Patents

Literature

186 results about "Manufacturing capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing capability refers to the technical and physical limitations of a manufacturing firm and each of its plants. Several dimensions of this capability can be identified: Technological processing capability, Physical size and weight of product, and.

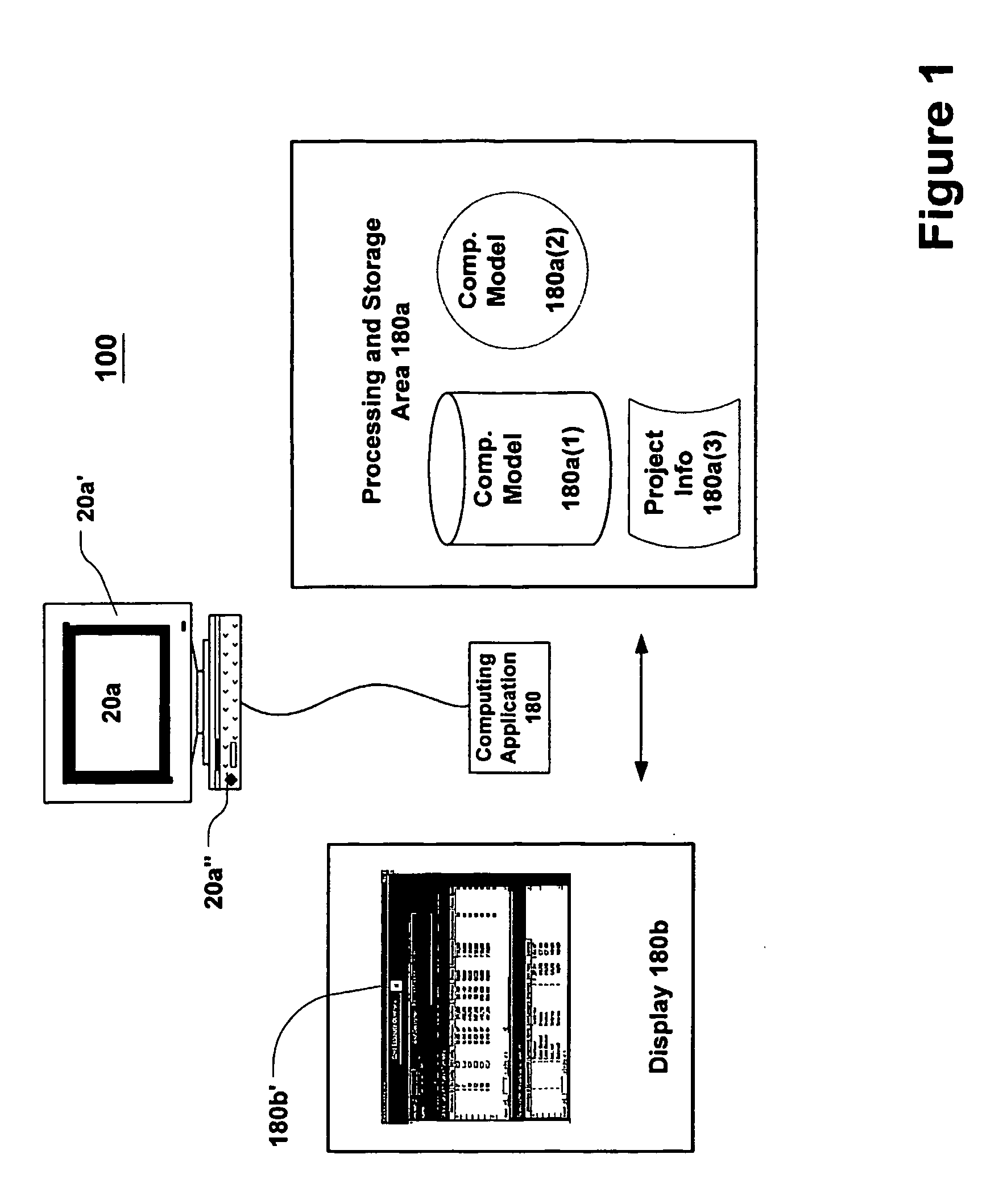

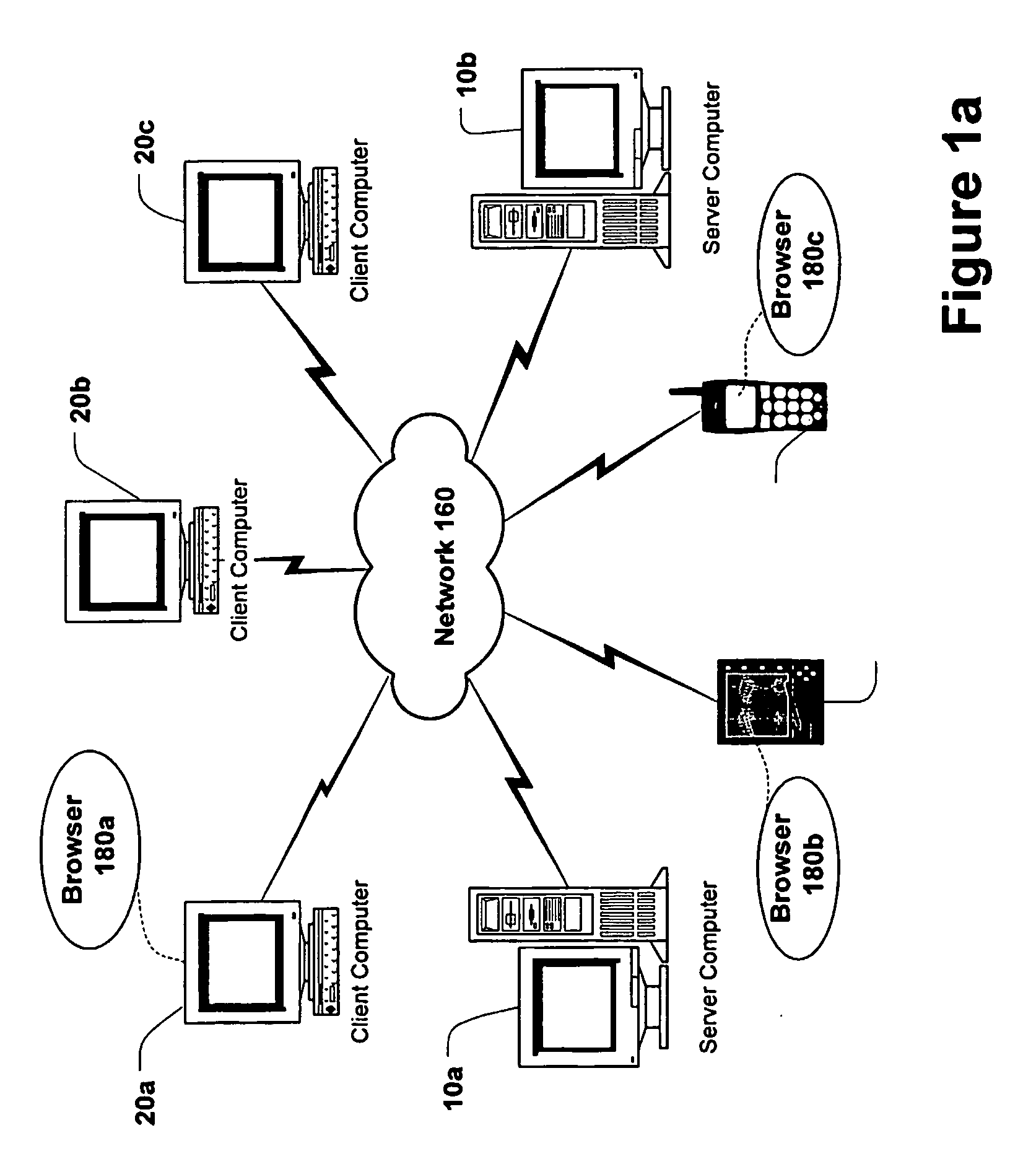

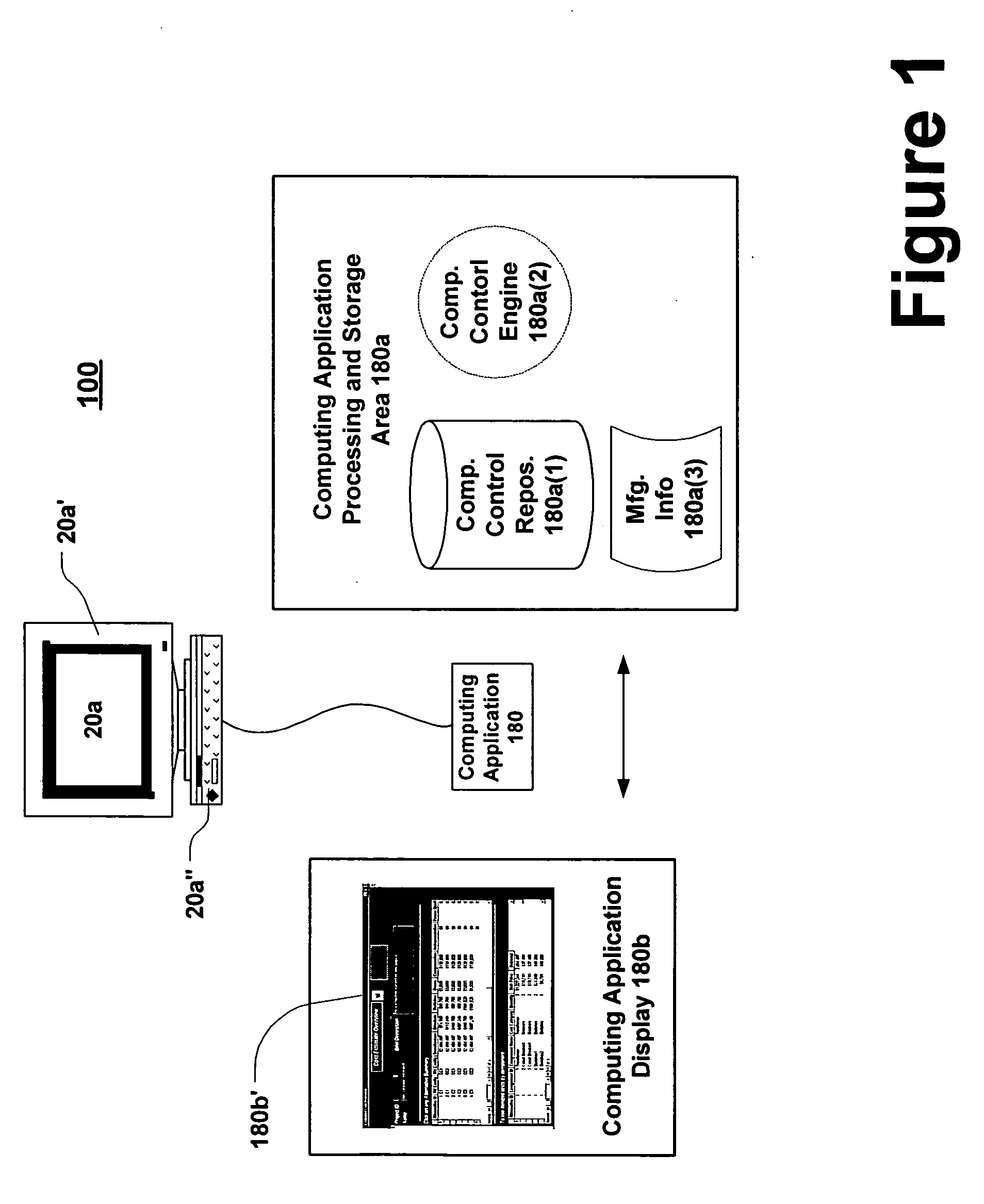

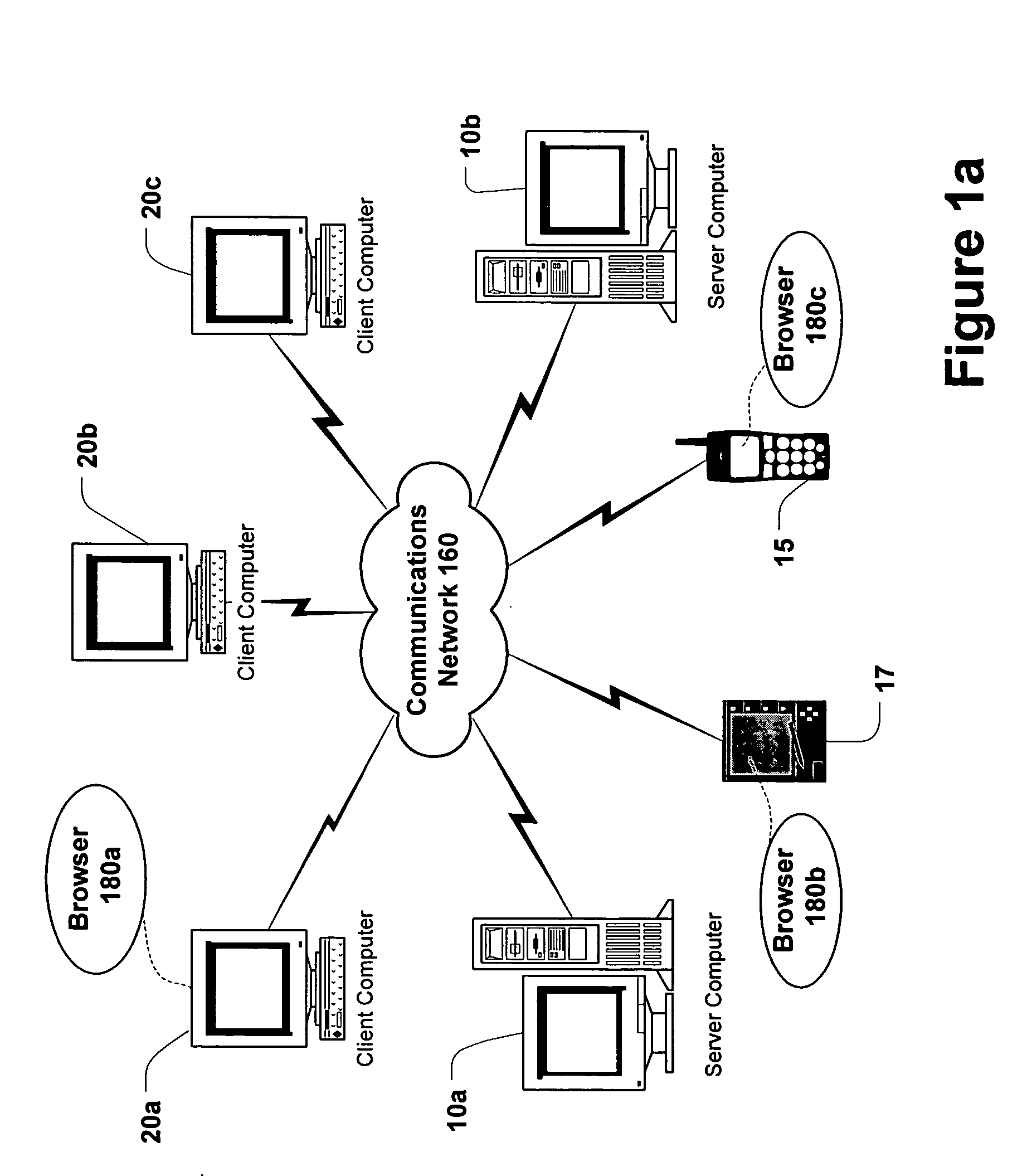

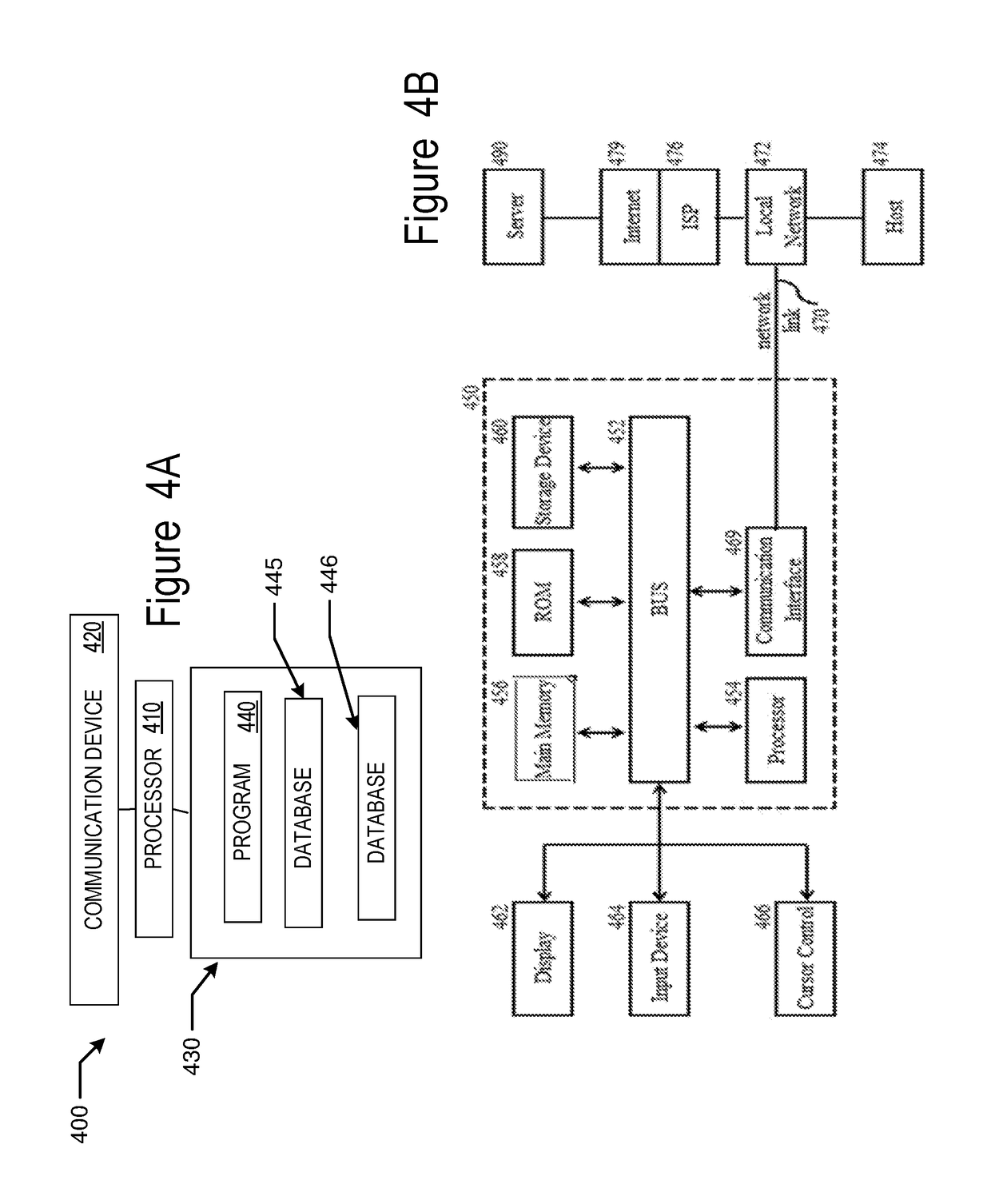

Intelligent personalization system and method

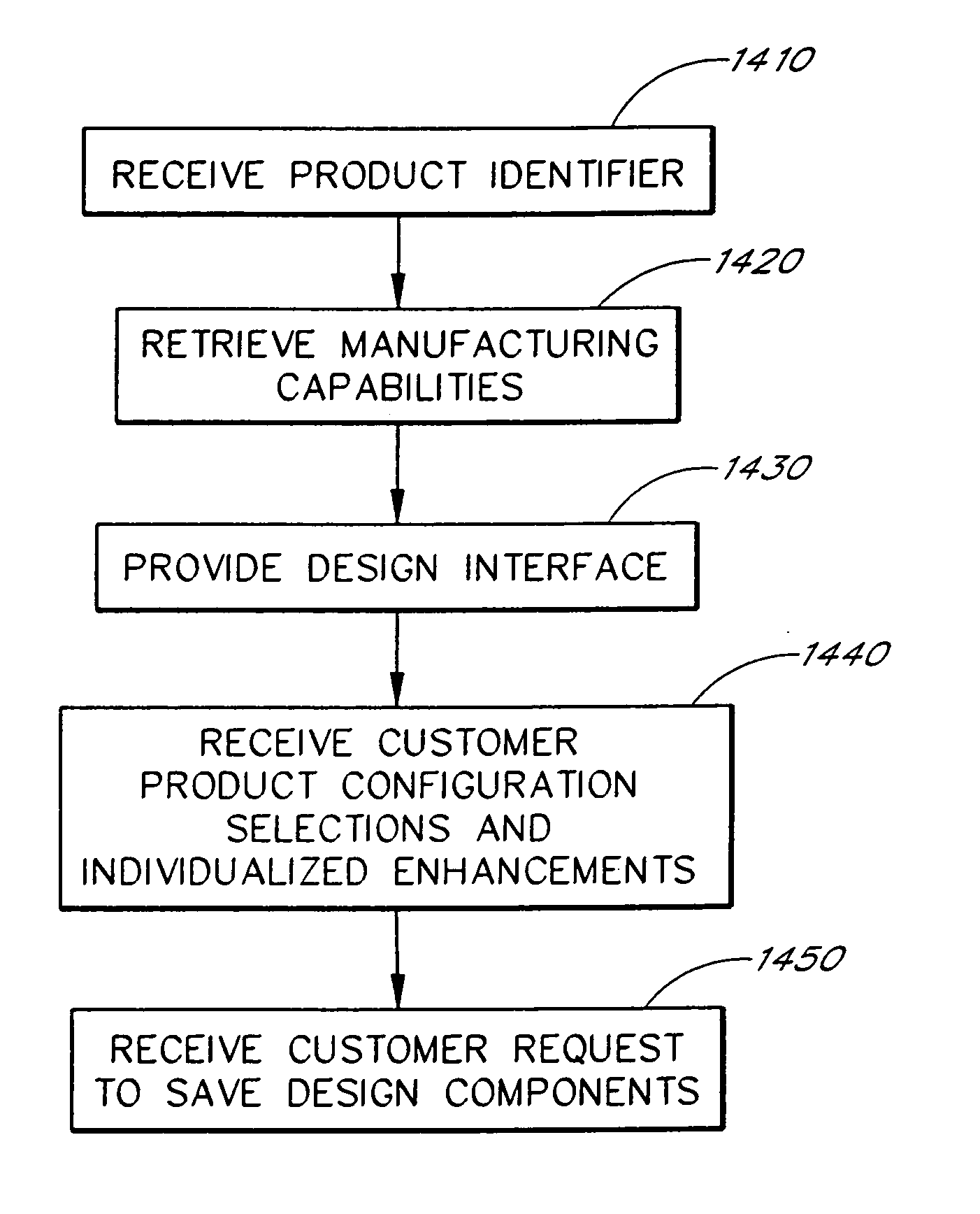

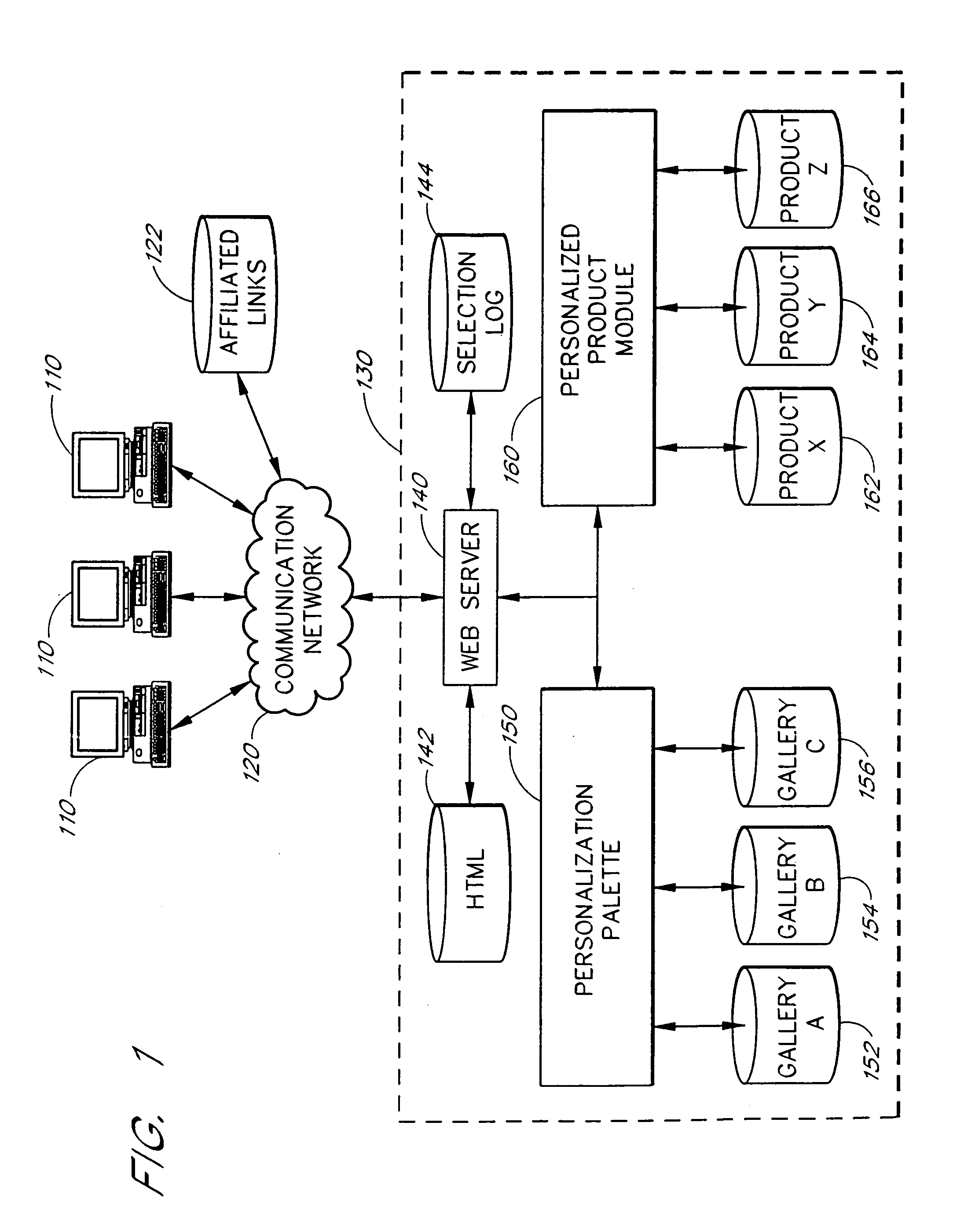

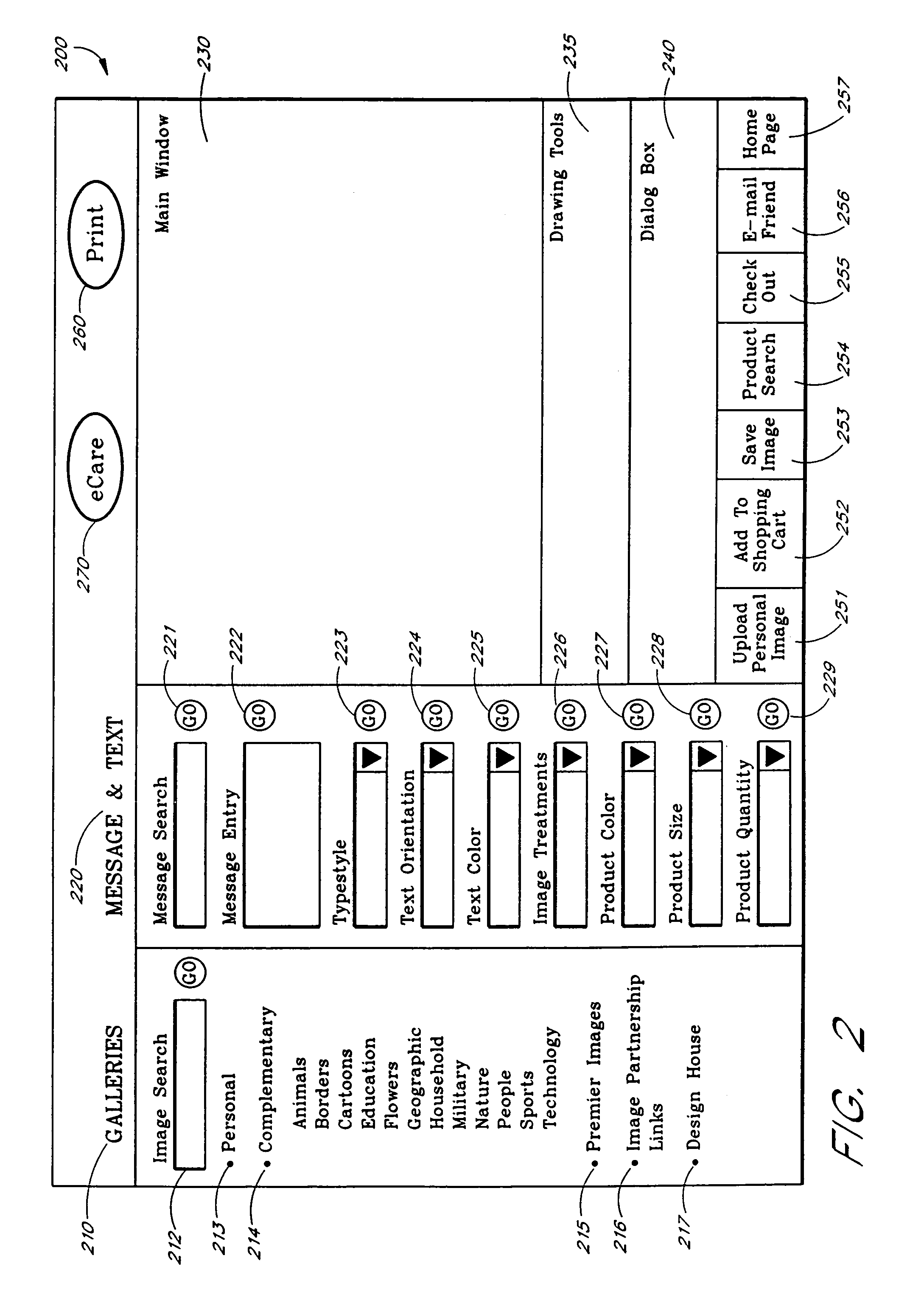

A system and method for facilitating the creation of personalized products is disclosed, wherein a user on a user computer can access a host merchant computer via a communication network, such as the Internet. The host merchant computer communicates with a products database containing information on products available for personalization and further contains manufacturing capabilities for the products. The method includes providing to the user via the communication network an assortment of product selections available in the products database, receiving a message from the user via the communication network indicating a selection of a product from the assortment, retrieving a set of manufacturing capabilities for the selected product from the products database, and providing to the user via the communication network a design interface including design tools which allow the user to select product configuration options and to create individualized enhancements, wherein the design tool is conformed to only allow configuration options and enhancements that satisfy the manufacturing capabilities.

