A kind of preparation method of PET-based heat-absorbing film

A heat-absorbing and near-infrared absorber technology, applied in the direction of radiation-absorbing coatings, coatings, etc., can solve the problems of poor weather resistance and heat resistance, lack of UV resistance, poor anti-shedding resistance, etc., to improve temperature resistance. and weather resistance, thermal stability and flexibility, high strength and heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

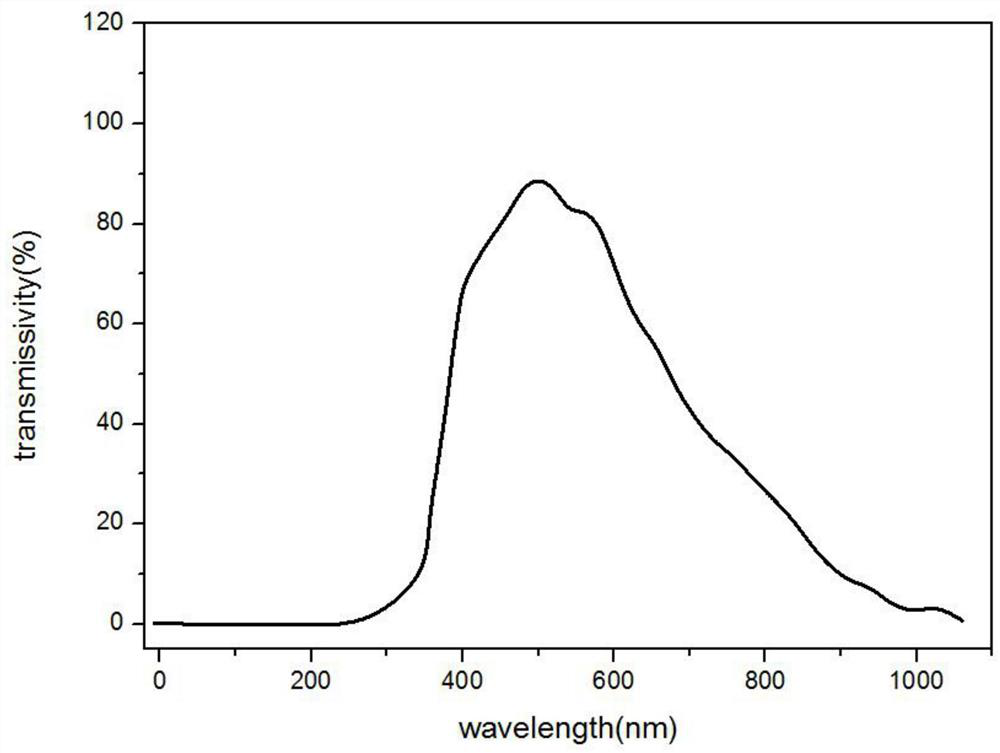

Image

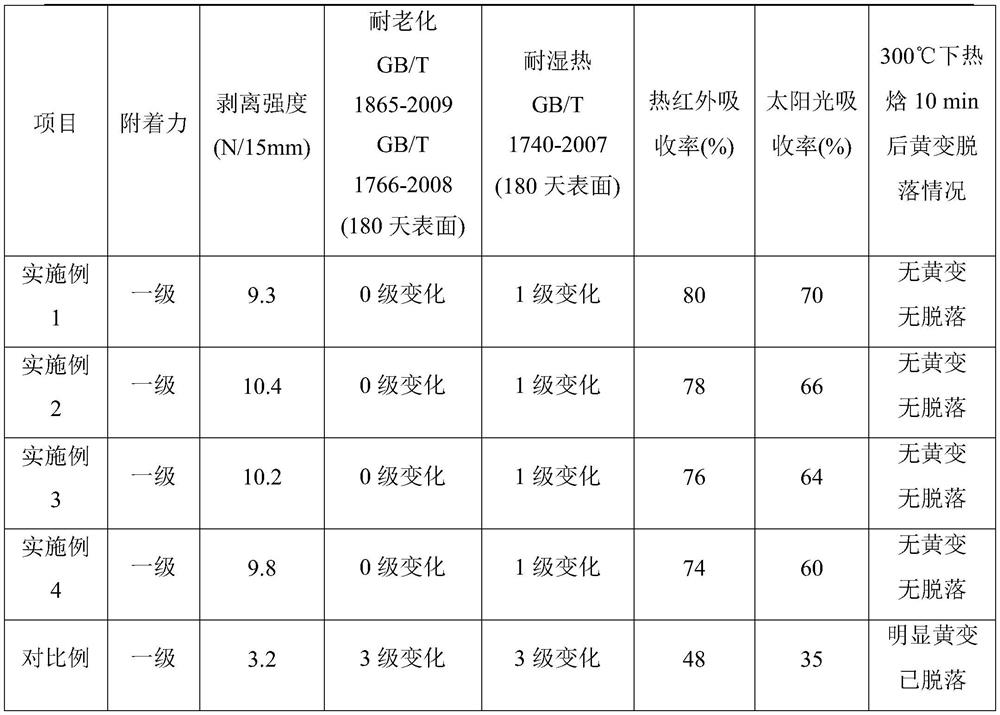

Examples

Embodiment 1

[0024] The specific steps of the preparation method of the PET-based heat-absorbing film are as follows:

[0025] (1) Modification of PET film

[0026] Pass the PET film with a particle size of 4nm nanometer SiO 2 Particle modification to obtain modified PET film;

[0027] (2) Preparation of polymer membrane

[0028] (a) Film preparation material: prepare a polyvinyl alcohol solution with a mass fraction of 10% and add it to the reactor, add maleic anhydride and initiator to the reactor, add styrene, tackifier rosin resin and near-infrared Absorbent polypyrrole, under nitrogen atmosphere stirring conditions, reaction temperature 60 ° C, reaction time 4.5h, to obtain a film preparation solution, the film preparation solution is placed in a vacuum oven, dried to obtain a film preparation material; wherein, the The mass ratio of maleic anhydride, styrene, polyvinyl alcohol solution, initiator, tackifier and near-infrared absorber is 1:1.06:2.3:0.003:0.009:0.25;

[0029] (b) P...

Embodiment 2

[0032] The specific steps of the preparation method of the PET-based heat-absorbing film are as follows:

[0033] (1) Modification of PET film

[0034] Pass the PET film with a particle size of 8nm nanometer SiO 2 Particle modification to obtain modified PET film;

