Patents

Literature

110 results about "Oxygen plasma etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen plasma etching is done using low-pressure plasma systems. Oxygen is used as the precursor gas and is channeled into the vacuum chamber with the wafer. Then, high power radio waves are applied in the chamber and this, along with the low pressure of the vacuum chamber, causes the oxygen molecules to ionize, forming plasma.

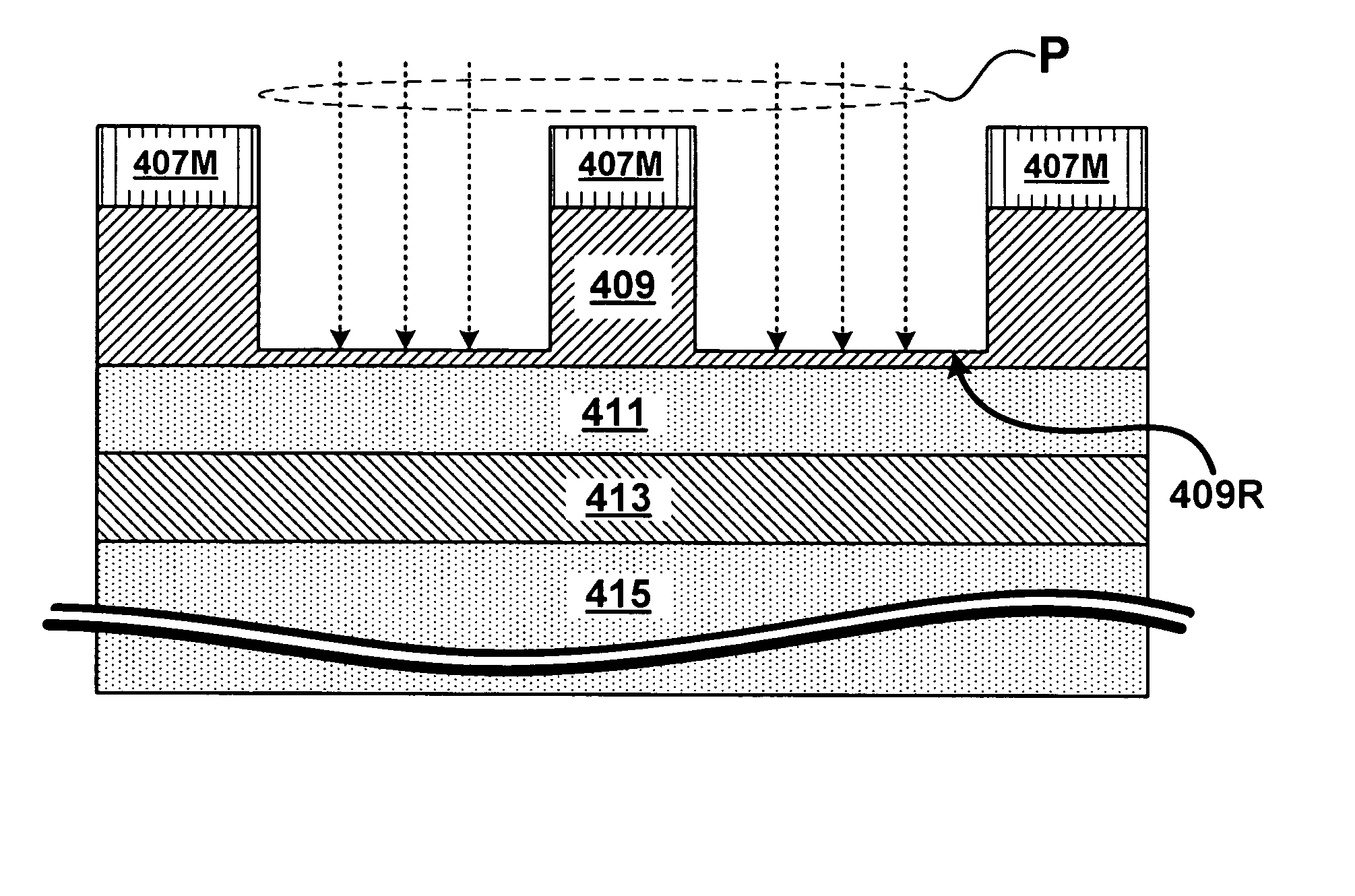

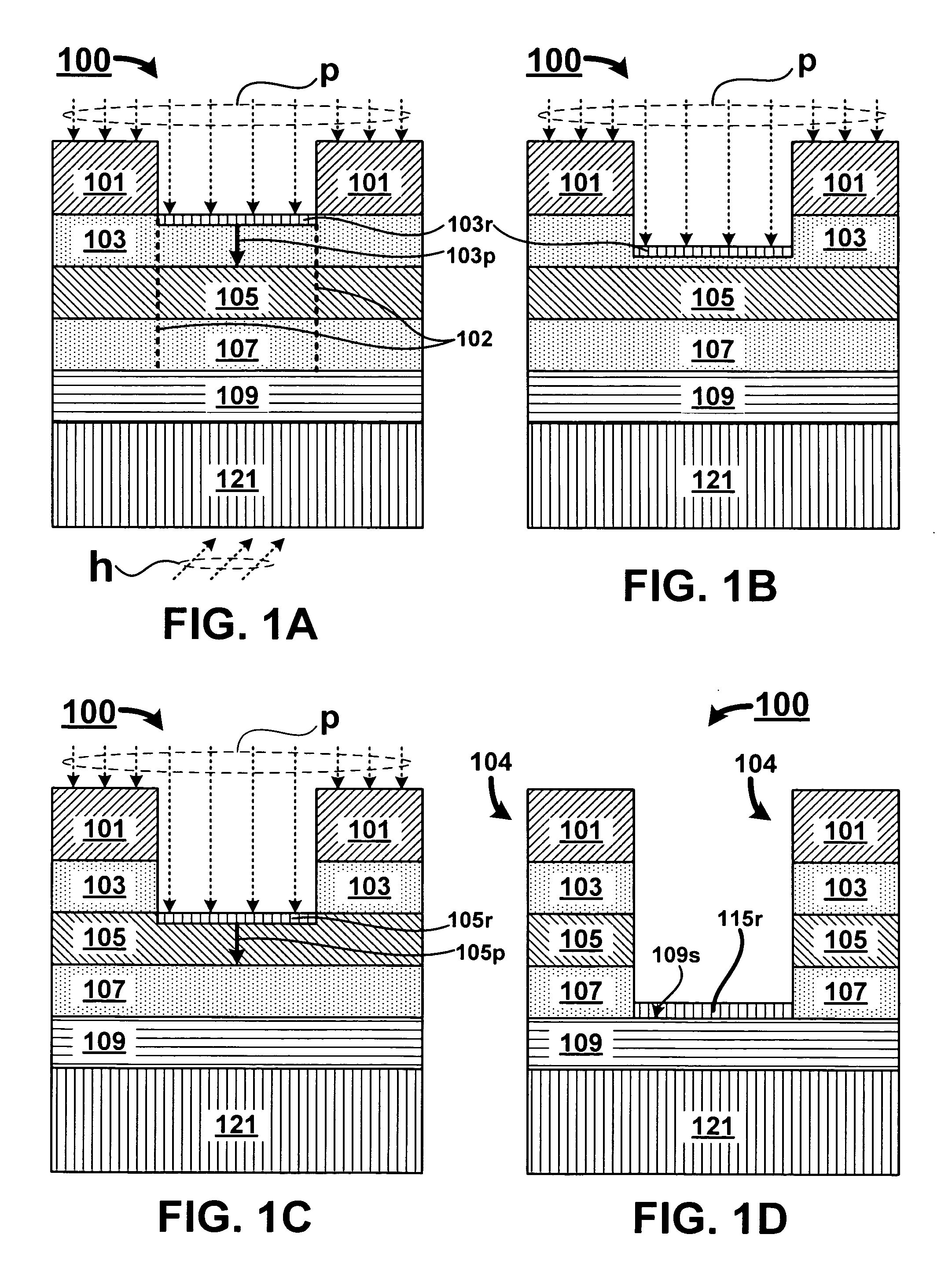

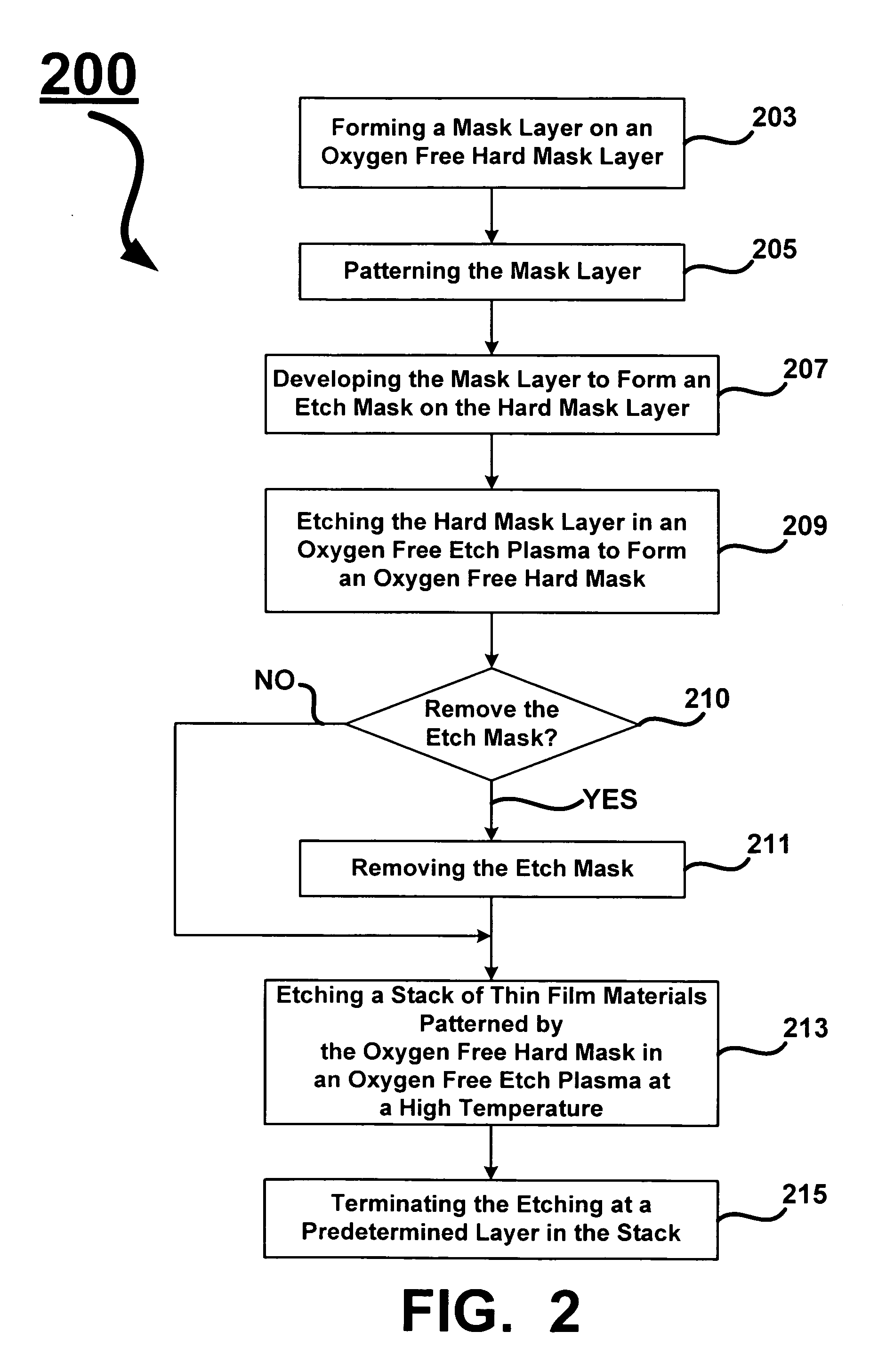

Oxygen depleted etching process

A method for oxygen depleted plasma etching and mixed mode plasma etching are disclosed. The method includes using an oxygen free etch plasma or a substantially oxygen free etch plasma at a high temperature to etch a stack including a plurality of layers of thin film materials. The oxygen depleted etching prevents or substantially reduces by-product re-deposition of titanium oxides generated by etching of titanium thin films in the stack. The titanium oxides can serve as a secondary mask layer that can cause defects in devices formed from the stack. Mixed mode plasma etching can include etching the stack with an oxygen free plasma, a substantially oxygen free plasma, and an oxygen containing plasma at different stages of a process.