Owner:DELUXE CORPORATION

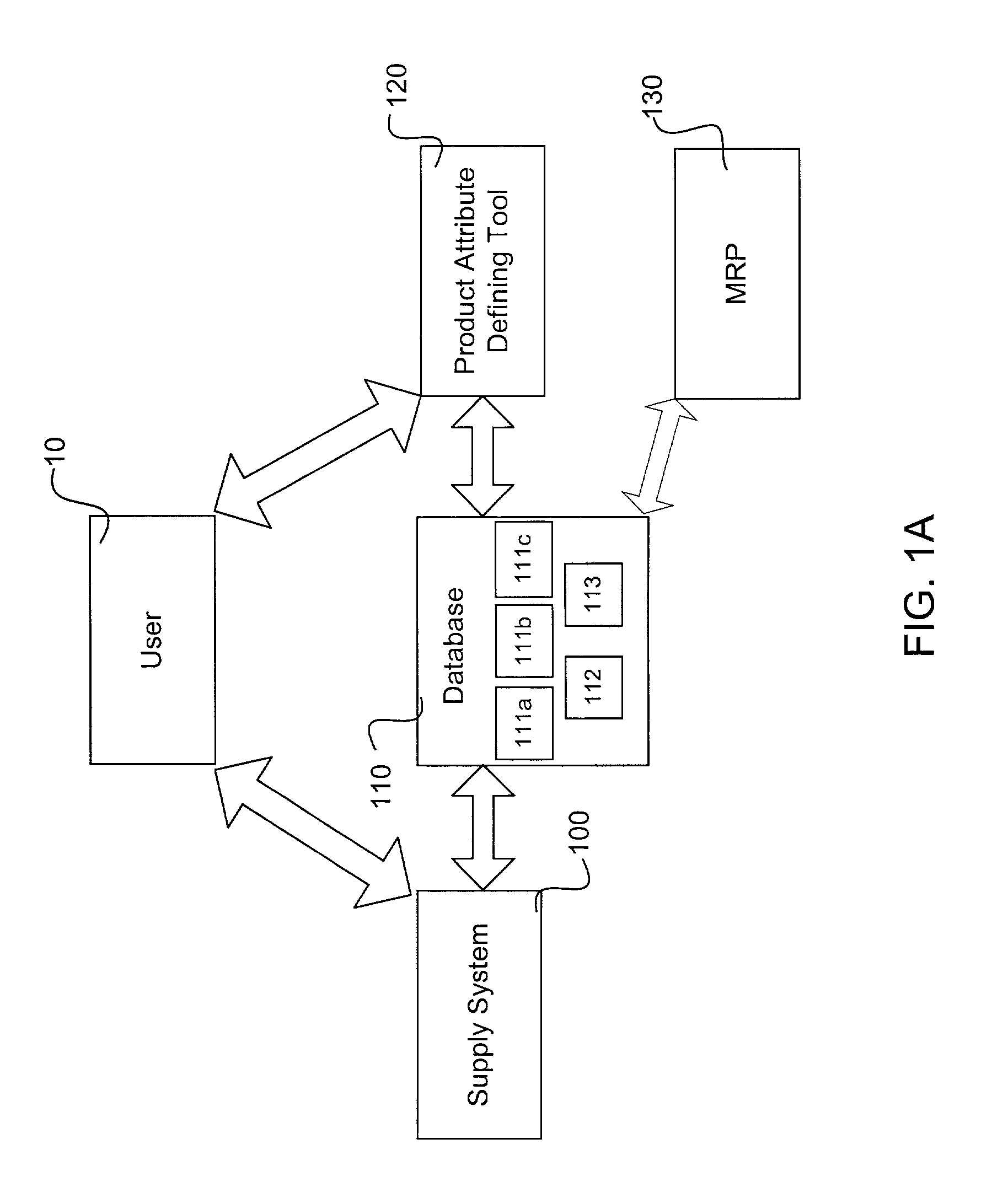

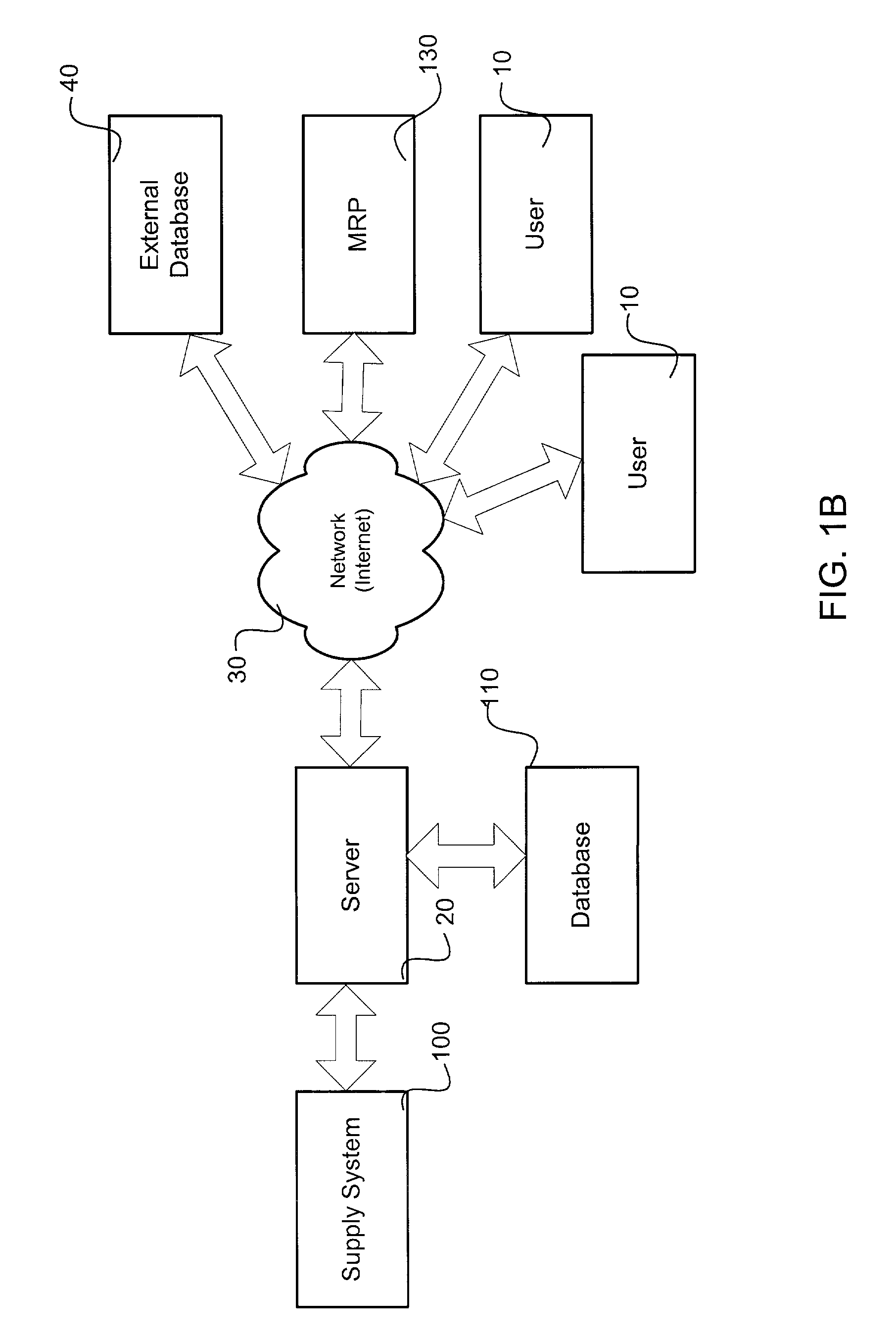

System and method for allocating the supply of critical material components and manufacturing capacity

InactiveUS7058587B1Improve responsivenessMaximize inventory useResourcesSpecific program execution arrangementsProgram planningChange analysis

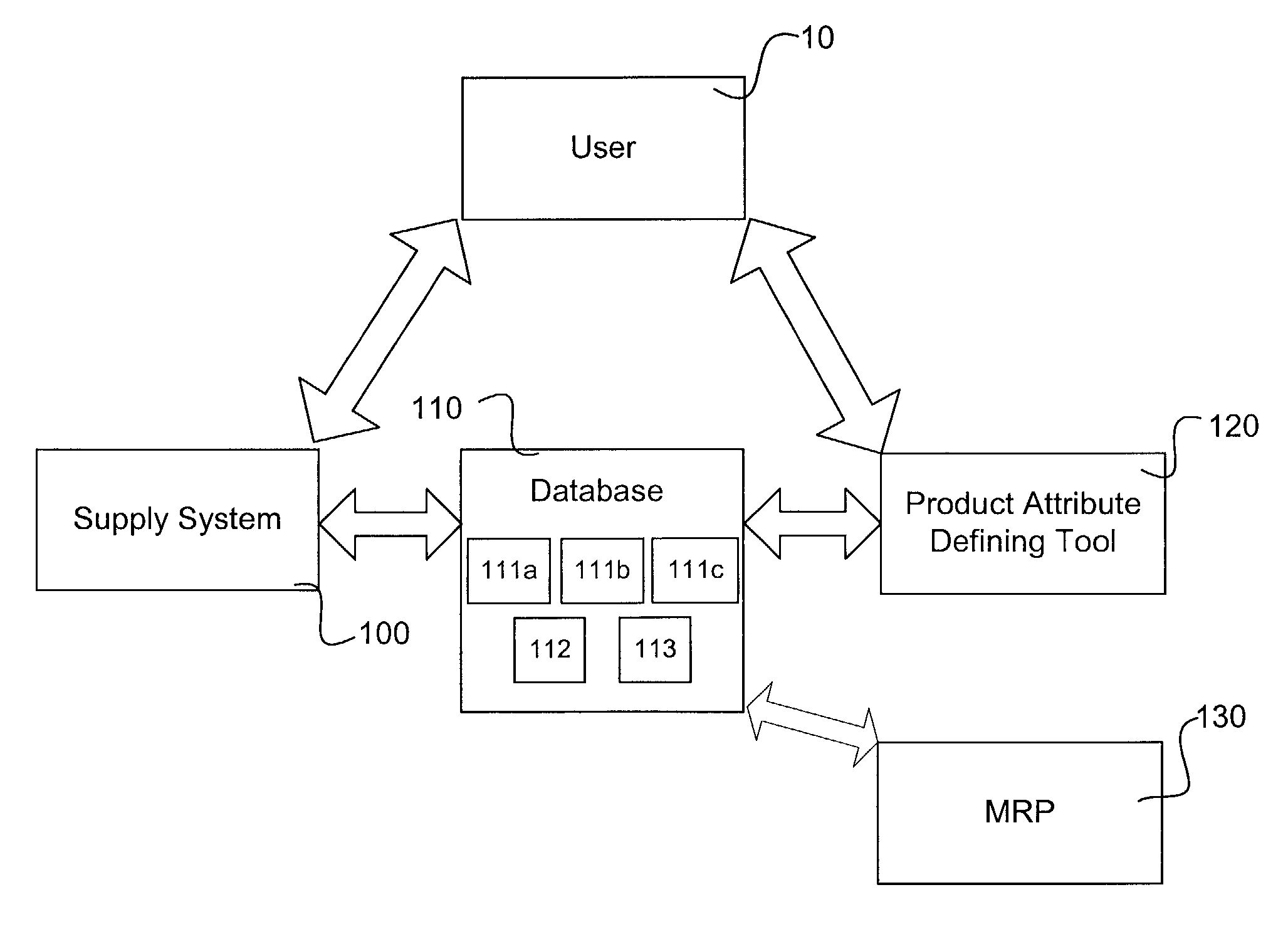

The present invention allocates the supply of critical components and manufacturing capacity by optimizing critical material planning decisions and dynamically allocating constrained materials using advanced substitution logic that considers alternate suppliers and supports product life cycle from design through end-of-life. The present invention may utilize unique synchronized allocations and matched sets logic. The synchronized allocations ensure that all materials necessary for production are available in the appropriate time-phased allocation before beginning production to minimize wasted production capacity and materials. The supply system may include various combination of components, including a Supply Planner, a Resource Optimizer, a Constraint Based Master Planner, a Product Change Analyzer, a Comparer, a Resource Requirements Planner, a Finite Resource Planner, a Customer Promiser, and an Interactive Master Scheduler. Another embodiment of the supply system includes a tool that allows users to define products using engineering specifications.

Owner:BLUE YONDER GRP INC

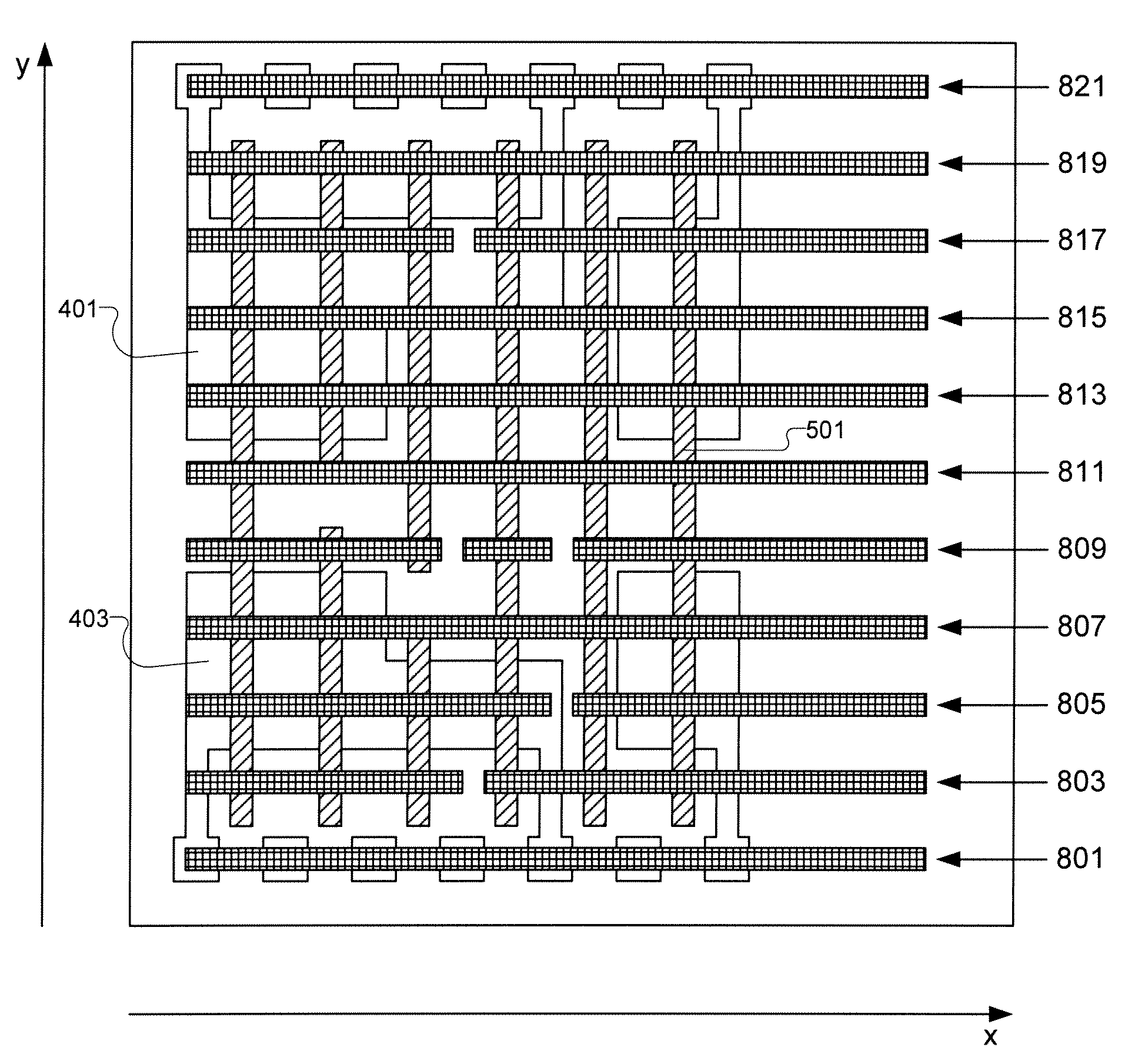

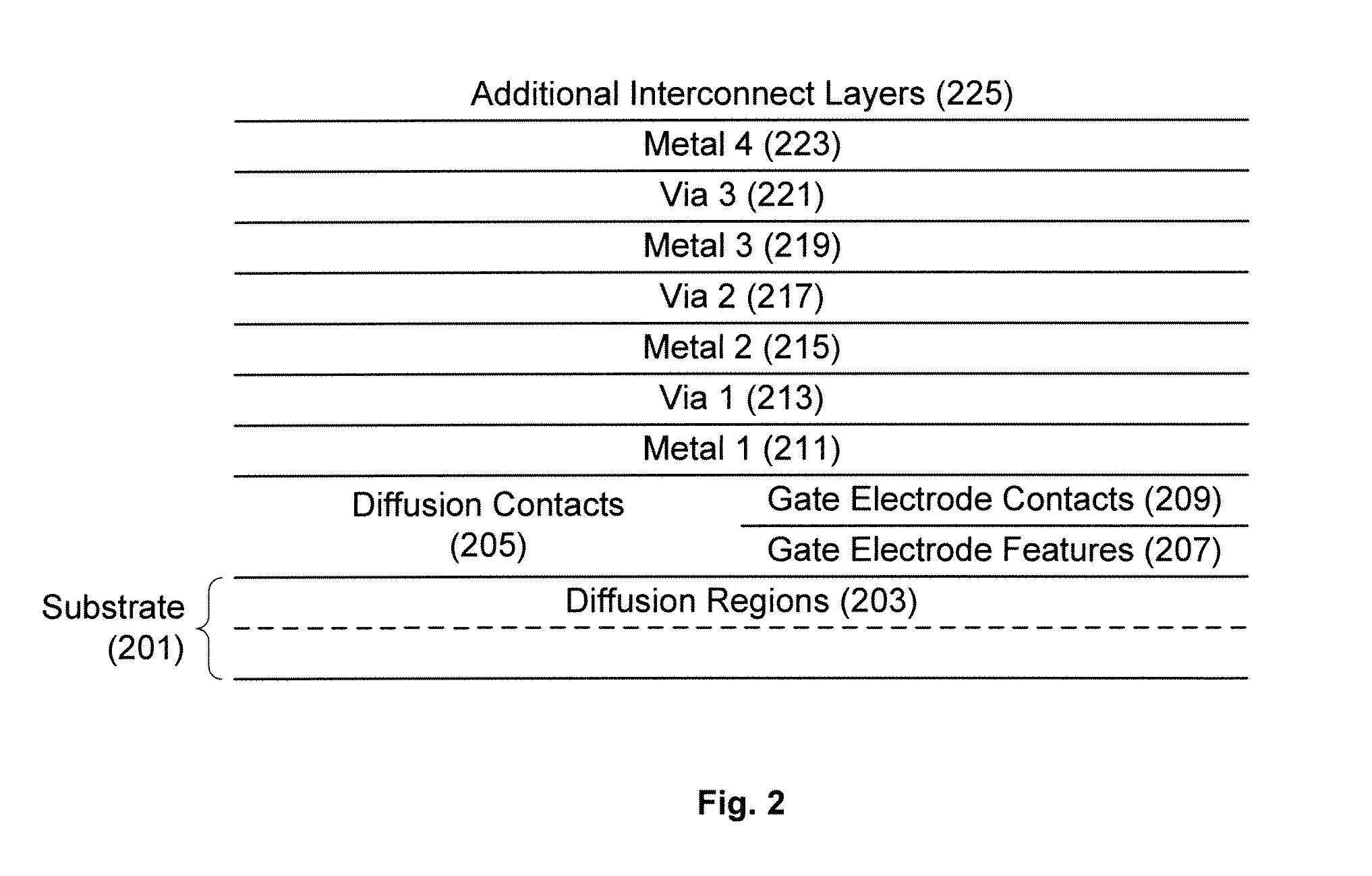

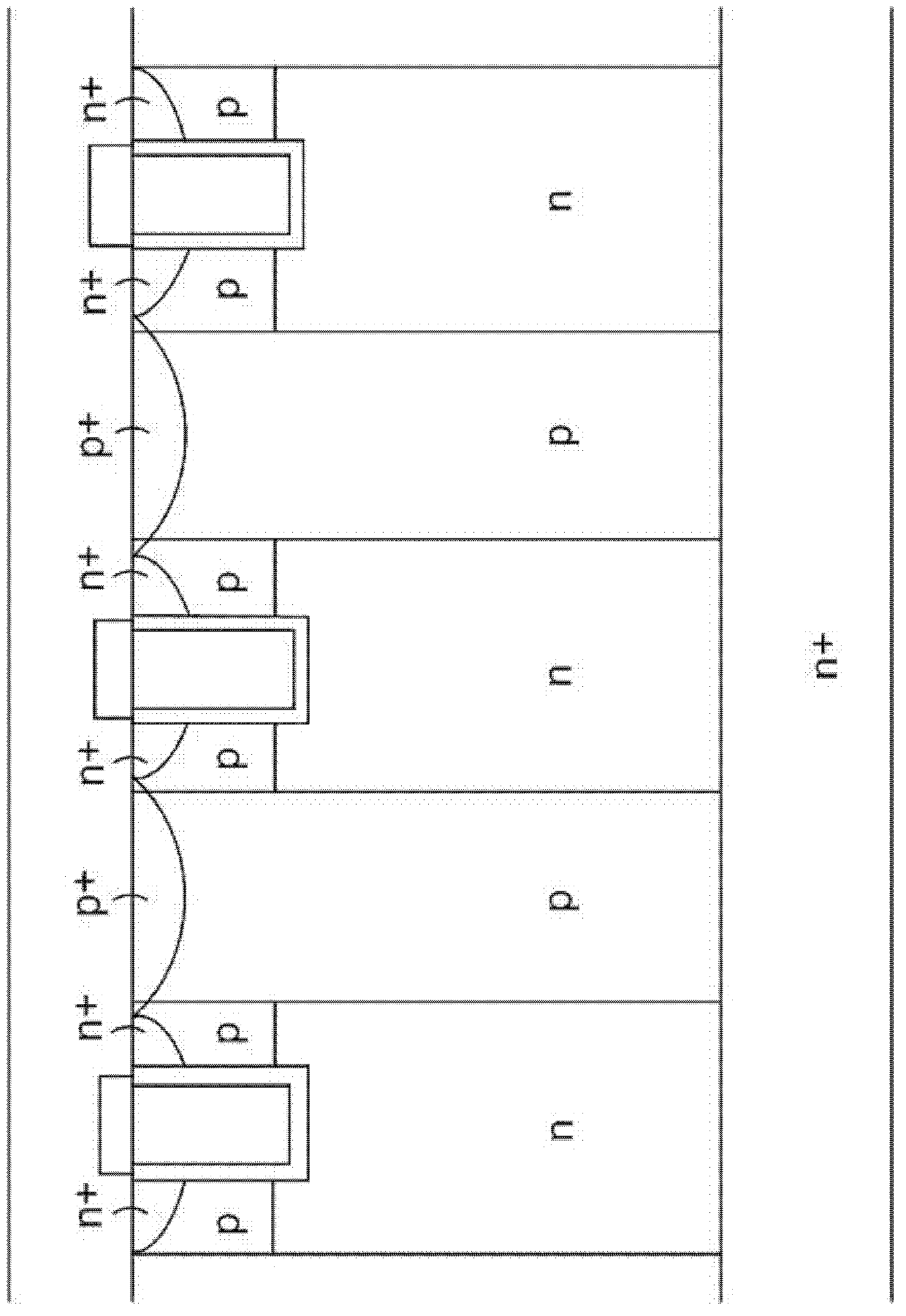

Semiconductor device and associated layouts having transistors formed from six linear conductive segments with gate electrode connection through single interconnect level

A cell layout of a semiconductor device includes a diffusion level layout including a plurality of diffusion region layout shapes. The cell layout also includes a gate electrode level layout defined to include linear-shaped layout features placed to extend in only a first parallel direction. Adjacent linear-shaped layout features that share a common line of extent in the first parallel direction are separated from each other by an end-to-end spacing that is substantially equal across the gate electrode level layout and that is minimized to an extent allowed by a semiconductor device manufacturing capability. The gate electrode level layout includes linear-shaped layout features defined along at least four different lines of extent in the first parallel direction. The cell layout also includes a number of interconnect level layouts each defined to pattern conductive features within corresponding interconnect levels above the gate electrode level of the cell.

Owner:RPX CORP

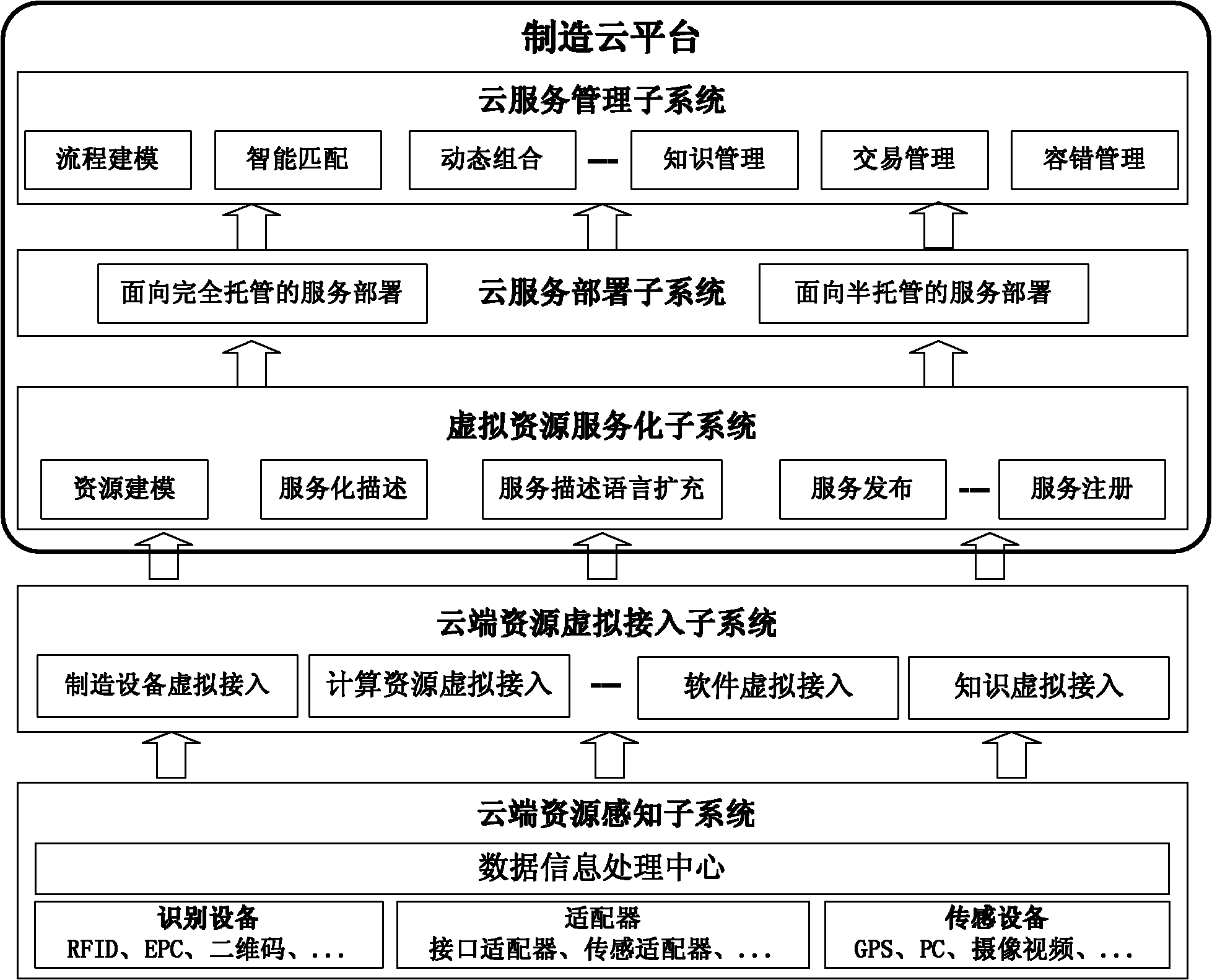

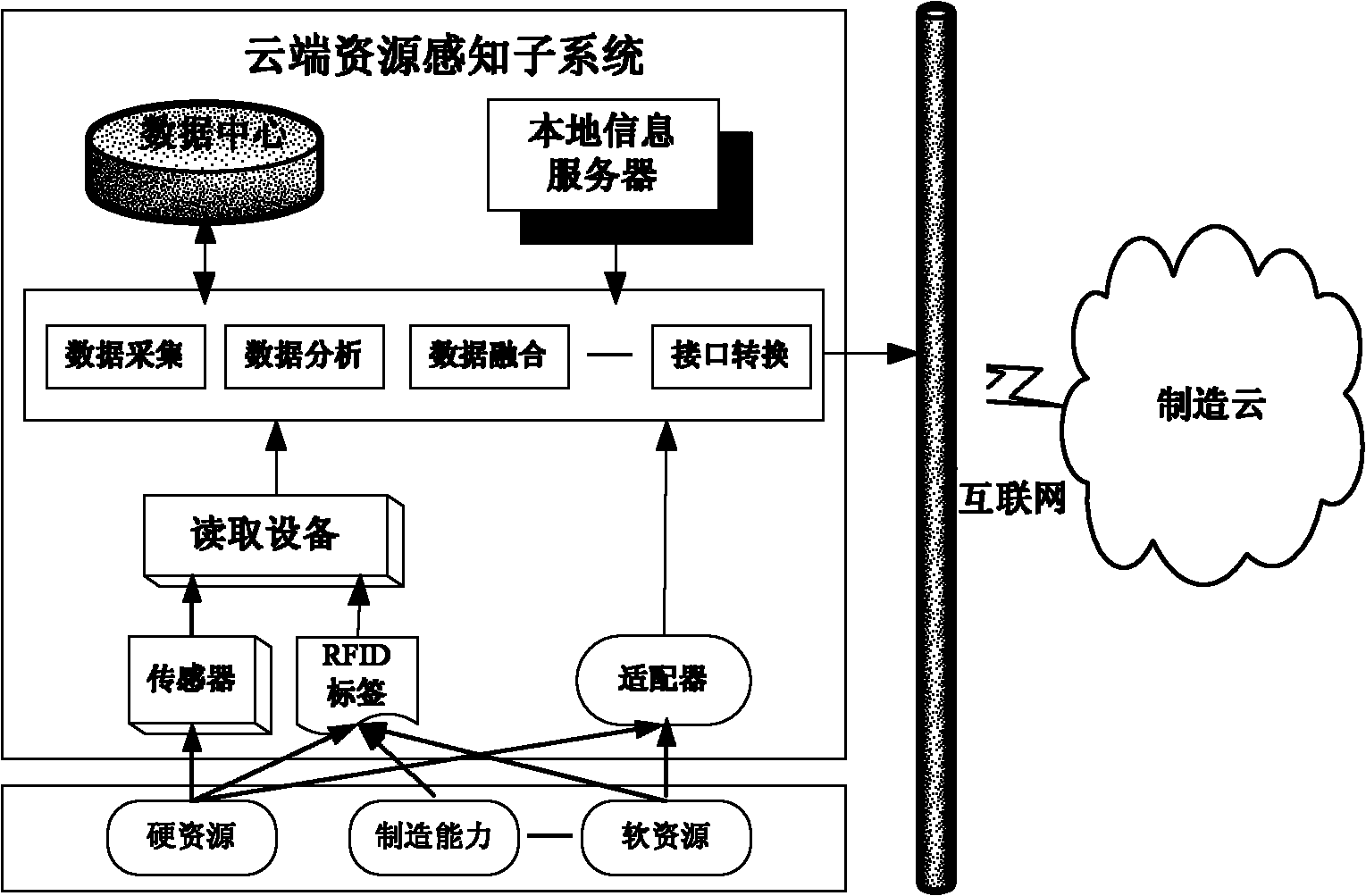

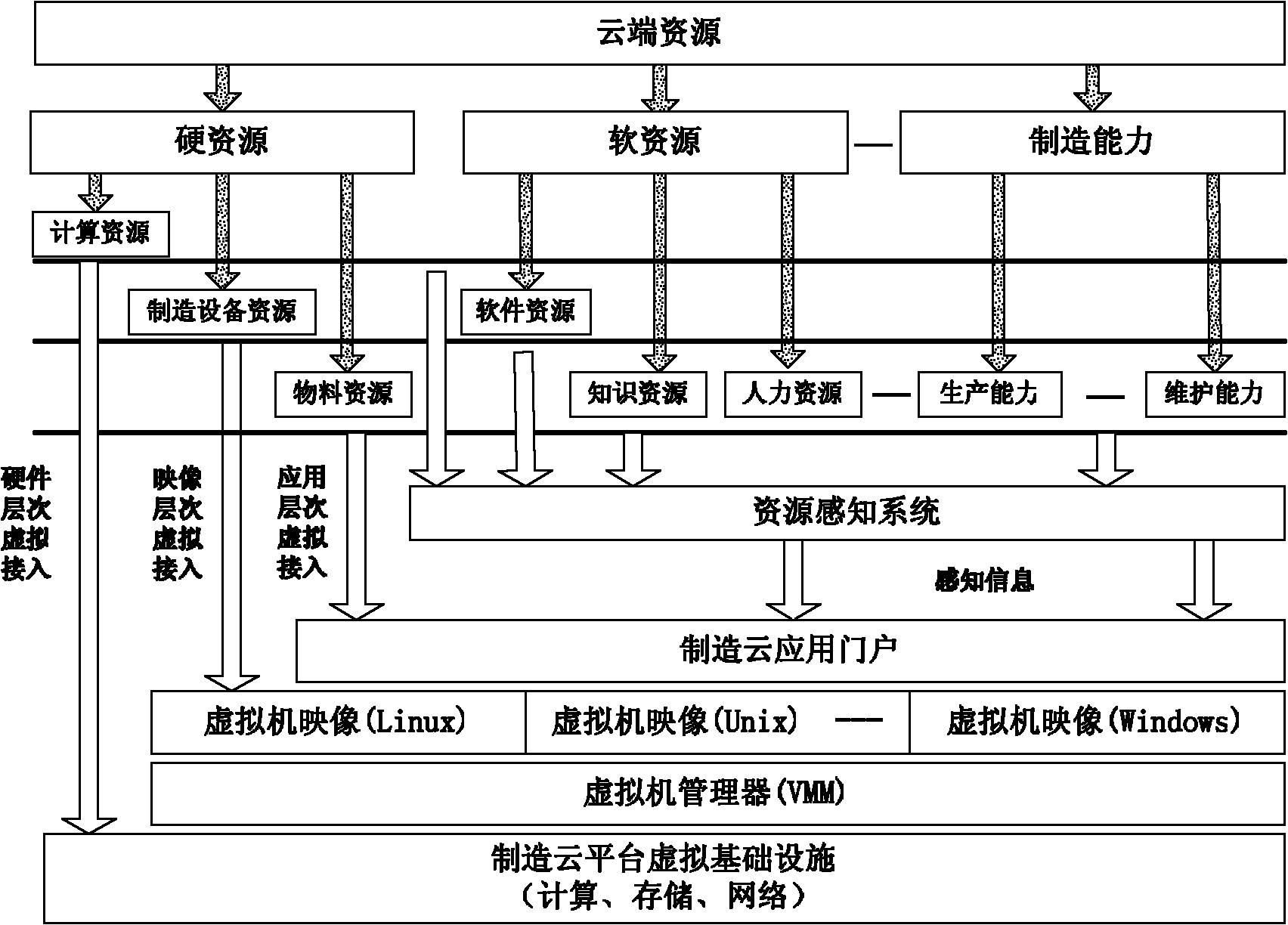

Manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities

InactiveCN102176723ARealize analysisAchieving processing powerTransmissionSoftware simulation/interpretation/emulationInformatizationResource utilization

The invention provides a manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities, which is used for solving the problems that the use ratio of resources is low, the sharing of the manufacturing capacities is insufficient, effective business operation management measures are short and the like in the process of manufacturing enterprise informatization in China. Aiming at the characteristics of the manufacturing resources and the actual demands of an enterprise for a cloud manufacturing service platform, and according to the lifeline of a cloud service life cycle, the manufacturing resources and the manufacturing capacity in the manufacturing cloud system are designed and stated in five system modules namely intellisense, virtual access, virtual resource servicesation, deployment of cloud services, and integrated management of the cloud services, thus meeting the demand of the on-demand use and the dynamic collaboration of the manufacturing resources and the manufacturing capacities. The manufacturing cloud system has the advantages that the intellisense, the servicesation of the manufacturing capacities and service life cycle demands which are accessed to the manufacturing resources are supported, the intelligence is supported, the services are shared on demand, the system structure is flexible, the levels are distinct, and the expandability is strong.

Owner:BEIHANG UNIV

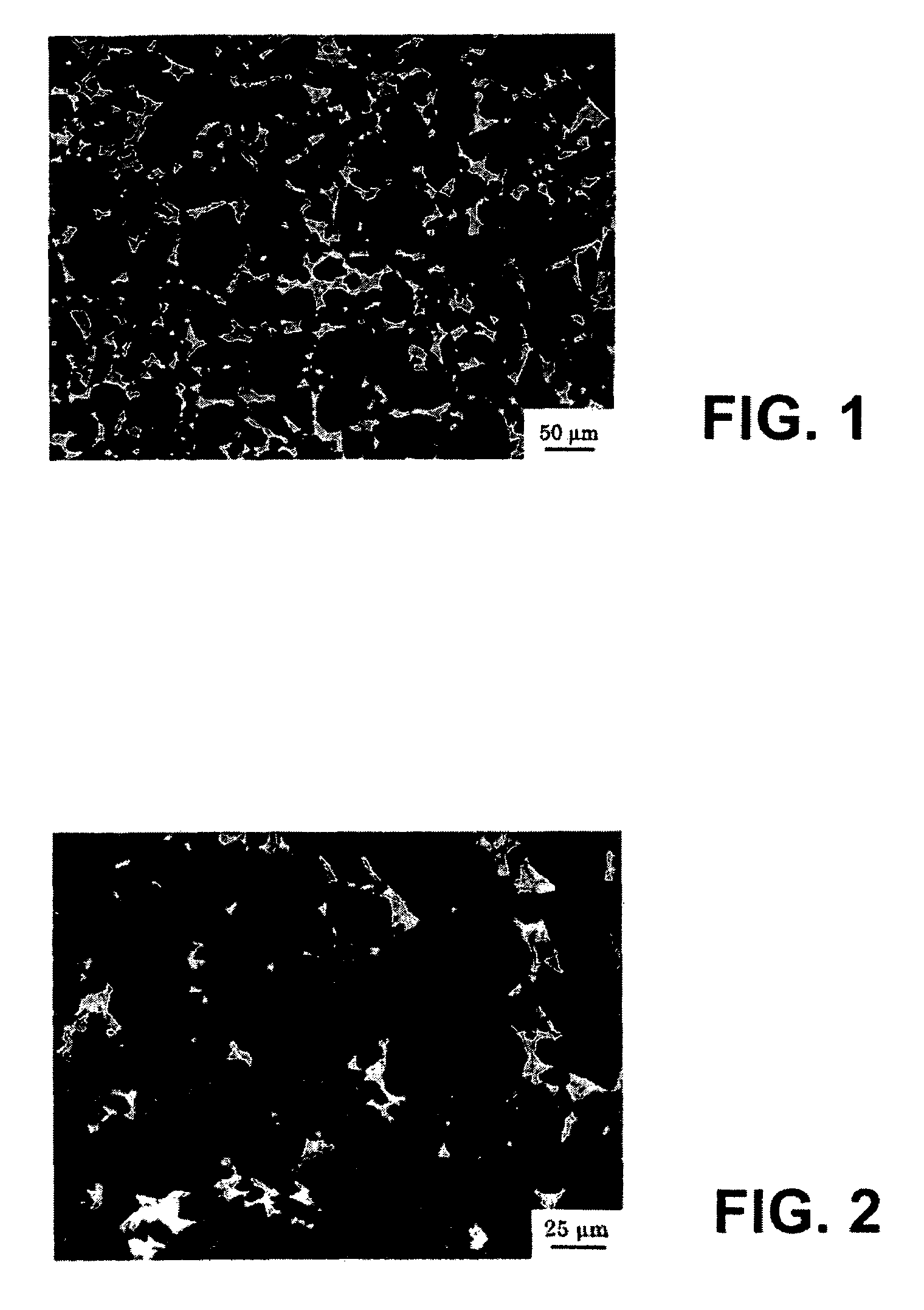

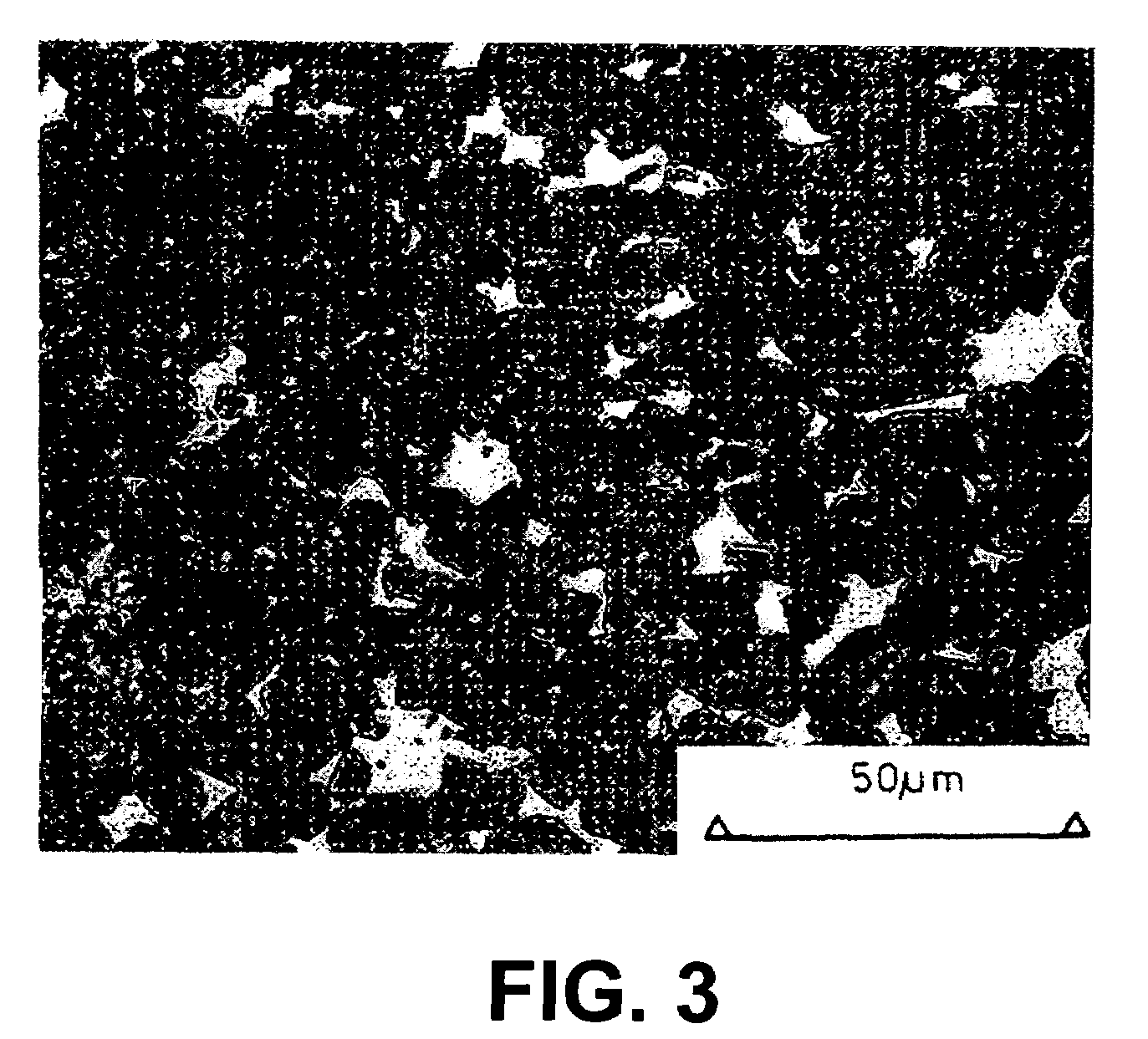

Silicon carbide composites and methods for making same

InactiveUS6503572B1Improve permeabilityReduce the amount requiredPretreated surfacesCoatingsNet shapeToughness

Improved silicon carbide composites made by an infiltration process feature a metal phase in addition to any residual silicon phase. Not only are properties such as mechanical toughness improved, but the infiltrant can be so engineered as to have much diminished amounts of expansion upon solidification, thereby enhancing net-shape-making capabilities. Further, multi-component infiltrant materials may have a lower liquidus temperature than pure silicon, thereby providing the practitioner greater control over the infiltration process. In particular, the infiltration may be conducted at the lower temperatures, where low-cost but effective bedding or barrier materials can terminate the infiltration process once the infiltrant has migrated through the permeable mass up to the boundary between the mass and the bedding material.