[0035] (2) Preparation of polymer membrane

[0036] (a) Membrane preparation material: prepare a polyvinyl alcohol solution with a mass fraction of 12% and add it to the reactor, add maleic anhydride and initiator to the reactor, and then add styrene, tackifier rosin resin and near-infrared Absorbent polypyrrole, under nitrogen atmosphere stirring conditions, reaction temperature 50 ° C, reaction time 6h, to obtain a film preparation solution, the film preparation solution is placed in a vacuum oven, and dried to obtain a film preparation material; wherein, the horse The mass ratio of anhydride, styrene, polyvinyl alcohol solution, initiator, tackifier and near-infrared absorber is 1:1.05:2.2:0.004:0.007:0.22; ...

Embodiment 3

[0040] The specific steps of the preparation method of the PET-based heat-absorbing film are as follows:

[0041] (1) Modification of PET film

[0042] Pass the PET film with a particle size of 16nm nanometer SiO 2 Particle modification to obtain modified PET film;

[0043] (2) Preparation of polymer membrane

[0044] (a) film preparation material: the preparation mass fraction is that the polyvinyl alcohol solution of 14% is added in the reactor, and maleic anhydride, initiator are added in the reactor, add styrene, tackifier terpene resin and nearly Infrared absorbing agent polypyrrole, under nitrogen atmosphere stirring condition, reaction temperature 65 ℃, reaction time 8h, obtain film preparation solution, put the film preparation solution in a vacuum oven, dry to obtain film preparation material; wherein, the The mass ratio of maleic anhydride, styrene, polyvinyl alcohol solution, initiator, tackifier and near-infrared absorber is 1:1.07:2.5:0.005:0.008:0.18;

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com