Owner:UNITY SEMICON

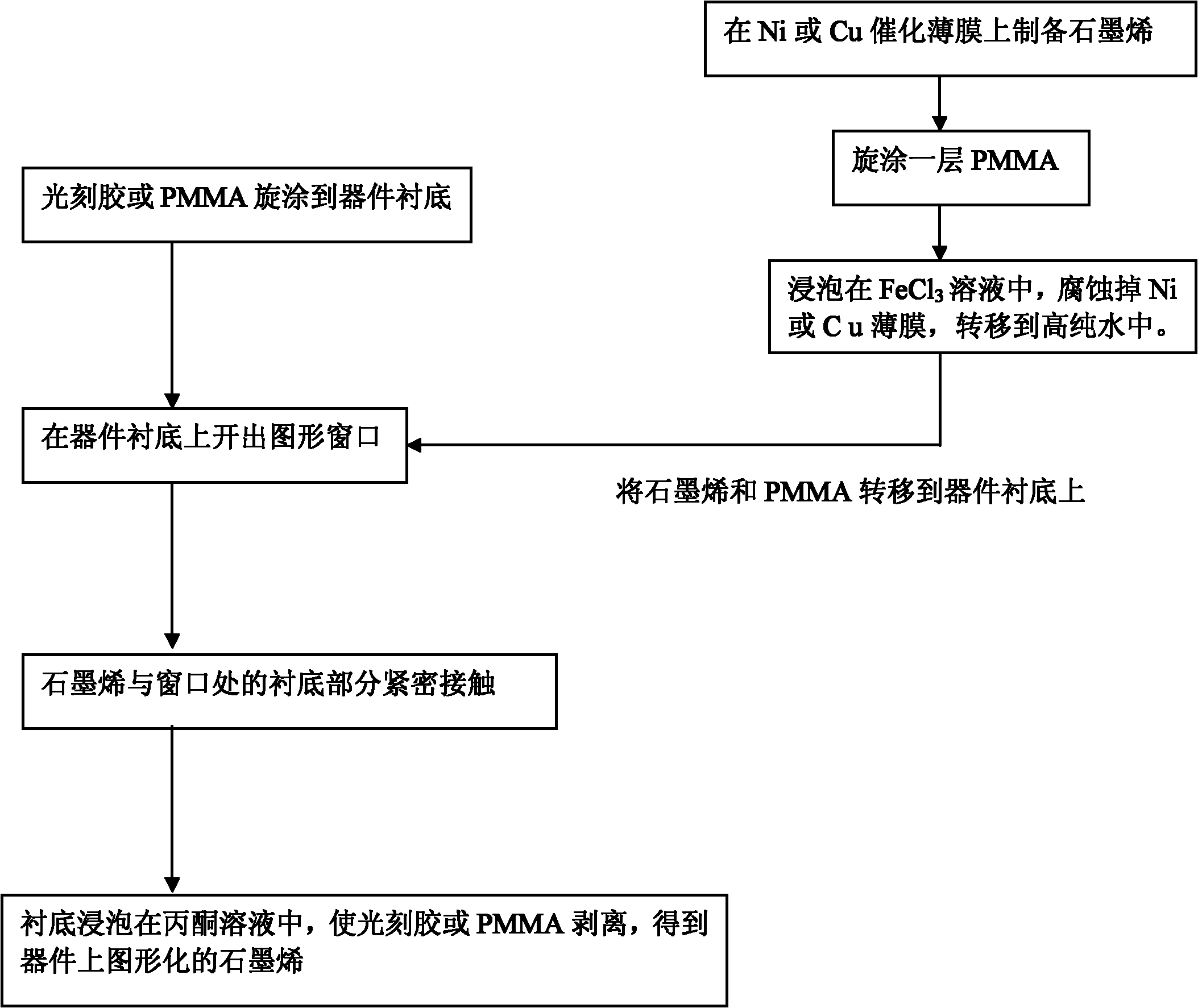

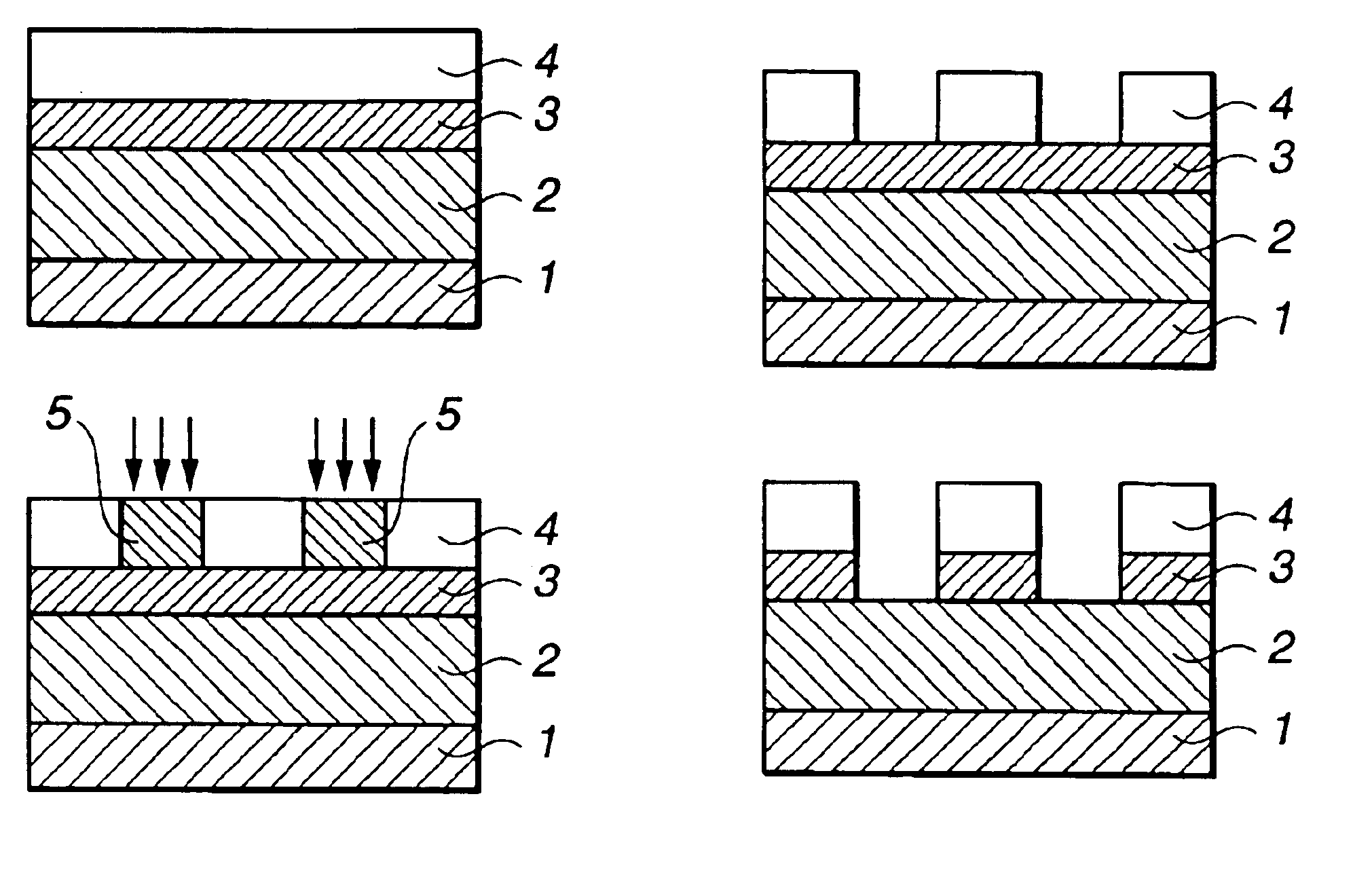

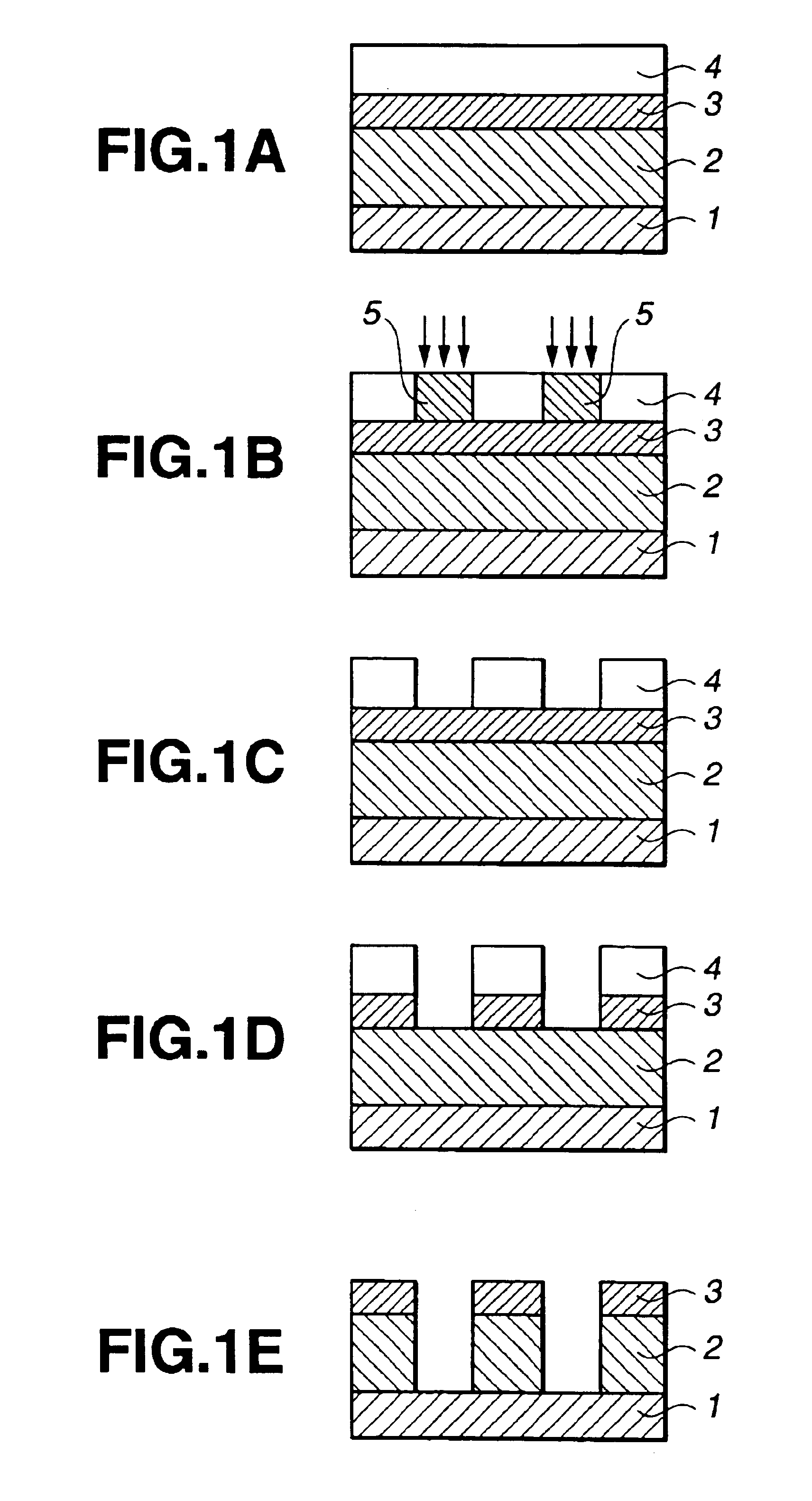

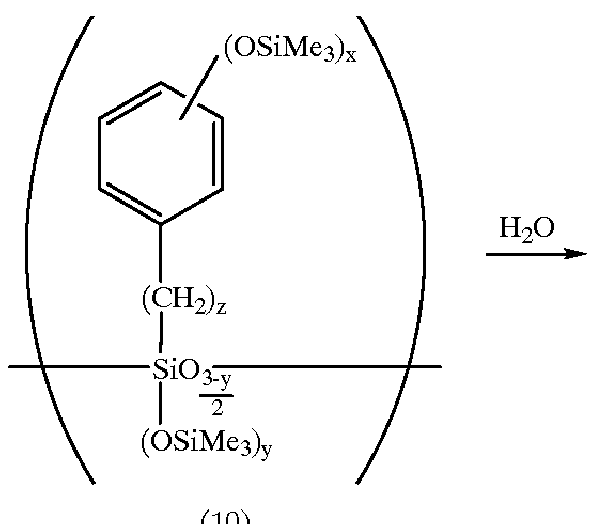

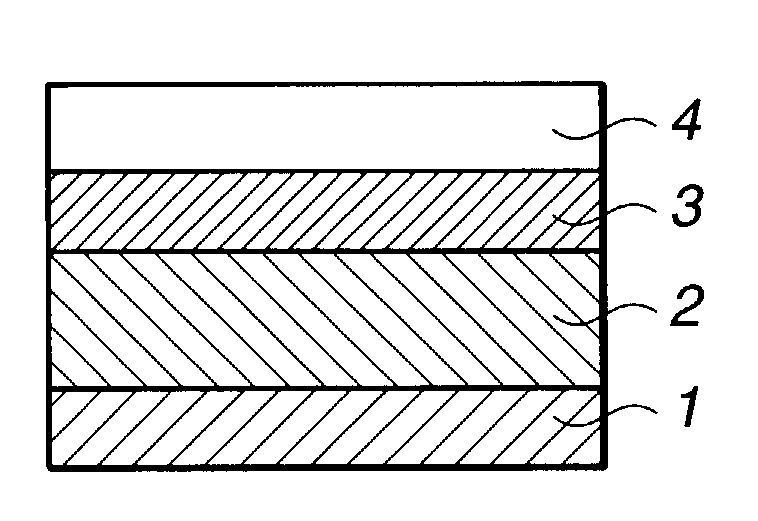

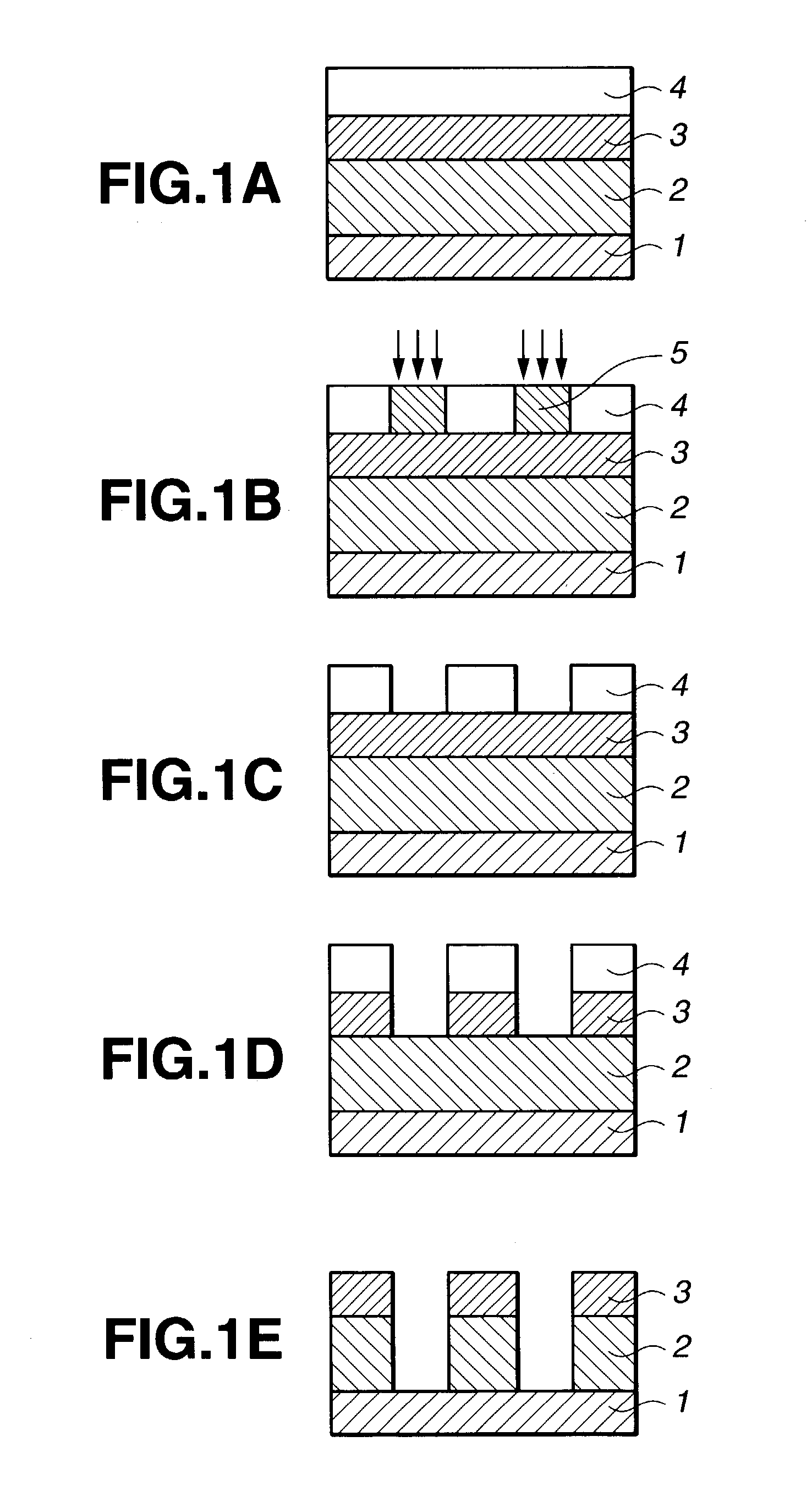

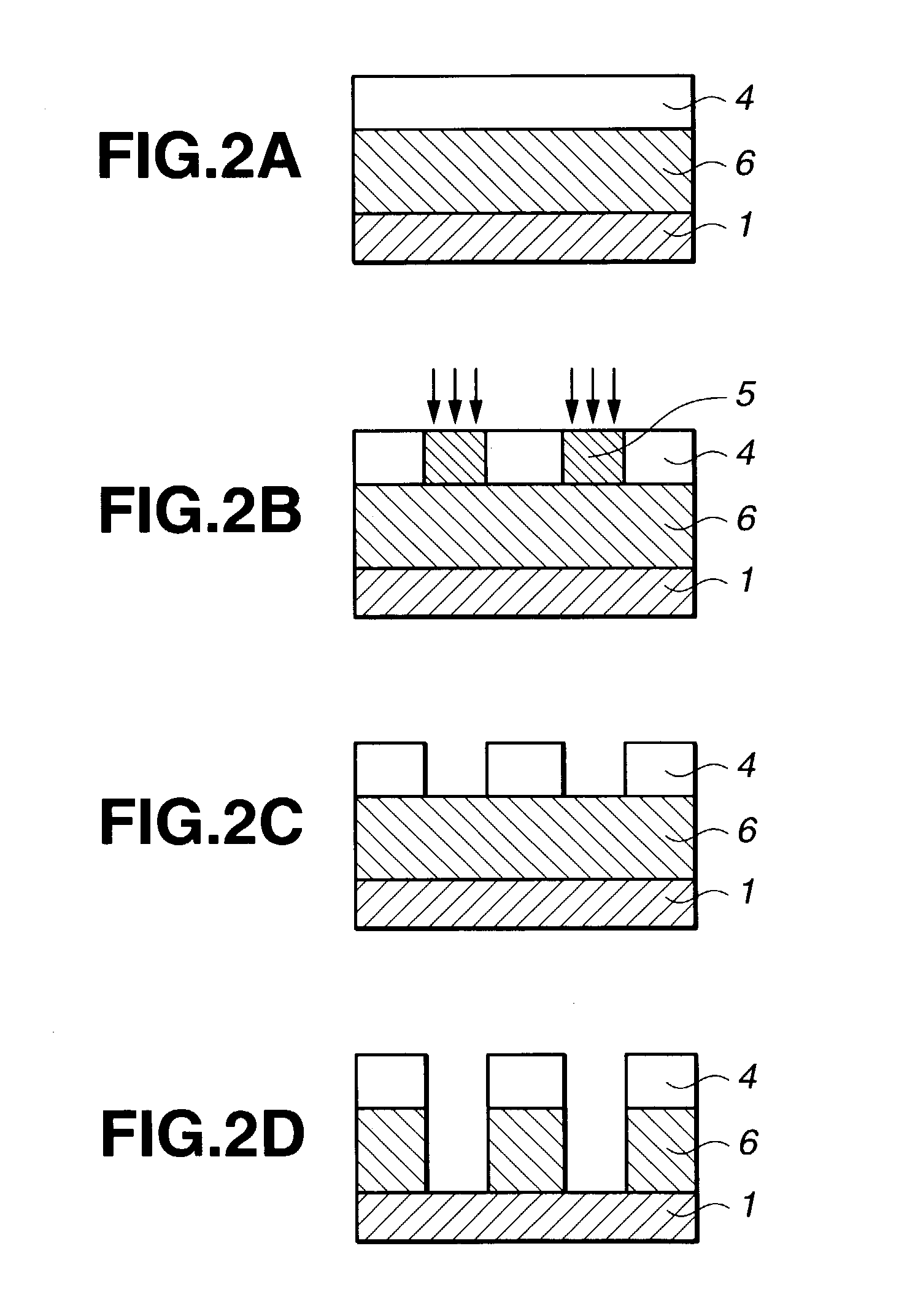

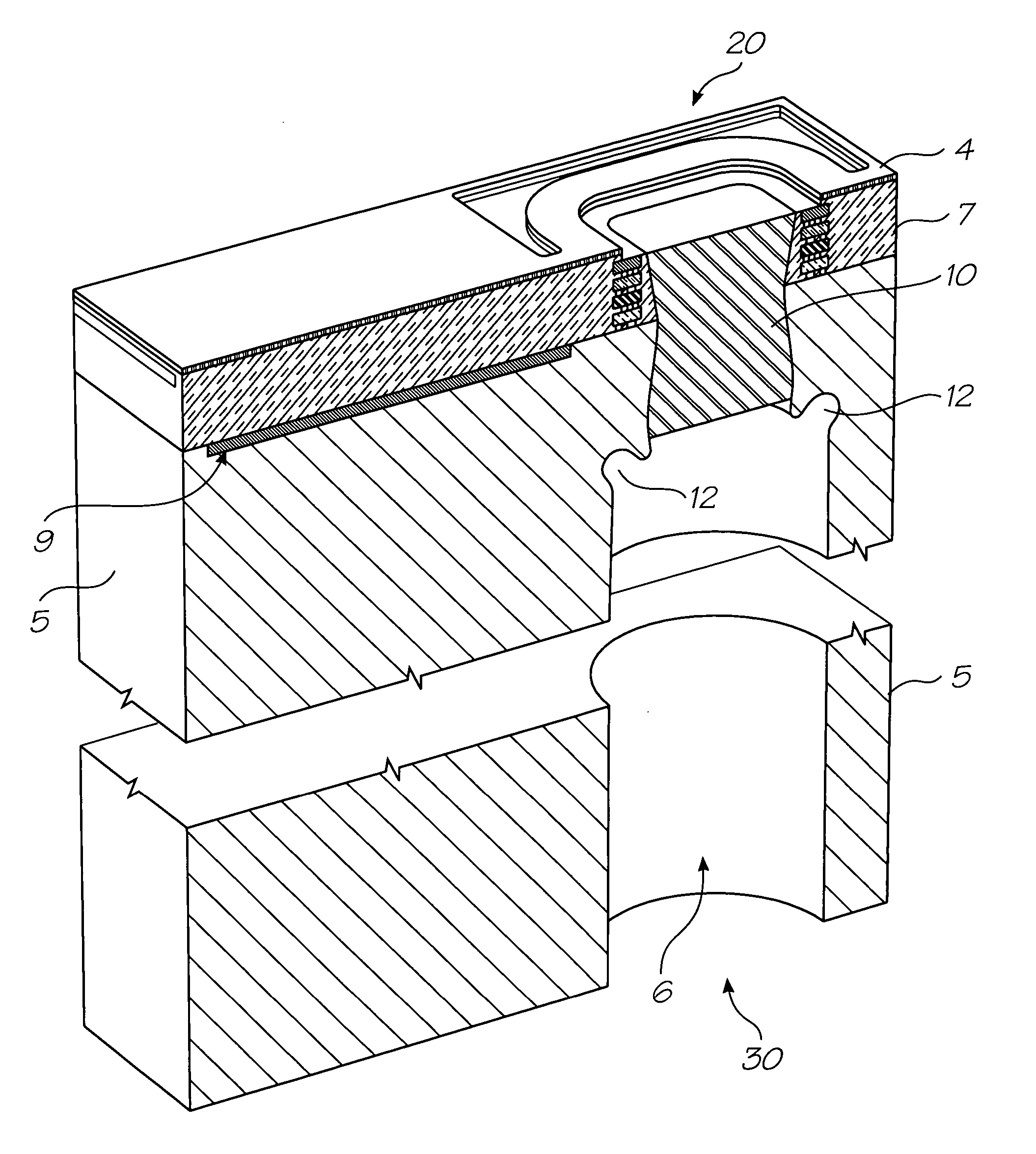

Method of nanopatterning, a resist film for use therein, and an article including the resist film

InactiveUS20070122749A1Surface energy is lowEasy to demouldNanoinformaticsPhotomechanical apparatusResistOxygen plasma etching

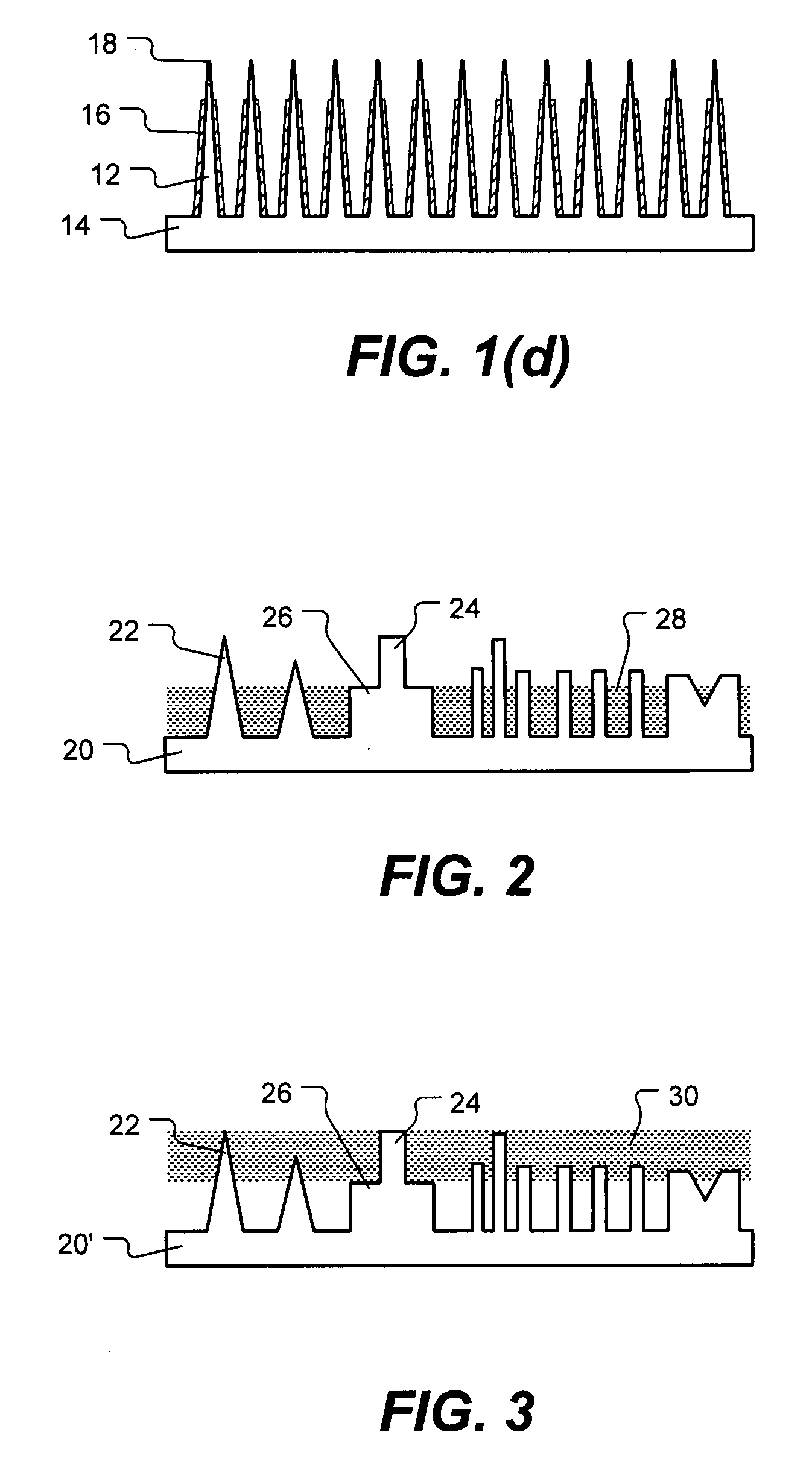

A method of nanopatterning includes the steps of providing a resist film (12) and forming a pattern in the resist film (12). The resist film (12) includes a copolymer consisting of an organosilicone component and an organic component. An article (10) includes a substrate (14) and the resist film (12) disposed on the substrate (14). The copolymer of the organosilicone component and the organic component is sufficiently elastic, due to the presence of the organosilicone component, to be capable of resisting fracture and delamination during mold release. Furthermore, during pattern formation, the copolymer develops relatively low surface energy at an interface with the surface of a mold, as compared to conventional polymeric materials, and preferentially adheres to the substrate (14) rather than the mold, which provides for relatively easy mold release. The presence of the organosilicone component in the copolymer also allows the resist film (12) to exhibit excellent resistance to oxygen plasma etching.