Owner:BUSINESS ALLIANCE CAPITAL +1

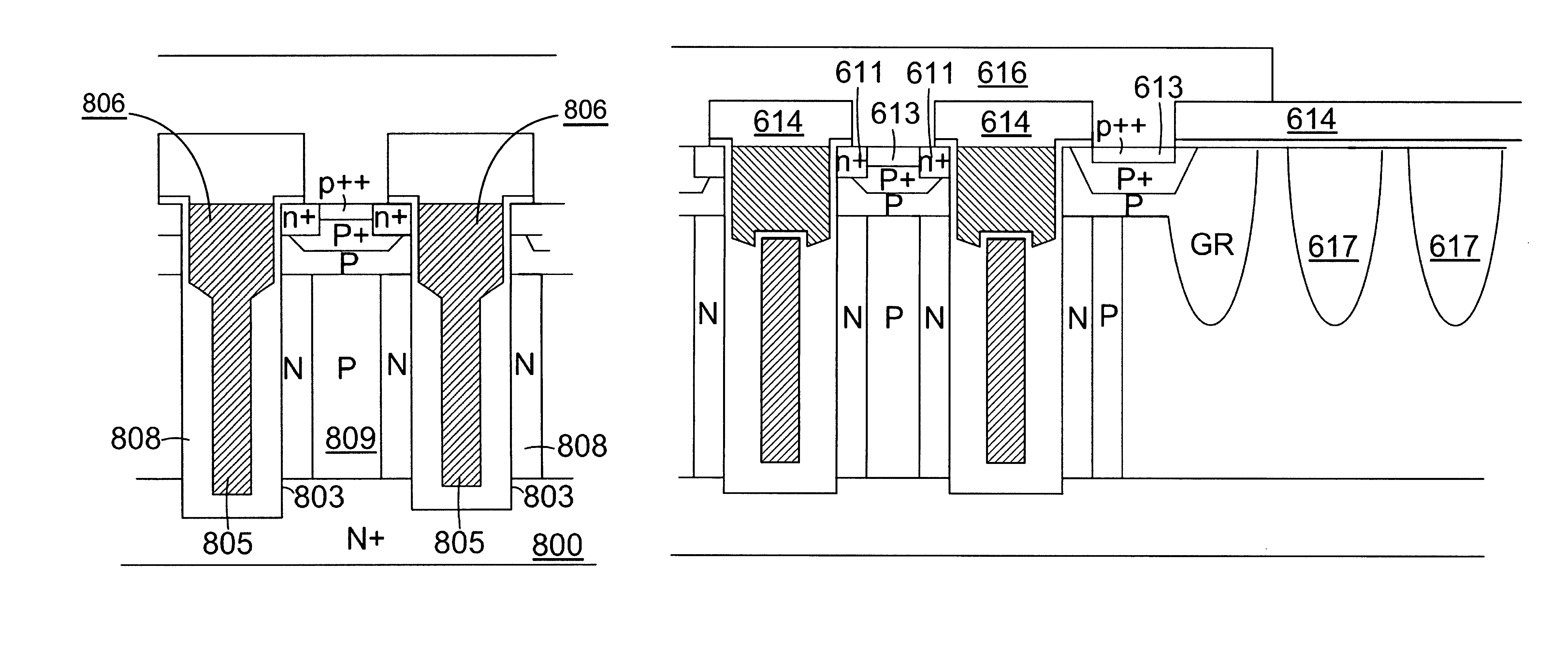

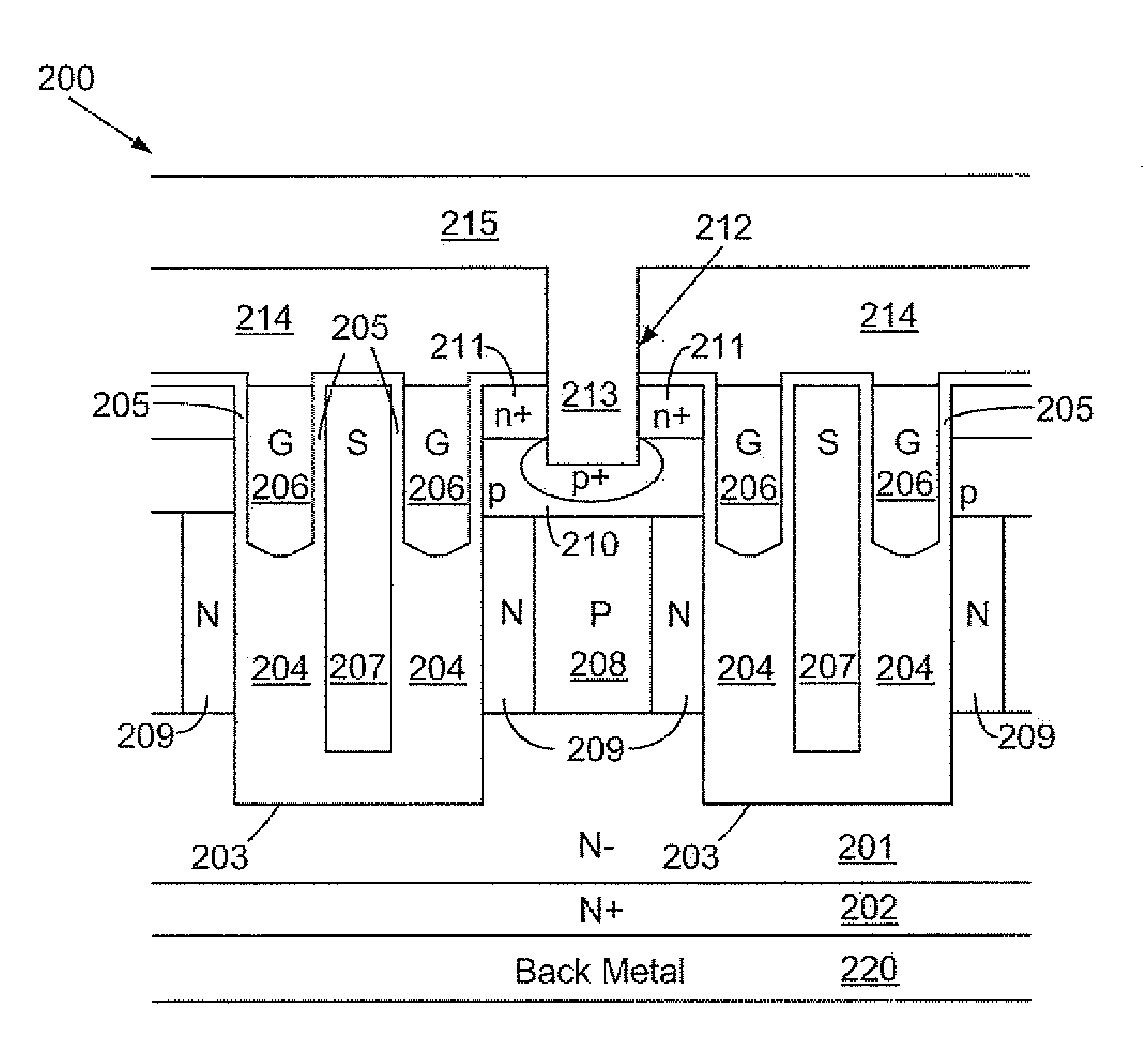

Super-junction trench MOSFET with resurf step oxide and the method to make the same

ActiveUS8067800B2Minimize impactImprove rendering capabilitiesSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

A super-junction trench MOSFET with Resurf Stepped Oxide is disclosed. The inventive structure can apply additional freedom for better optimization and manufacturing capability by tuning thick oxide thickness to minimize influence of charge imbalance, trapped charges, etc. . . . . Furthermore, the fabrication method can be implemented more reliably with lower cost.

Owner:FORCE MOS TECH CO LTD

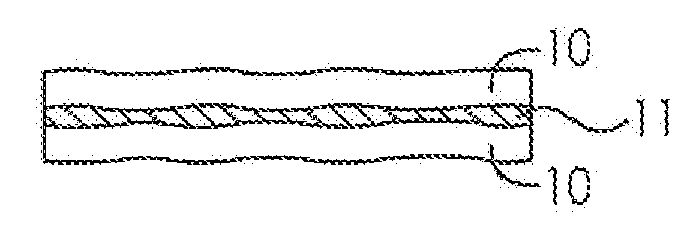

Polymer interlayers comprising epoxidized vegetable oil

InactiveUS20130074931A1Synthetic resin layered productsGlass/slag layered productsVegetable oilPlasticizer

An interlayer comprised of a thermoplastic resin, varying amounts of an epoxidized vegetable oil, and, optionally, a conventional plasticizer. The use of a thermoplastic resin, an epoxidized vegetable (plant) oil, and, optionally, a conventional plasticizer creates synergy allowing the flow of the interlayer to be increased without sacrificing other characteristics typically associated with an increased flow (e.g., increased blocking and creep, exudation, surface roughness formation, decreased mechanical strength, and decreased manufacturing capability). In this regard, the epoxidized vegetable oil acts as a flow improvement agent, resulting in a high-flow interlayer. As a result, a thinner interlayer can be utilized in forming multiple layer panels because the resulting thinner interlayer has improved flow properties.

Owner:SOLUTIA INC

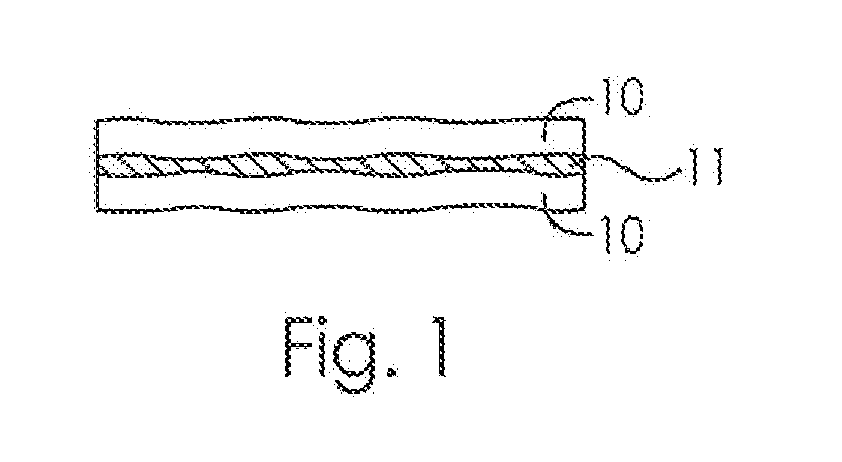

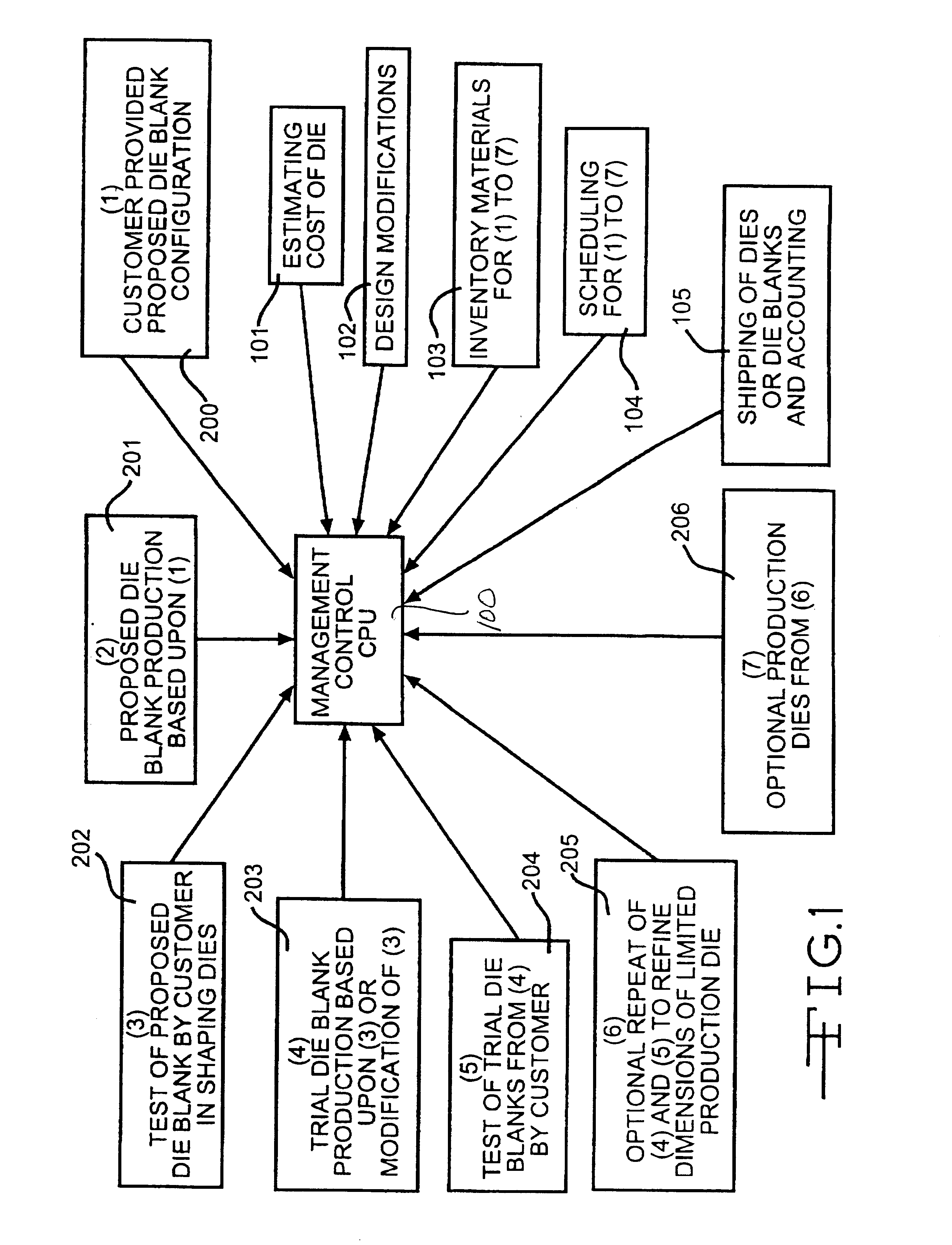

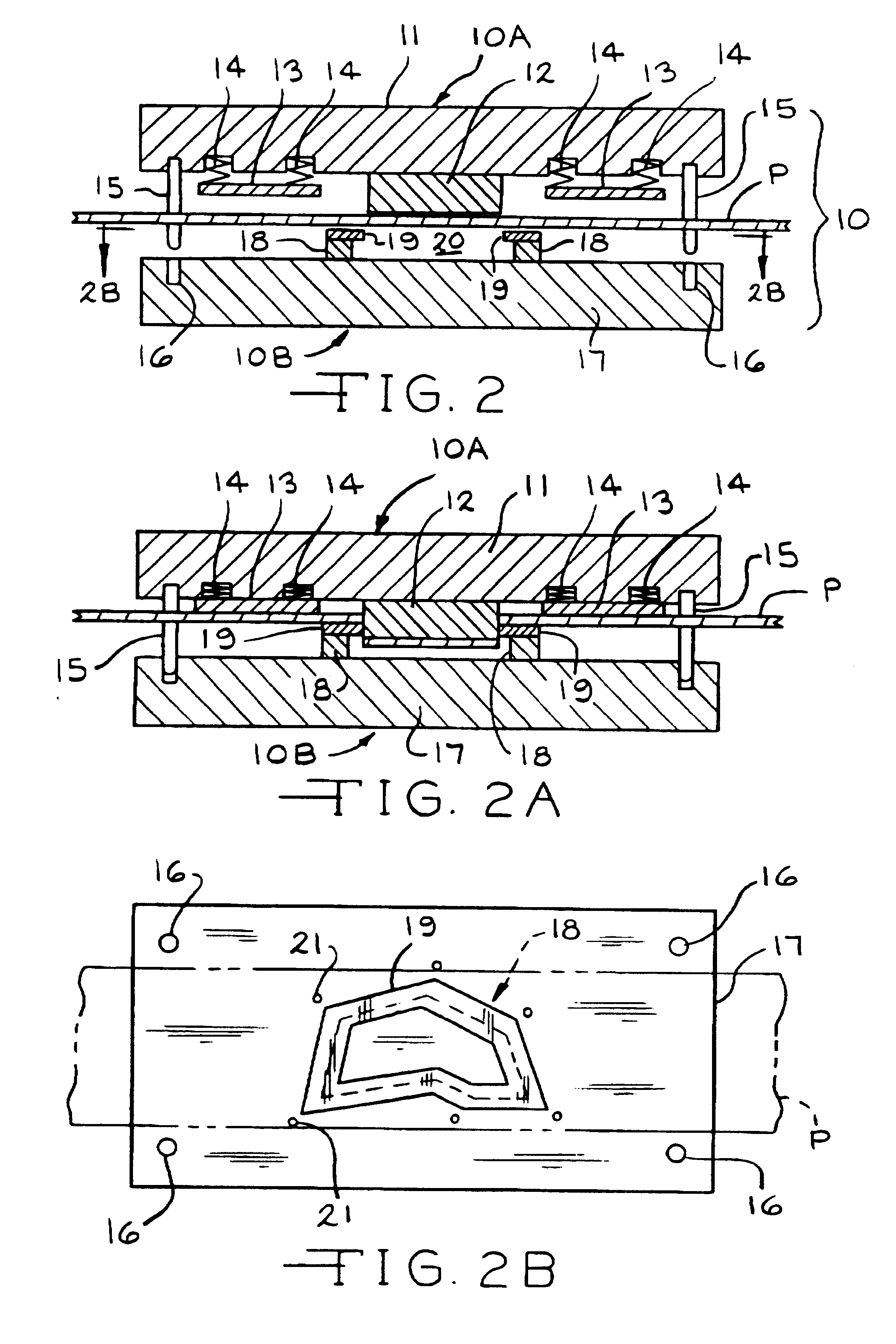

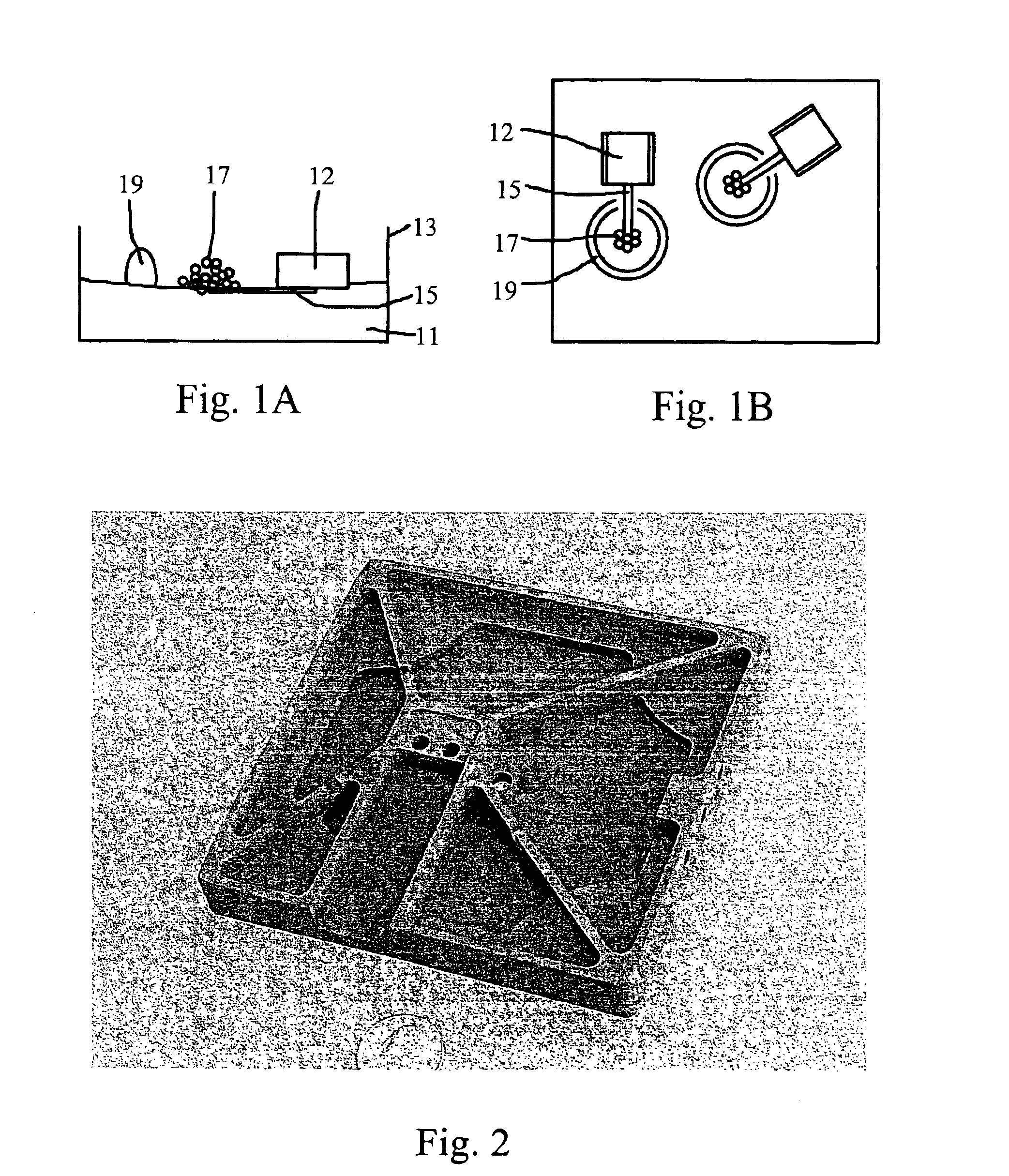

System and method for design and fabrication of stamping dies for making precise die blanks

The present invention provides a system and method for a manufacturing operation for fabricating production stamping dies for making precise die blanks wherein the operation is controlled by computer. The method and system produces proposed die blanks from a customer's proposed die blank configuration which are evaluated by the customer before trial and / or production stamping dies are made. In particular, the method provides a computer processing unit, which is accessible to the customer, wherein the computer provides die blank and stamping die CAD / CAM designing and manufacturing capabilities, data storage and retrieval, and coordinates all or particular functions involved in the manufacture of proposed die blanks and trial or production stamping dies.

