Multilayer directional controlled release antibacterial film and preparation method and application thereof

An antibacterial film and double film technology, applied in the field of preparation of multi-layer directional controlled release antibacterial films, can solve the problems of inability to add bacteriostatic substances and inability to bond closely together, and achieve highly uniform coating effect and resistance to resistance. The effect of oxygen blocking water to improve and reduce air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

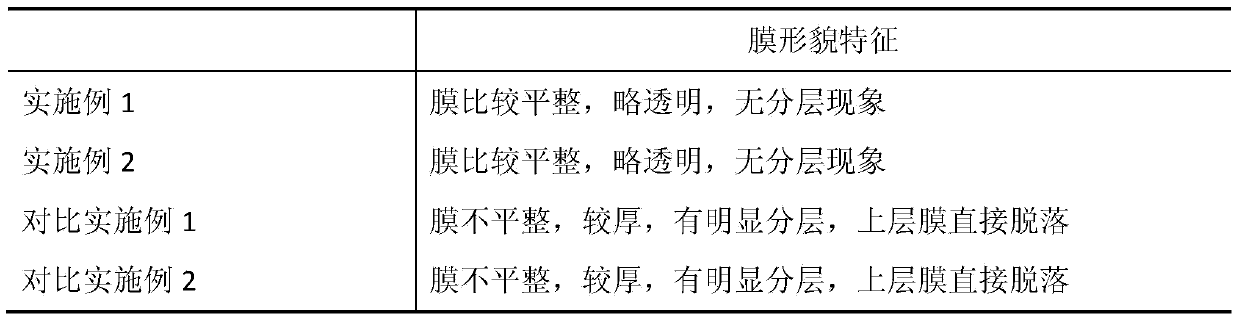

Examples

Embodiment 1

[0031] Accurately weigh 1g PLA, dissolve it in 20mL chloroform, and stir for 20min under the condition of avoiding light; add 0.1g oleic acid to the above solution, continue stirring for 10min, then pour the film-forming solution into a glass plate to form a film, at RH40%, 25 The PLA film was obtained after drying at °C for 4 hours.

[0032] Accurately weigh 2g of zein and dissolve it in 20ml of a mixed solution of ethanol and water with a volume ratio of 95:5, stir well and mix well; add 0.2g catechin to the above solution, stir well and place in boiling water After bumping for 5 minutes, the mixed solution A was obtained.

[0033] Weigh 1 g of zein and dissolve it in 20 ml of a mixed solution of ethanol and water with a volume ratio of 82:18, stir well and mix evenly. Weigh 0.75g of carrageenan and dissolve it in 50ml of distilled water, place it in a magnetic water bath stirring pot at 65°C and stir for 20min. Quickly pour the ethanol / water solution of zein into the carr...

Embodiment 2

[0037] Accurately weigh 2g PLA, dissolve it in 20mL chloroform, and stir for 20min under the condition of avoiding light; add 0.18g oleic acid to the above solution, continue stirring for 10min, then pour the film-forming solution into a glass plate to form a film, at RH40%, 25 PLA films were obtained after drying at °C for 4 h.

[0038] Accurately weigh 1.5g of zein and dissolve it in 20ml of a mixed solution of ethanol and water with a volume ratio of 97:3, stir and mix well; add 0.25g of catechin to the above solution, stir well and place in boiling water After bumping for 7 minutes, the mixed solution A was obtained.

[0039] Weigh 1 g of zein and dissolve it in 20 ml of a mixed solution of ethanol and water with a volume ratio of 80:10, stir well and mix evenly. Weigh 1g of carrageenan and dissolve it in 50ml of distilled water, place it in a magnetic water stirring pot at 65°C and stir for 20min. Weigh 1g of zein and dissolve it to 20ml, stir well and mix evenly. Weig...

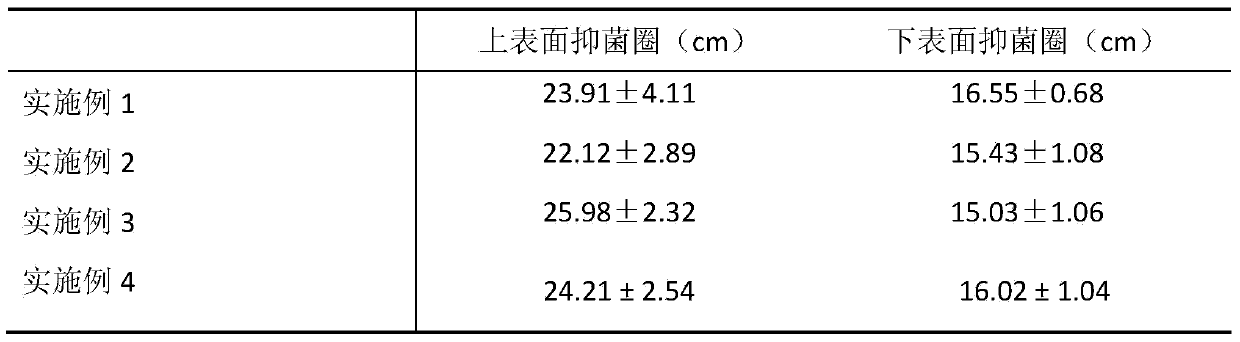

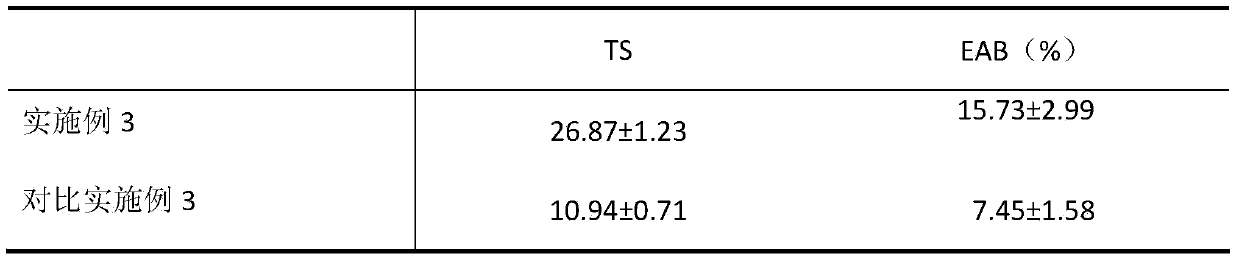

Embodiment 3

[0042] Accurately weigh 1.5g PLA, dissolve it in 20mL chloroform, and stir for 20min under the condition of avoiding light; add 0.15g oleic acid to the above solution, continue stirring for 10min, then pour the film-forming solution into a glass plate to form a film, at RH40%, PLA films were obtained after drying at 25 °C for 4 h.

[0043] Accurately weigh 1g of zein and dissolve it in 20ml of a mixed solution of ethanol and water with a volume ratio of 92:8, stir and mix well; add 0.18g of catechin to the above solution, stir well and place in boiling water After bumping for 10 minutes, the mixed solution A was obtained.

[0044] Weigh 1 g of zein and dissolve it in 20 ml of a mixed solution of ethanol and water with a volume ratio of 85:15, stir well and mix evenly. Weigh 1g of carrageenan and dissolve it in 50ml of distilled water, place it in a magnetic water stirring pot at 65°C and stir for 20min. Weigh 1g of zein and dissolve it to 20ml, stir well and mix evenly. Wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com