Owner:DOW CORNING CORP

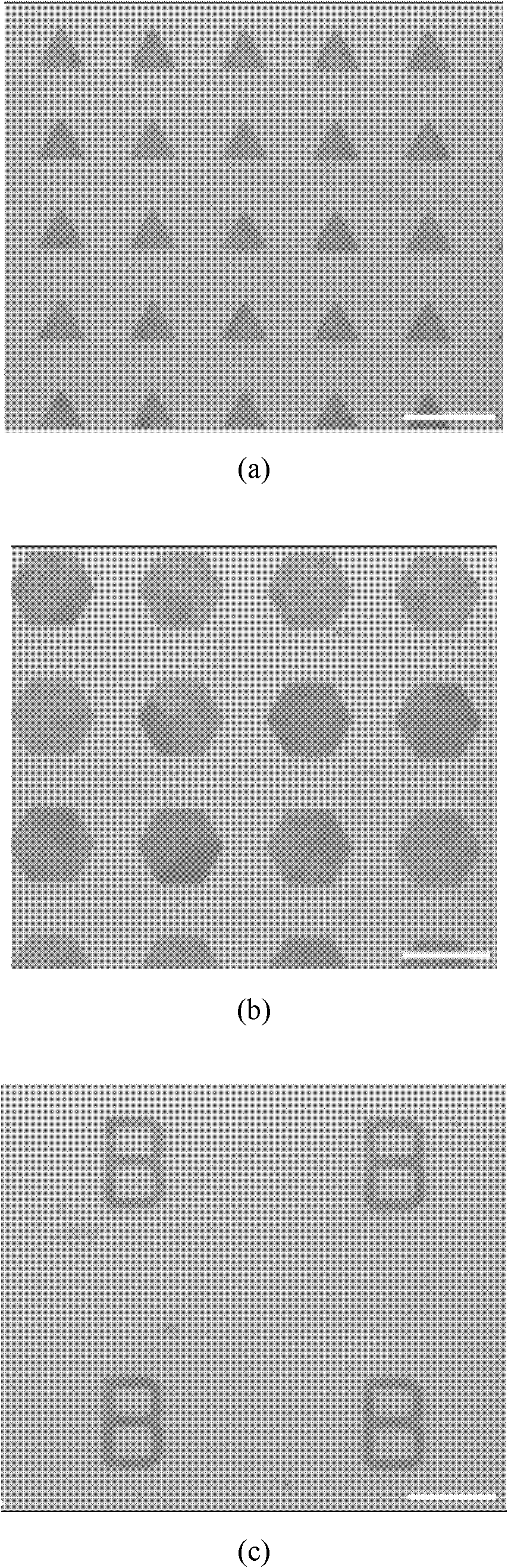

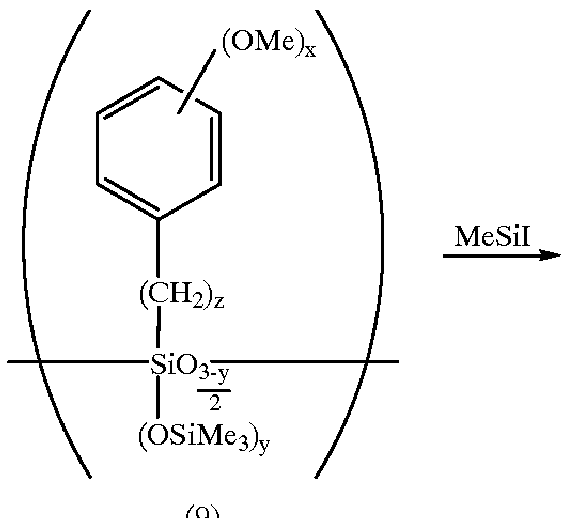

Method for preparing patterned graphene

InactiveCN101872120AReduce performancePrecise positioningPhotomechanical apparatusLithographic artistOxygen plasma etching

The invention discloses a method for preparing patterned graphene. In the method, a photoresist is patterned on a device substrate by a microelectronic process such as UV lithography and electron beam lithography, and windows are formed at positions needing graphene; by a graphene transfer method, large-area graphene is transferred onto the patterned photoresist; and the photoresist and the graphene thereon are stripped by an acetone immersion method so as to obtain the patterned graphene required by the device. Compared with the prior art, the method has the advantages of accurate positioning, and does not require etching or manufacturing an imprint template so as to have low cost. Through the method, the patterned graphene is accurately positioned, and the integration of large-area devices is easy to realize. Besides, by exposure and stripping methods, an oxygen plasma-etching step is avoided, so the reduction of the device performance caused by radiation damage is avoided.

