Rapid leak detection method for TCA cooler of gas turbine air cooling system

An air cooling system and cooler technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, etc. The problem of reducing the vacuum degree of the steamer to achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

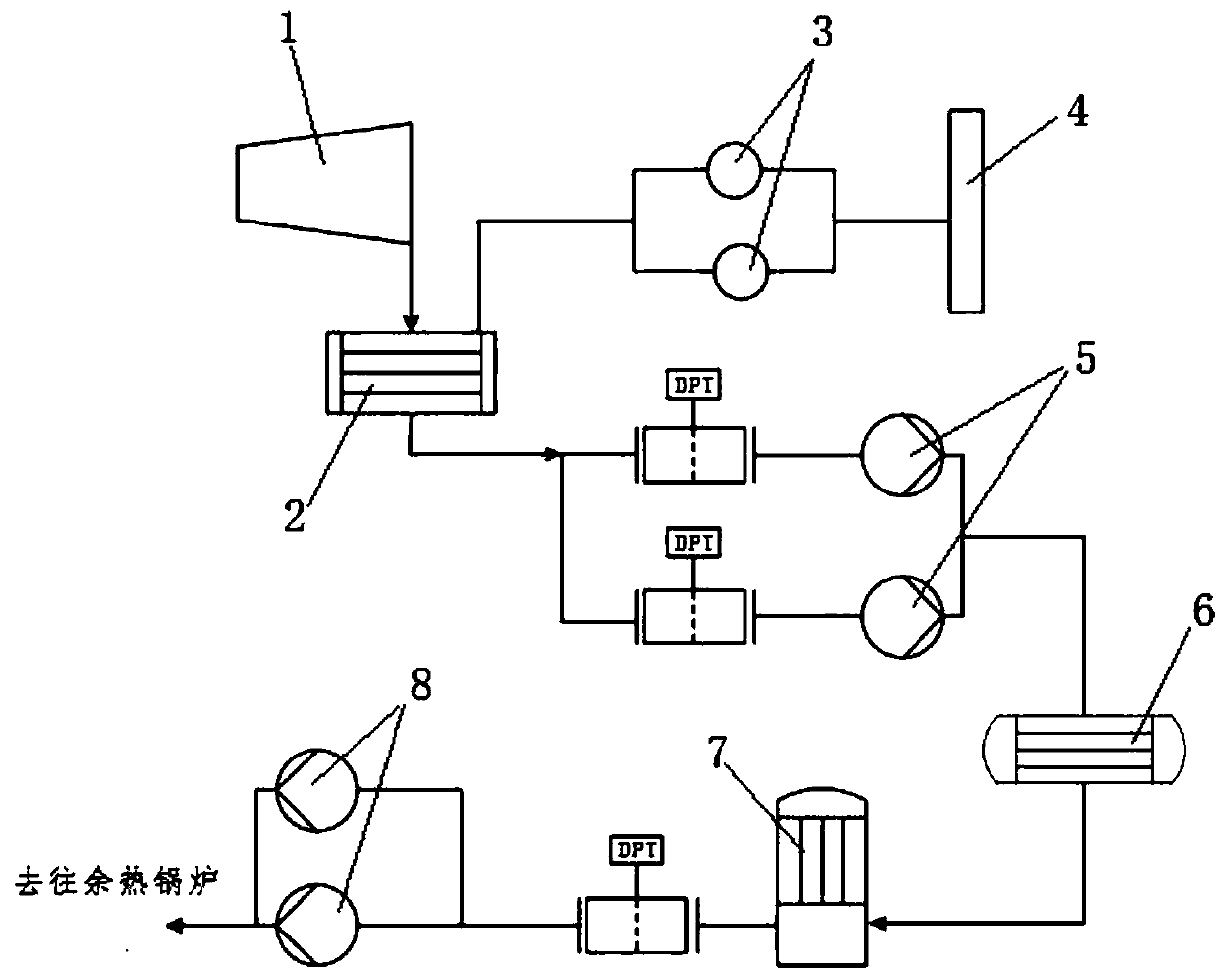

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] See figure 1 , a gas turbine air cooling system TCA cooler fast leak detection method according to the present invention comprises the following steps:

