A kind of preparation method of copper-zinc-tin-sulfur film

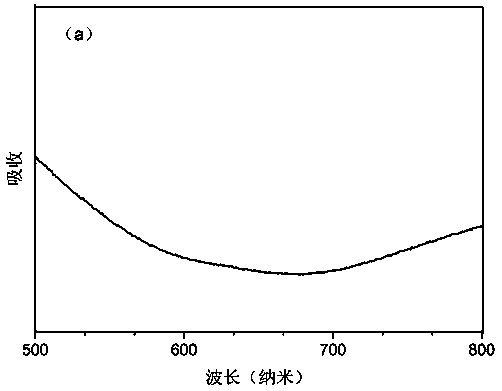

A copper-zinc-tin-sulfur and thin-film technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of component segregation and high reaction atmosphere requirements, and achieve the effects of short reaction time, improved optical properties of thin films, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

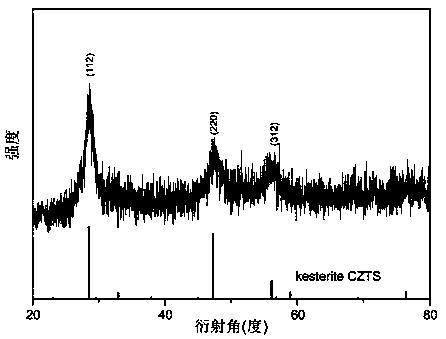

[0029] Embodiment 1: a kind of preparation method of copper-zinc-tin-sulfur film, concrete steps are as follows:

[0030] (1) According to the copper source (the copper source is copper chloride dihydrate (CuCl 2 ‧2H 2 O)), zinc source (zinc source is zinc acetate dihydrate (Zn(CH 3 COO) 2 ‧2H 2 O)), tin source (tin source is tin chloride dihydrate (SnCl 2 ‧2H 2 O)), sulfur source (sulfur source is thiourea (CS(NH 2 ) 2 )) in a molar ratio of 2:1.5:1.25:6 into an organic solvent (the organic solvent is a solution mixed with ethylene glycol and triethylenetetramine in a molar ratio of 1:10), stirred and sonicated to obtain Precursor solution;

[0031] (2) Ultrasonic cleaning and vacuum drying of silicon wafers; where ultrasonic cleaning is ultrasonic cleaning with absolute ethanol and deionized water in sequence, the temperature of vacuum drying is 60°C, and the vacuum drying time is 10h;

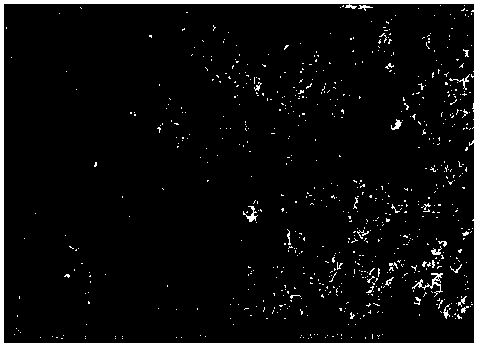

[0032] (3) Spin-coat the precursor solution of step (1) on the silicon wafer in...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of copper-zinc-tin-sulfur film, concrete steps are as follows:

[0042] (1) According to the molar ratio of copper source (copper source is copper nitrate), zinc source (zinc source is zinc nitrate), tin source (tin source is tin acetate), sulfur source (sulfur source is sodium sulfide) is 1:2 : 1.5:8 is added to the organic solvent (the organic solvent is a solution mixed with ethylene glycol and ethanol at a molar ratio of 2:8), and the precursor solution is obtained after stirring and ultrasonic treatment;

[0043] (2) Ultrasonic cleaning and vacuum drying of FTO conductive glass; where ultrasonic cleaning is ultrasonic cleaning with absolute ethanol and deionized water in sequence, the temperature of vacuum drying is 70°C, and the vacuum drying time is 8 hours;

[0044] (3) Spin-coat the precursor solution in step (1) on the FTO conductive glass in step (2) and dry it in vacuum for 8 h at a temperature of 80 °C. The spin-co...

Embodiment 3

[0047] Embodiment 3: a kind of preparation method of copper-zinc-tin-sulfur film, concrete steps are as follows:

[0048] (1) According to the mole of copper source (copper source is copper acetylacetonate), zinc source (zinc source is zinc sulfate), tin source (tin source is tin tetraiodide), sulfur source (sulfur source is ammonium thiocyanate) The ratio of 1.5:1:2:10 is added to the organic solvent (the organic solvent is acetic acid), and the precursor solution is obtained after stirring and ultrasonic treatment;

[0049] (2) Ultrasonic cleaning and vacuum drying of silicon wafers; where ultrasonic cleaning is ultrasonic cleaning with absolute ethanol and deionized water in sequence, the temperature of vacuum drying is 80 ° C, and the vacuum drying time is 7 hours;

[0050] (3) Spin-coat the precursor solution of step (1) on the silicon wafer in step (2) and dry it in vacuum at 90°C for 7 h, where the spin-coating rate is 3000 r / min and the spin-coating time is 20s ; Then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com