Manufacturing method of circuit board plated hole

A manufacturing method and circuit board technology, applied in the direction of electrical connection formation of printed components, etc., can solve problems such as difficulty in manufacturing circuits, uneven surface copper thickness, and lack of covering copper, so as to improve production yield and avoid hole pitting Abnormal, the effect of improving the crafting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

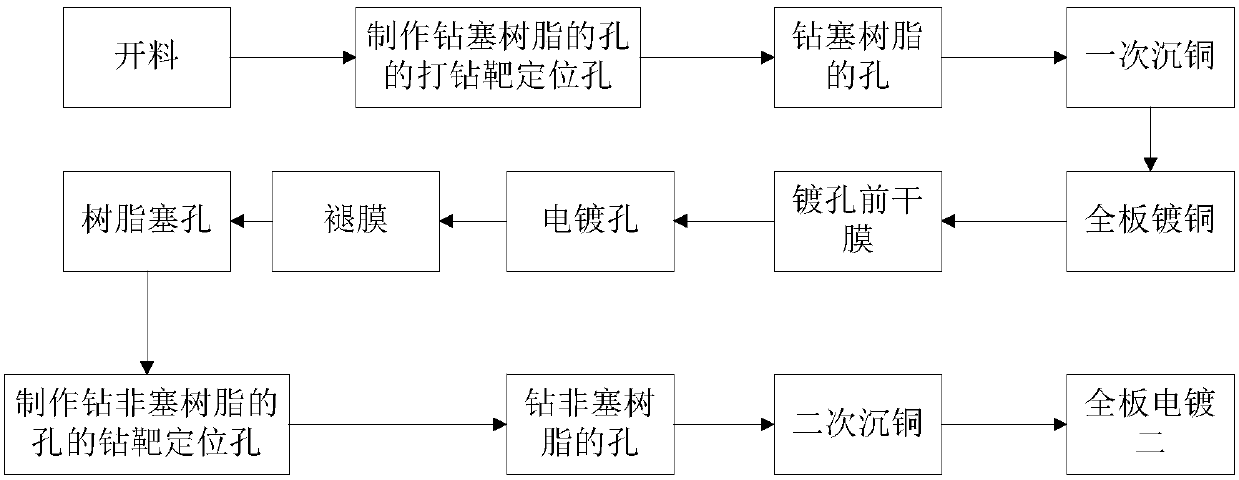

[0015] Such as figure 1 Shown, a kind of manufacturing method of plated hole of circuit board, it comprises the following steps: material cutting, inner layer, inspection, press-fit, make the drilling target positioning hole of the hole of drilling plug resin, the hole of drilling plug resin, primary copper sinking , Copper plating on the whole board, dry film before plating holes, electroplating holes, film fading, resin plug holes, resin grinding, drilling target positioning holes for drilling non-plug resin holes, drilling non-plug resin holes, secondary copper sinking, Full board electroplating II.

[0016] The following is a description of the specific process:

[0017] 1) The dry film before plating refers to pasting the dry film on the copper plated board. The dry film is a photosensitive substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com