Owner:DEMMER CORP

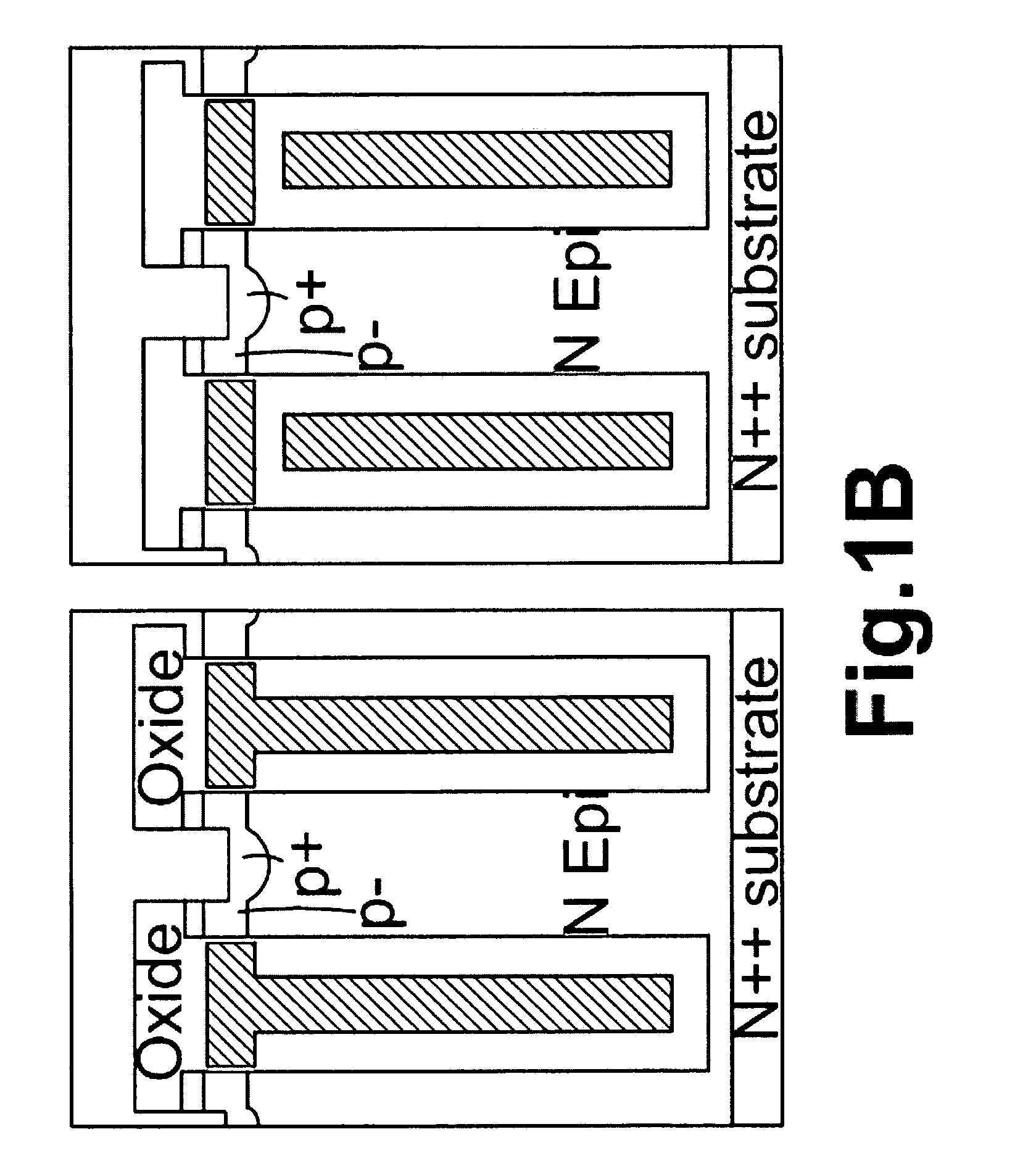

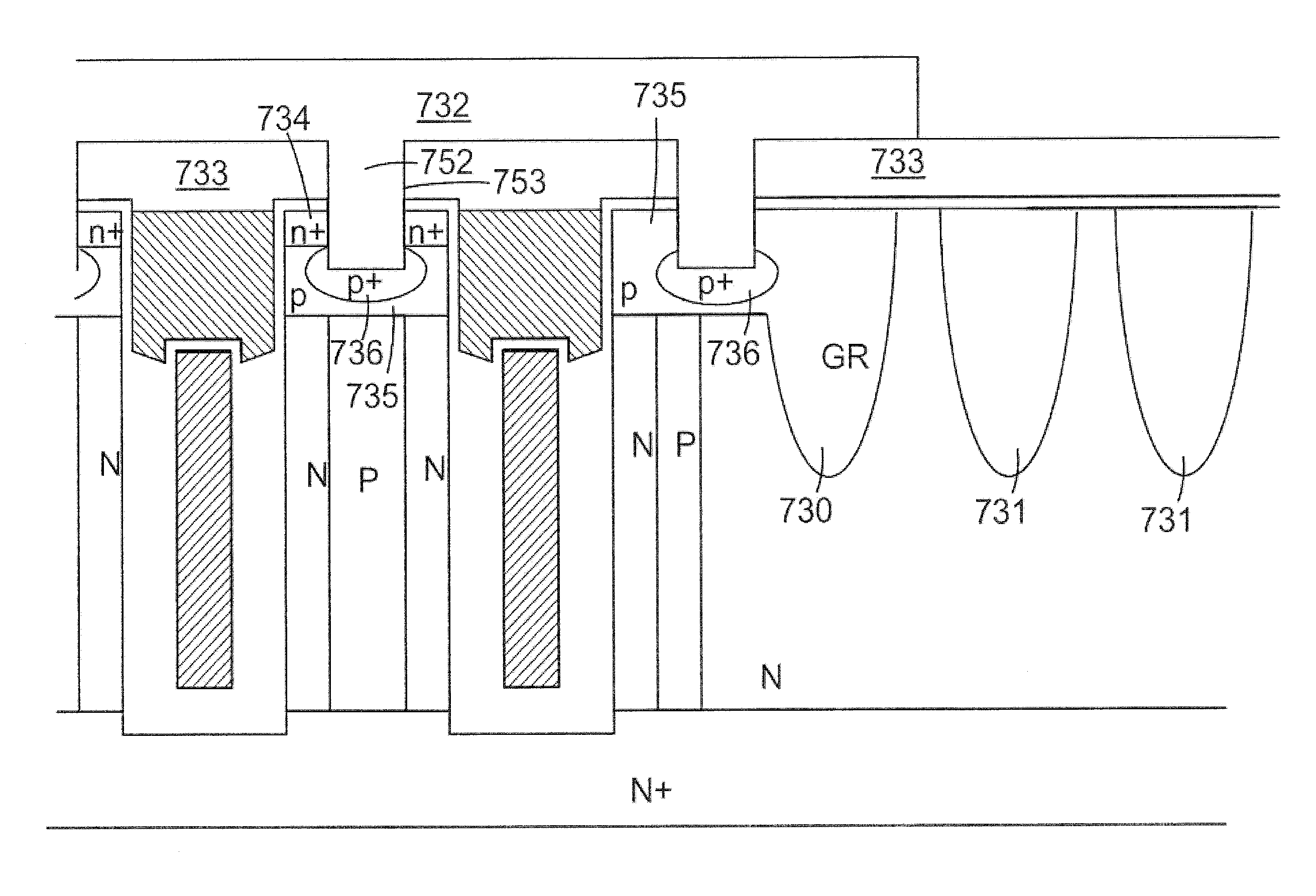

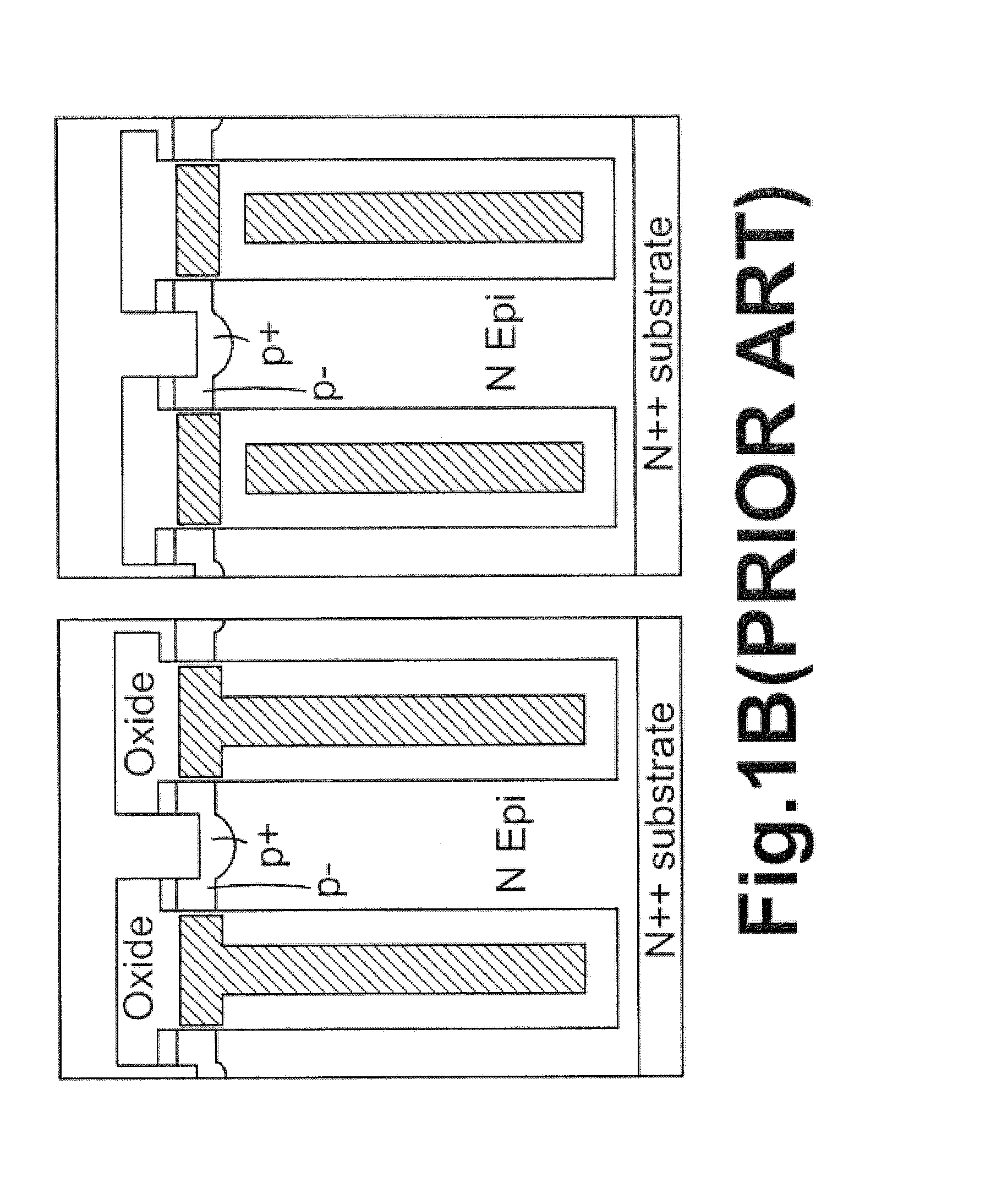

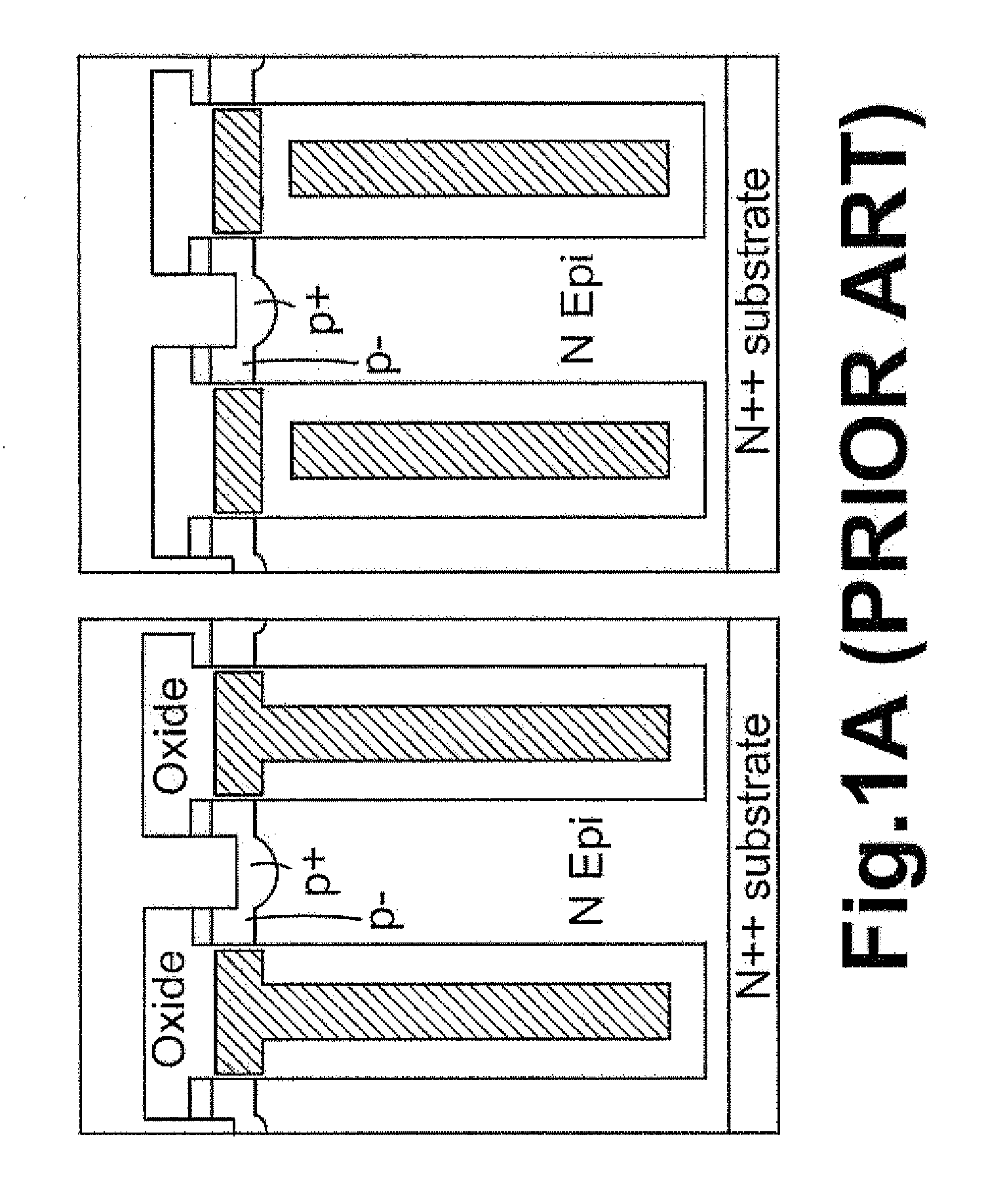

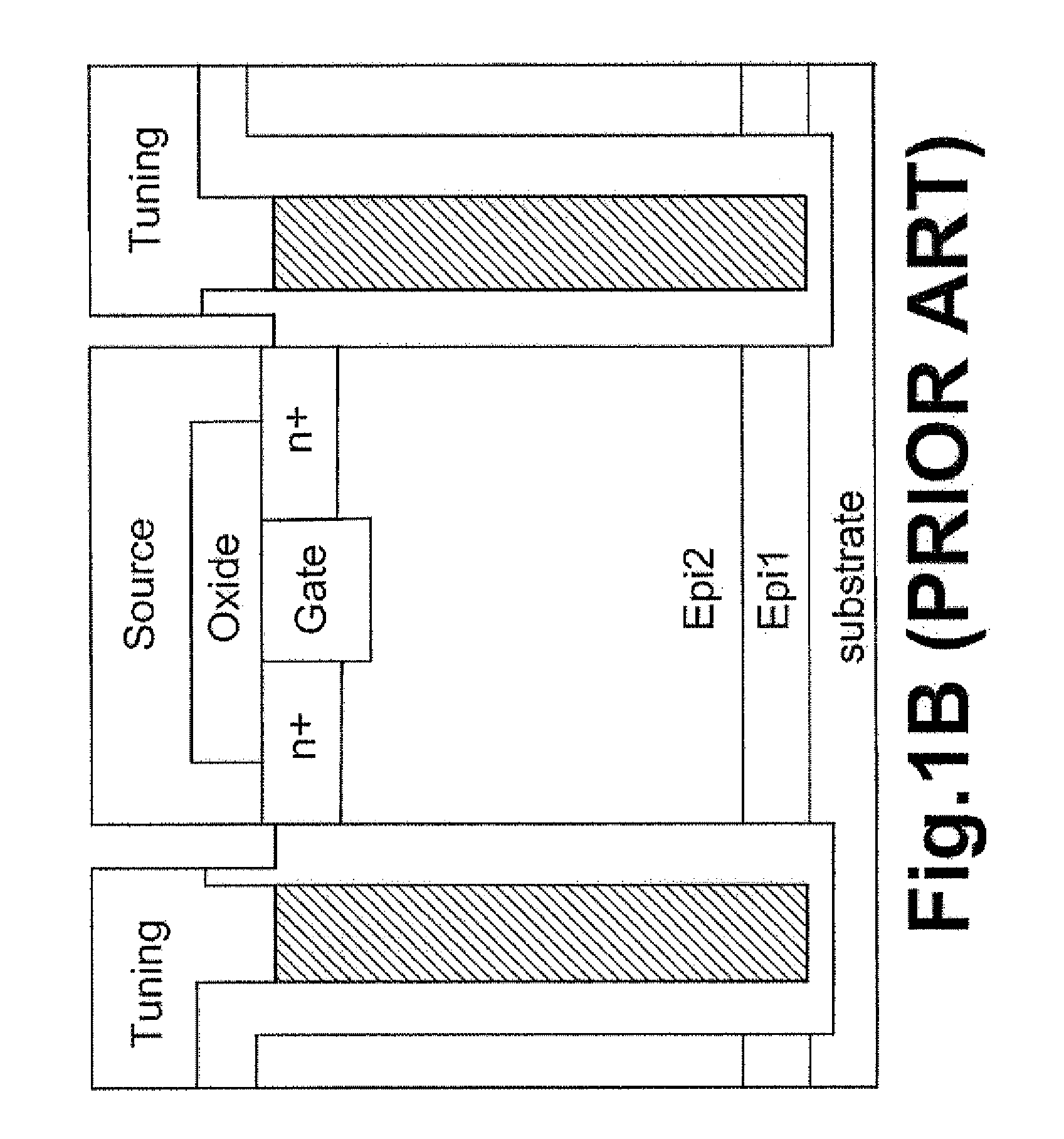

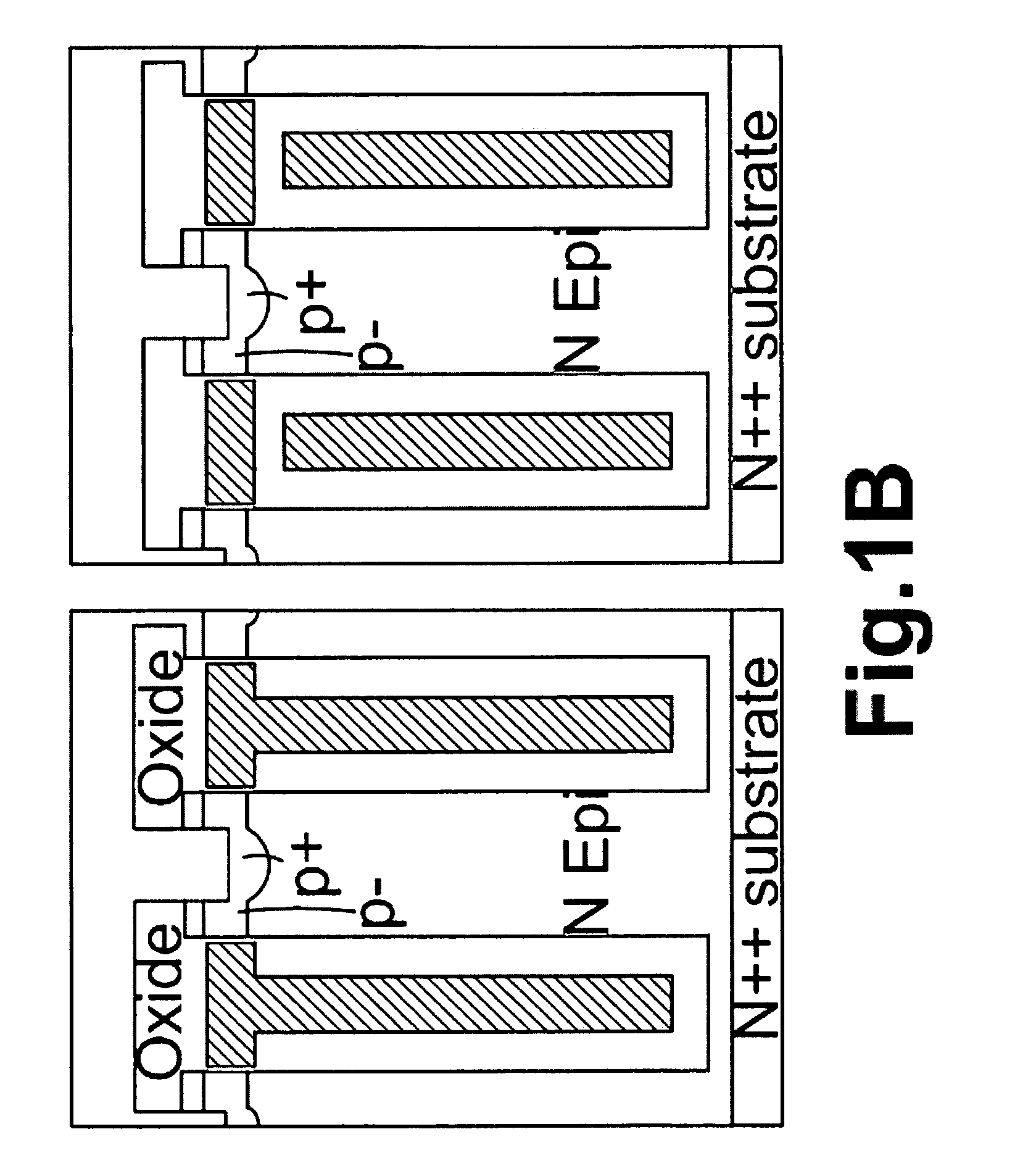

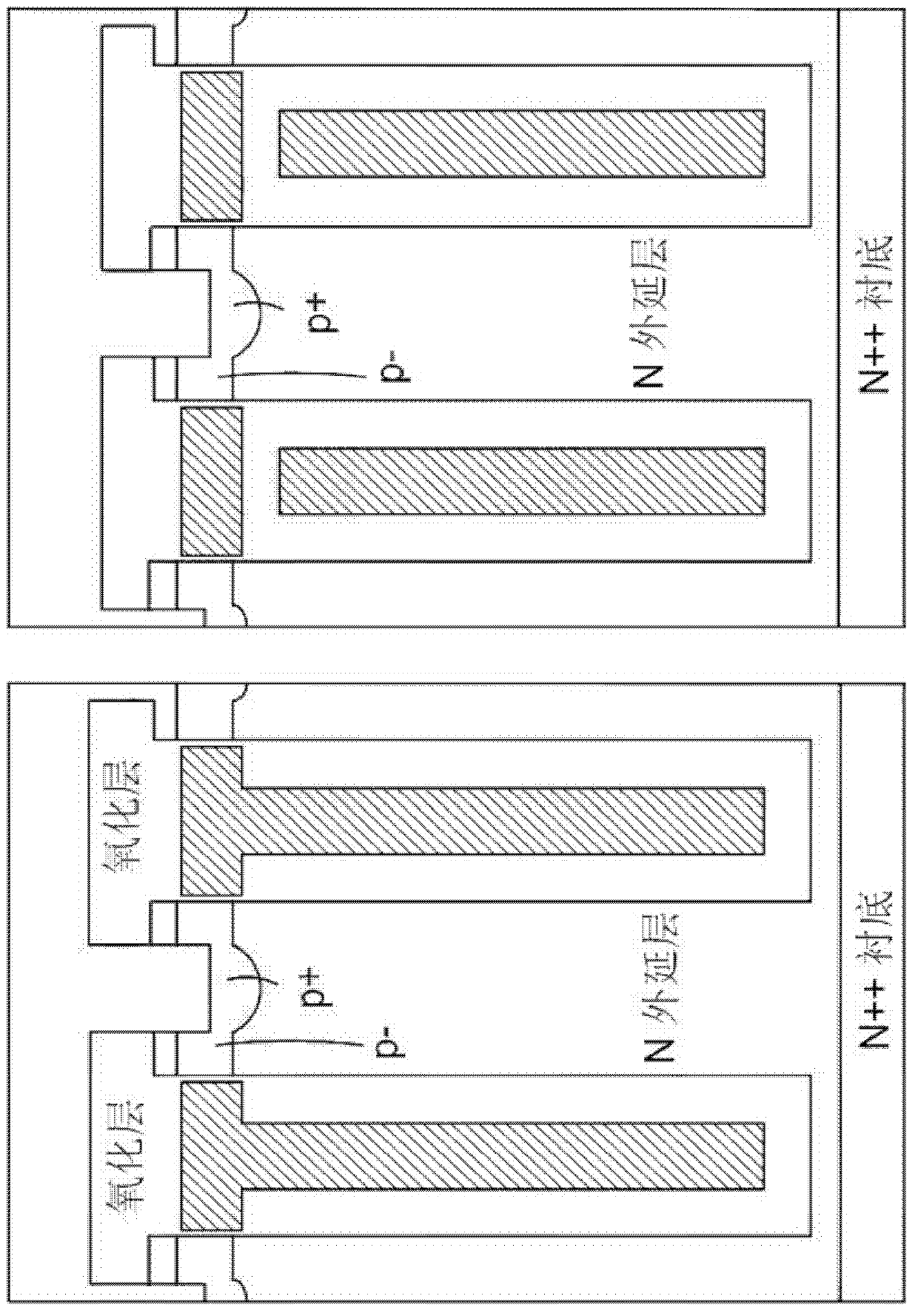

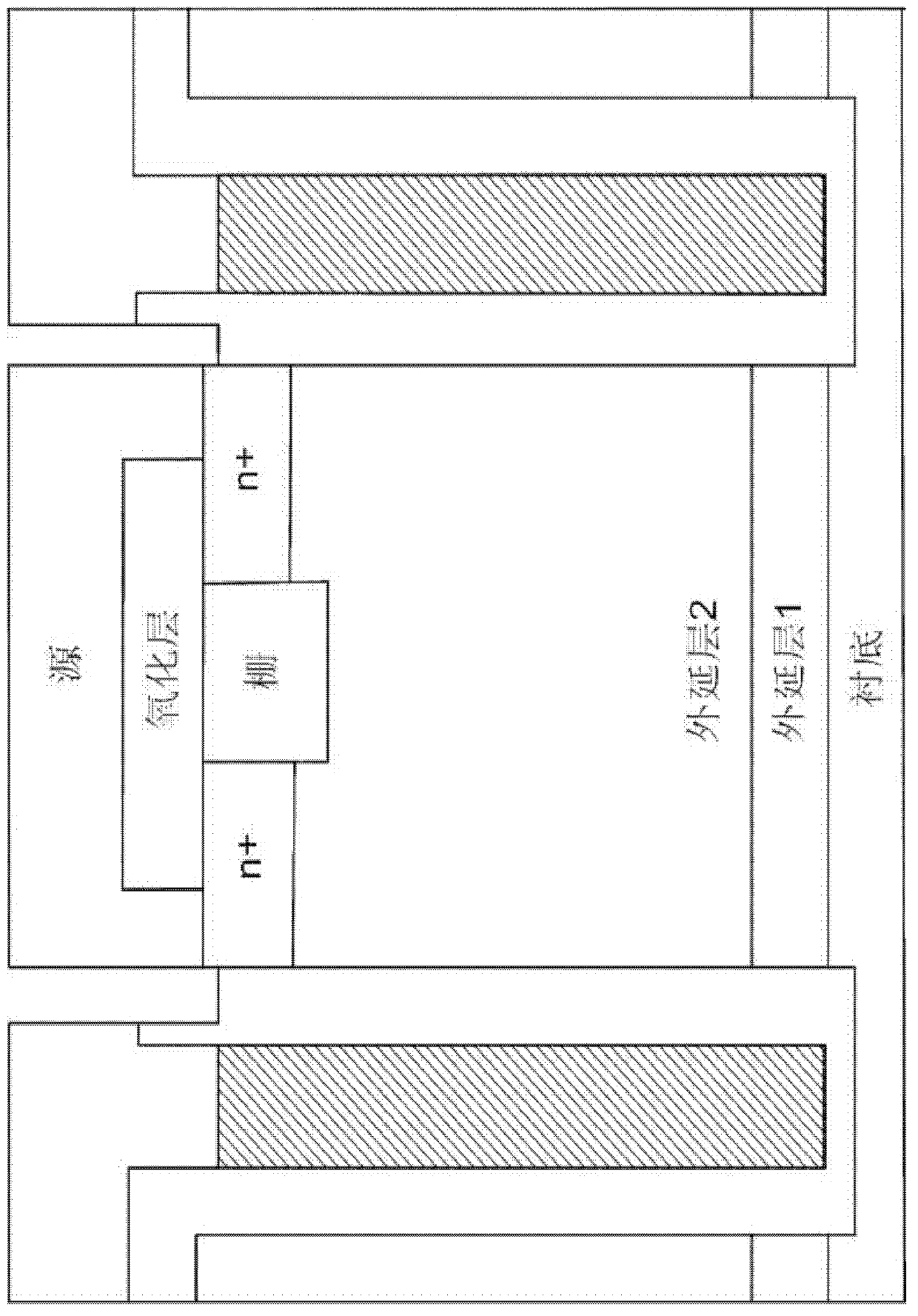

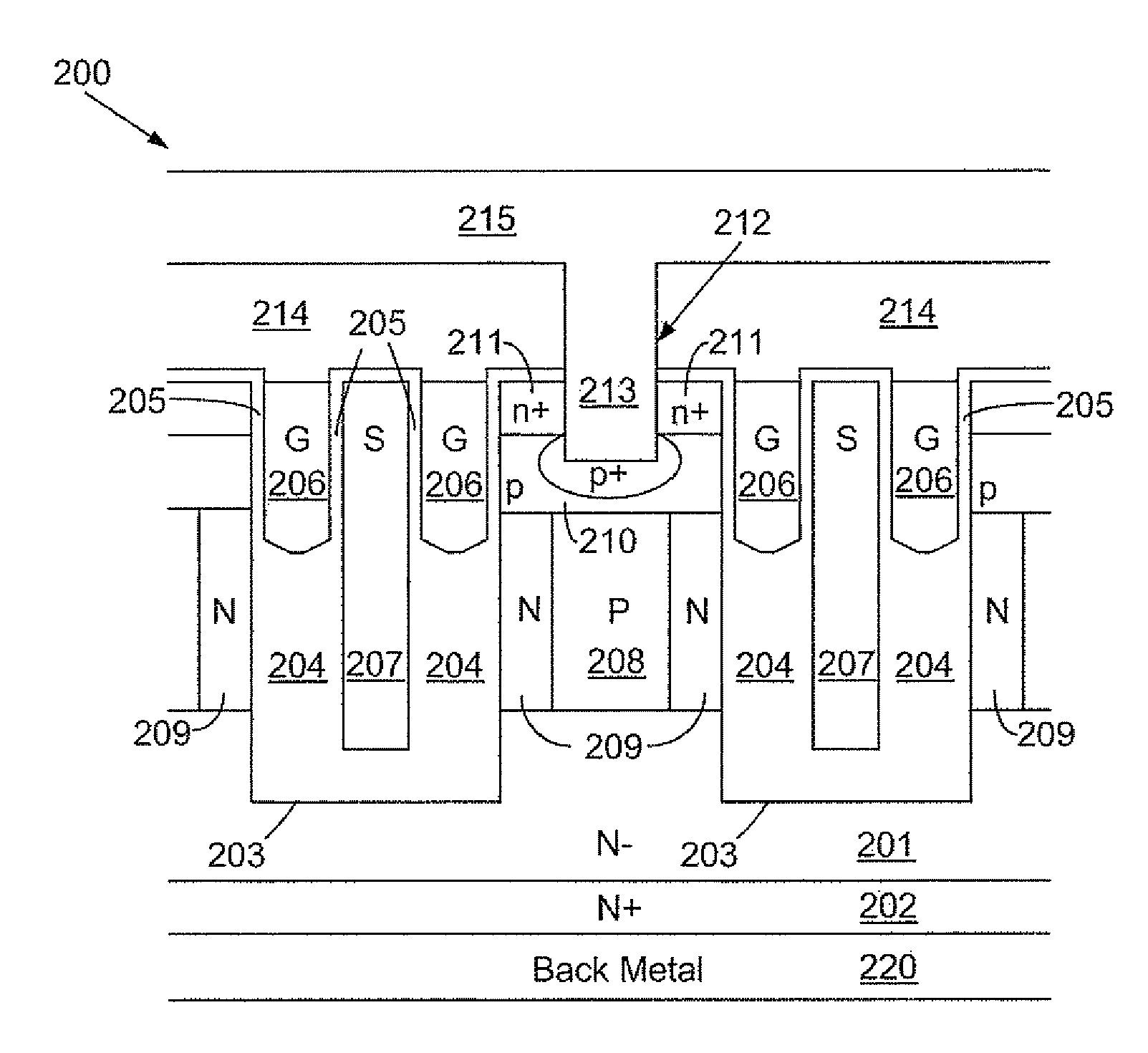

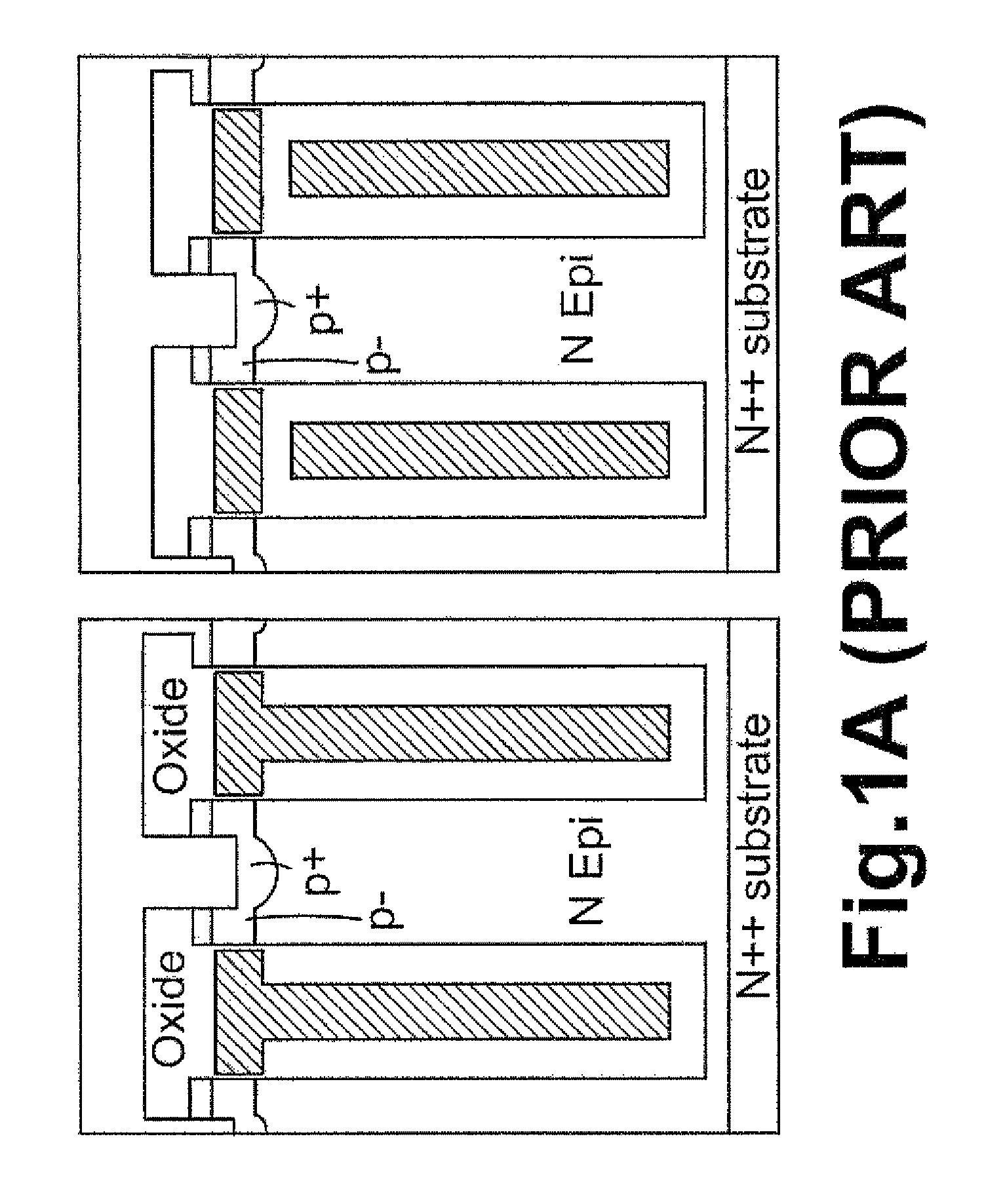

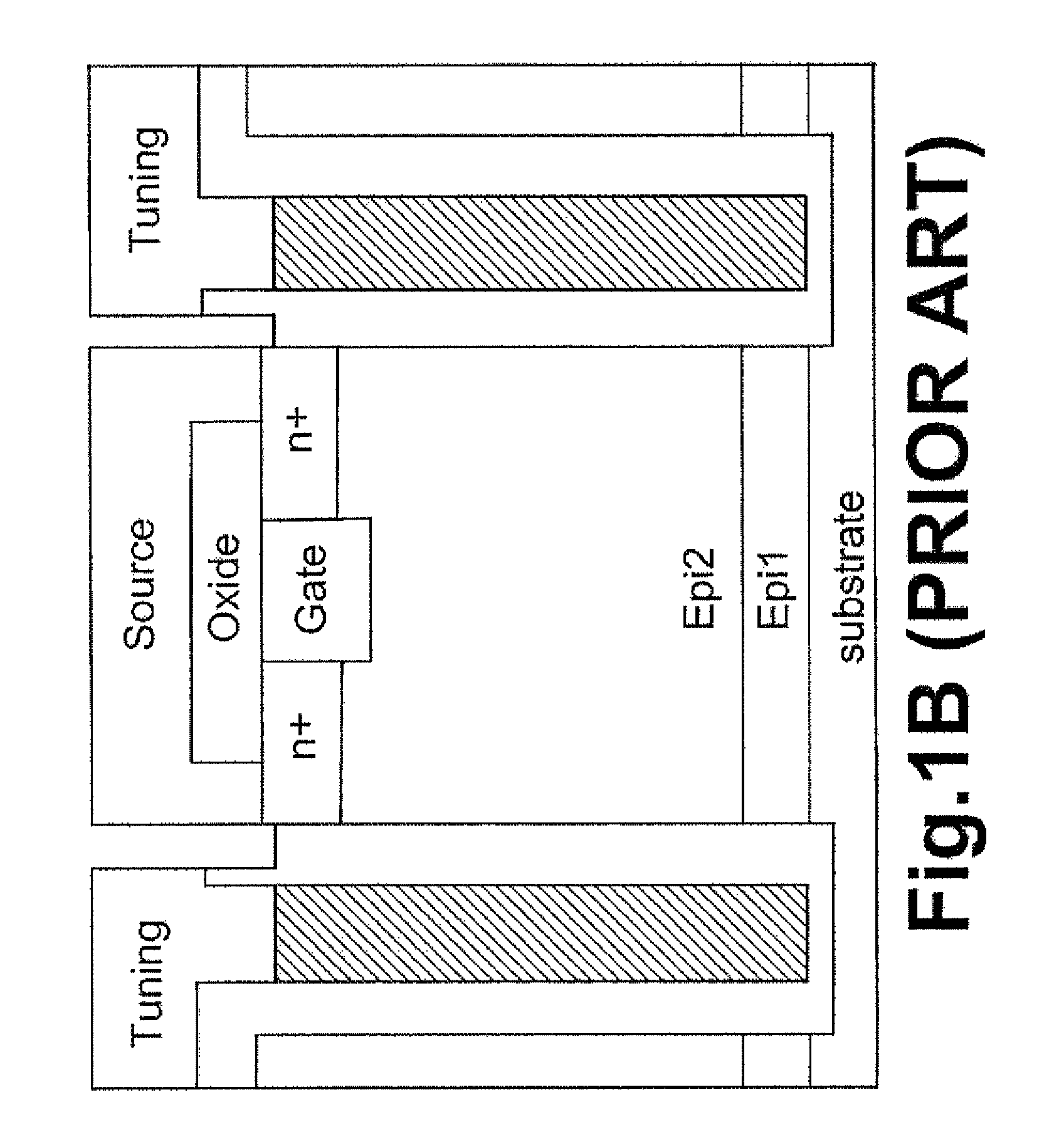

Super-junction trench mosfet with resurf stepped oxides and trenched contacts

ActiveUS20120074489A1Good performance optimizationGood manufacturing capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

A super-junction trench MOSFET with Resurf Stepped Oxide and trenched contacts is disclosed. The inventive structure can apply additional freedom for better optimization and manufacturing capability by tuning thick oxide thickness to minimize influence of charge imbalance, trapped charges, etc. . . . Furthermore, the fabrication method can be implemented more reliably with lower cost.