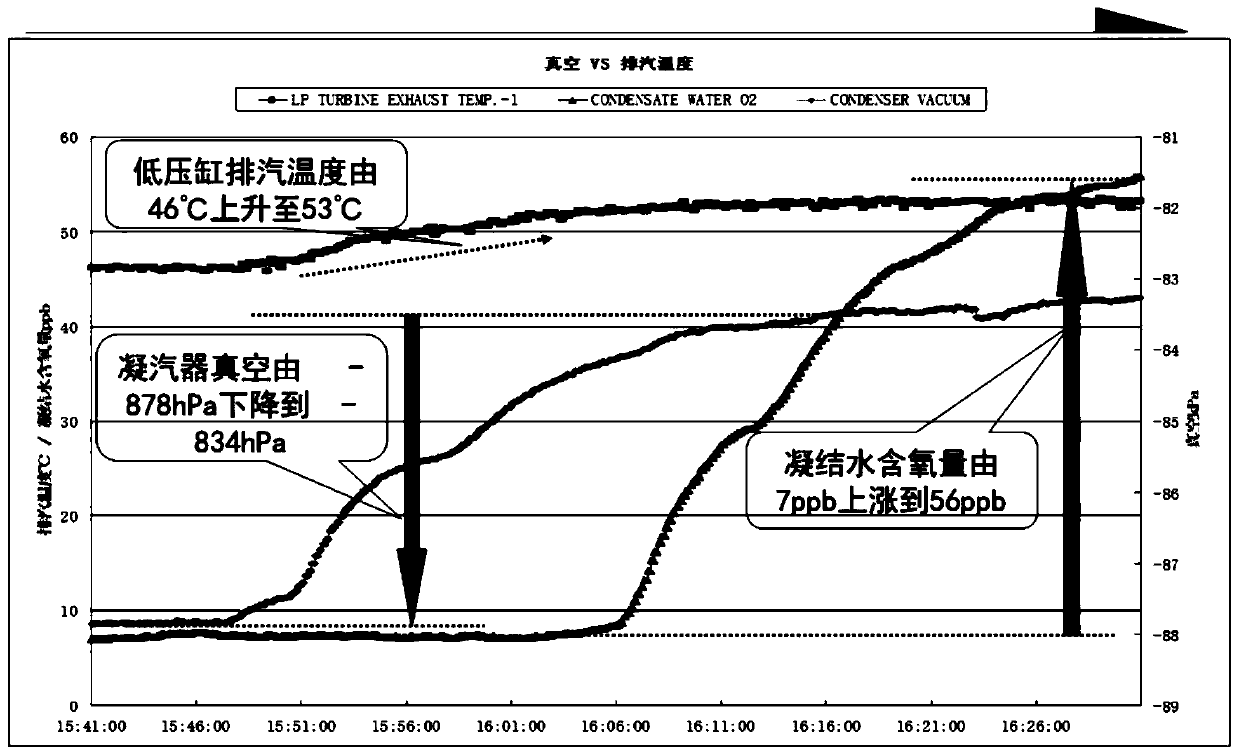

[0025] 1) Run a vacuum pump to obtain the condensed water dissolved oxygen amount DD1 at the outlet of the condenser, the condensed water dissolved oxygen amount DT1 at the outlet of the TCA cooler, and the condenser vacuum degree VD1 under the stable operation state of the combined generator set;

[0026] 2) Interlock start the standby vacuum pump, that is, two vacuum pumps run at the same time, respectively obtain the condensed water dissolved oxygen amount DD2 at the outlet of the condenser, the condensed water dissolved oxygen amount DT2 at the outlet of the TCA cooler, and the condenser Vacuum degree VD2;

[0027] 3) Within the range of no more than 70% to 100% of the design load, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com