Temperature difference control method for rolling pieces for steckel mill

A temperature difference control, furnace coil mill technology, applied in the direction of temperature control, etc., can solve the problems of destroying the rolling stability, unable to improve the temperature difference between the middle and tail of the strip, and rolling force fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

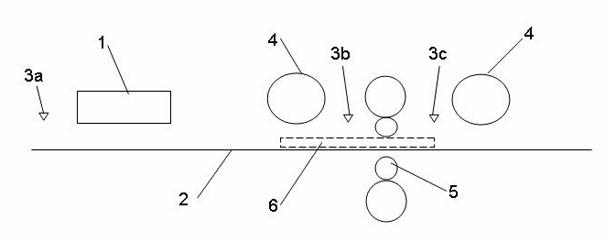

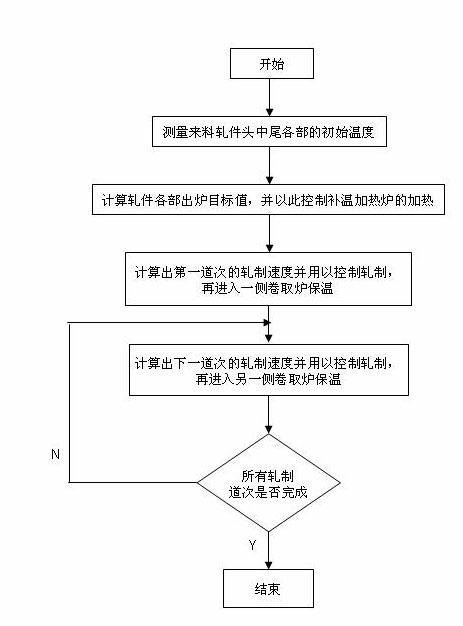

[0026] Please combine Figure 1 ~ Figure 3 As shown, the method for controlling the temperature difference of the rolled piece of the steckel mill of the present invention adopts the following specific steps:

[0027] A. Since the incoming rolled piece is a hot slab or a cold slab, first measure the initial temperature of the rolled piece 6 by being located at the radiation pyrometer 3a before the temperature-supplementing heating furnace 1;

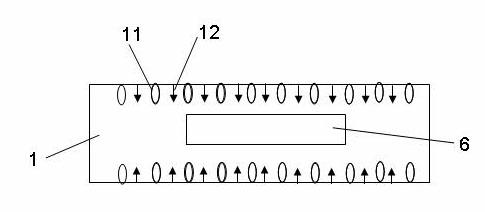

[0028] B. Use the positioning sensor to locate on the roller table 2 in front of the furnace door, and load it into the supplementary temperature heating furnace 1 by the steel loading machine. Since the heating furnace 1 is equipped with a pulse burner 11, each pair of burner 11 is equipped with a corresponding The thermocouples 12 can be used to control the heating effect separately. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com