Owner:FORCE MOS TECH CO LTD

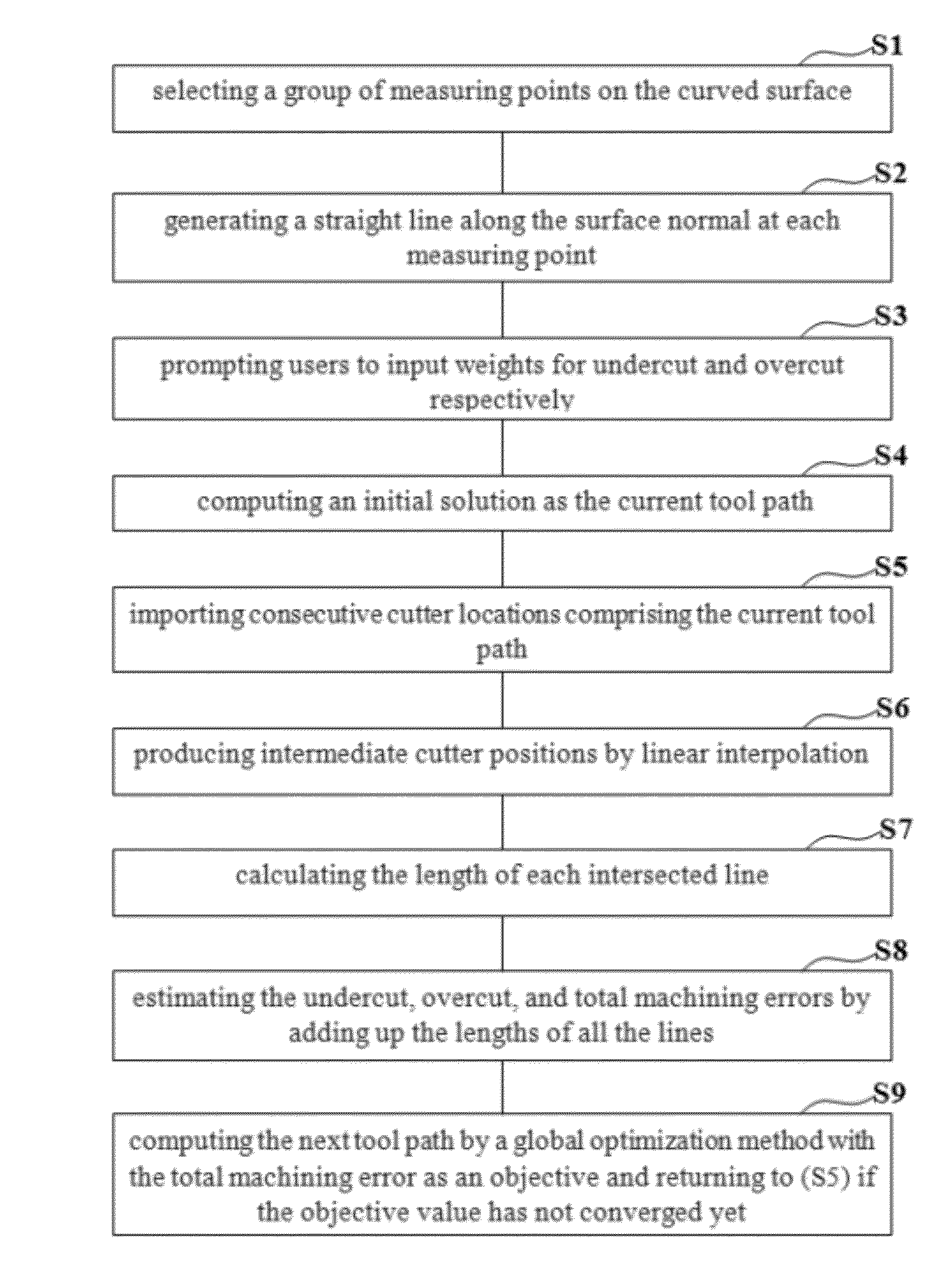

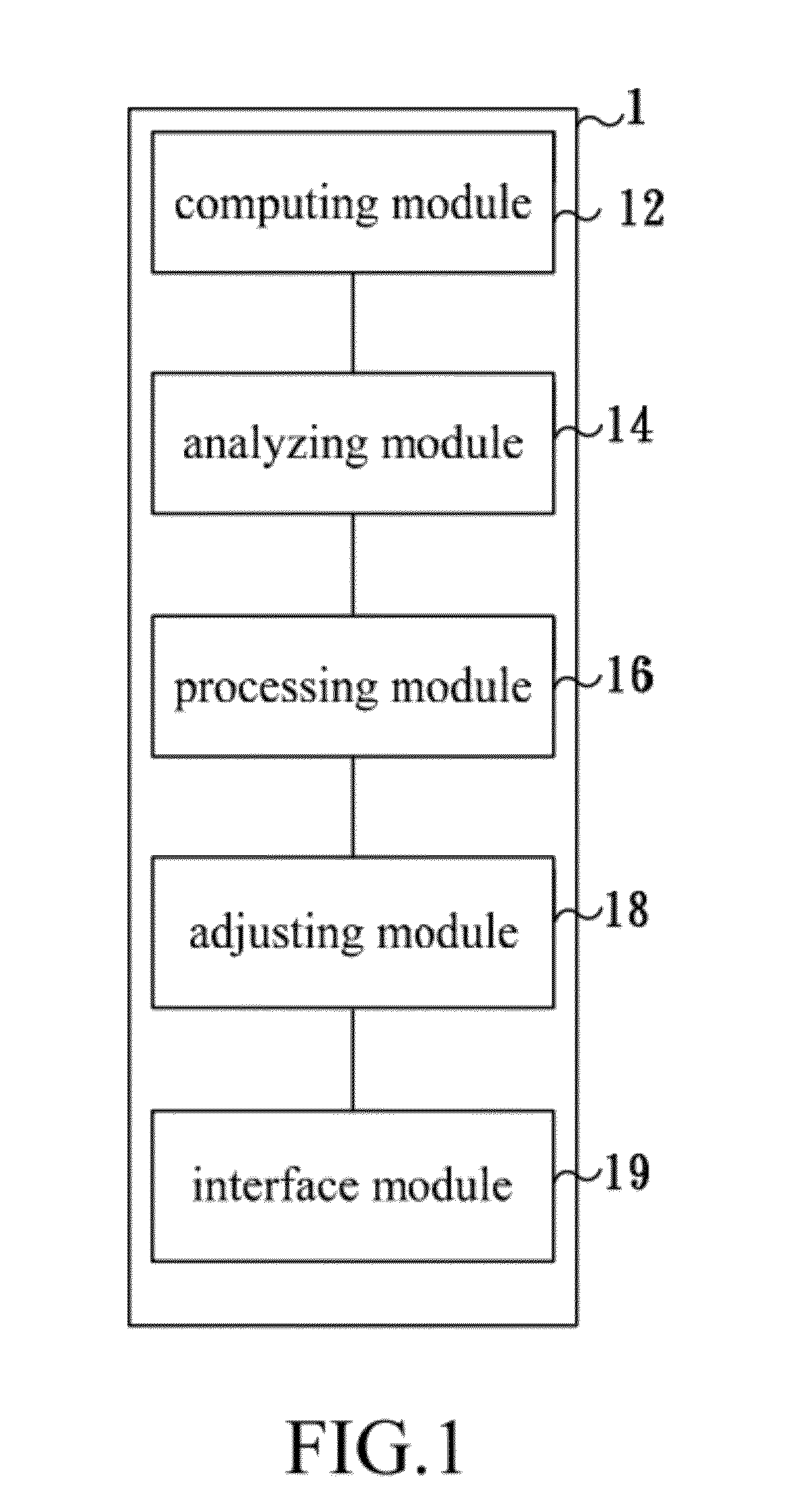

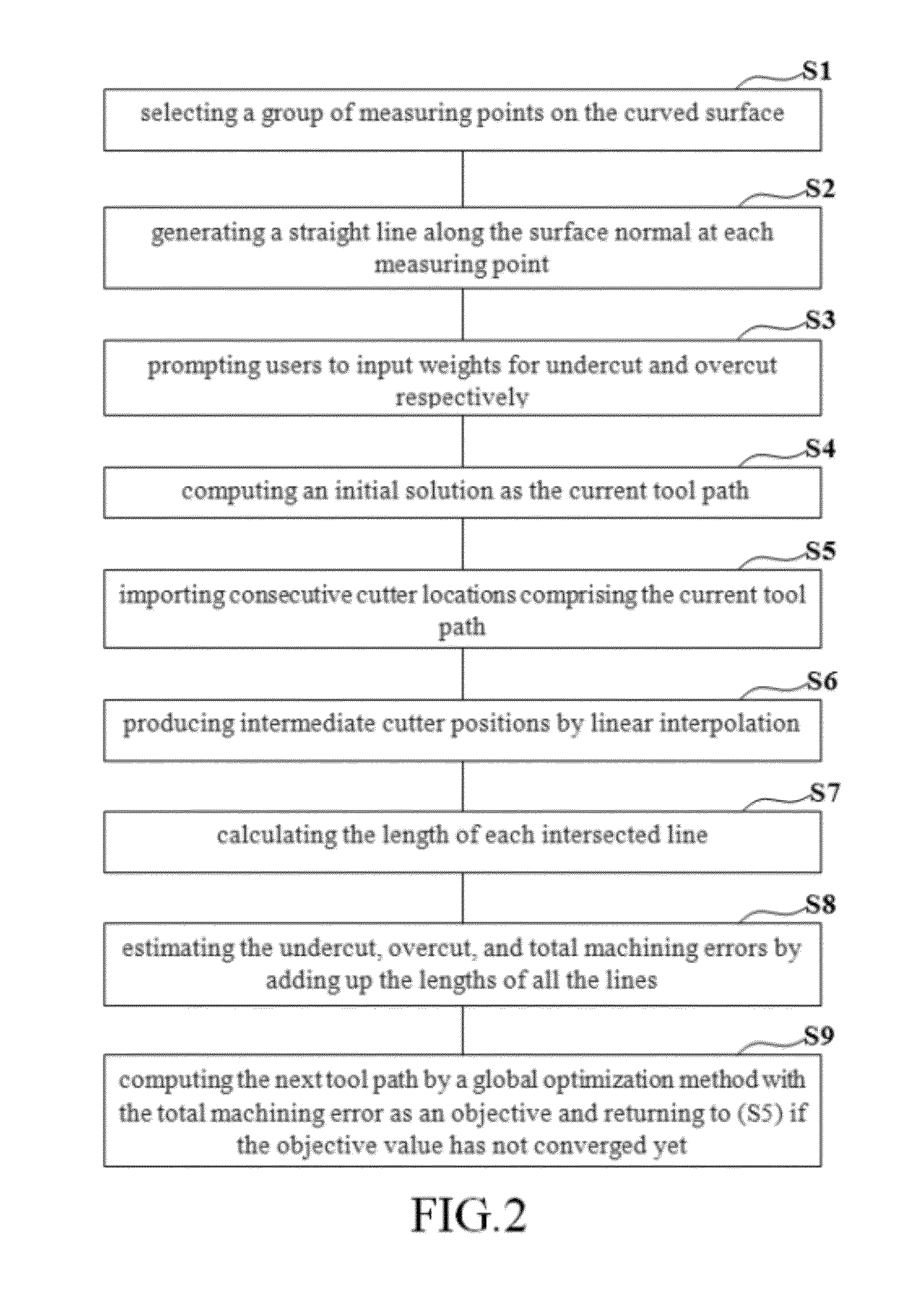

Five-axis flank milling system for machining curved surface and the tool-path planning method thereof

InactiveUS20120265331A1Error minimizationProgramme controlComputer aided designCutter locationPlanning method

The invention discloses a five-axis flank milling system for machining curved surface and the method thereof, the system is capable of generating a tool path that minimizes the undercut error, overcut error, or the total machining error. The amount of the overcut, undercut, or total machining errors can be precisely controlled by adjustment of the cutter locations contained in a tool path. This invention is to transform tool path planning in five-axis flank milling into an optimal matching problem. The proposed mechanism of the invention significantly improves the manufacturing capability of five-axis flank milling. It enhances the machining quality by reducing various machining errors and provides a systematic approach to precise control of machining error in five-axis flank milling.

Owner:NATIONAL TSING HUA UNIVERSITY

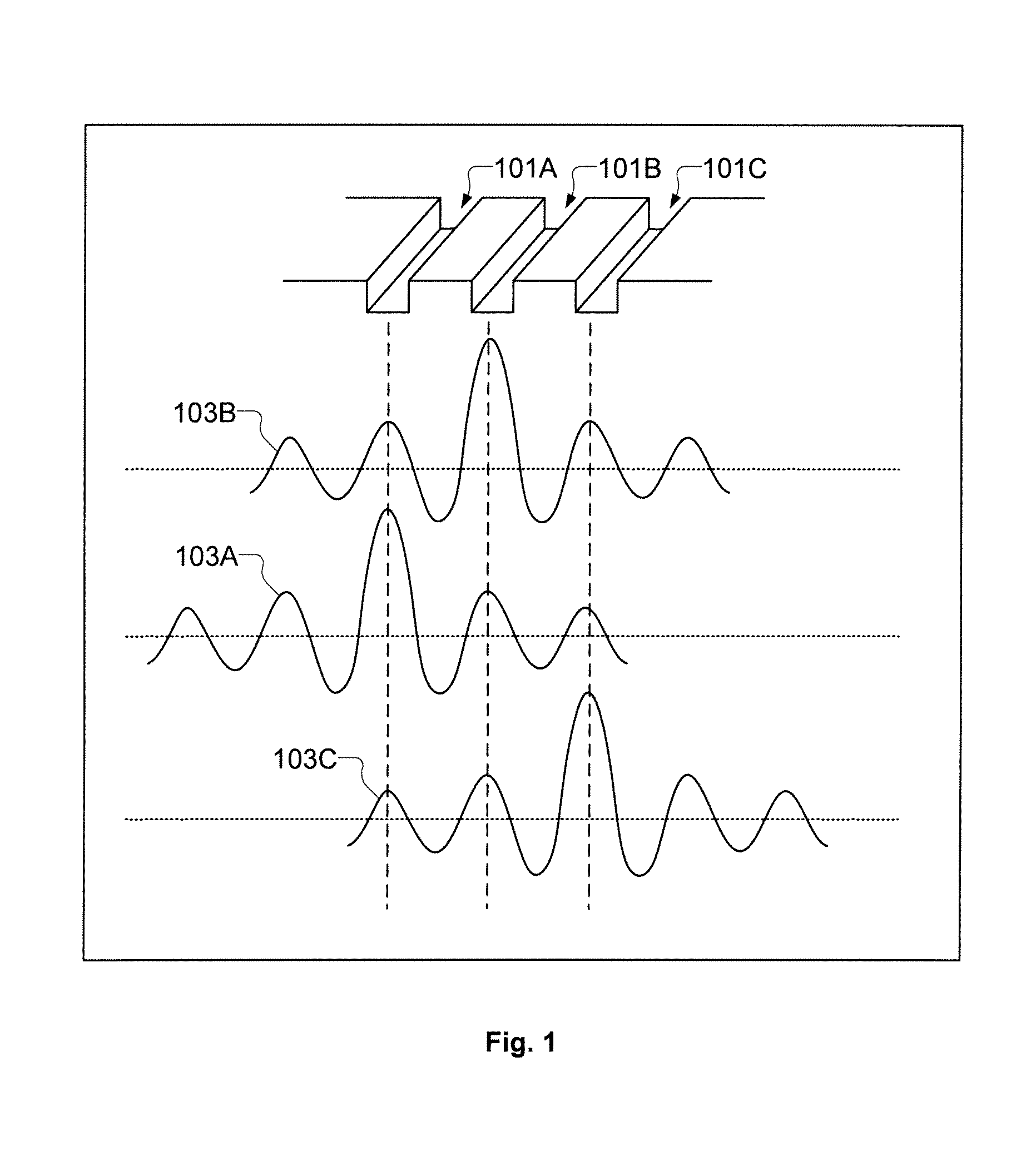

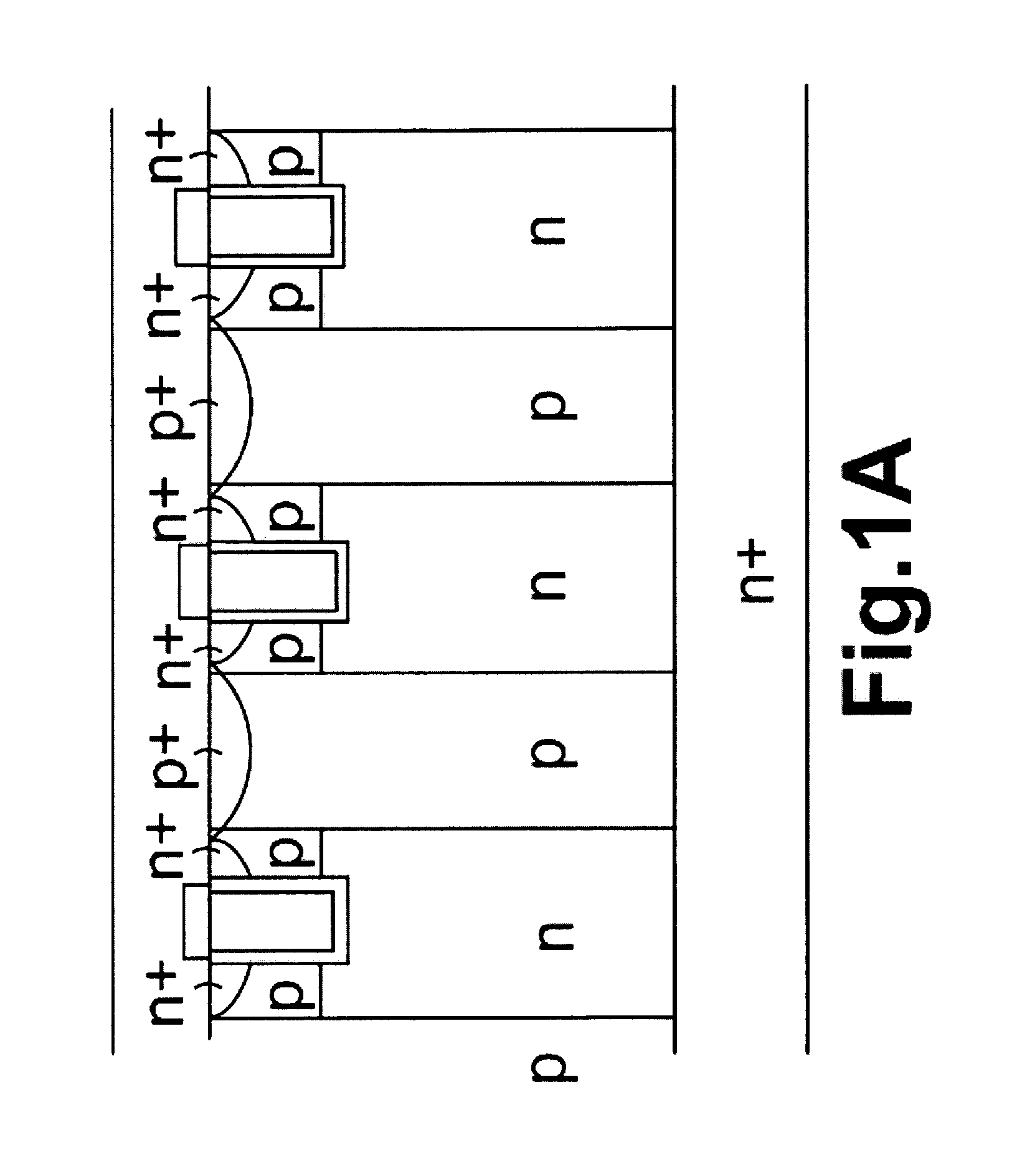

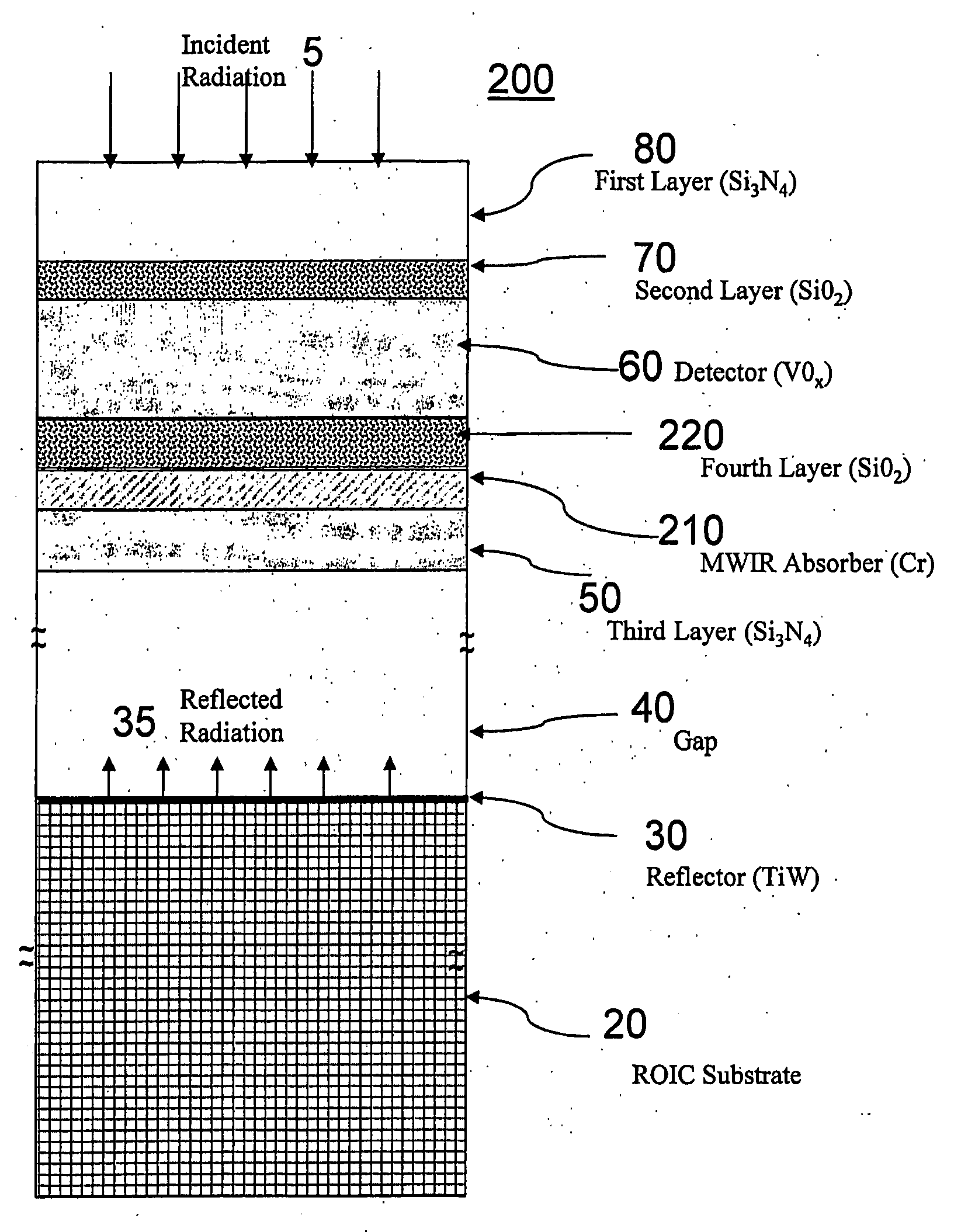

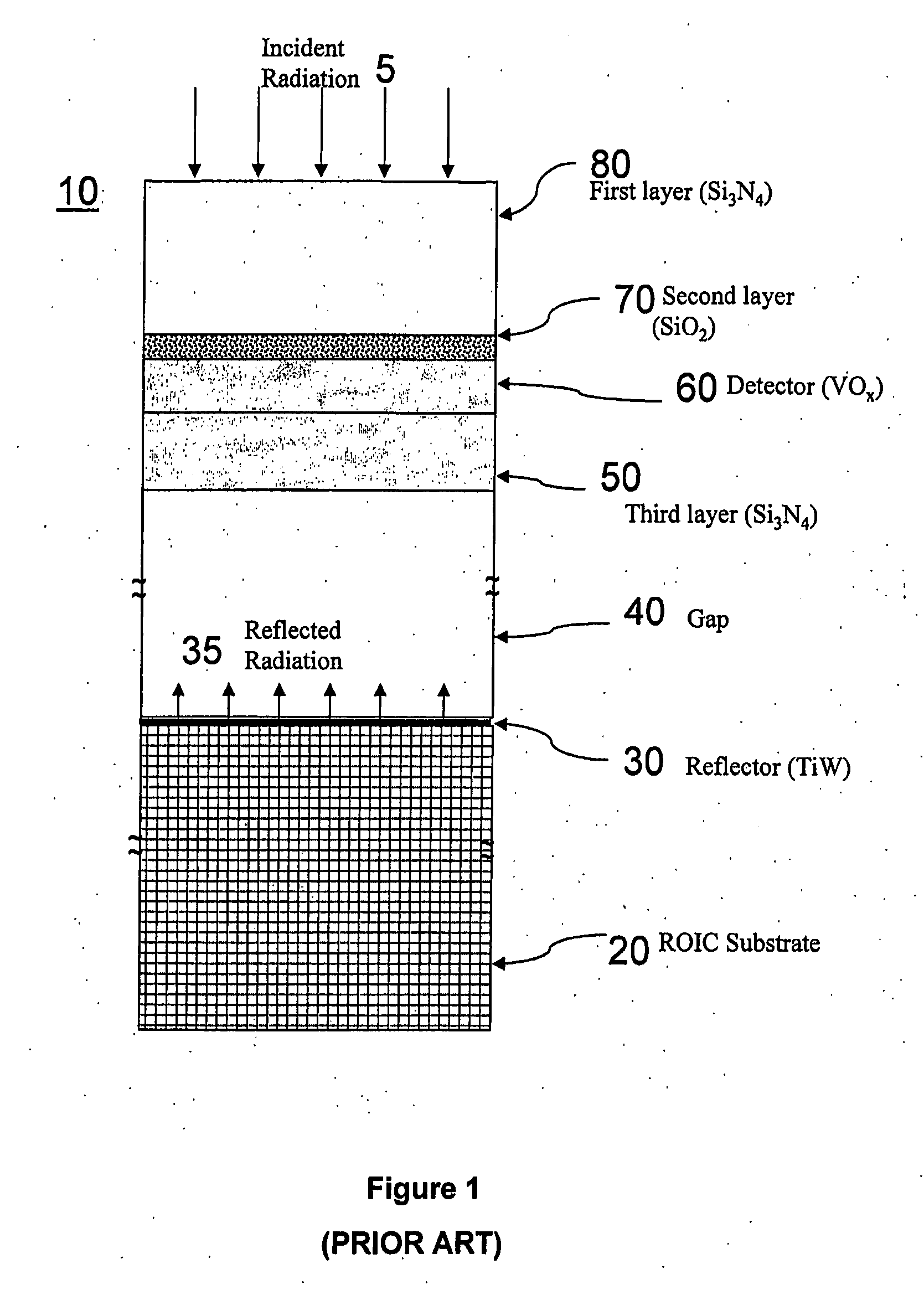

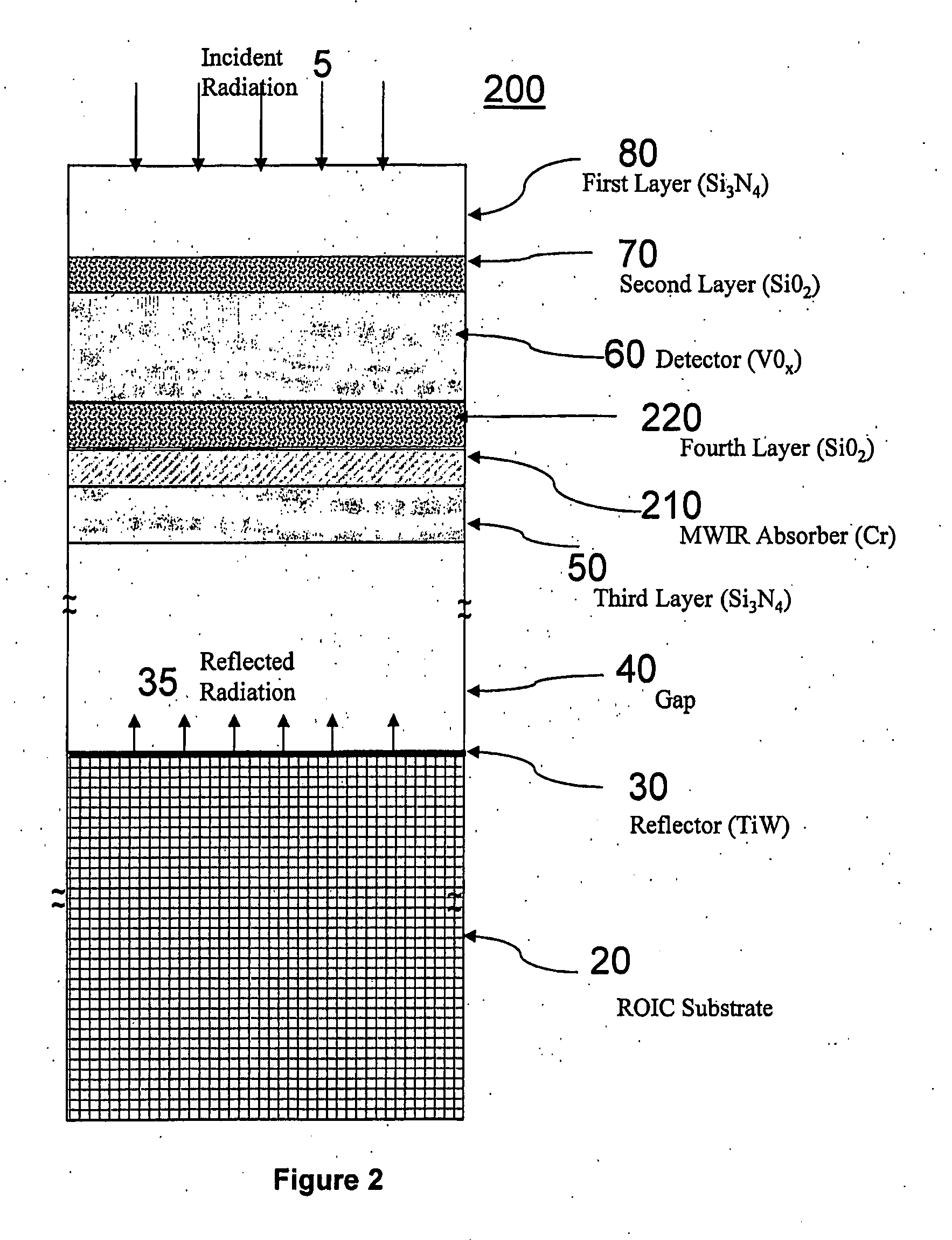

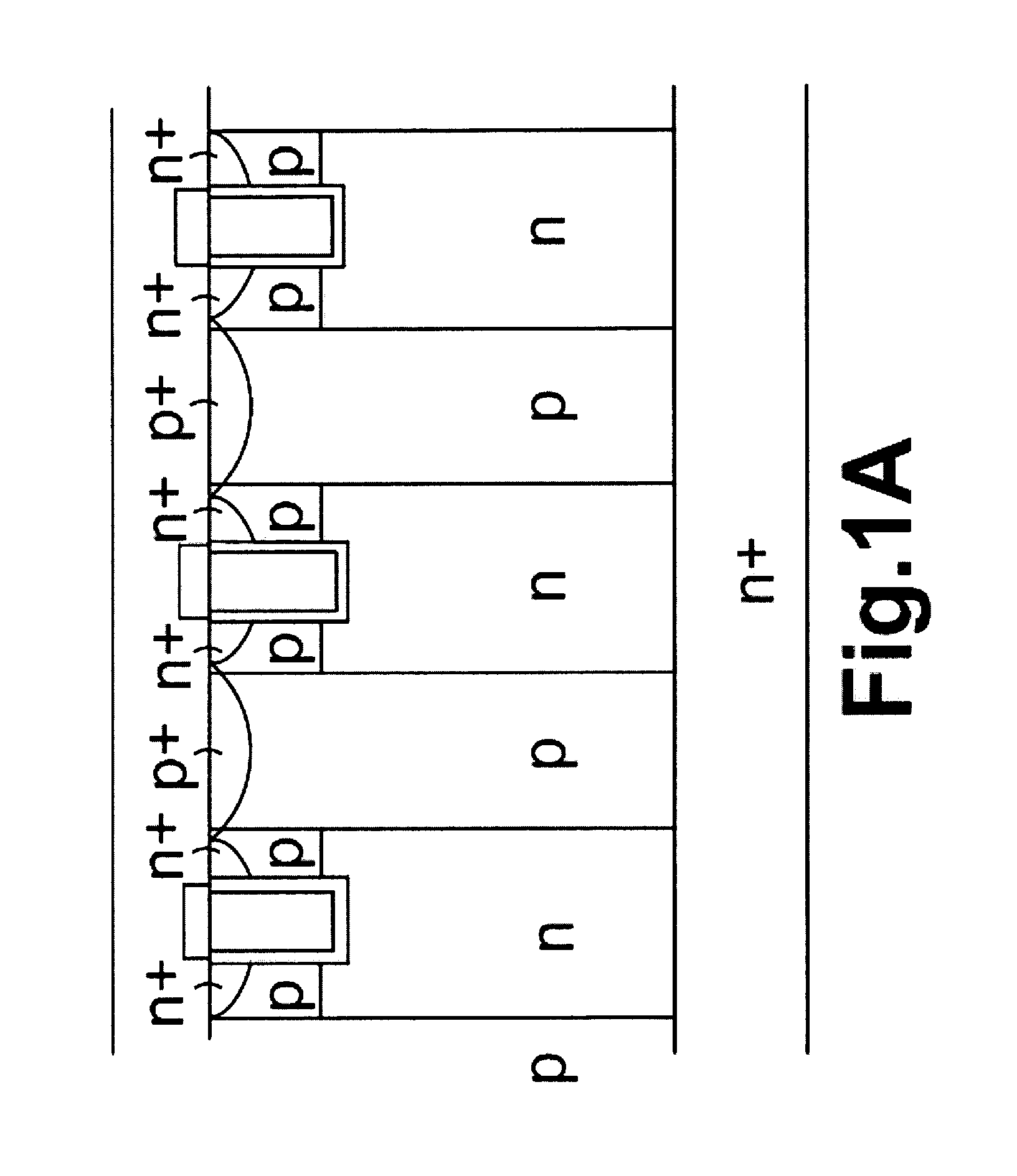

Multi-spectral uncooled microbolometer detectors

InactiveUS20070176104A1High sensitivitySpectrum investigationSolid-state devicesMicrobolometerWave band

A process and system for a medium wave infrared (MWIR) uncooled microbolometer focal plane array (FPA). One embodiment is for a single MWIR band uncooled IR detector, wherein the design and fabrication utilizes standard silicon processing techniques reducing manufacturing costs and preserving existing manufacturing capabilities. Another embodiment is a two color uncooled microbolometer IR detector providing broadband detection.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

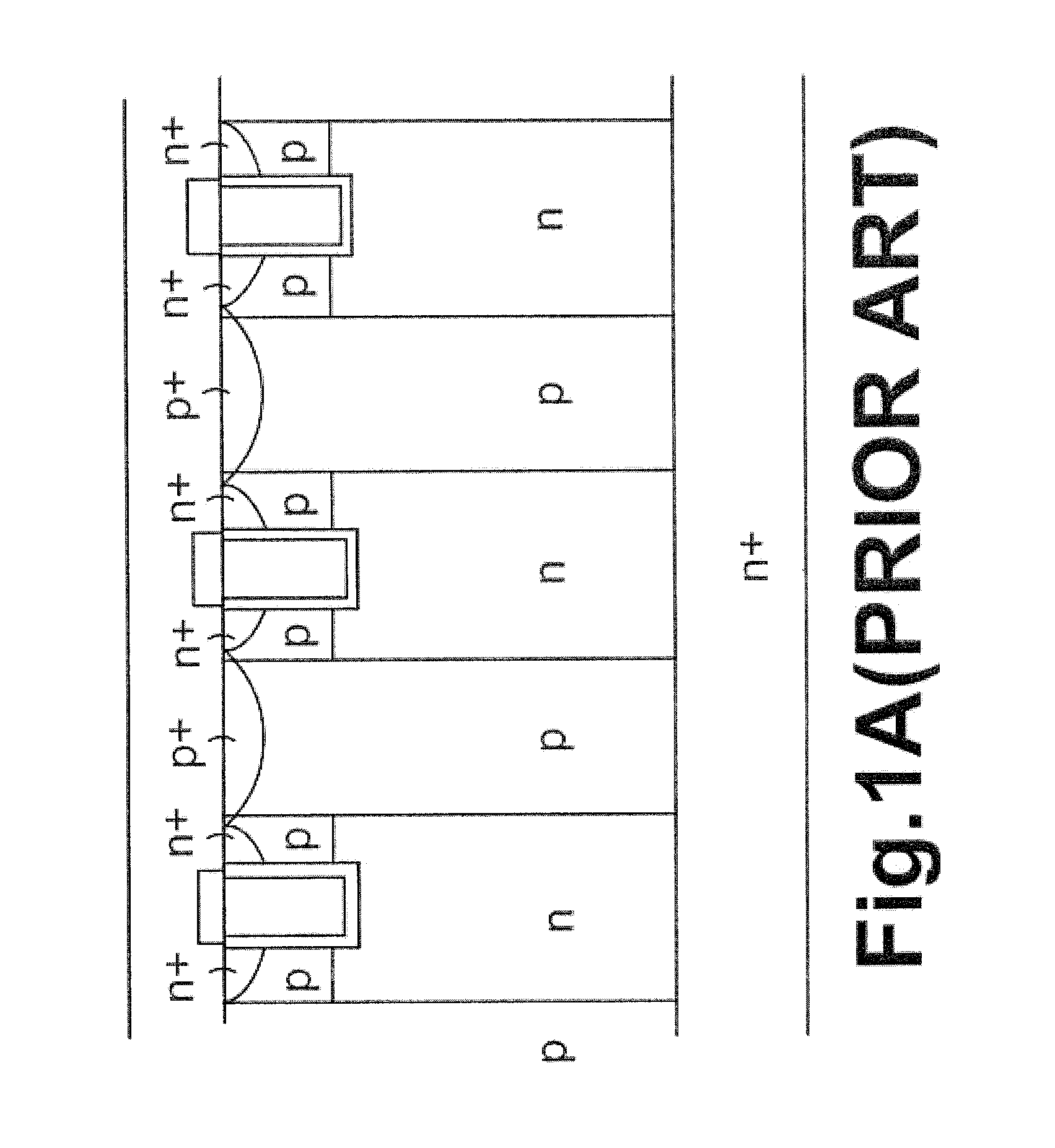

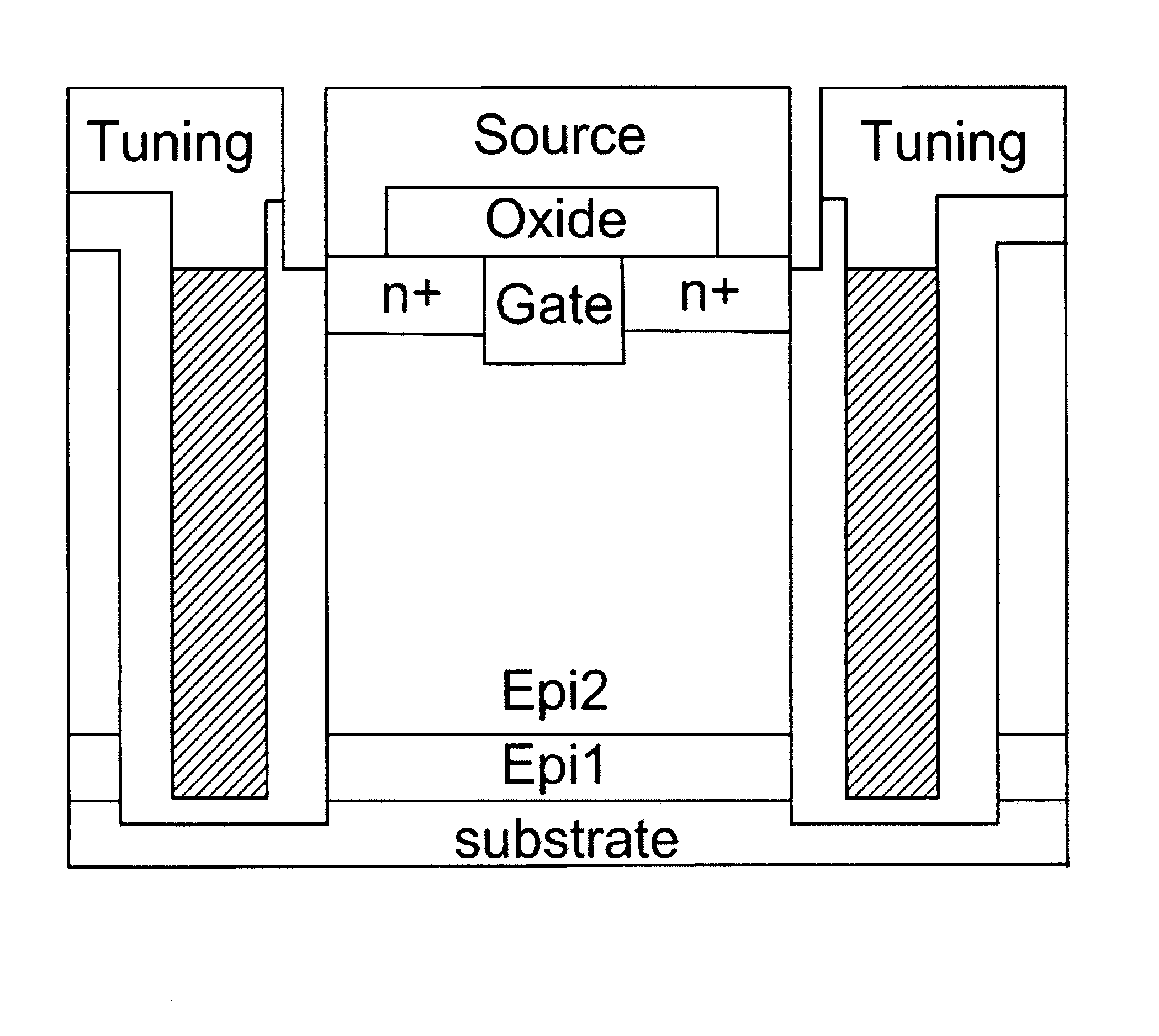

Super-junction trench mosfet with resurf stepped oxides and split gate electrodes

ActiveUS20120061754A1Good performance optimizationGood manufacturing capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetElectrical and Electronics engineering

A super-junction trench MOSFET with Resurf Stepped Oxide and split gate electrodes is disclosed. The inventive structure can apply additional freedom for better optimization of device performance and manufacturing capability by tuning thick oxide thickness to minimize influence of charge imbalance, trapped charges, etc. Furthermore, the fabrication method can be implemented more reliably with lower cost.