Owner:PEKING UNIV

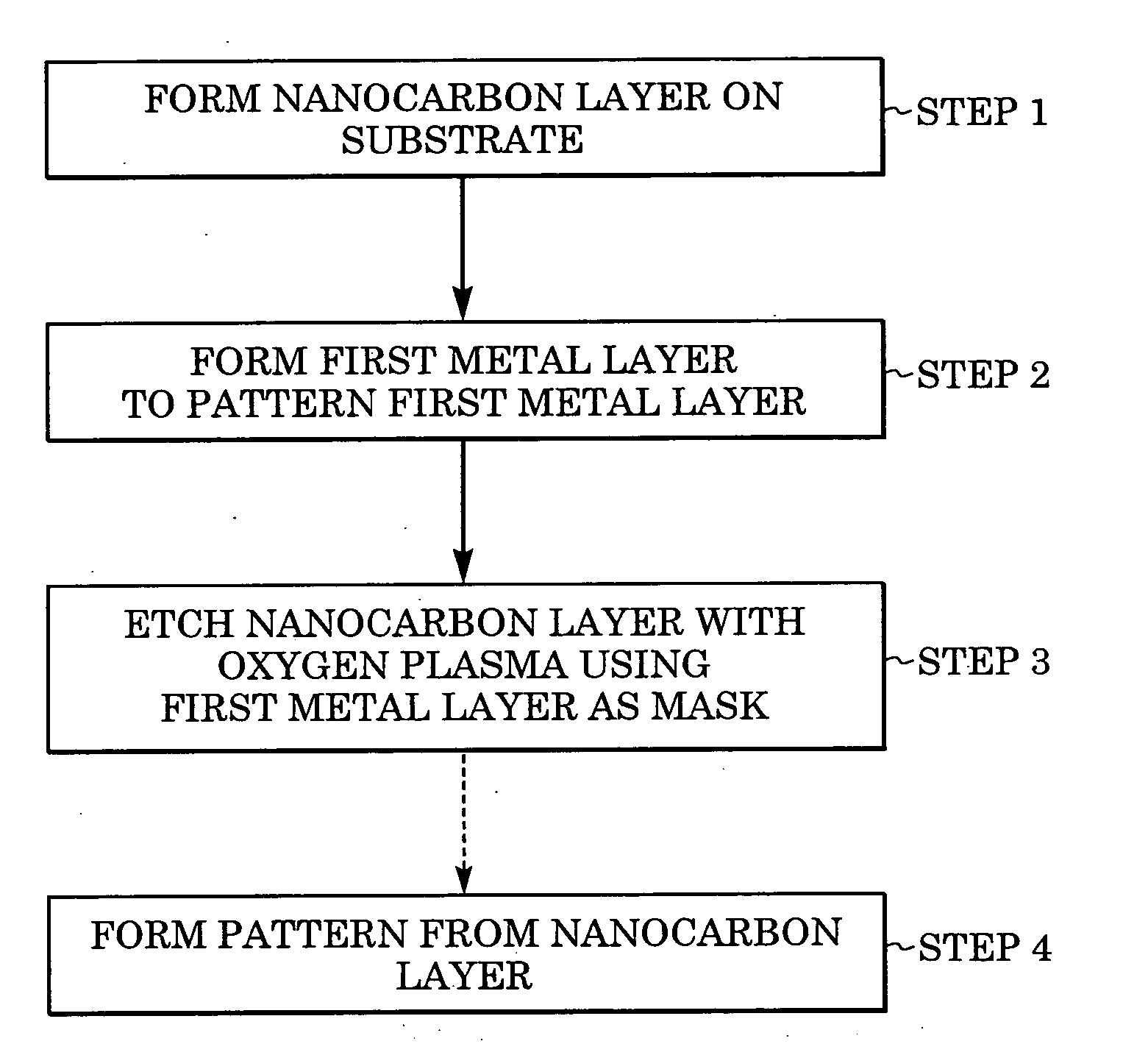

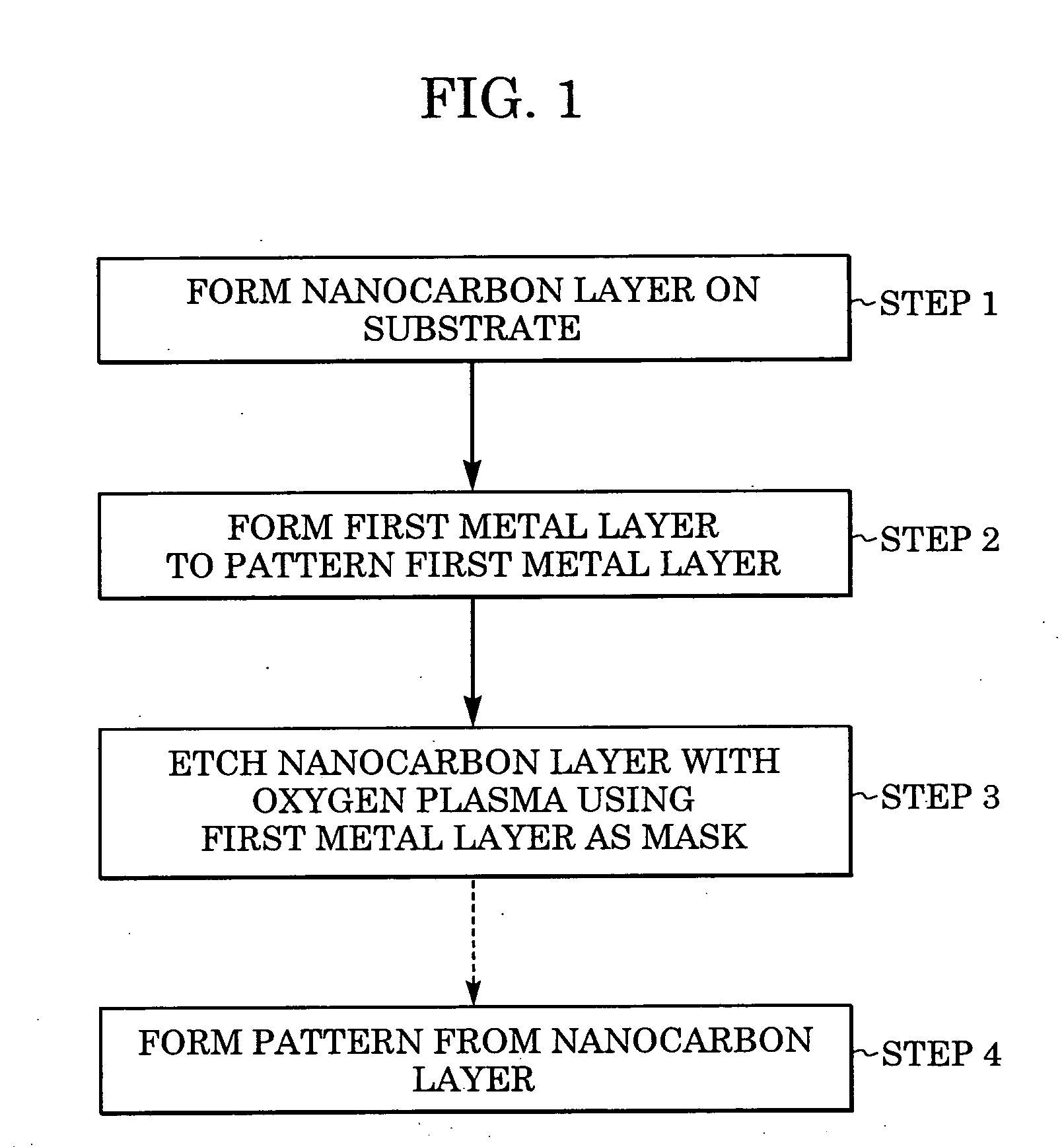

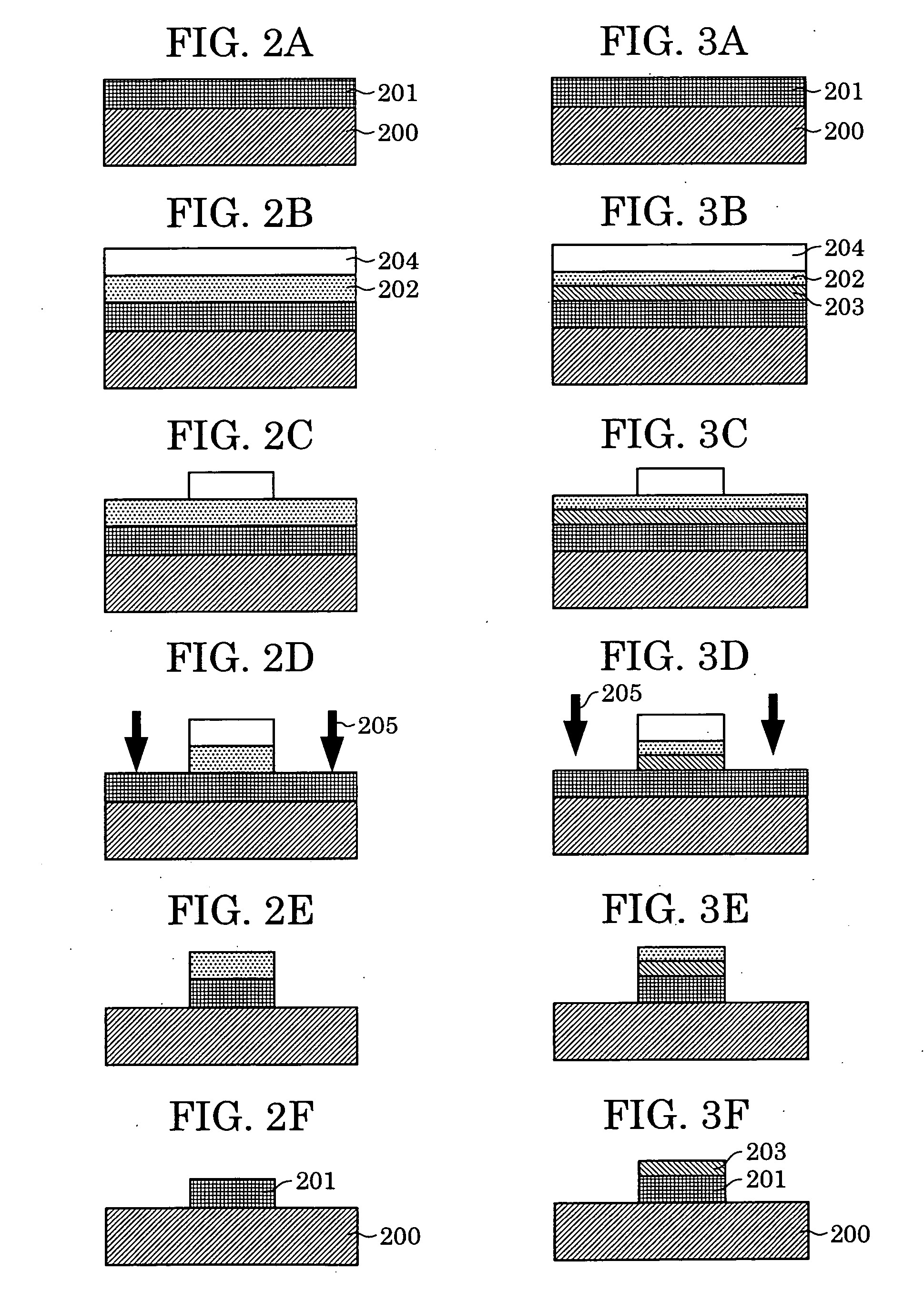

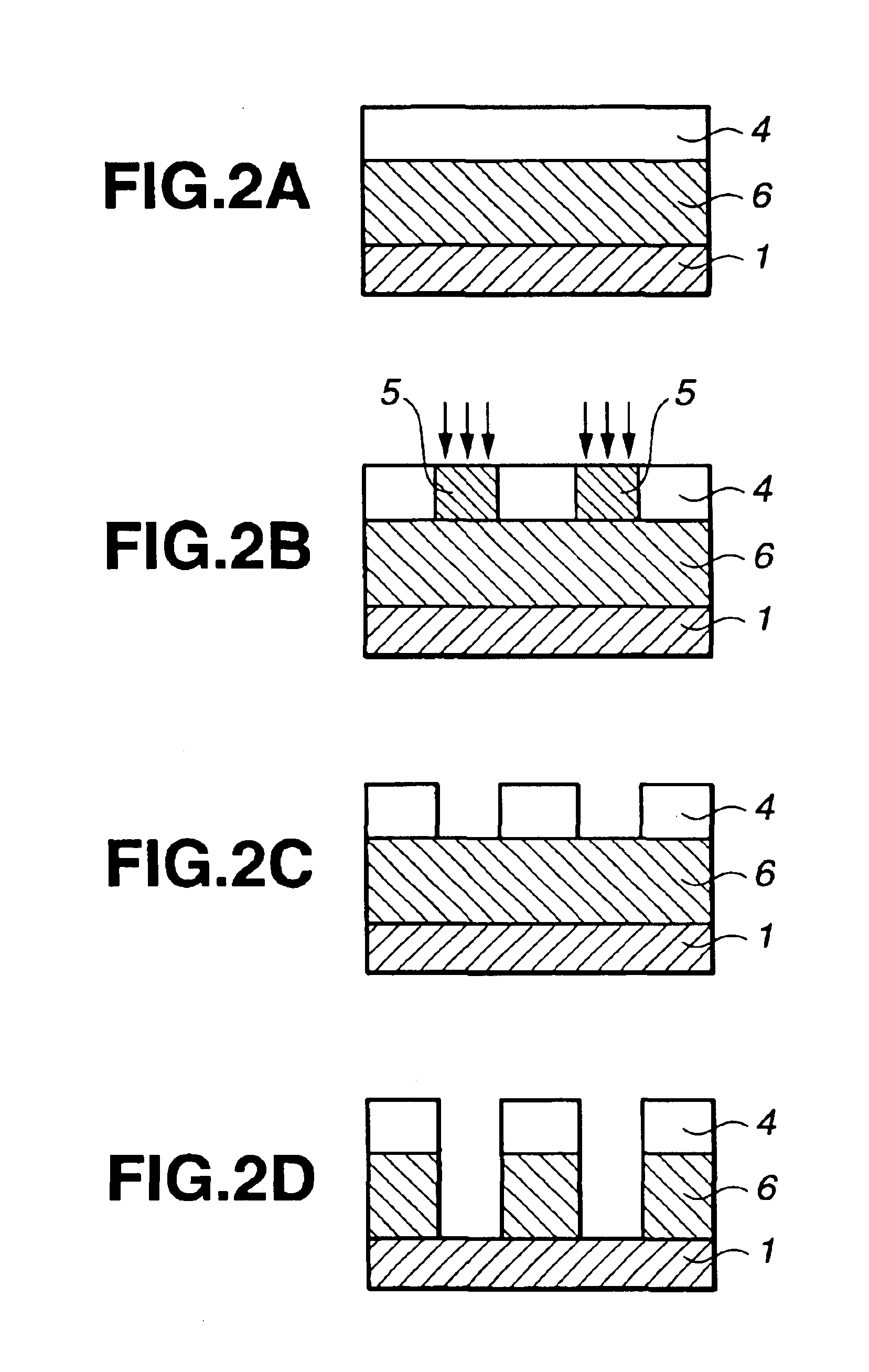

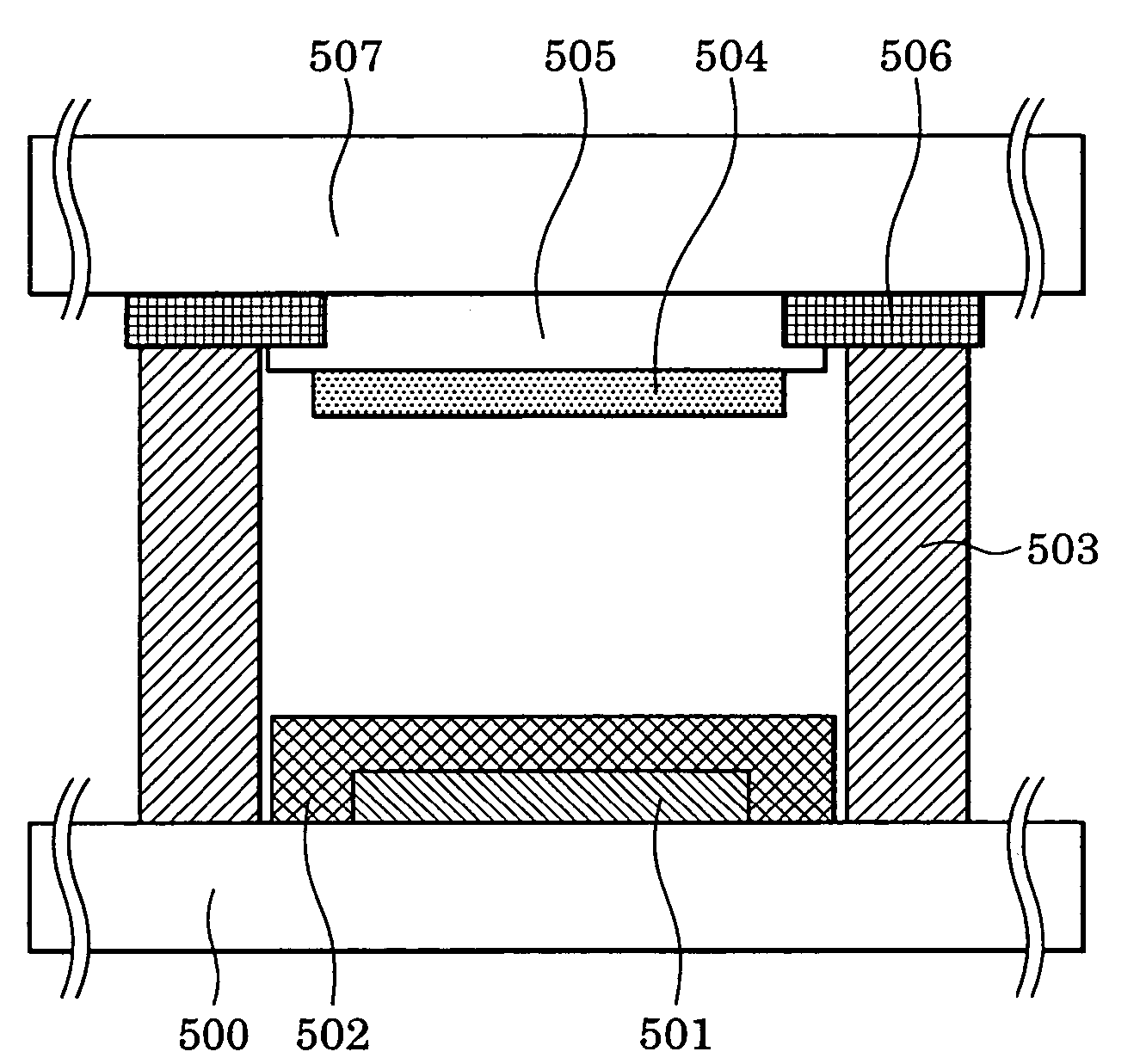

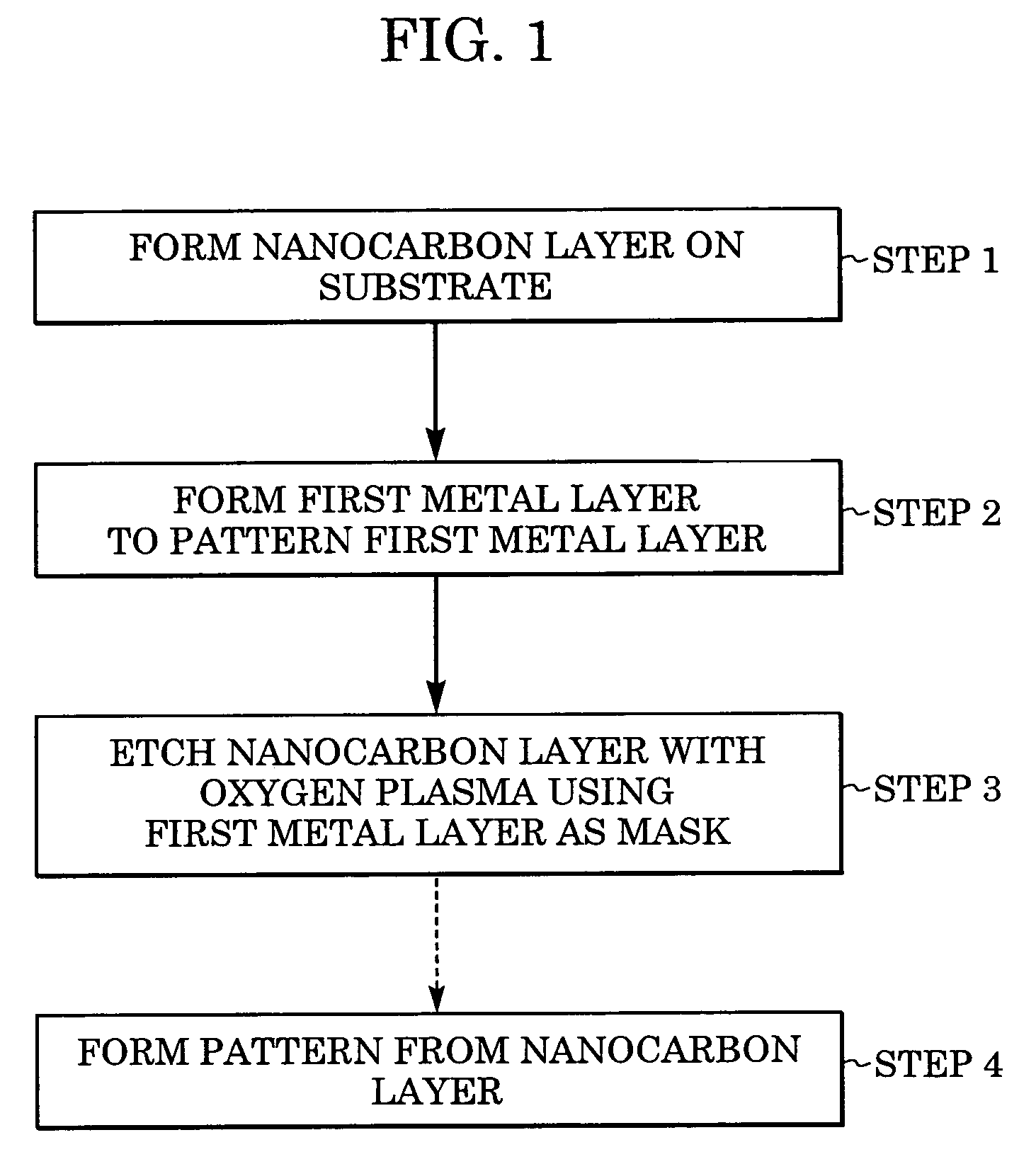

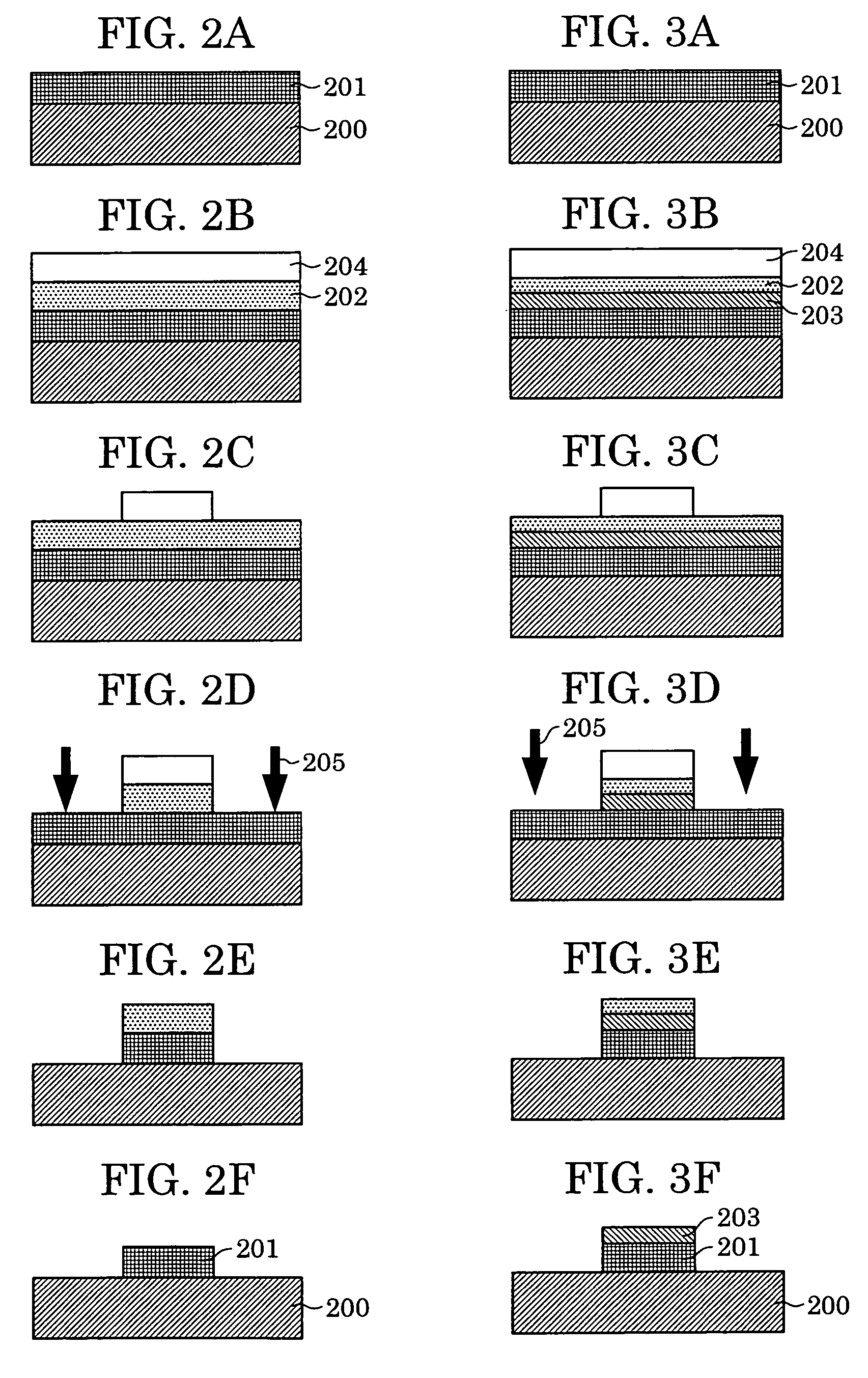

Process for patterning nanocarbon material, semiconductor device, and method for manufacturing semiconductor device

InactiveUS20050266605A1Easy to makeMaterial nanotechnologyElectric discharge tubesIndiumDevice material

A process for patterning a nanocarbon material includes a step of forming a nanocarbon layer on a substrate; a step of forming a first metal layer on the nanocarbon layer to pattern the first metal layer, the first metal layer containing at least one selected from the group consisting of zinc, tin, indium, aluminum, and titanium; and a step of etching the nanocarbon layer with oxygen plasma using the first metal layer as a positive pattern. Also, a method for manufacturing a semiconductor device including a semiconductor layer containing a nanocarbon material includes a step of patterning a nanocarbon material by the above process; and, a semiconductor device containing a nanocarbon material includes a semiconductor layer including a nanocarbon sub-layer patterned by the process.

