Liquid crystal display device and its driving method

A technology of liquid crystal display and driving method, which is applied in the field of liquid crystal display and its driving, and can solve the problems of increased line width of black matrix light-shielding film, reduced aperture ratio, poor driving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

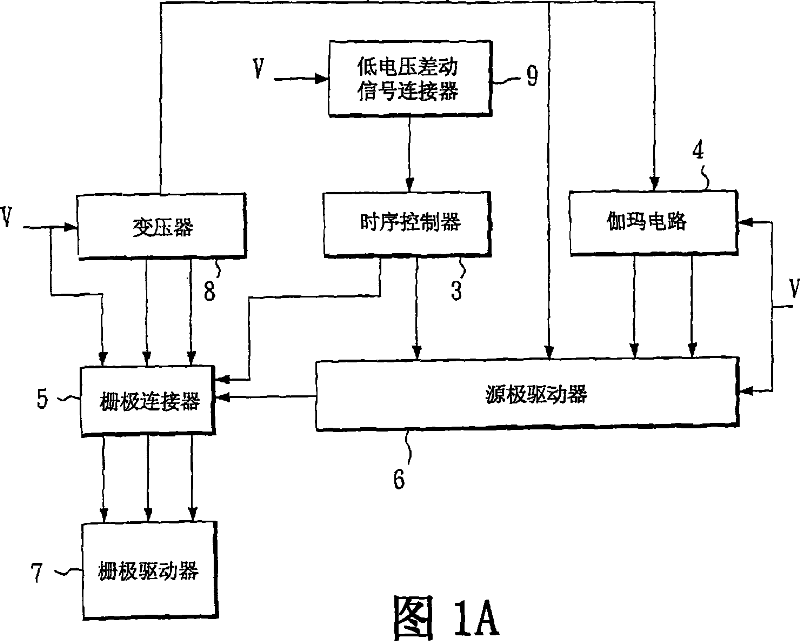

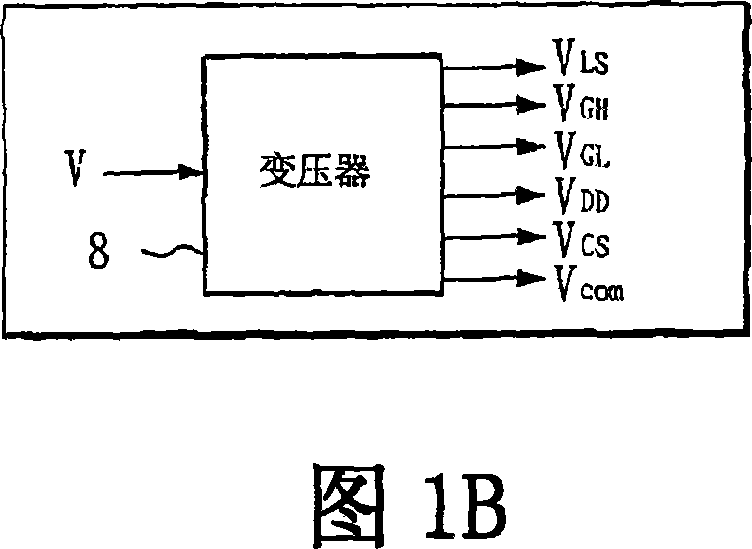

[0048] Please refer to FIG. 1A and FIG. 1B together. FIG. 1A is a block diagram of a liquid crystal display driving system according to a preferred embodiment of the present invention, and FIG. 1B is a schematic diagram showing a transformer of a liquid crystal display driving system according to a preferred embodiment of the present invention.

[0049] The liquid crystal display driving system shown in FIG. 1A and FIG. 1B is electrically connected to a plurality of pixel electrodes 24 (as shown in FIG. 2D ), and it includes a low-voltage differential signal connector 9, a transformer 8, a timing controller 3, a Mal circuit 4 , gate connector 5 , source driver 6 , and gate driver 7 .

[0050] Among them, the low-voltage differential signal connector 9 is electrically connected to the timing controller 3, the transformer 8 is electrically connected to the gamma circuit 4, the gate connector 5, and the source driver 6, and the timing controller 3 is electrically connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com