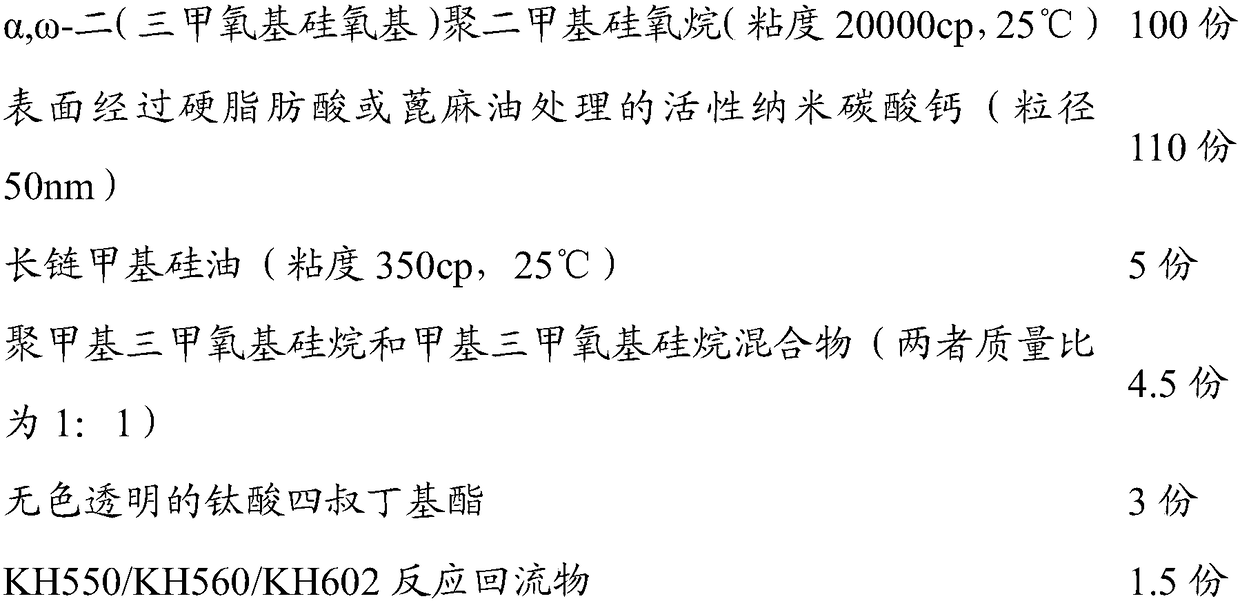

Embodiment 2

[0040] A one-component room temperature vulcanizing silicone sealant for LED lamps, the raw materials of which are composed of:

[0041]

[0042] The preparation method of the above-mentioned one-component room temperature vulcanizing silicone sealant for LED lamps in this embodiment, the steps are as follows:

[0043] Add the α,ω-bis(trimethoxysiloxy)polydimethylsiloxane and the active nano-calcium carbonate whose surface has been treated with hard fatty acid or castor oil into the kneader. Stir for 2 hours under the condition of vacuum degree of -0.095MPa, remove the moisture in the raw material under high temperature vacuum, and cool to room temperature to obtain a base material with uniform appearance;

[0044] Add the prepared base material, long-chain methyl silicone oil, and a mixture of polymethyltrimethoxysilane and methyltrimethoxysilane to the planetary machine, stir and react for 0.5h under nitrogen protection, and then add colorless and transparent titanic acid...

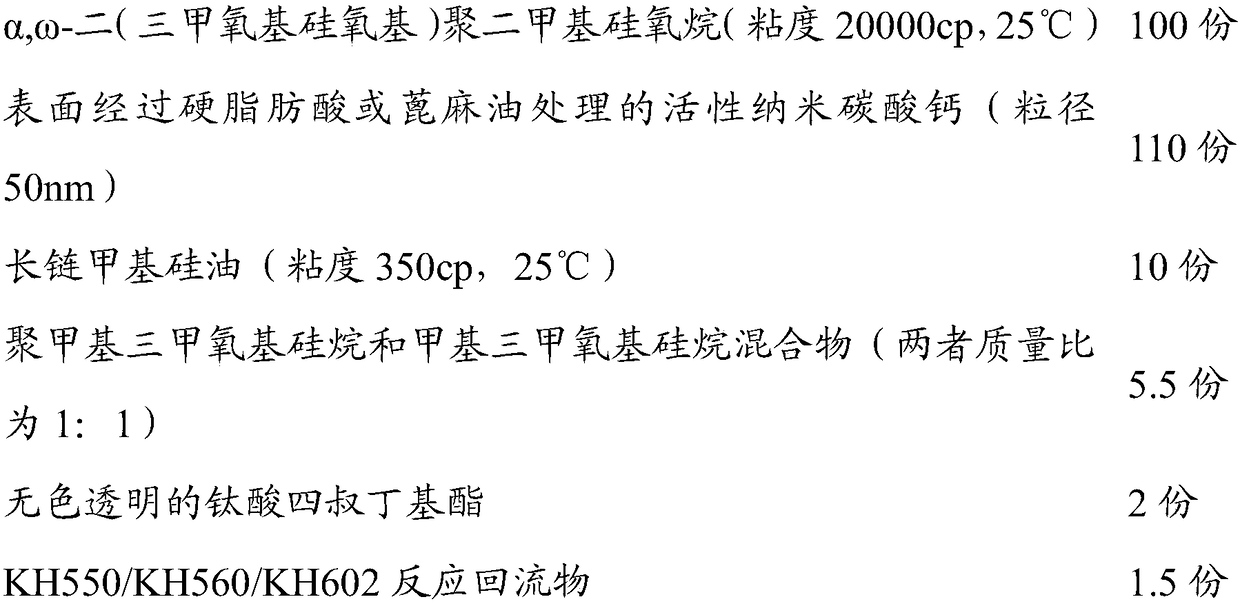

Embodiment 3

[0046] A one-component room temperature vulcanizing silicone sealant for LED lamps, the raw materials of which are composed of:

[0047]

[0048] The preparation method of the above-mentioned one-component room temperature vulcanizing silicone sealant for LED lamps in this embodiment, the steps are as follows:

[0049] Add the α,ω-bis(trimethoxysiloxy)polydimethylsiloxane and the active nano-calcium carbonate whose surface has been treated with hard fatty acid or castor oil into the kneader. Stir for 2 hours under the condition of vacuum degree of -0.095MPa, remove the moisture in the raw material under high temperature vacuum, and cool to room temperature to obtain a base material with uniform appearance;

[0050] Add the prepared base material, long-chain methyl silicone oil, and a mixture of polymethyltrimethoxysilane and methyltrimethoxysilane to the planetary machine, stir and react for 0.5h under nitrogen protection, and then add colorless and transparent titanic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com