Owner:FORCE MOS TECH CO LTD

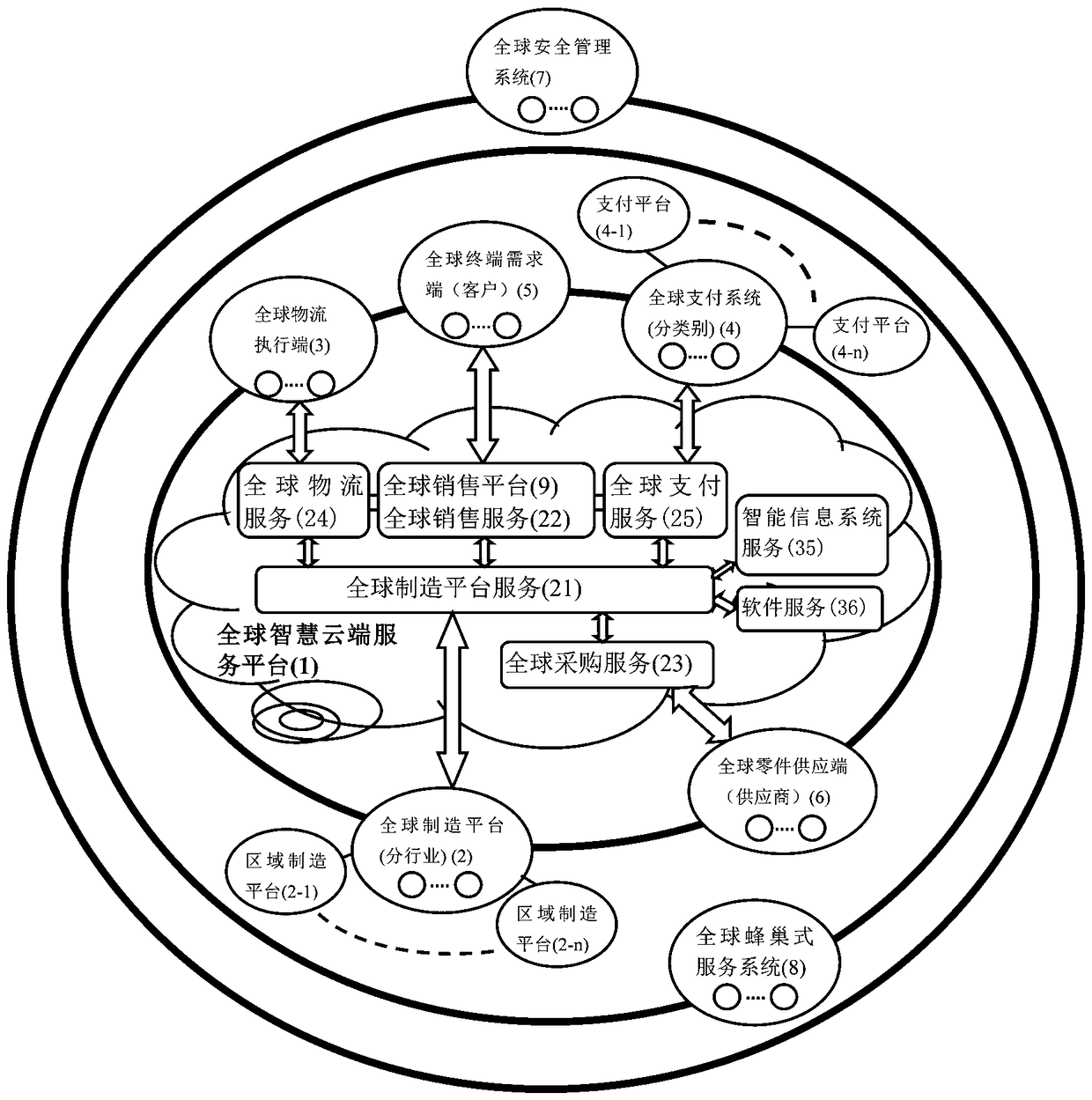

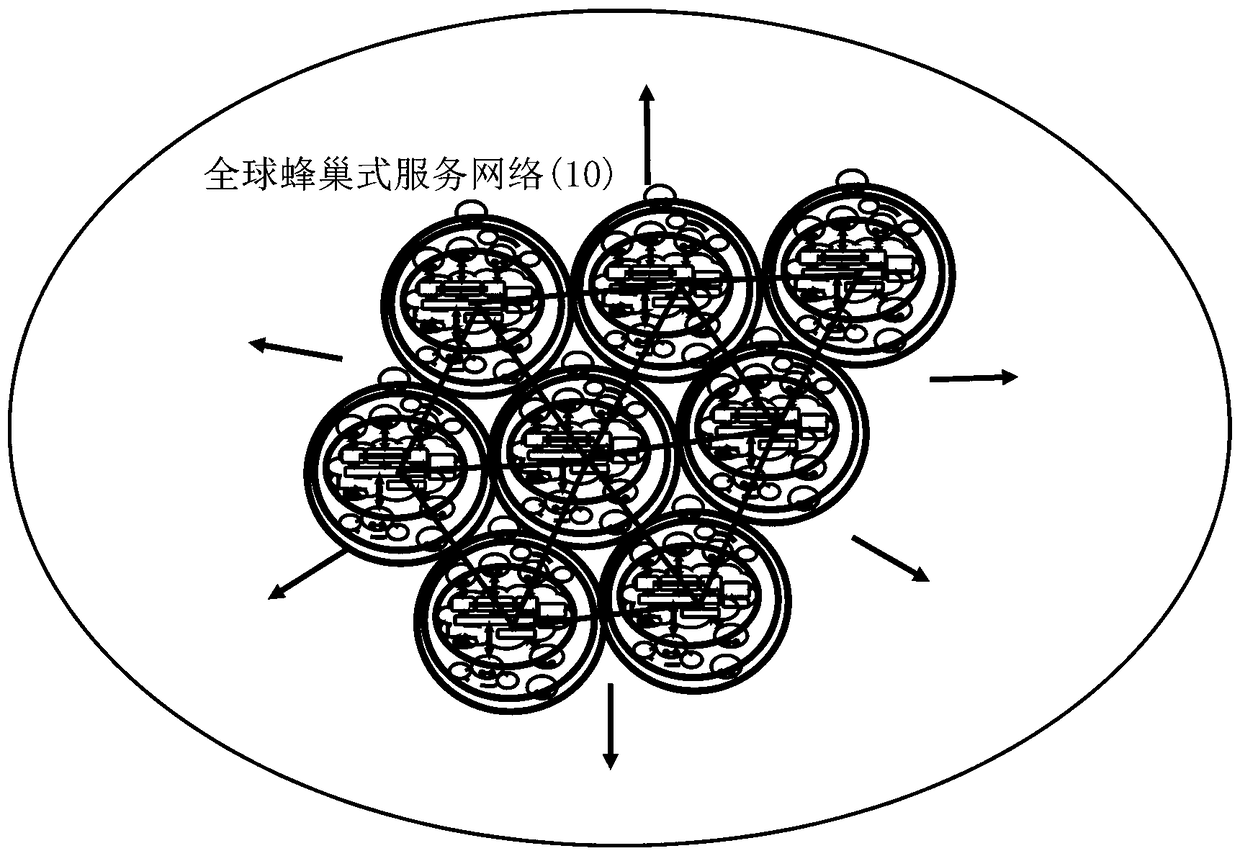

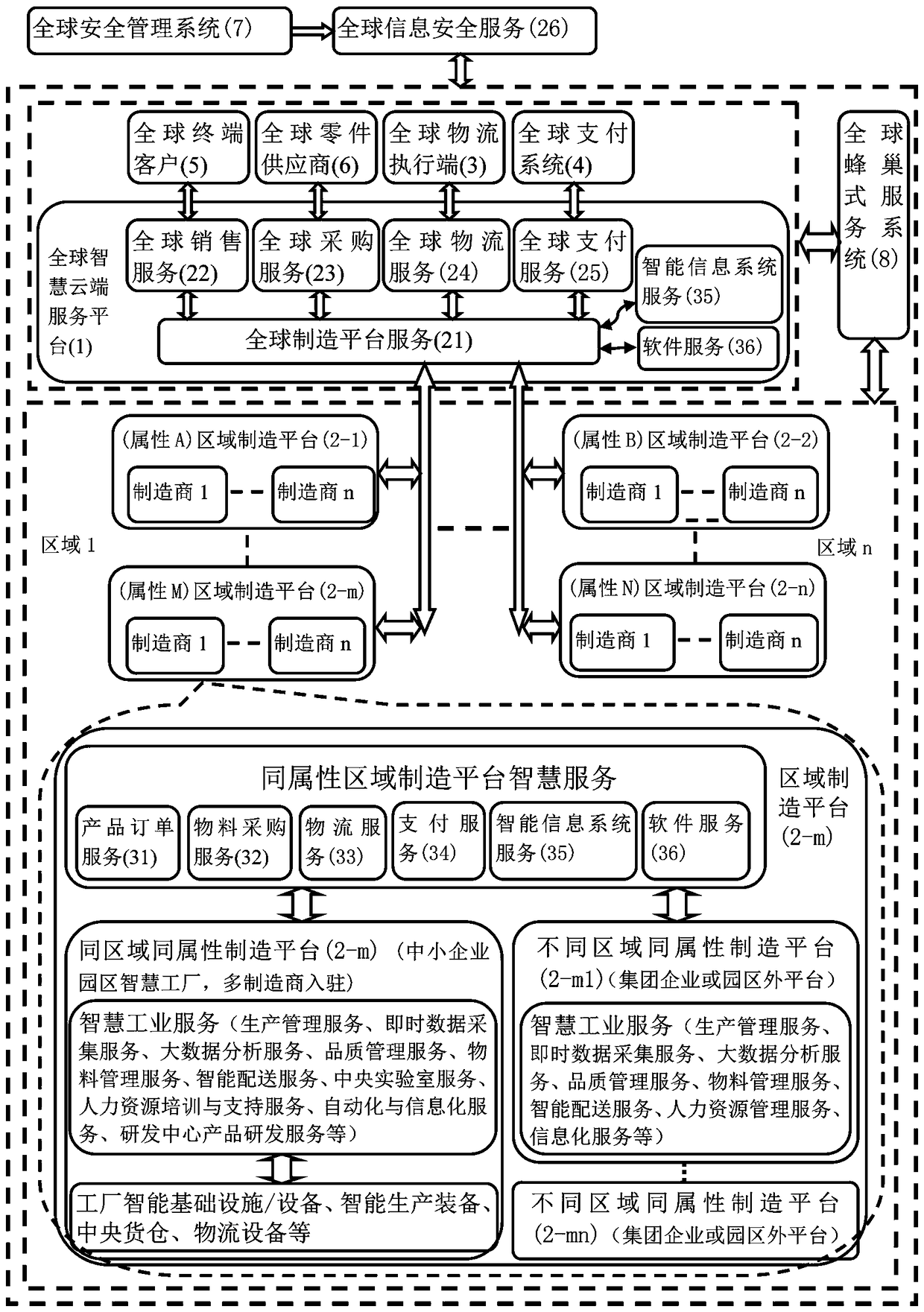

Global Smart Manufacturing Sales Service System

PendingCN109146372ALow costGuarantee product qualityOffice automationBuying/selling/leasing transactionsConfidentialityDigitization

The invention relates to a global smart manufacturing sales service system integrating information technology, Digital and intelligent global purchasing, Payment, Intelligent Manufacturing, sales andlogistics distribution as one, enabling Global Power, Small and medium-sized enterprises, making them available for global procurement, Global sales, Intelligent manufacturing capabilities, and improving global logistics and distribution, efficiency of global payments. At the same time, in order to ensure the independence of enterprise operation information, based on confidentiality and security,global enterprises can share the experience of intelligent manufacturing, continuously improve product quality, Reduce operating costs, deep integration of end customers and manufacturers can also beachieved, on the basis of big data analysis, the global enterprises can adjust their business decisions in real time, and can accurately push the product information to the customers to improve customer satisfaction and shopping experience, which greatly improves the efficiency of the supply chain, reduces the purchase cost of end-user products, and reduces the operating costs of enterprises, andhas great social benefits.

Owner:福建宏泰智能工业互联网有限公司

Super-Junction trench mosfet with resurf step oxide and the method to make the same

ActiveUS20110156139A1Good performance optimizationGood manufacturing capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

A super-junction trench MOSFET with Resurf Stepped Oxide is disclosed. The inventive structure can apply additional freedom for better optimization and manufacturing capability by tuning thick oxide thickness to minimize influence of charge imbalance, trapped charges, etc. . . . . Furthermore, the fabrication method can be implemented more reliably with lower cost.

Owner:FORCE MOS TECH CO LTD

Silicon-containing composite bodies, and methods for making same

Composite bodies made by a silicon metal infiltration process that feature a metal phase in addition to any residual silicon phase. Not only does this give the composite material engineer greater flexibility in designing or tailoring the physical properties of the resulting composite material, but the infiltrant also can be engineered compositionally to have much diminished amounts of expansion upon solidification, thereby enhancing net-shape-making capabilities. These and other consequences of engineering the metal component of composite bodies made by silicon infiltration permit the fabrication of large structures of complex shape. Certain liquid-based preforming techniques are particularly well suited to the task, particularly where a high volumetric loading of the reinforcement component is desired.

Owner:II VI DELAWARE INC

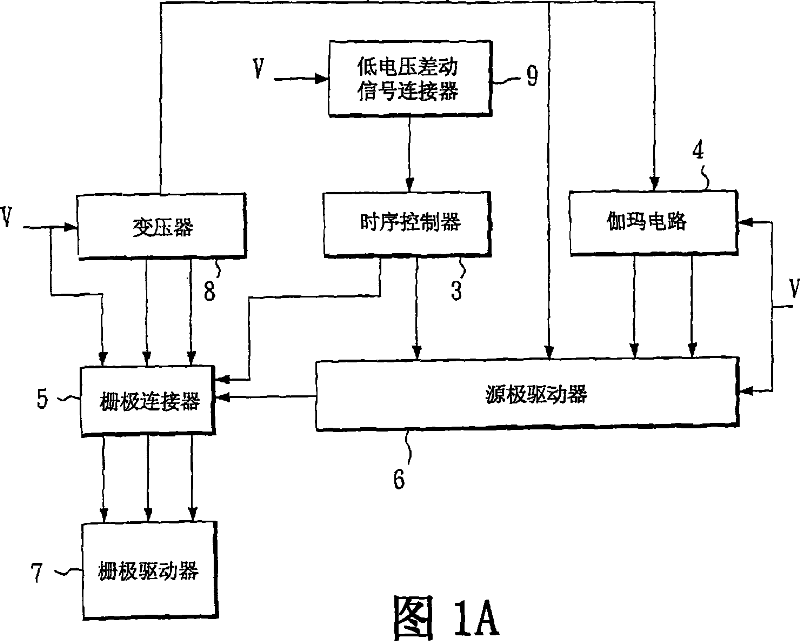

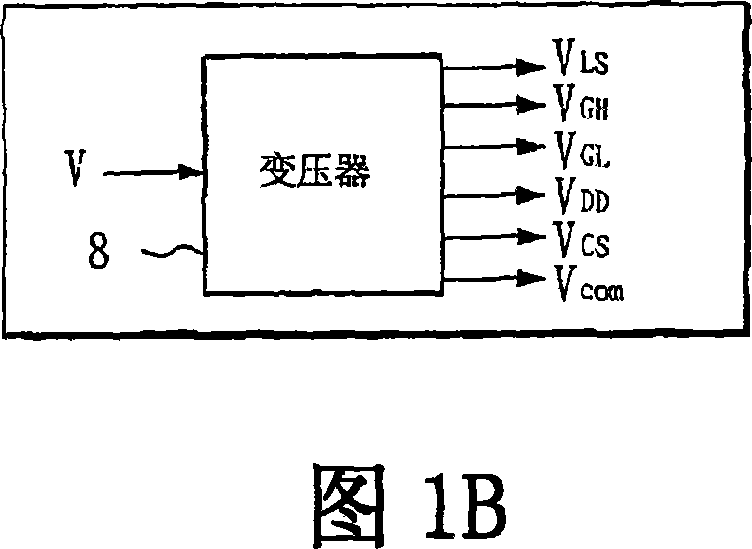

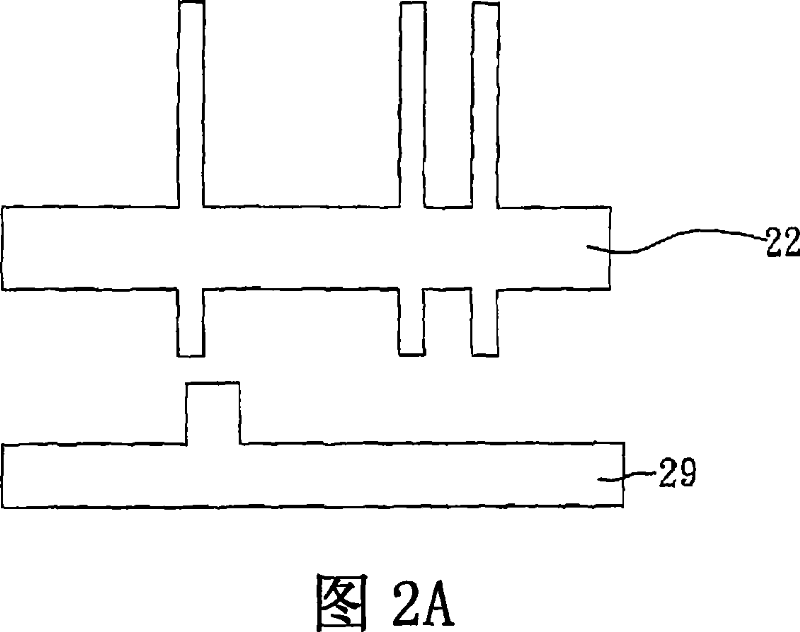

Liquid crystal display device and its driving method

InactiveCN101038716AImprove side light leakageReduce line widthStatic indicating devicesCapacitanceLiquid-crystal display

The invention provides a liquid crystal display driving system and a driving method thereof, the method comprises: supplying a special voltage to an auxiliary shade storage capacitor electrode plate on a liquid crystal display panel having an upper substrate, a lower substrate, and a liquid crystal layer; applying a common electrode voltage on a common electrode, and applying a special voltage to a storage capacitor so that a predetermined voltage difference is formed between the voltages of the auxiliary shade storage capacitor electrode plate and the common electrode, thereby improving side light-leakage of the liquid crystal display, increasing manufacturing ability when the upper substrate and the lower substrate are assembled, and reducing a line width of an upper substrate black matrix shade sheet to increase an opening degree.

Owner:AU OPTRONICS CORP

Mosfet and the method to make the same

ActiveCN103137698AImprove performanceLow balanceSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETEngineering

The invention discloses a MOSFET of a super-junction trench having a function of reducing surface electric-field stepped oxide and a split grid structure. The inventive structure can apply additional freedom for better optimization and manufacturing capability by tuning thick oxide thickness to minimize influence of charge imbalance, trapped charges, etc. . . . . Furthermore, the fabrication method can be implemented more reliably with lower cost.

Owner:FORCE MOS TECH CO LTD

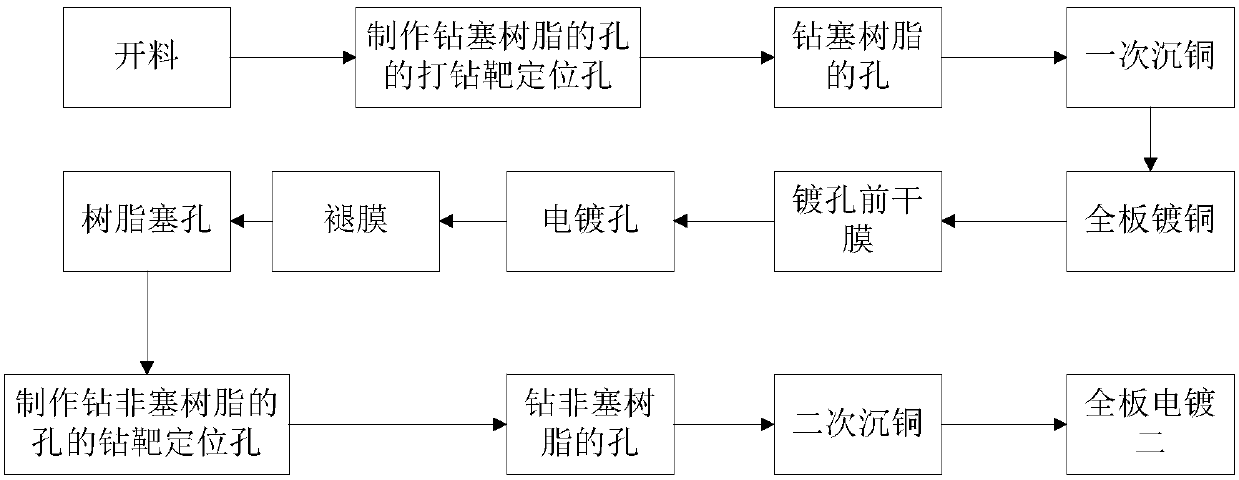

Manufacturing method of circuit board plated hole

InactiveCN107613671ASolve the phenomenon of uneven copper thicknessAvoid Etching AnomaliesPrinted element electric connection formationCopper platingProcess manufacturing

The invention discloses a manufacturing method of a circuit board plated hole. The manufacturing method comprises the following steps of material cutting, internal layer, inspection, pressing, manufacturing the drilling target locating hole for drilling the resin filling hole, drilling the resin filling hole, primary copper plating, whole plate copper plating, film drying before hole plating, holeelectroplating, film stripping, resin hole filling, resin grinding, manufacturing the drilling target locating hole for drilling the non-resin-filling hole, drilling the non-resin-filling hole, secondary copper plating and secondary whole plate electroplating. The method that the resin filling hole is completed and then the non-resin-filling hole and the external line are completed is adopted sothat the phenomenon of non-uniform copper thickness after whole plate copper thickening and chemical copper thinning can be successfully solved, the porthole pit abnormity of the resin filling hole after chemical copper thinning can be avoided, the manufacturing yield rate can be greatly enhanced, the process manufacturing capability can be powerfully enhanced and thus wide application and preference of the circuit board manufacturers can be received. The manufacturing method of the circuit board plated hole is widely suitable for the technical field of circuit board production.

Owner:深圳明阳电路科技股份有限公司

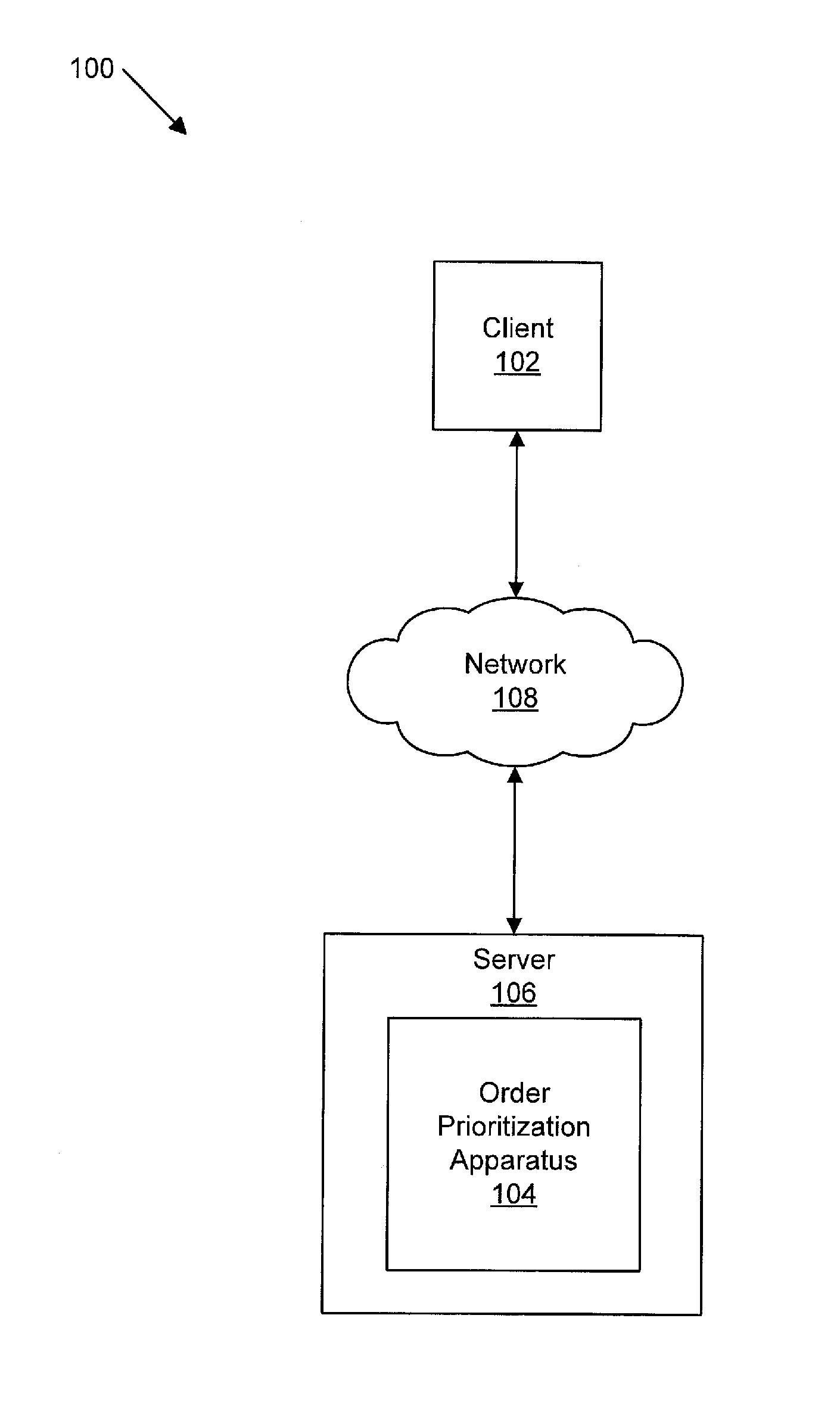

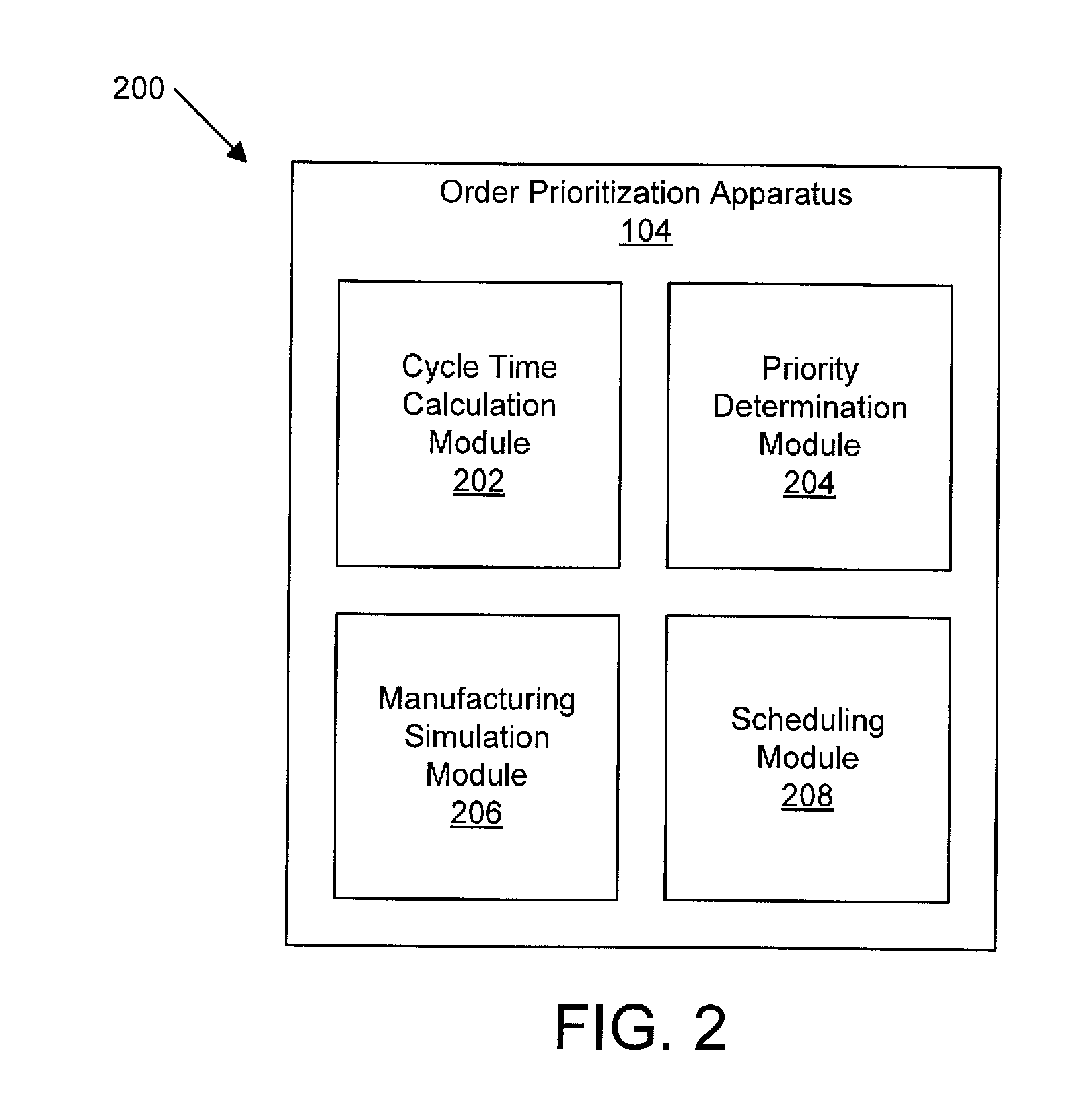

Decision support system for order prioritization

A method for order prioritization includes calculating a cycle time for a product order of a plurality of product orders using an artificial neural network, determining a first order priority of the product order based on a priority index using an analytic hierarchy process, determining a second order priority of the product order based on event based simulation model, and determining a shipping date for the product order based on the second order priority. The artificial neural network calculates the cycle time based upon product order type and a plurality of component counts. The analytic hierarchy process determines a first order priority based upon a plurality of product order attributes. The simulation model determines a second order priority and completion time based upon the first order priority, product model, product type, a plurality of component counts, manufacturing capacity and inventory data, and production time data for historical product orders.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

Silicon carbide composites, and methods for making same

InactiveUS6919127B2Improve permeabilityReduce the amount requiredCeramic shaping apparatusCeramic layered productsNet shapeToughness

Improved silicon carbide composites made by an infiltration process feature a metal phase in addition to any residual silicon phase. Not only are properties such as mechanical toughness improved, but the infiltrant can be so engineered as to have much diminished amounts of expansion upon solidification, thereby enhancing net-shape-making capabilities. Further, multi-component infiltrant materials may have a lower liquidus temperature than pure silicon, thereby providing the practitioner greater control over the infiltration process. In particular, the infiltration may be conducted at the lower temperatures, where low-cost but effective bedding or barrier materials can terminate the infiltration process once the infiltrant has migrated through the permeable mass up to the boundary between the mass and the bedding material.

Owner:II VI DELAWARE INC

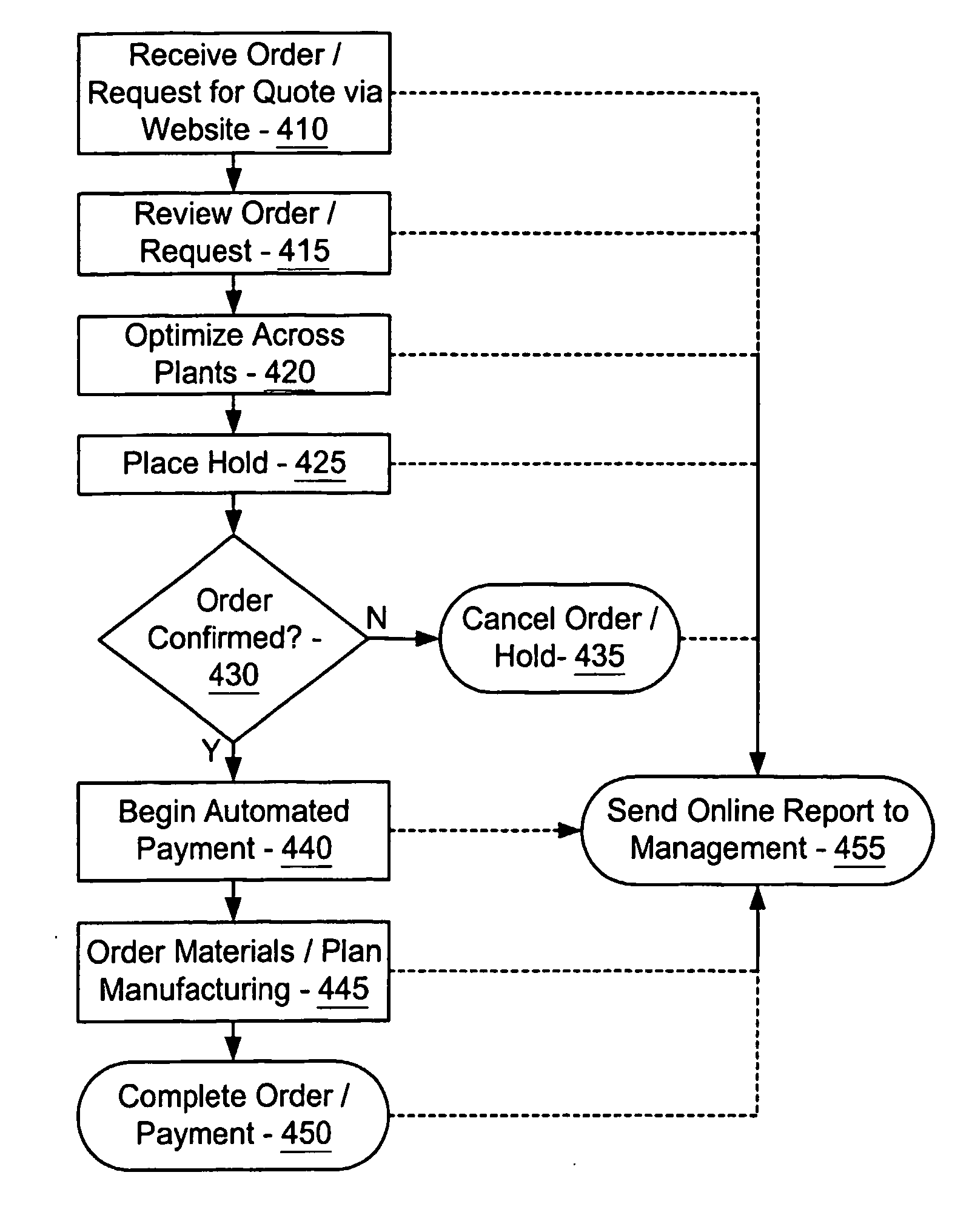

Industrial it system for production of distribution power transformers

InactiveUS20050256776A1Buying/selling/leasing transactionsSpecial data processing applicationsPaymentDistribution transformer

An order for a product from a customer by way of a website viewed on a display device of a customer computer is received and reviewed. An optimization across a plurality of manufacturing plants is requested, where each plant has a product manufacturing capacity, and the optimization takes place according to the capacity. The optimization is then received and a determination whether to confirm the order is made. If the order is confirmed, materials are ordered and a hold is placed on all or part of the capacity. Finally, an automated payment process is initiated with the customer.

