Perforating device

A punching device and guide rail technology, applied in metal processing, etc., can solve the problems of non-recyclable, high cost of the punching system, and non-circulation, etc., and achieve the effect of simple structure, avoiding complicated procedures, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

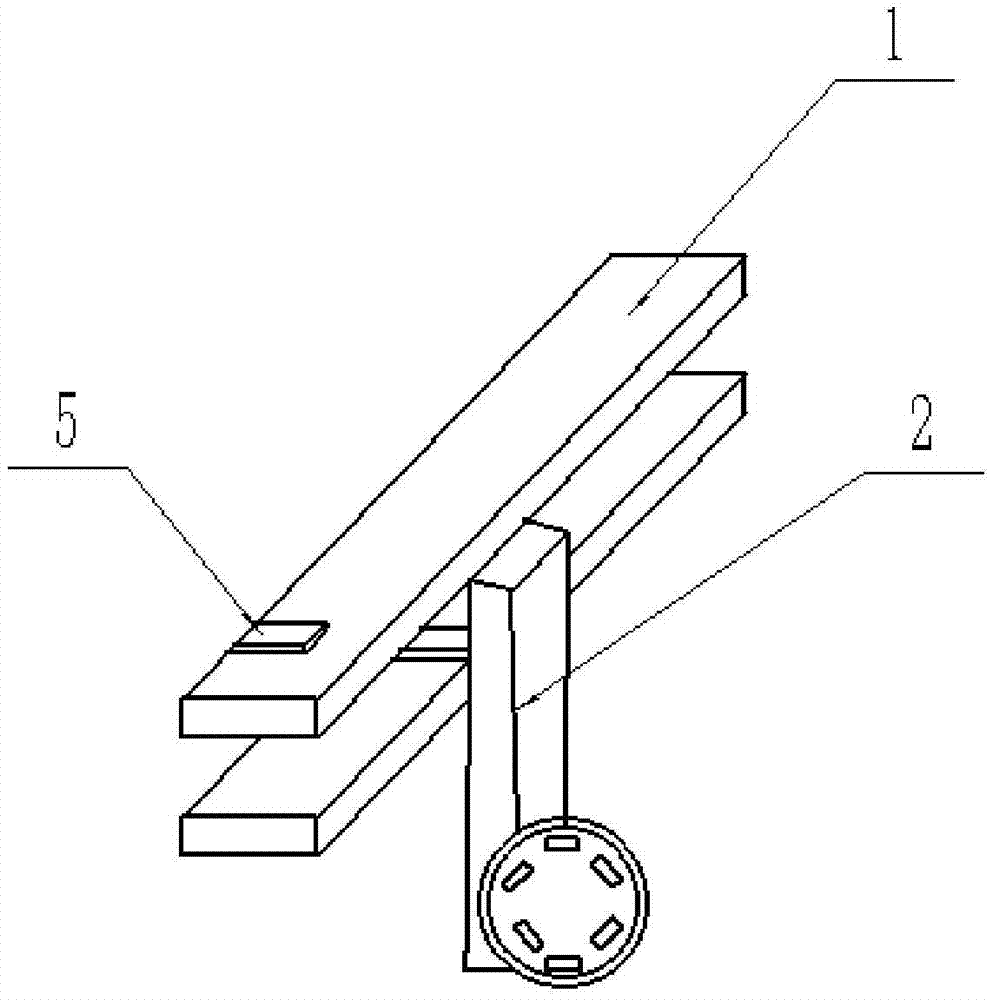

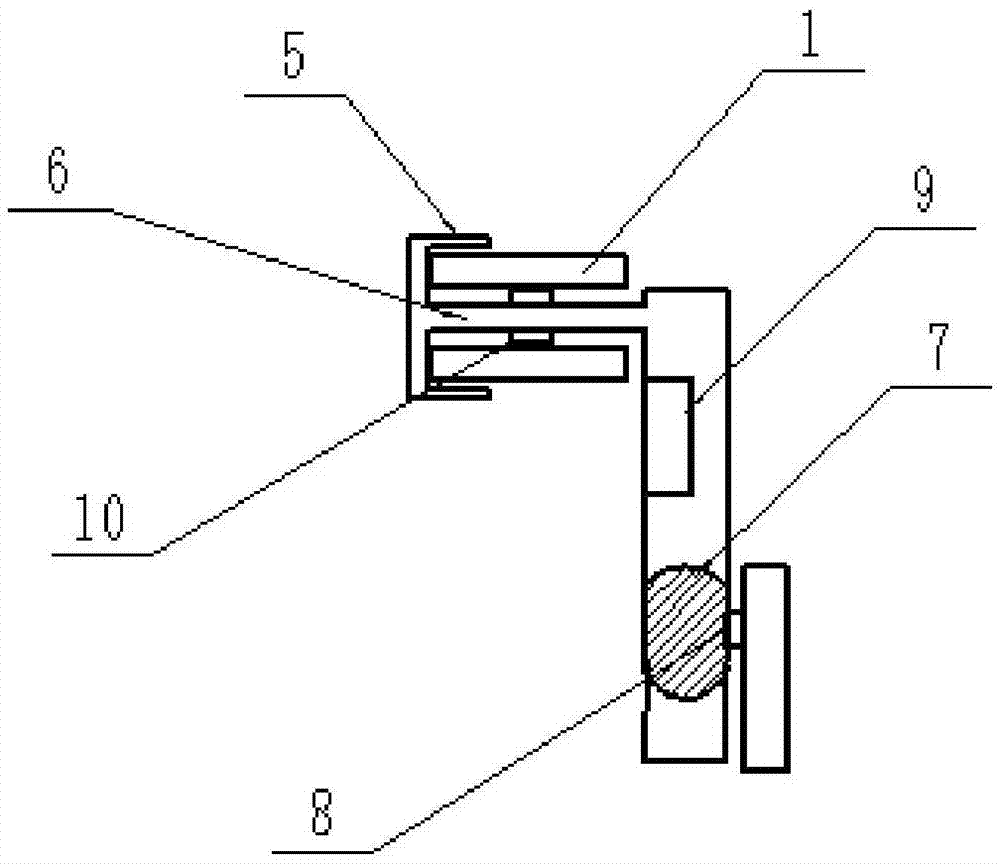

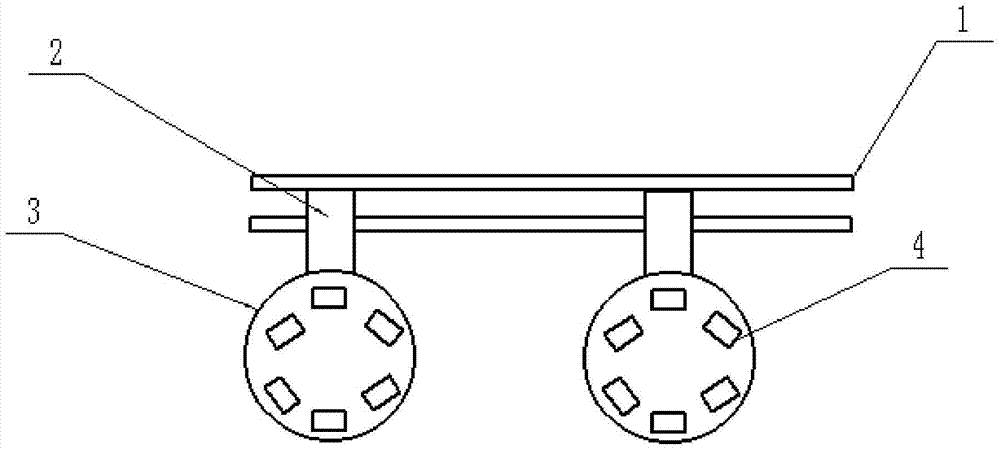

[0014] Such as figure 1 , 2 3, the present invention provides a punching device, including two sliding frames 1, the two sliding frames 1 are parallel to each other; between the two sliding frames 1 is provided with a horizontal sliding guide 6, one end of the horizontal sliding guide 6 There are two sliding limit grooves 5, and the two sliding frames 1 are respectively located in the two sliding limit grooves 5. The sliding limit grooves 5 can slide on the sliding frame 1 while driving the entire horizontal sliding guide 6 Sliding, the other end of the horizontal sliding guide 6 is fixed with a longitudinal sliding guide 2, and the longitudinal sliding guide 2 and the sliding frame 1 are perpendicular to each other; a fixed disk 3 is installed on the longitudinal sliding guide 2. The fixing plate 3 can fix the corresponding material that needs to be punched, and the two sliding limit grooves 5 are located on both sides of the lateral sliding guide 6 and are symmetrical to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com