Owner:CANON KK

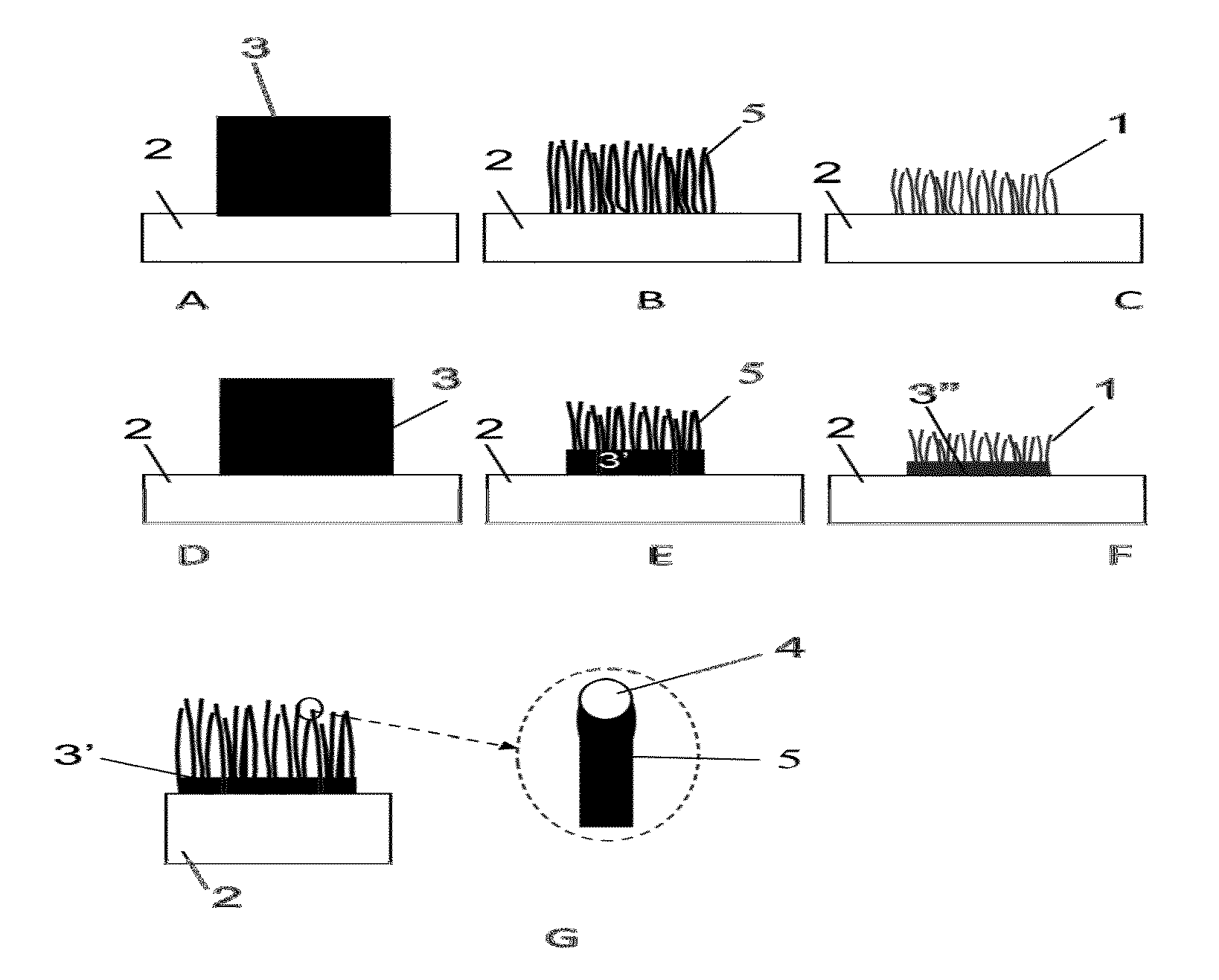

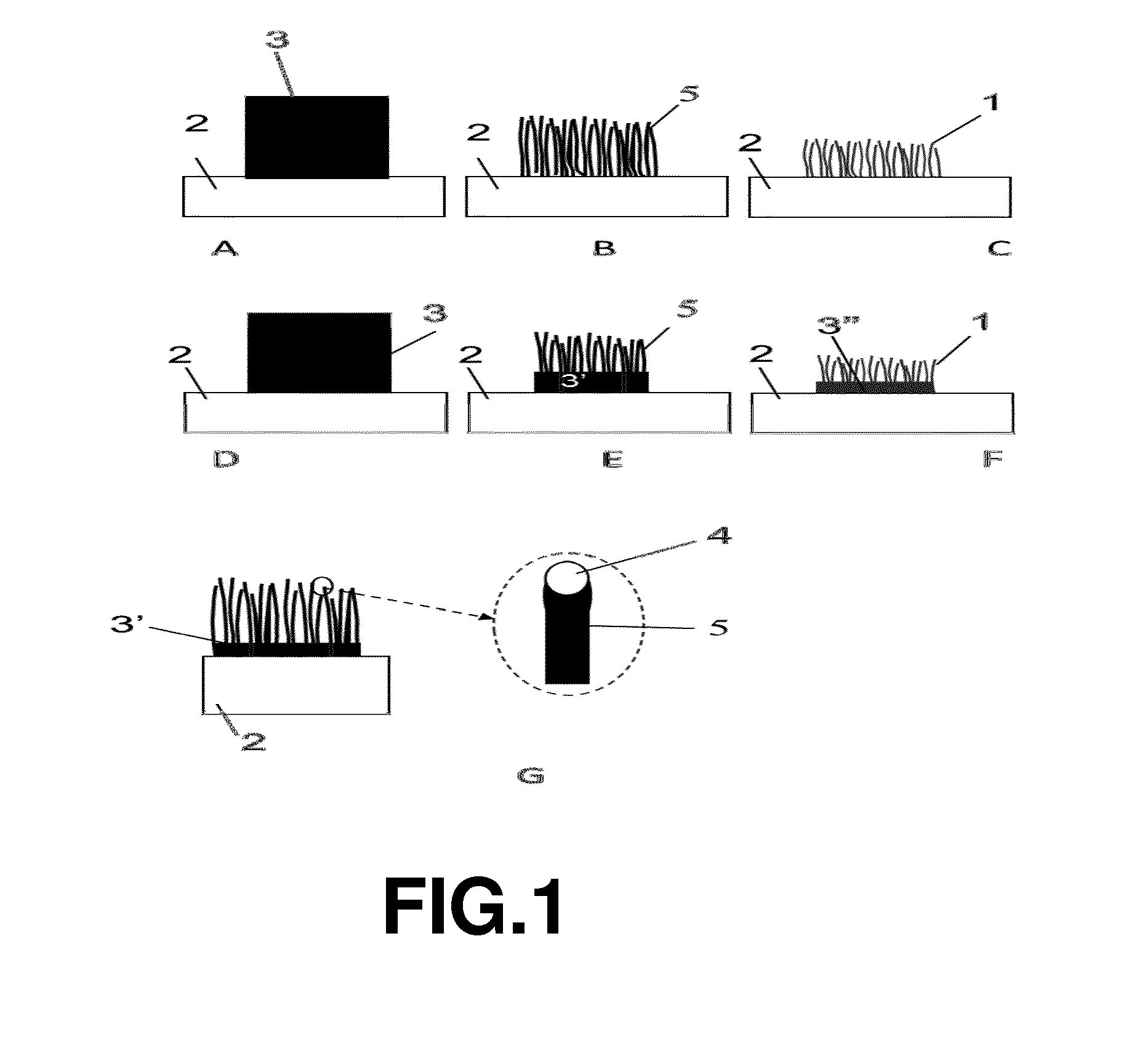

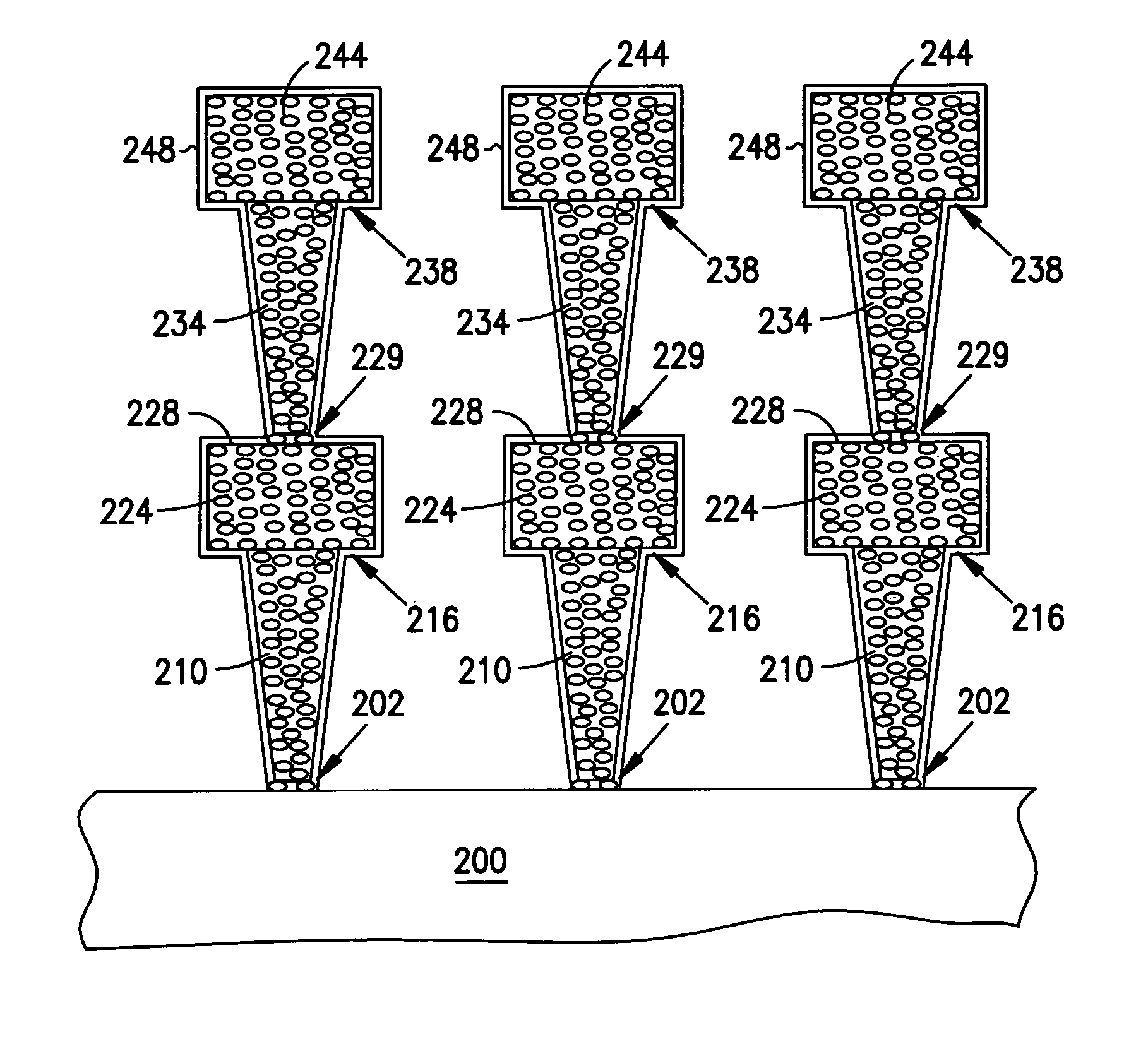

Hierarchical Carbon Nano and Micro Structures

ActiveUS20140079921A1Material nanotechnologyDecorative surface effectsMicro structureOxygen plasma etching

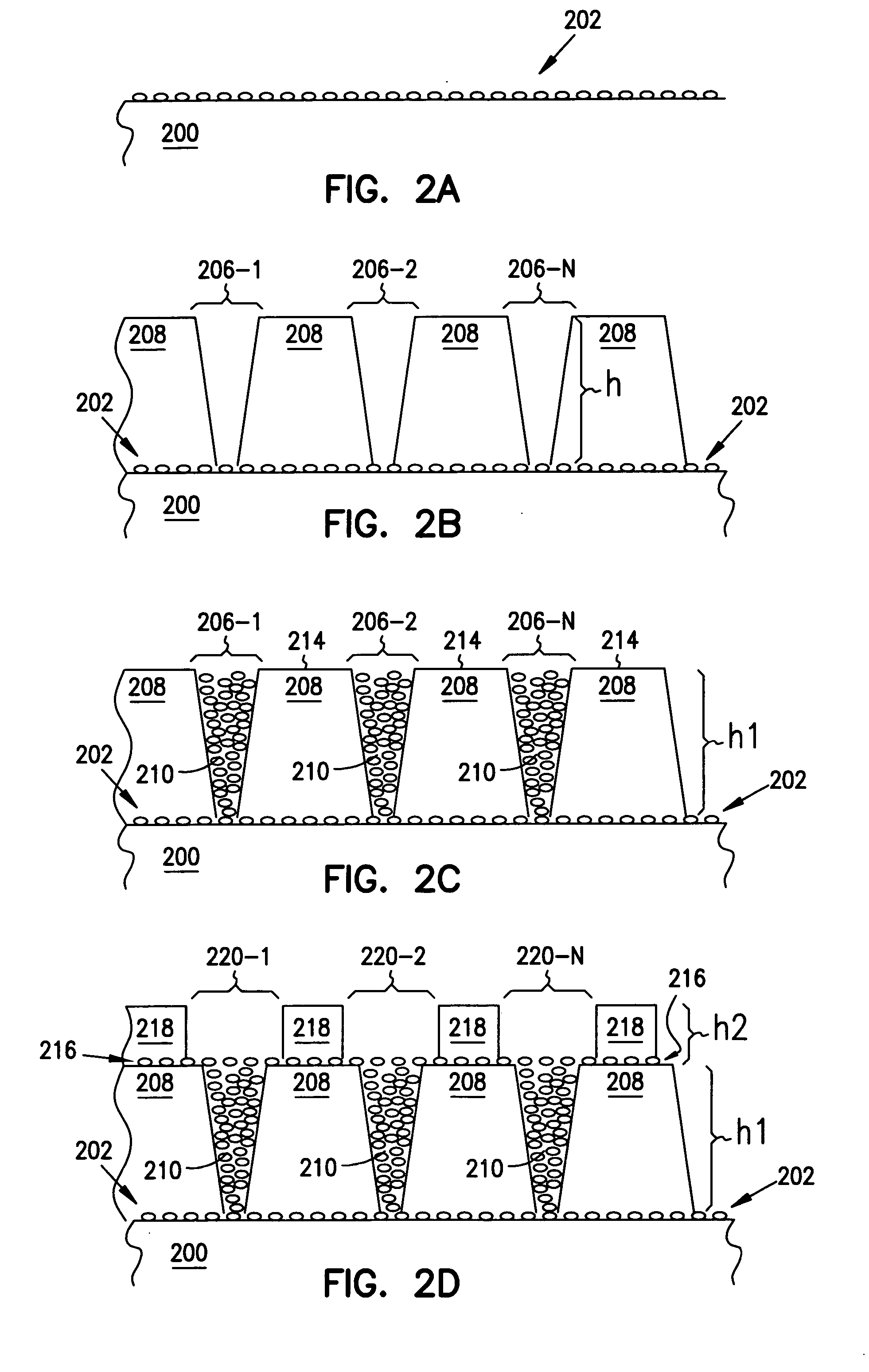

Disclosed are methods for fabricating pyrolysed carbon nanostructures. An example method includes providing a substrate, depositing a polymeric material, subjecting the polymeric material to a plasma etching process to form polymeric nanostructures, and pyrolysing the polymeric nanostructures to form carbon nanostructures. The polymeric material comprises either compounds with different plasma etch rates or compounds that can mask a plasma etching process. The plasma etching process may be an oxygen plasma etching process.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