Owner:ABB RES LTD

Super-junction trench MOSFET with Resurf stepped oxides and split gate electrodes

ActiveUS8373225B2Minimize impactImprove rendering capabilitiesSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

Owner:FORCE MOS TECH CO LTD

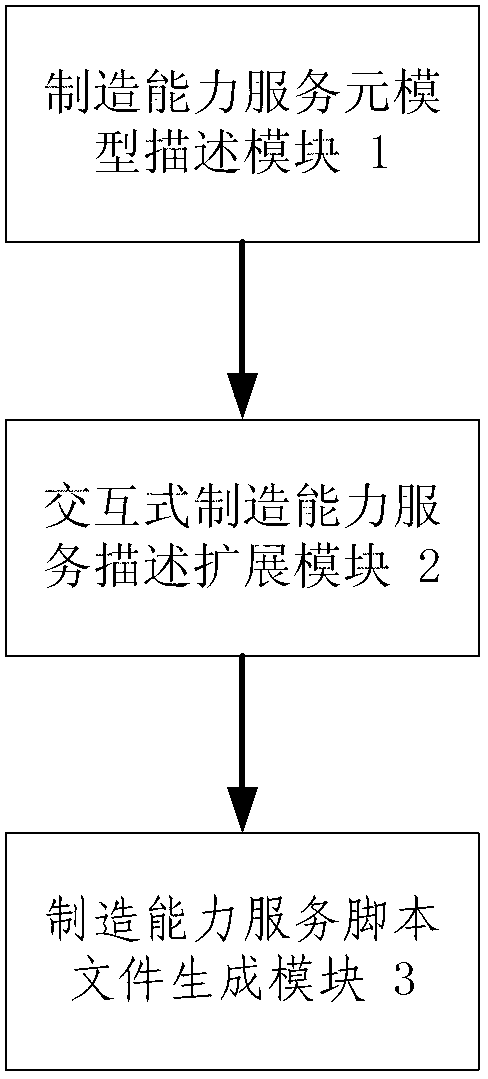

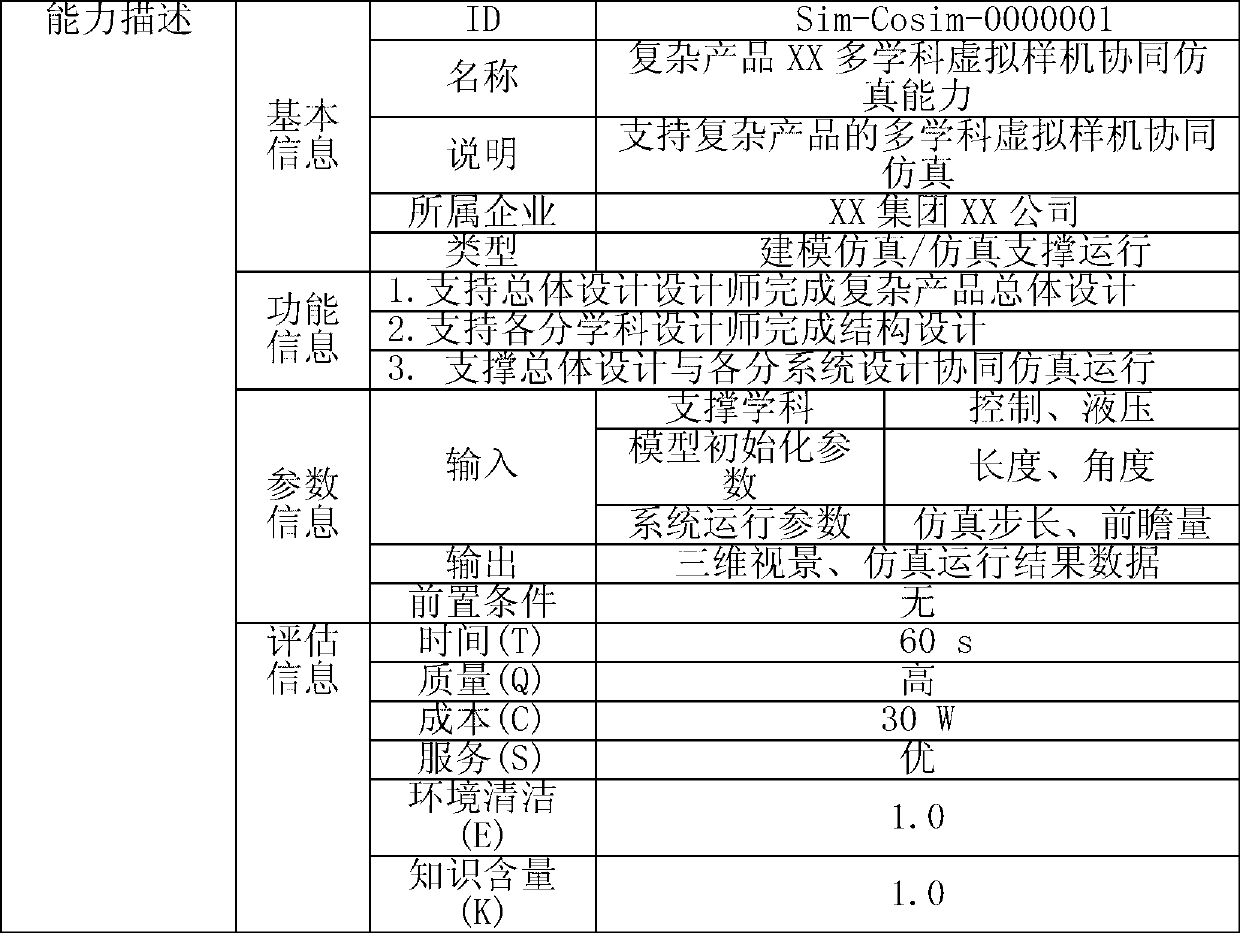

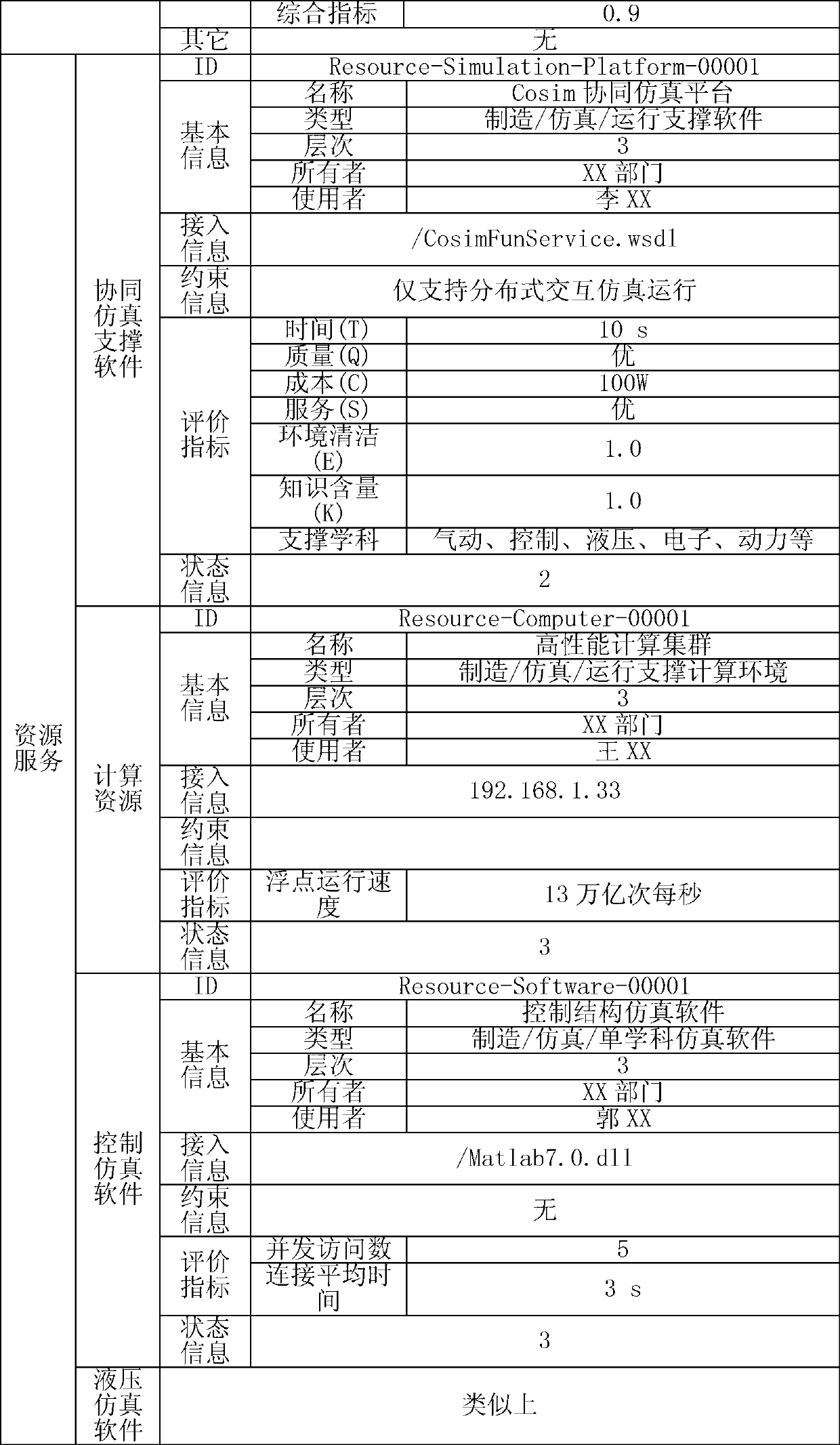

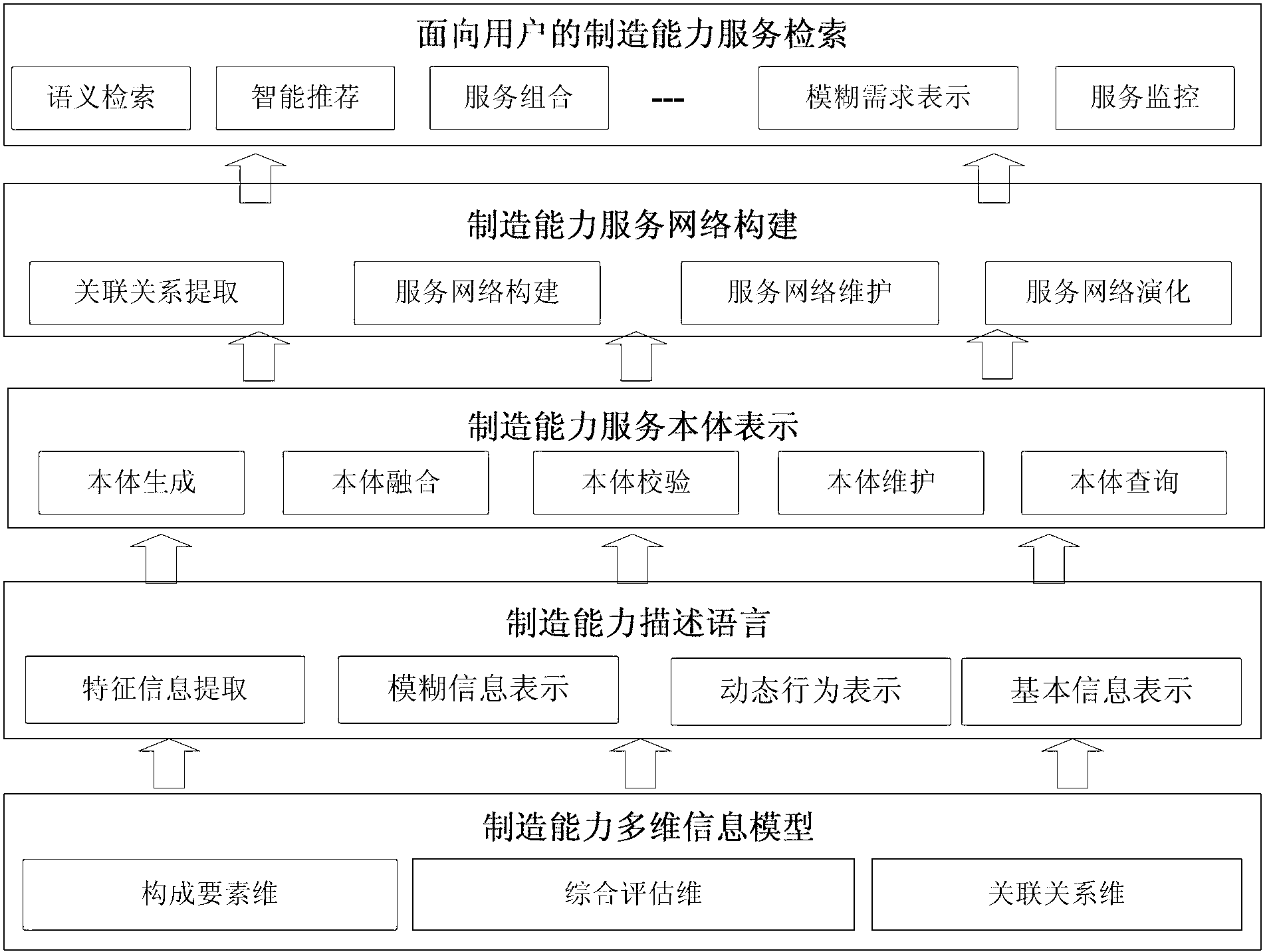

Cloud manufacture capacity service modeling method based on meta-model

ActiveCN103150623AValid conversionEnsuring Competency Knowledge AcquisitionResourcesModel descriptionComputer science

The invention relates to a cloud manufacture capacity service modeling method based on a meta-model. The method comprises the following steps: (1) constructing a system achieving the method, enabling the system to comprise a manufacture capacity service meta-model description module, an interactive type manufacture capacity service description expansion module and a manufacture capacity service script file generating module; (2) enabling the manufacture capacity service meta-model description module to abstract the manufacture capacity service meta-model; (3) enabling the interactive type manufacture capacity service description expansion module to expand and perfect various contents of the manufacture capacity service meta-model; and (4) enabling the manufacture capacity service script file generating module to generate a service description script file which can be processed by a cloud manufacture serve engine. According to the cloud manufacture capacity service modeling method based on the meta-model, the service description script file which can be processed by the cloud manufacture service engine can be fast and effectively produced through conversion, and efficiency of capacity knowledge acquisition and model construction is ensured.

Owner:BEIJING SIMULATION CENT

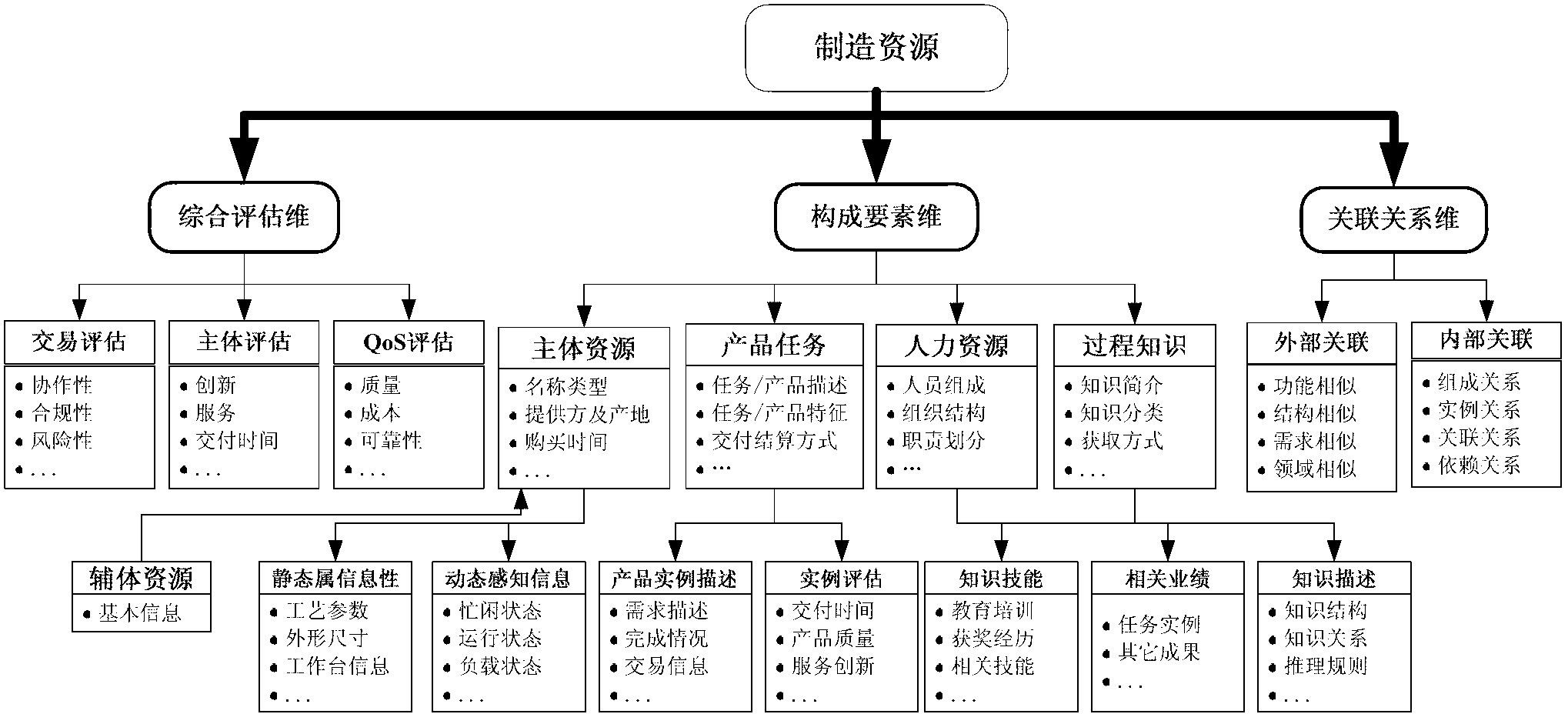

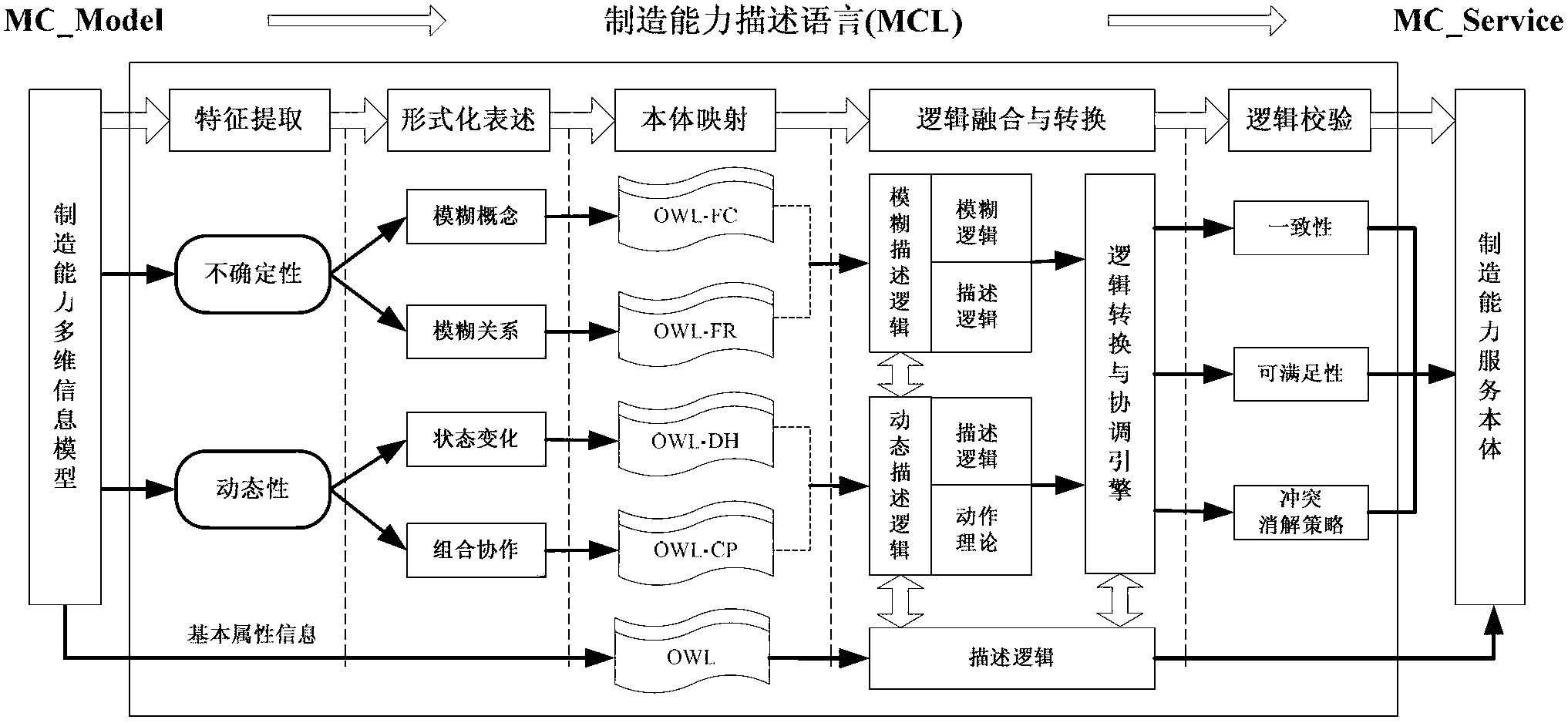

Cloud manufacturing capability description method supporting use on demand and sharing circulation of manufacturing capability

ActiveCN103020722ARealize intelligent recommendationRealize "Secondary RecommendationData processing applicationsTransmissionComputer scienceInformation model

The invention provides a cloud manufacturing capability description method supporting use on demand and sharing circulation of manufacturing capability. The method comprises the following steps of: extracting and classifying fuzzy information and dynamic behavior information in a knowledge-based manufacturing capability description model (namely a multi-dimension manufacturing capability information model); formalizing a fuzzy concept and a fuzzy role relationship according to a fuzzy description logic; describing service state change and dynamic combination flow according to a dynamic description logic; and giving an intelligent search and recommendation mechanism of the manufacturing capability based on the description method. According to the cloud manufacturing capability description method, the qualitative and quantitative properties of each dimension and each level of manufacturing capability can be taken into sufficient consideration, and a knowledge-based manufacturing capability language is provided, so that manufacturing capability services are stored in a cloud manufacturing service platform in an ontology mode, and a manufacturing capability service network is formed on the basis of various relationships among the services and supports the intelligent search and the use on demand of users.

Owner:BEIHANG UNIV

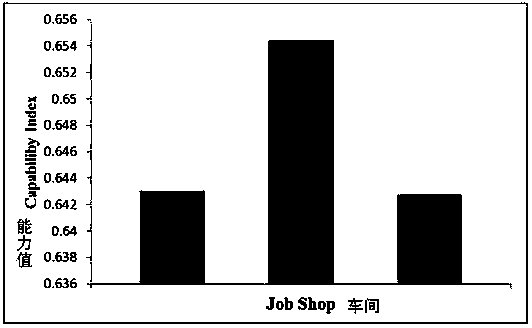

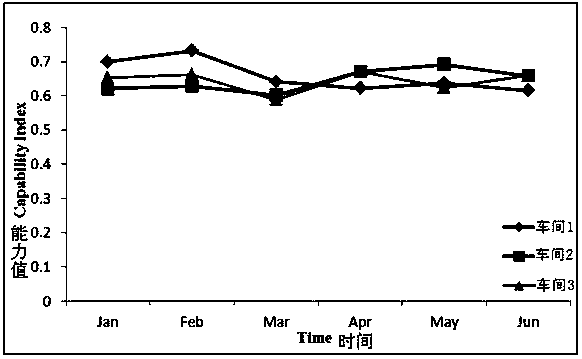

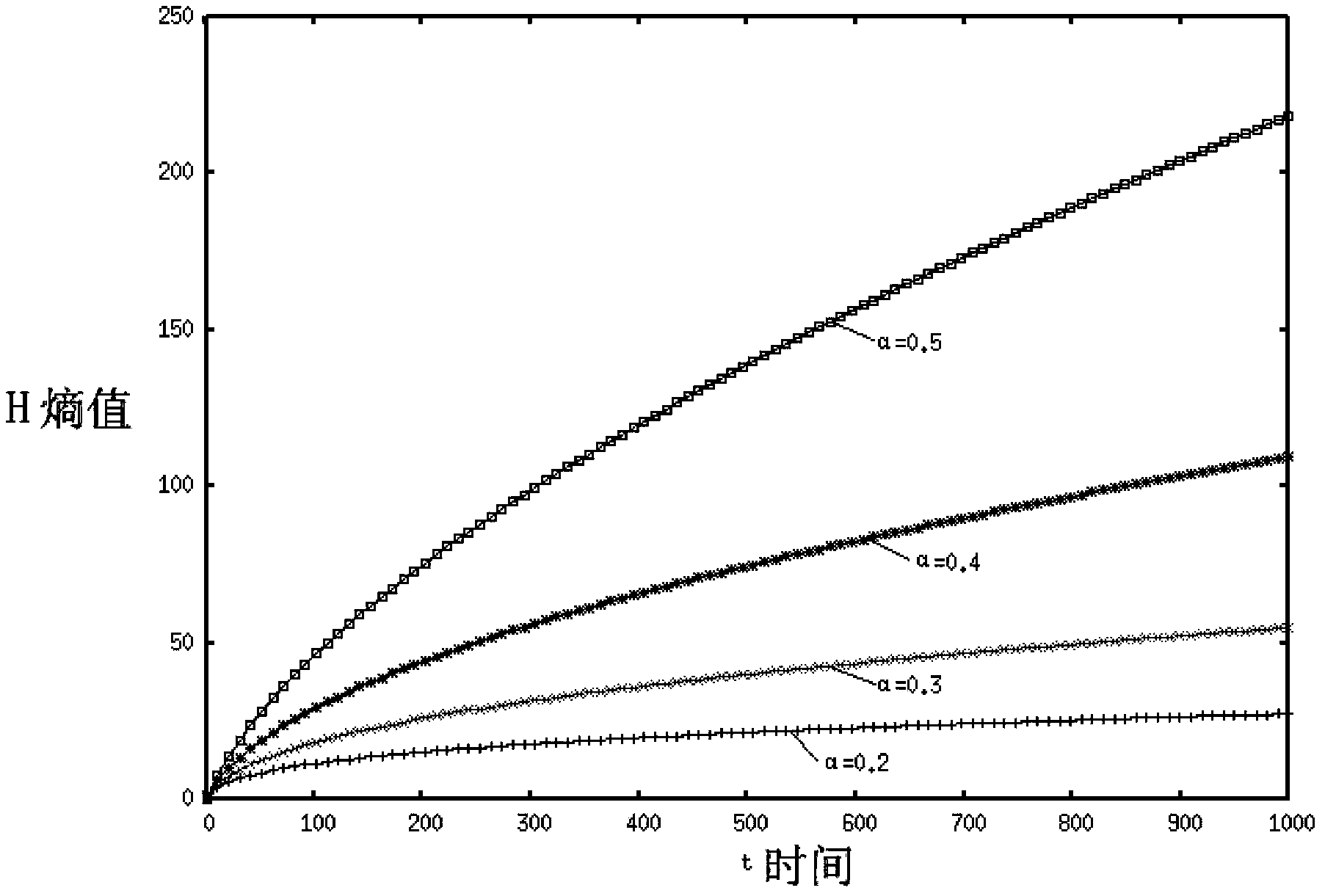

Workshop-level manufacturing capability oriented dynamic comprehensive assessment method

InactiveCN103413020AHigh dynamicGuaranteed relative importanceSpecial data processing applicationsMathematical modelManufacturing data

The invention discloses a workshop-level manufacturing capability oriented dynamic comprehensive assessment method. The method includes the steps that at first, composition elements of the workshop-level manufacturing capability are concluded and analyzed, an index system of workshop-level manufacturing capability dynamic comprehensive assessment is established, then a mathematical model of the workshop-level manufacturing capability dynamic comprehensive assessment is set up, and the manufacturing capability is assessed aiming at the mathematical model by means of combination of an entropy time empowerment and an analytic hierarchy process. According to the method, historical manufacturing data are used as the basis, an dynamic accurate assessment is conducted on the workshop-level manufacturing capability mainly for real-time workshop manufacturing data collected through the sensor technology, the radio frequency identification technology and other technologies with comprehensive consideration of manufacturing data in different manufacturing time periods, and support is provided for workshop production scheduling optimization and cooperation of enterprises.

Owner:WUHAN UNIV OF TECH

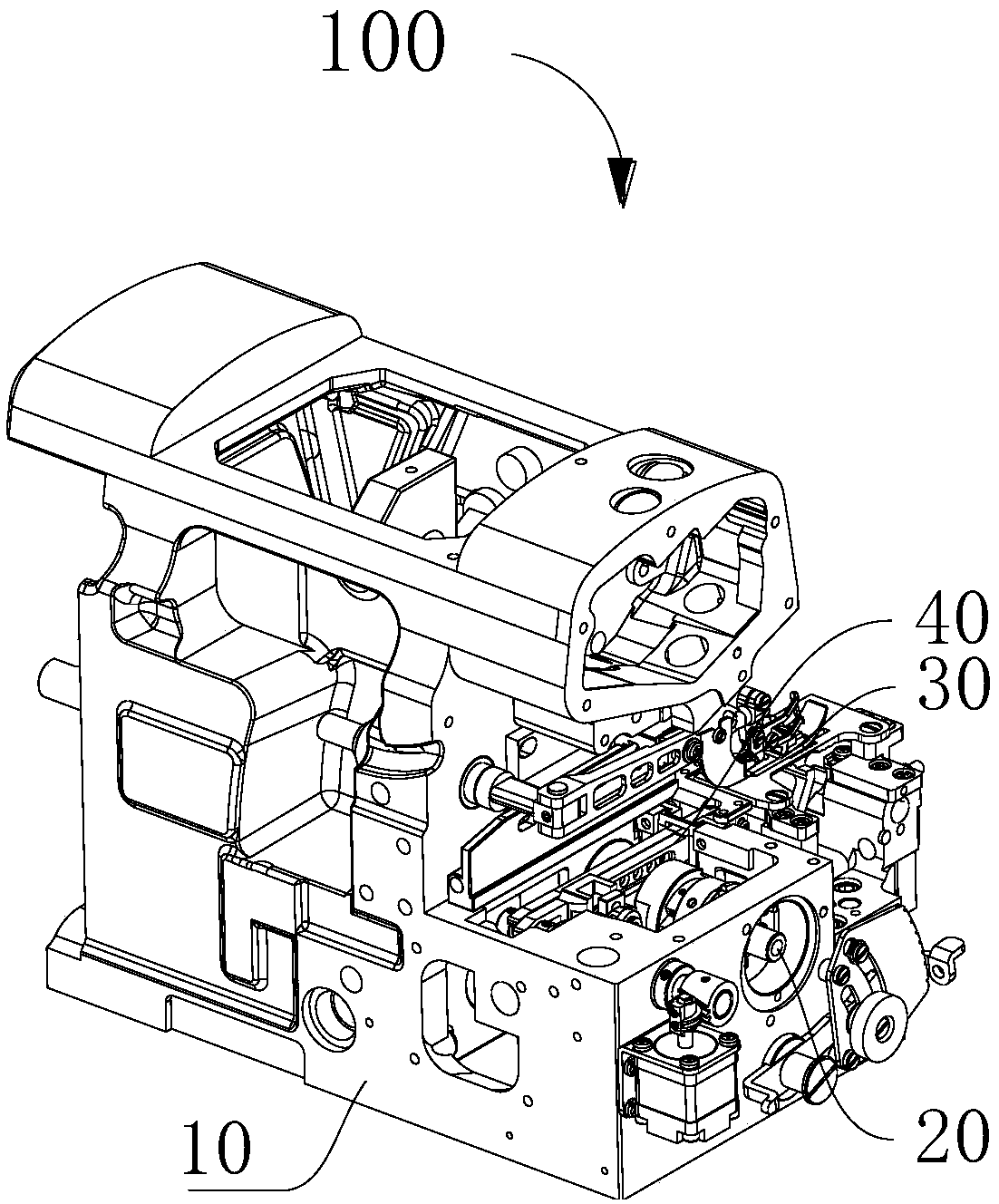

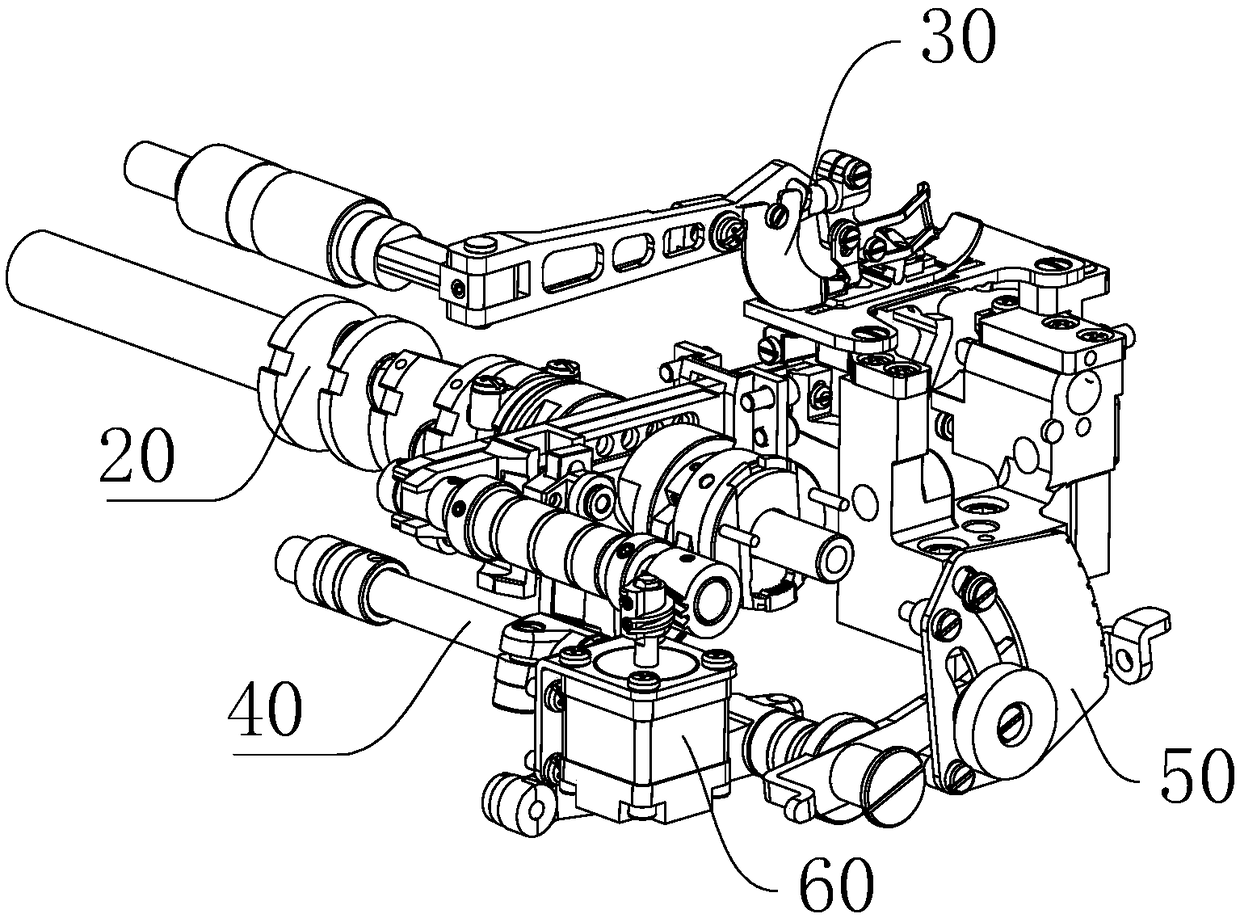

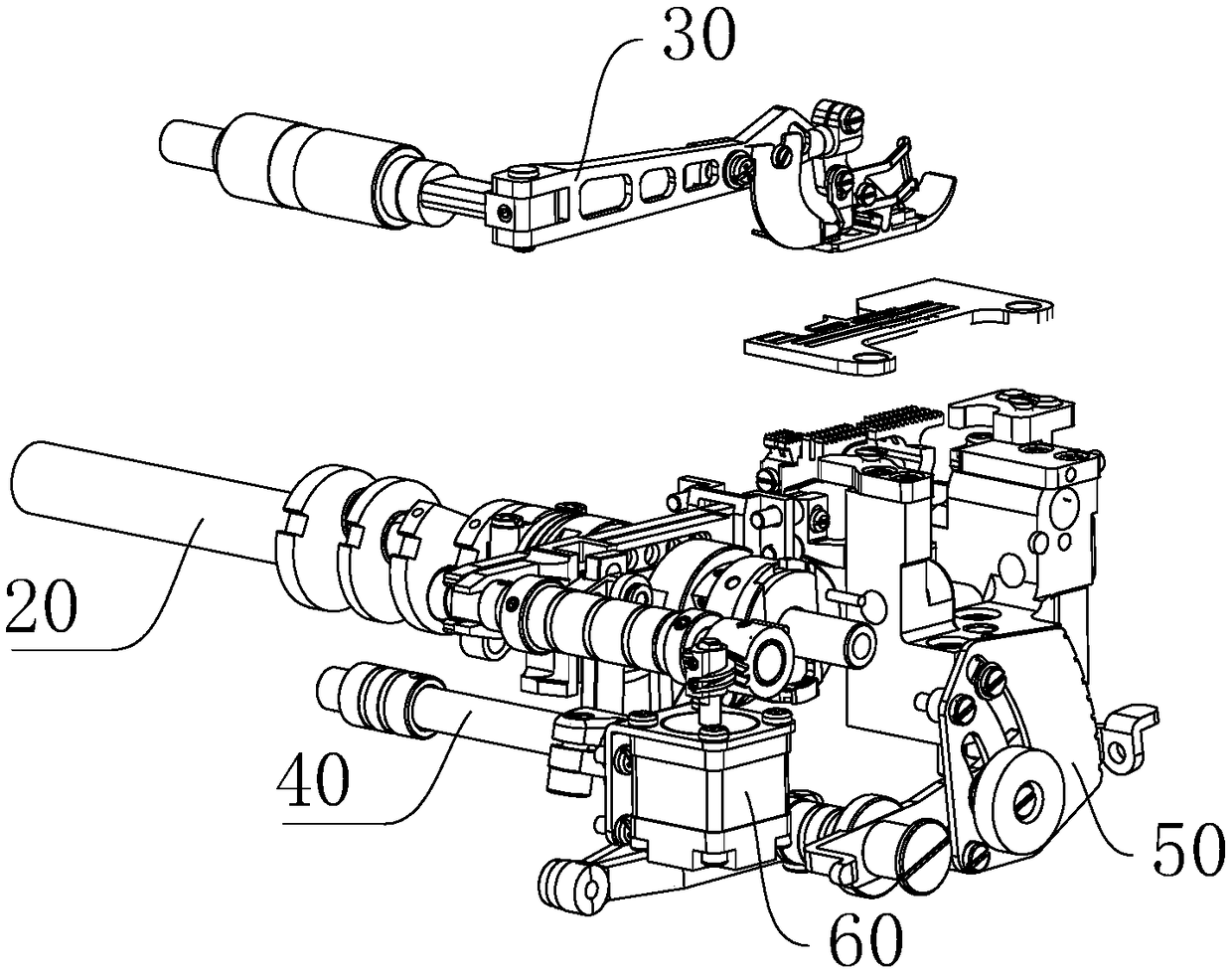

Cloth feeding tooth rack adjusting mechanism and overedger using same

ActiveCN109371576AEnhancement of flexible manufacturing capabilitiesImprove sewing qualityWork-feeding meansSewing-machine control devicesEngineeringElectric control

