Method for Rapid Leak Detection of Cooler in Air Cooling System of Gas Turbine

An air cooling system and cooler technology, which is applied in the testing of machine/structural components, instruments, fluid tightness testing, etc. time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

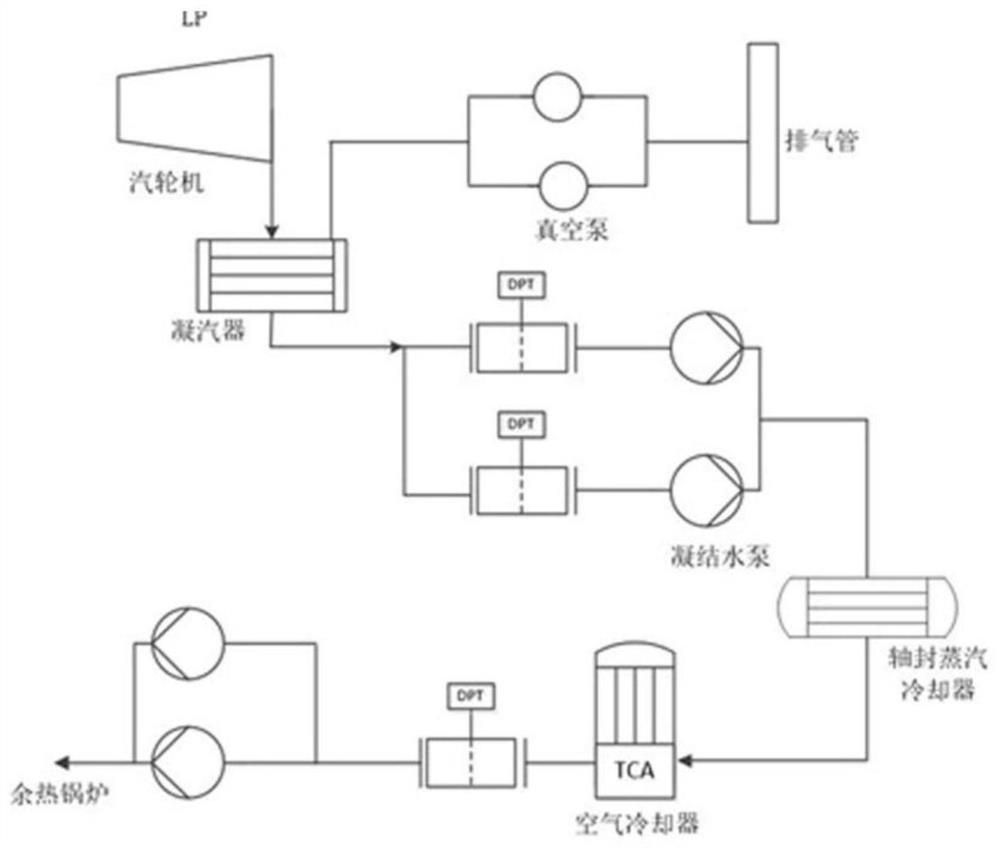

[0036] Such as figure 1 As shown, this method can quickly analyze the causes of gas turbine TCA cooler leakage and condenser vacuum reduction in the M701S(F) gas-steam combined cycle power generation system through the measurement and analysis of the amount of dissolved oxygen in condensed water and the vacuum degree of the condenser. judge.

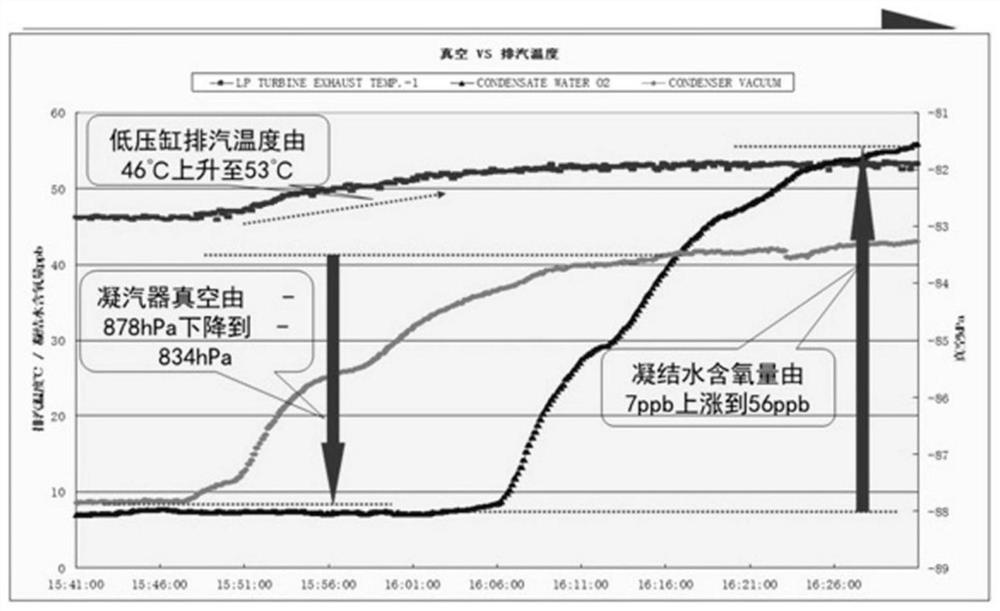

[0037] In this embodiment, when the unit is running stably under a certain load, the vacuum degree of the condenser decreases. At this time, the standby vacuum pump is started according to the normal operation, so that the two vacuum pumps can run at the same time. The two vacuum pumps can also be switched to run and measure ΔDD value and ΔVD 1 If the vacuum degree of the condenser and the amount of dissolved oxygen in the condensed water are improved after taking the above measures, it can be judged that the vacuum pump system is operating normally.

[0038] If the vacuum degree of the condenser and the dissolved oxygen content of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com