The invention provides a cloth feeding tooth rack adjusting mechanism, which is used for adjusting a cloth feeding tooth rack in an overedger. The cloth feeding tooth rack adjusting mechanism comprises an adjusting component and an operating component, wherein the adjusting component comprises an adjusting slide block and an eccentric shaft, the adjusting slide block is embedded in the cloth feeding tooth rack and can slide relative to the cloth feeding tooth rack, the eccentric shaft is provided with a concentric section and an eccentric section connected with the concentric section, the eccentric section of the eccentric shaft runs through the adjusting slide block and is rotatably matched with the adjusting slide block, the operating component comprises an electric control element, theconcentric section of the eccentric shaft is connected with the electric control element, and the electric control element controls the eccentric shaft to rotate in an electric control mode and drivesthe adjusting slide block to adjust the inclination angle and height of the cloth feeding tooth rack. The invention also provides an overedger using the cloth feeding tooth rack adjusting mechanism.The cloth feeding tooth rack adjusting mechanism can adjust the inclination angle and height of the cloth feeding tooth rack. The overedger using the cloth feeding tooth rack adjusting mechanism has improved sewing quality and flexible manufacturing capability of the system, and the cloth feeding tooth rack adjusting mechanism has a wide application prospect.

Owner:浙江杰克智能缝制科技有限公司

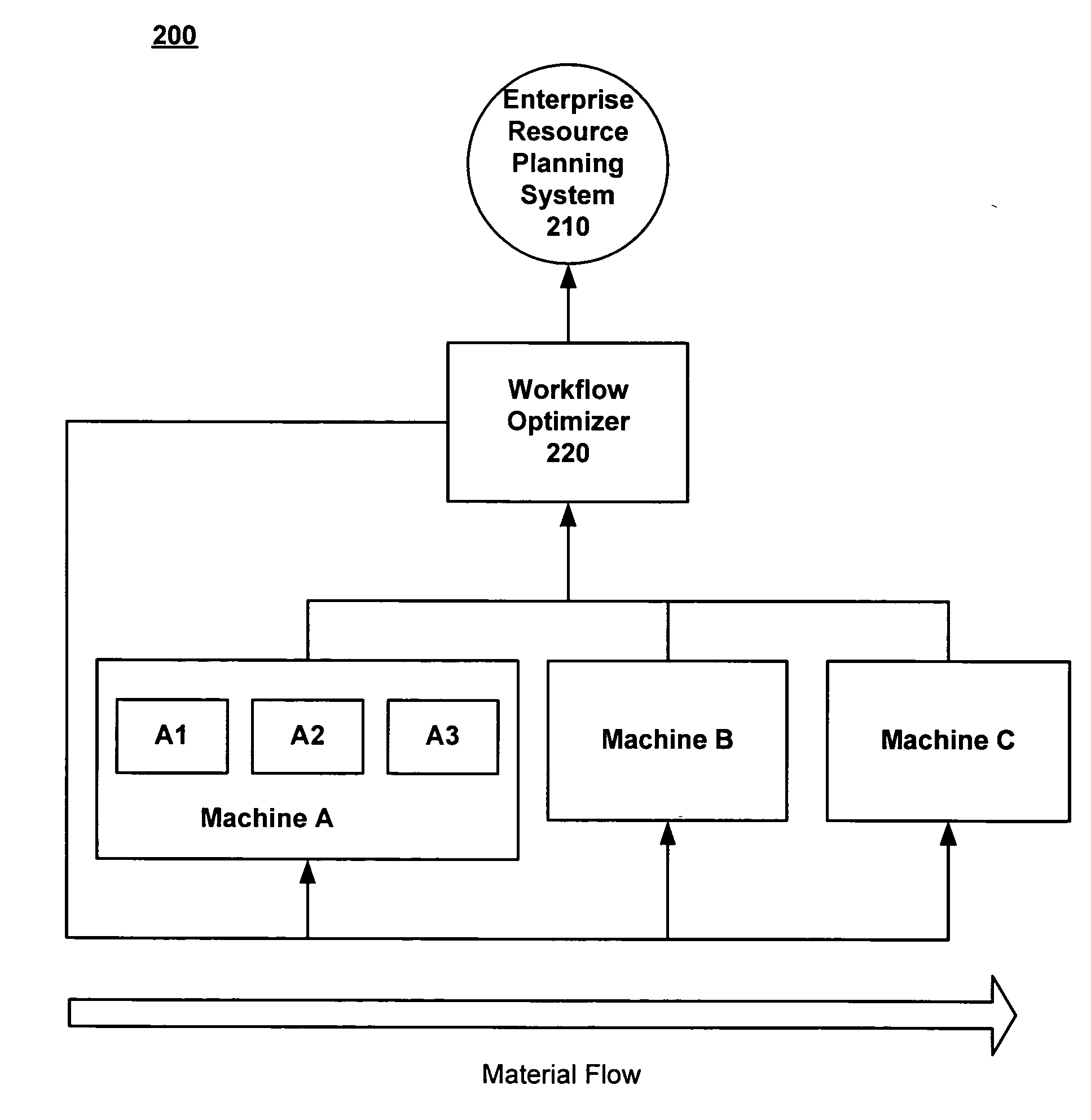

Industrial information technology (IT) workflow optimizer for discrete manufacturing

InactiveUS20050096769A1Improve manufacturing capacityAvoid manufacturing down-timeForecastingSpecial data processing applicationsProcess optimizationManufacturing data

The invention contemplates a system and method offering optimization and management of manufacturing resources to obtain optimal manufacturing capacities and to avoid manufacturing down-time currently realized through manual operation and control of manufacturing resources. In an illustrative implementation, the present invention contemplates an exemplary optimization computing application operating in a computing environment which communicates with, cooperates with, and provides optimization data for use in managing manufacturing resources (e.g. manufacturing machines). The computing application accepts a variety of manufacturing related information as input, processes such manufacturing data and generates optimization suggestions for use to manage manufacturing processes and to optimize manufacturing capacities. The optimization data may be applied to a particular manufacturing environment to control the operation of manufacturing resources such that optimization is realized.

Owner:ABB RES LTD

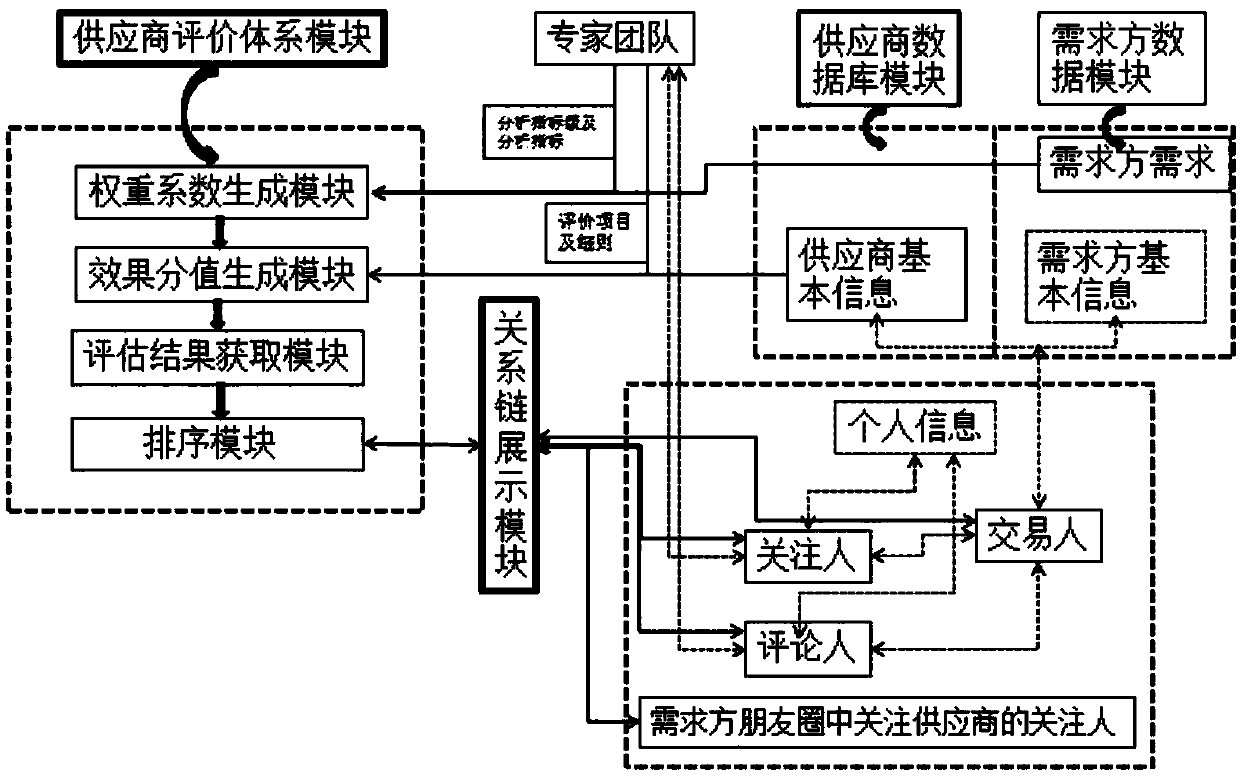

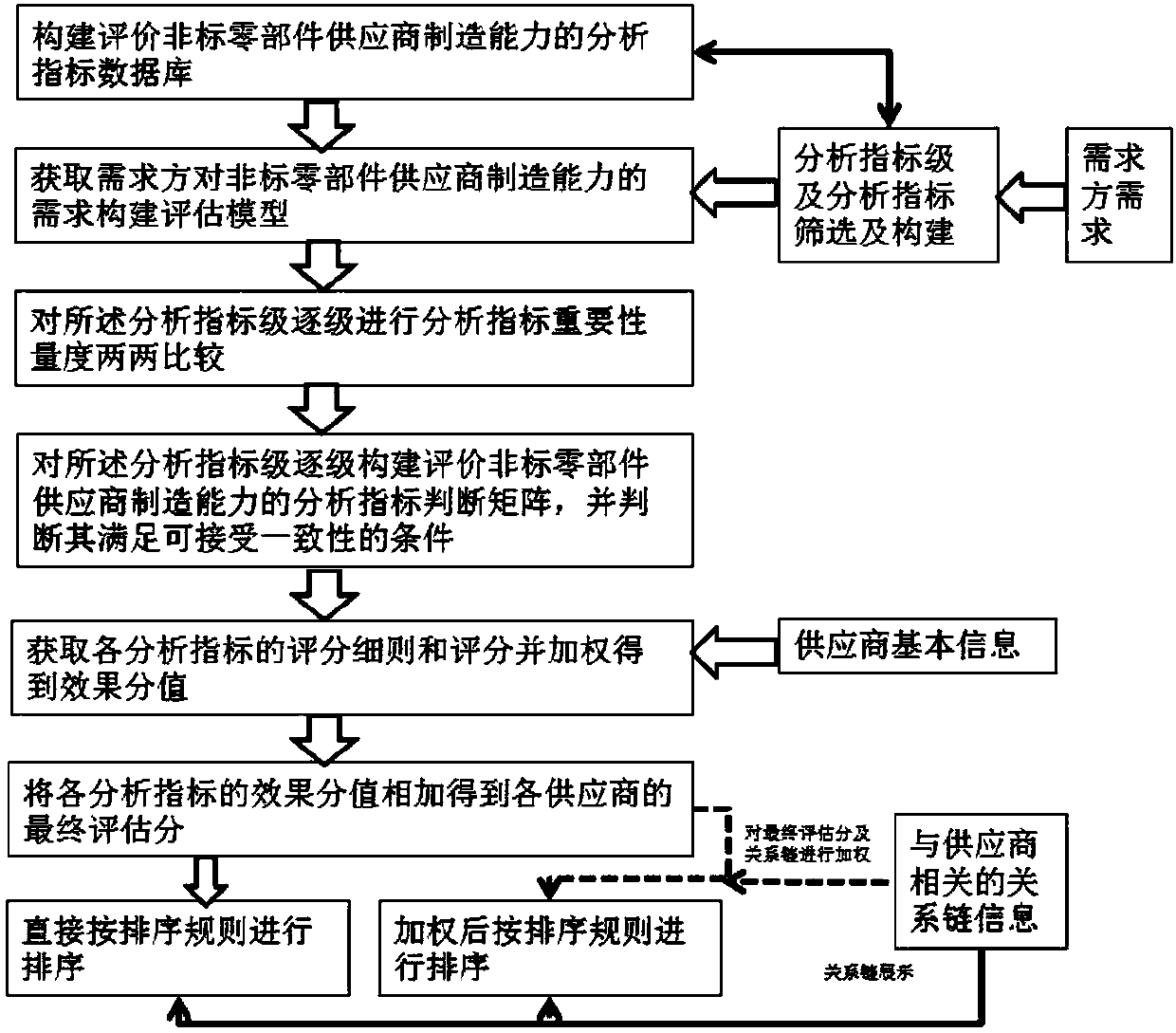

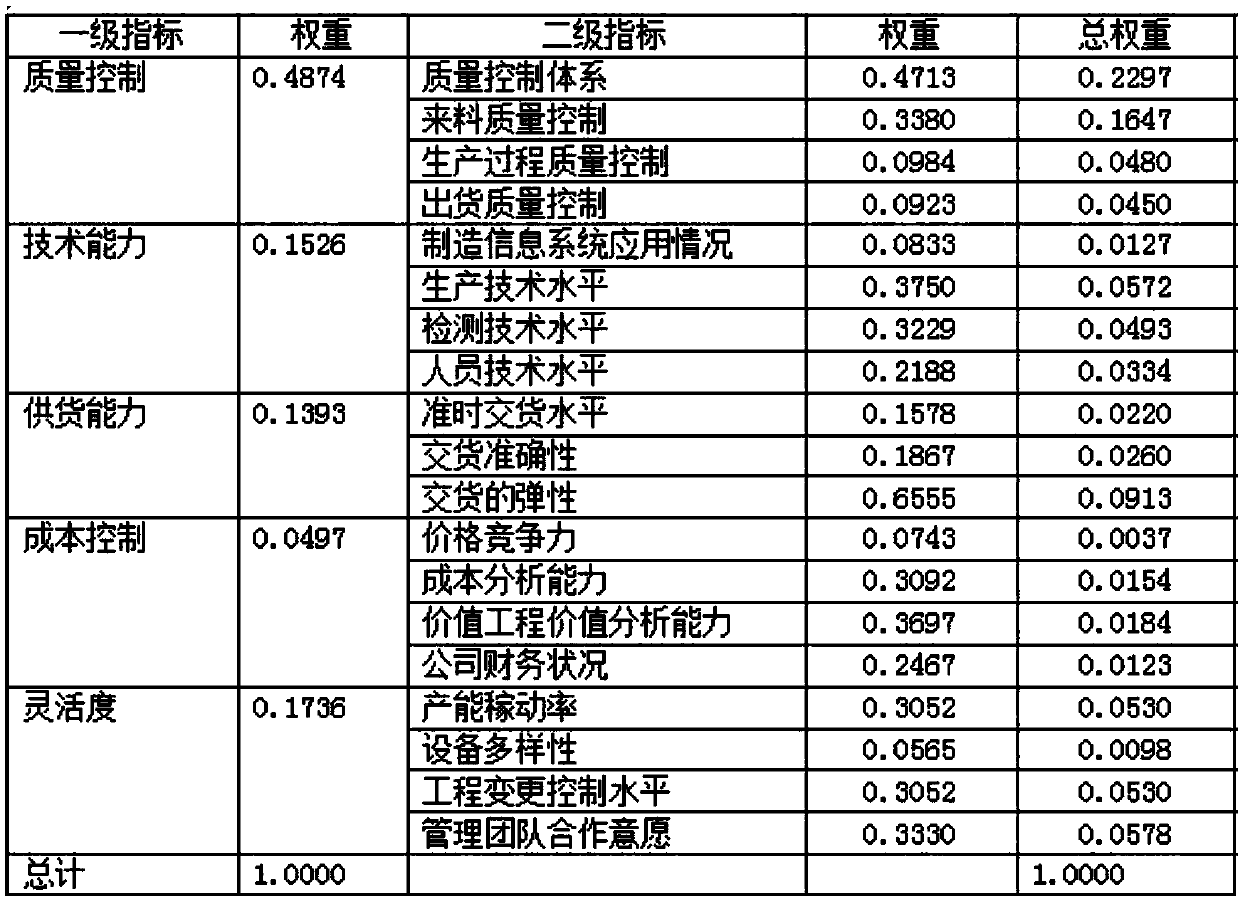

Non-standard part purchasing decision-making system based on manufacturing capability and relation chain

InactiveCN108154277ATake advantage ofReliable decision supportForecastingResourcesProgram planningComputer module

The invention discloses a non-standard part purchasing decision-making system based on the manufacturing capability and a relation chain. The non-standard part purchasing decision-making system is characterized by comprising a supplier database module, a supplier evaluation system module and a relation chain display module, wherein the supplier database module includes various types of data of suppliers, the supplier evaluation system module converts the data of the suppliers into evaluating scores of 0-10 based on the supplier database module, the total scores of all the suppliers are calculated according to the evaluating scores, and finally, all the suppliers are ranked. The relation chain display module displays relation chain information associated with all the suppliers. By means ofthe part purchasing decision-making system based on the manufacturing capability and the relation chain, a supplier database can be fully utilized, a reasonable supplier manufacturing capability evaluating system is built from the quantitative and qualitative angle, a relation chain system is built, and reliable decision-making support is provided when a purchasing plan is made.

Owner:苏州索及信息技术有限公司

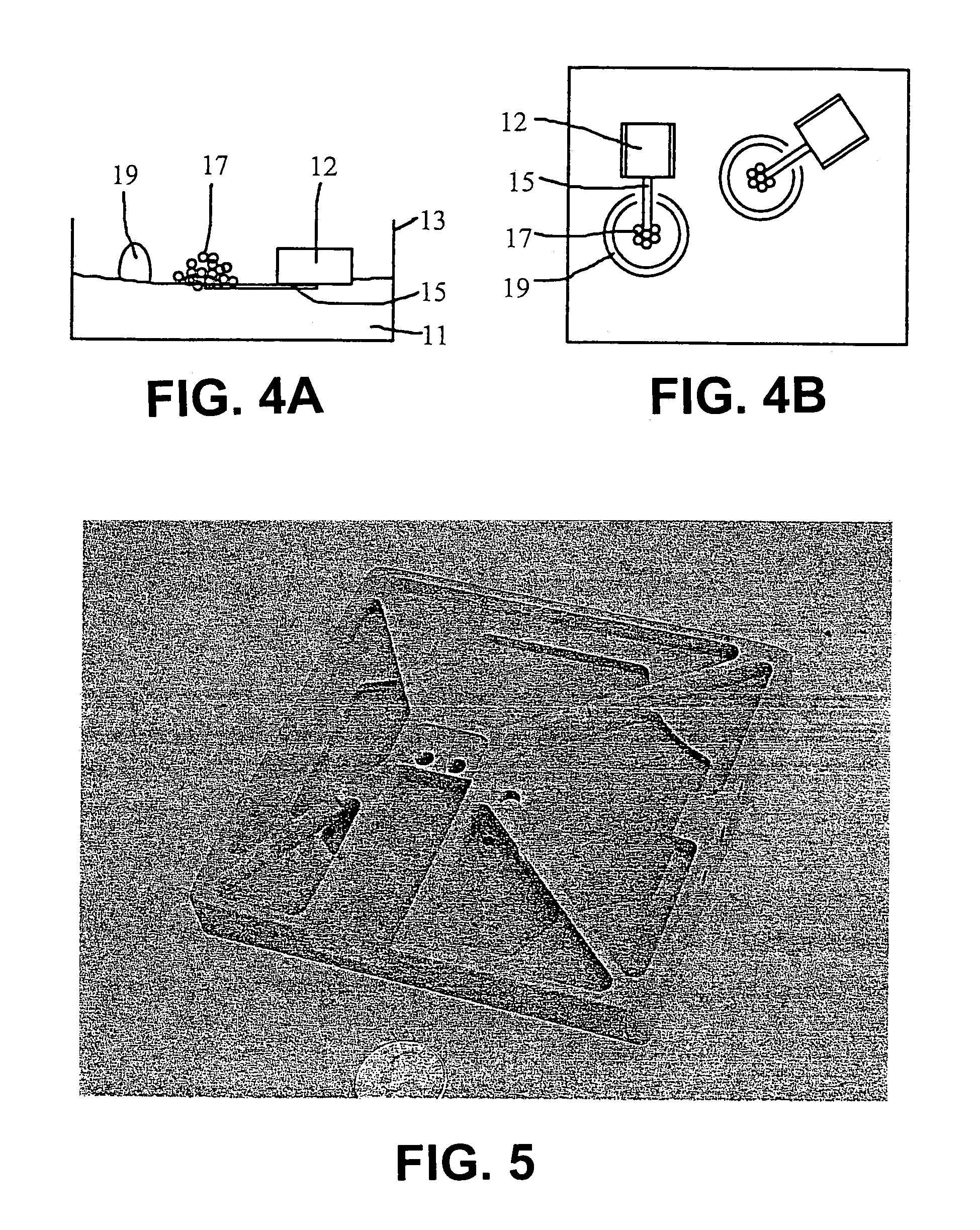

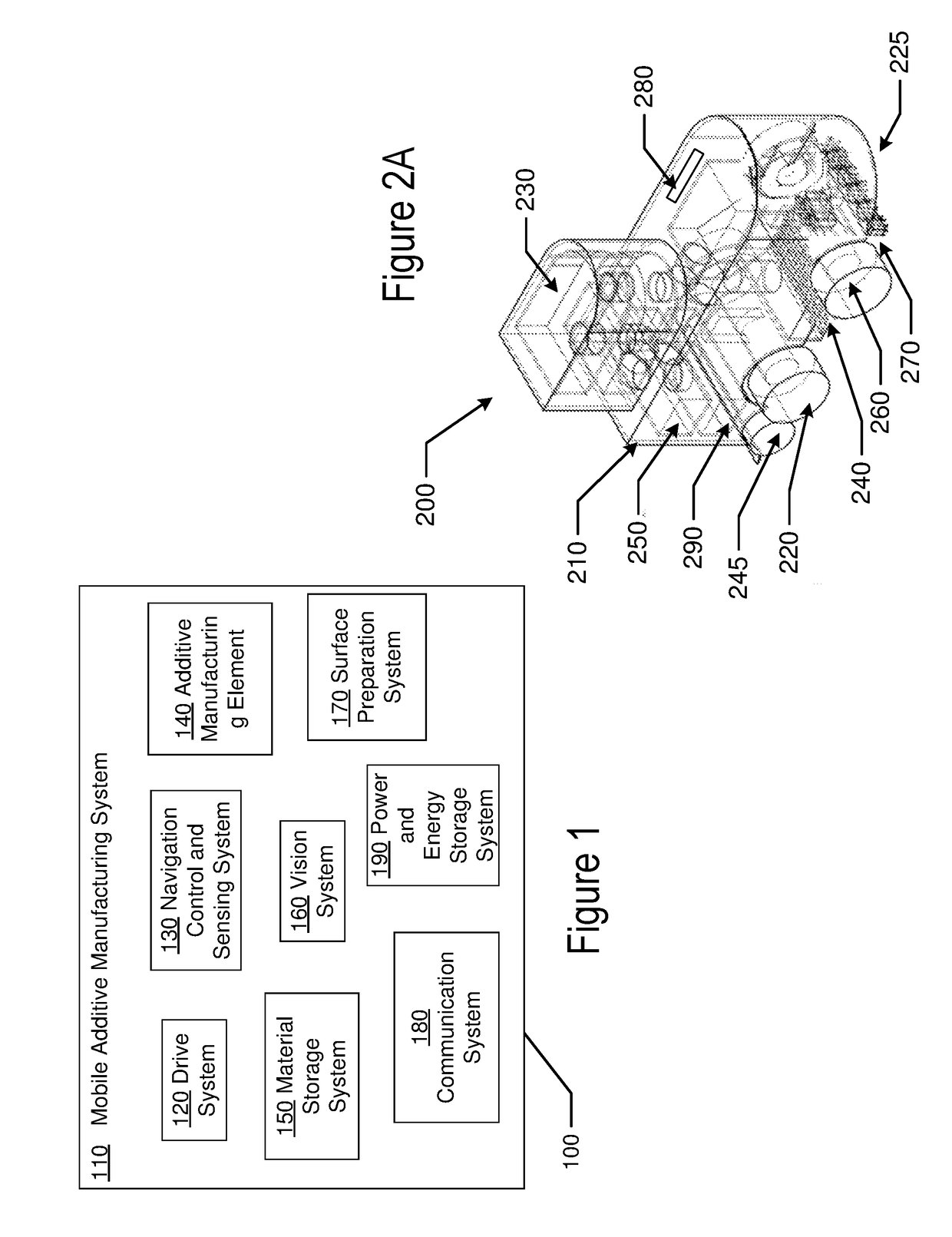

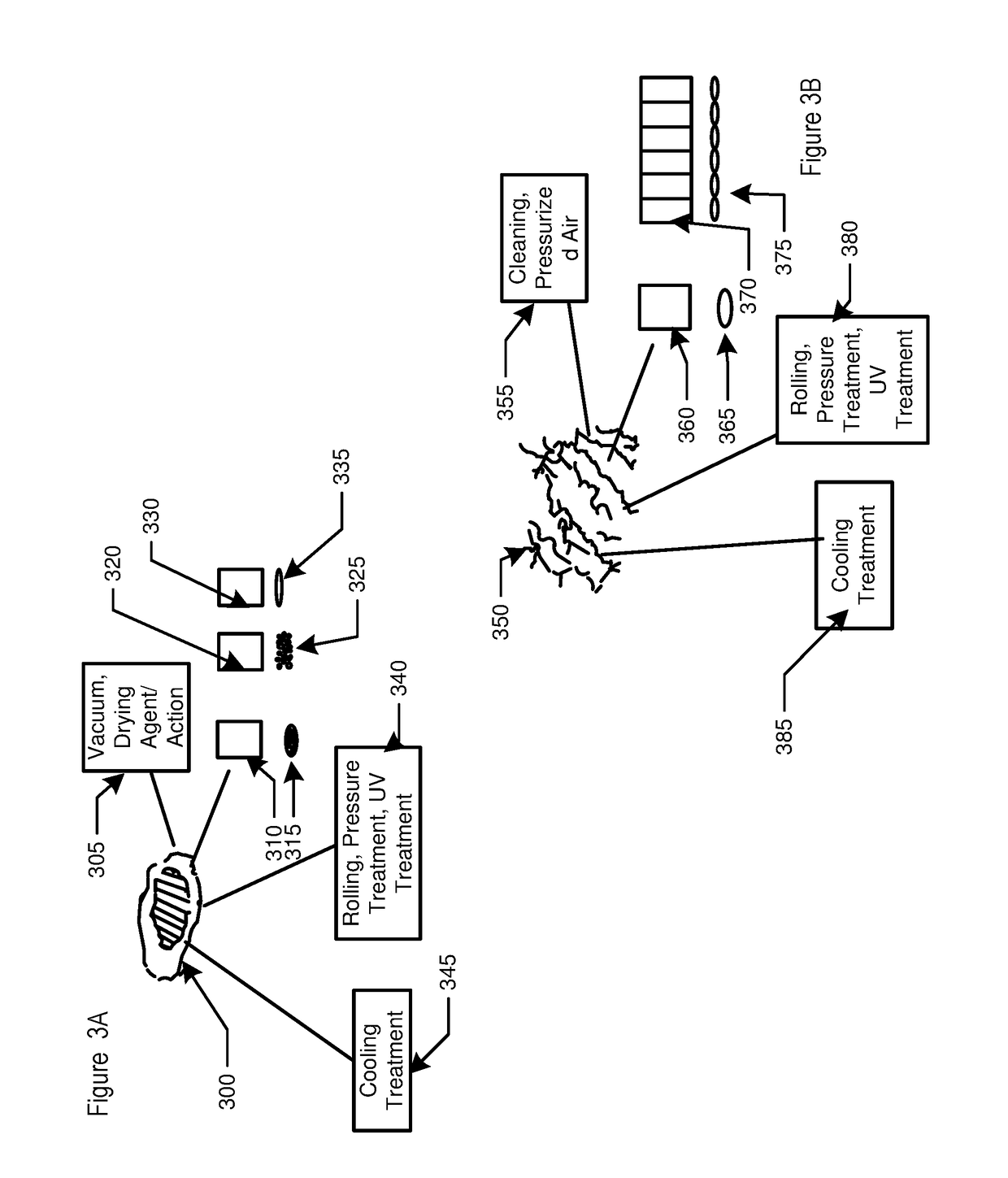

Methods, materials and apparatus for mobile additive manufacturing of advanced structures and roadways

ActiveUS20190055699A1Material granulation and coatingLiquid surface applicatorsAdditive layer manufacturingCoating

The present disclosure provides various aspects for mobile and automated processing utilizing additive manufacturing and the methods for their utilization. In some examples, discrete material formats for use in an Additive Manufacturing Array are disclosed. Methods of using the additive manufacturing robot, discrete materials, and the roadways produced with the additive manufacturing robot are provided. A combined function Addibot, with Additive Manufacturing capabilities, cleaning capabilities, line painting capabilities and seal coating capabilities which may be used in concert with a camera equipped aerial drone for design and characterization function is described.

Owner:FLITSCH ROBERT A +1

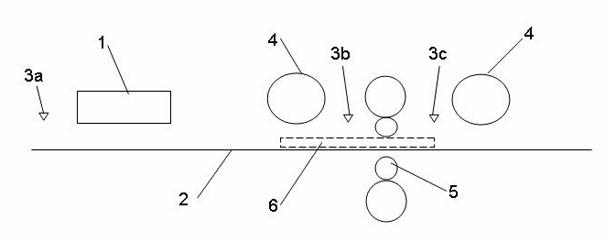

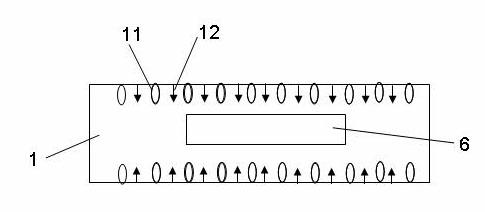

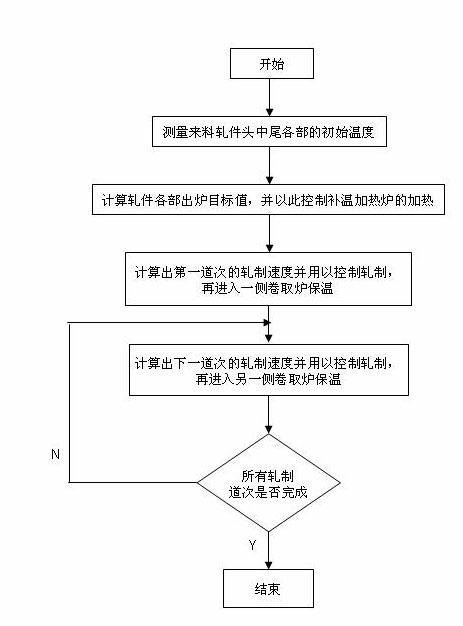

Temperature difference control method for rolling pieces for steckel mill

InactiveCN102601128AReduce temperature differenceImprove calculation accuracyTemperature control deviceProduction lineStrip mill

The invention discloses a temperature difference control method for rolling pieces for a steckel mill. The method includes steps of measuring initial temperature of the rolling pieces; calculating discharging target temperature value of a temperature complement furnace and heating the rolling pieces according to the target temperature value; calculating a set value of rolling speed of each rolling step and performing controlled rolling at each step according to the set value to reduce temperature difference; and measuring actual temperature of an exit and an entrance of a rolling mill and comparing the actual temperature with corresponding values to realize self-learning of the model and enhance calculating precision of the model. By the method, the temperature differences among the head, the middle and the tail of each rolling piece are reduced greatly, and rolling stability and quality of finished products and production ability of a production line are enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com