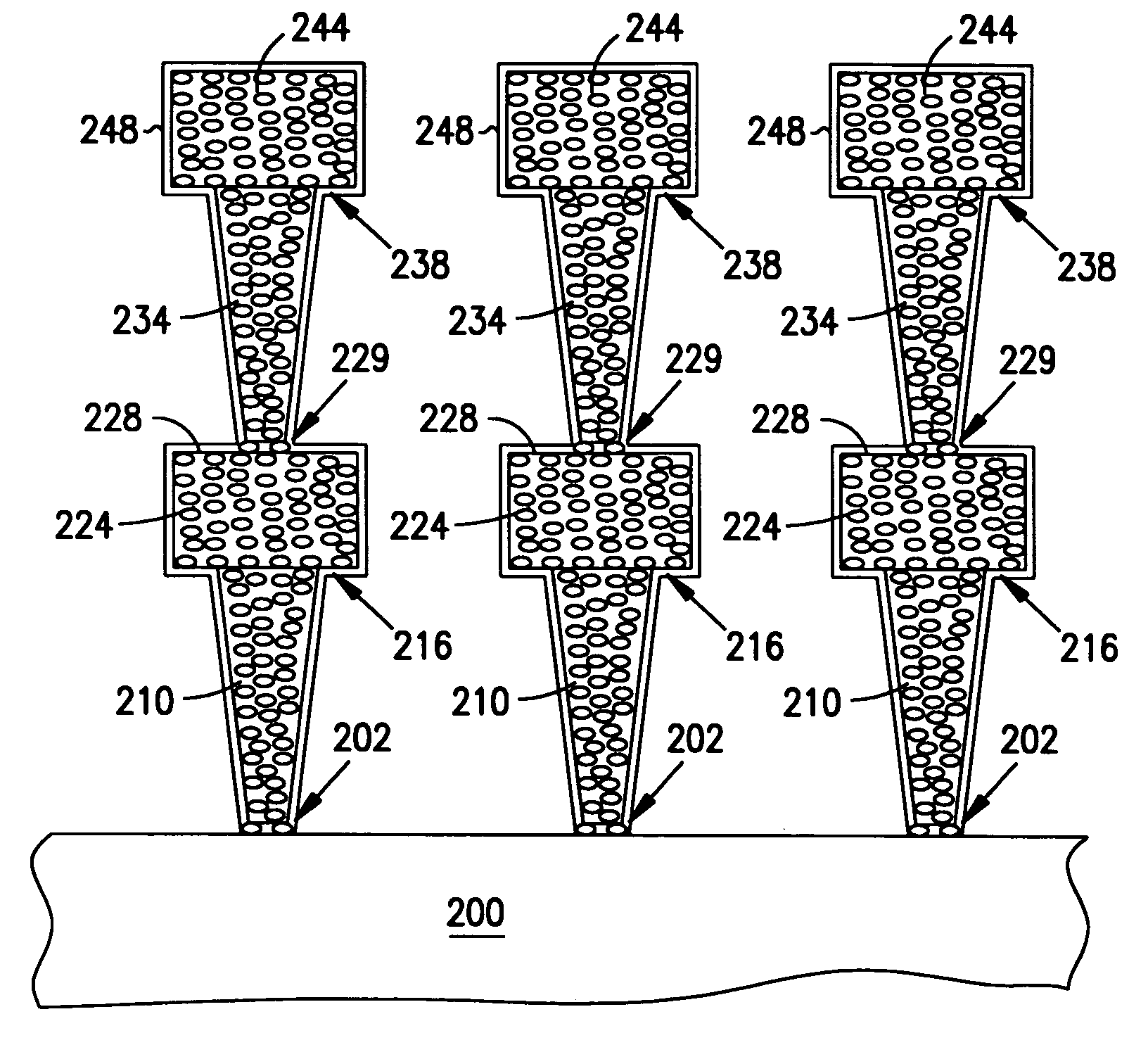

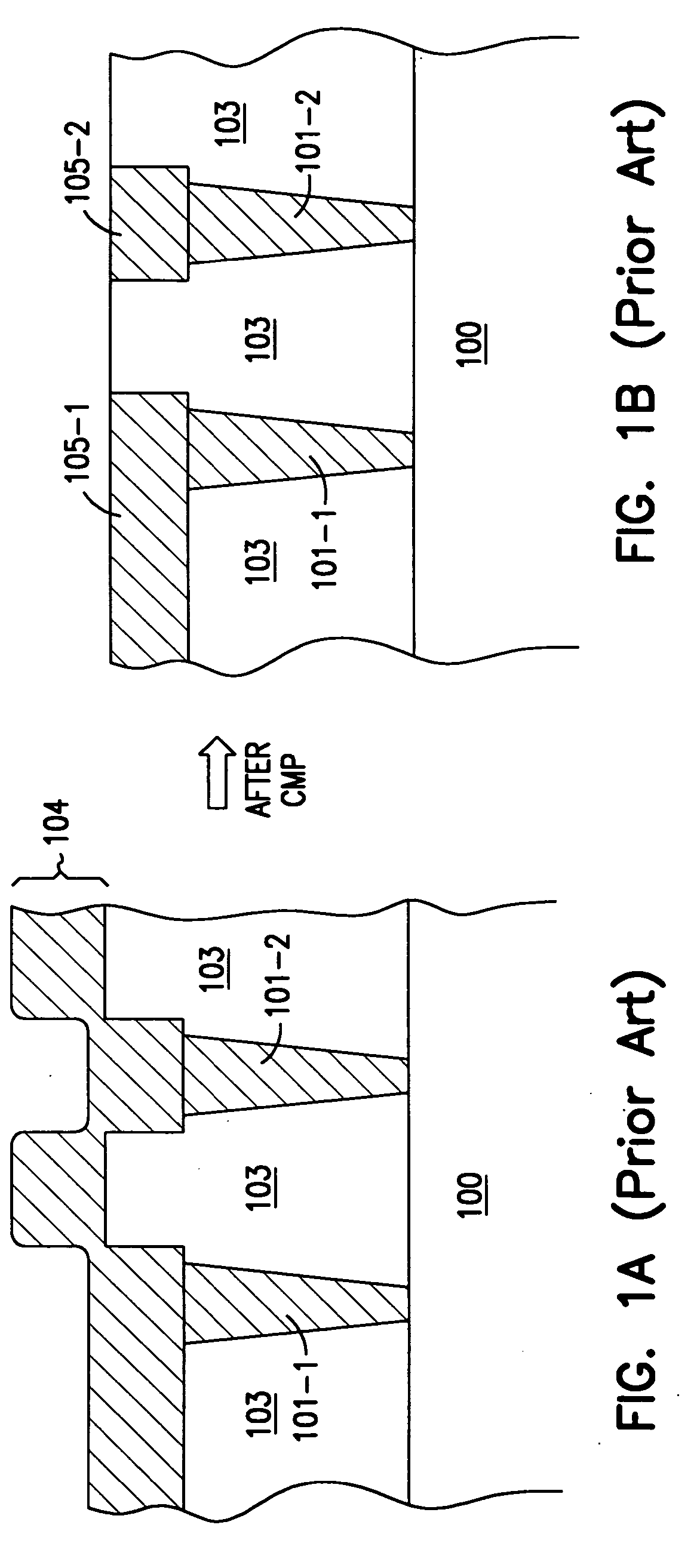

Selective electroless-plated copper metallization

InactiveUS20050023699A1Reduce amountReduce environmental problemsSemiconductor/solid-state device detailsSolid-state devicesCopper platingOxygen plasma etching

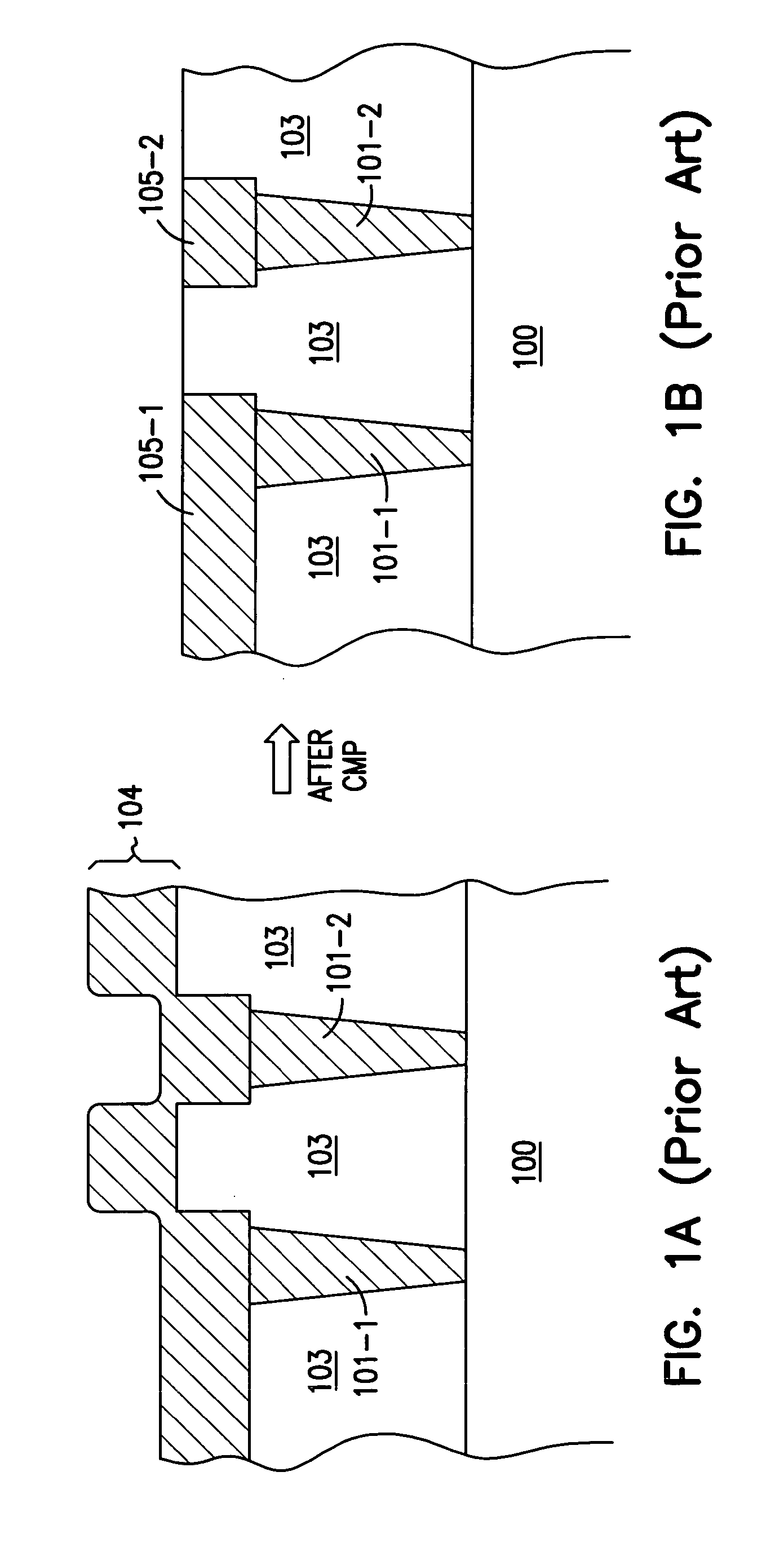

Structures and methods are provided which include a selective electroless copper metallization. The present invention includes a novel methodology for forming copper vias on a substrate, including depositing a thin film seed layer of Palladium (Pd) or Copper (Cu) on a substrate to a thickness of less than 15 nanometers (nm). A number of via holes is defined above the seed layer. A layer of copper is deposited over the seed layer using electroless plating to fill the via holes to a top surface of the patterned photoresist layer. The method can be repeated any number of times, forming second, third and fourth layers of copper. The photoresist layers along with the seed layers in other regions can then be removed, such as by oxygen plasma etching, such that a chemical mechanical planarization process is avoided.

Owner:MICRON TECH INC

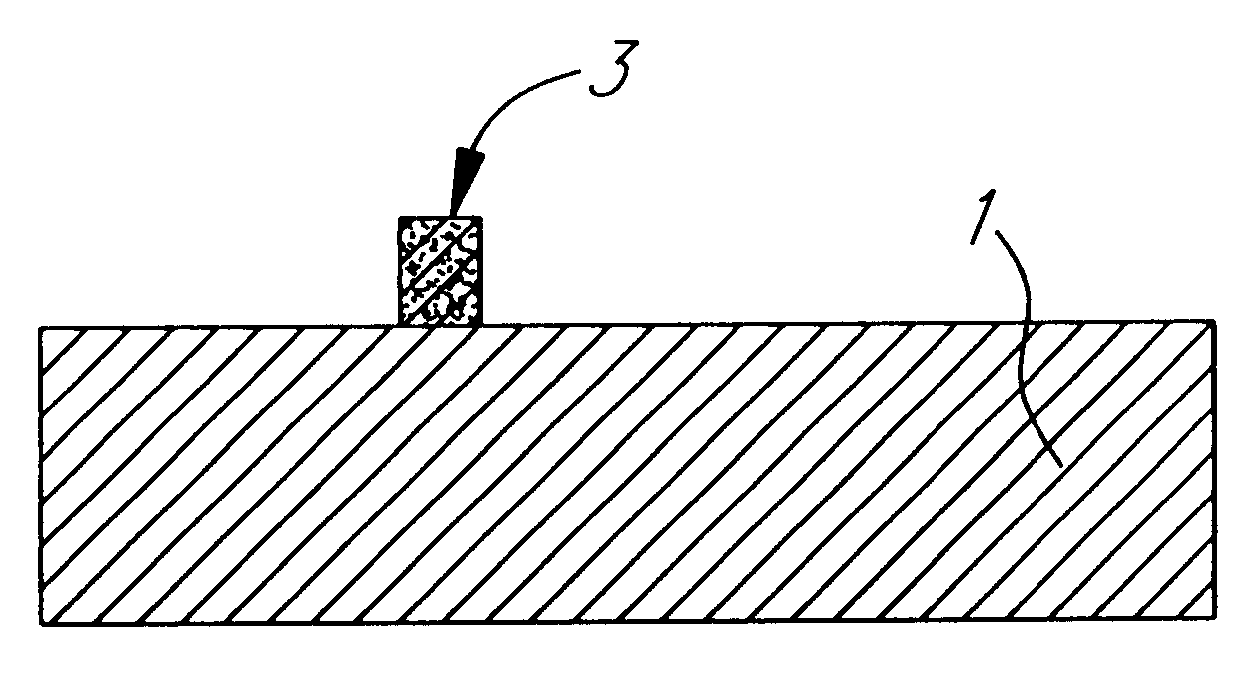

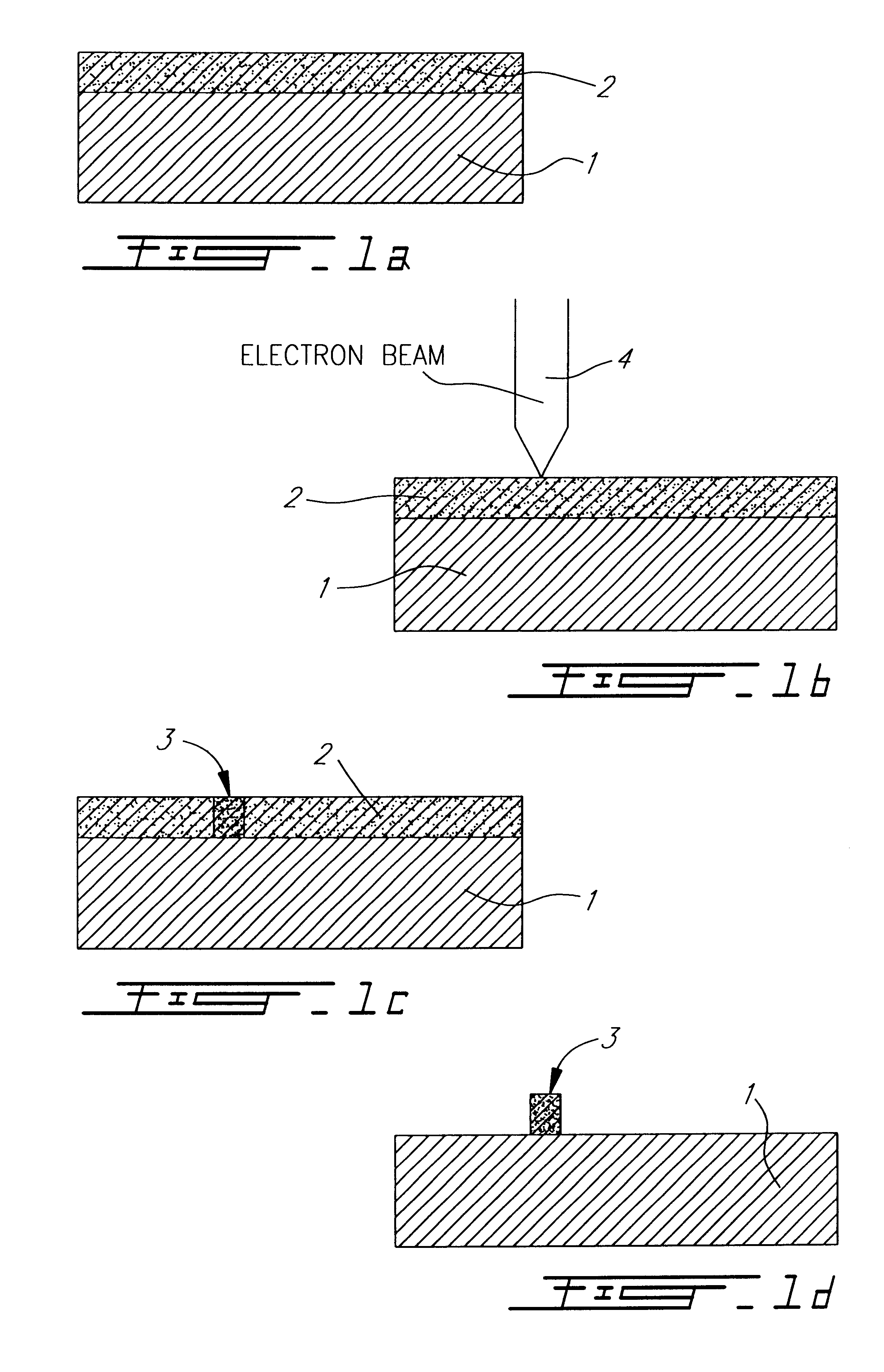

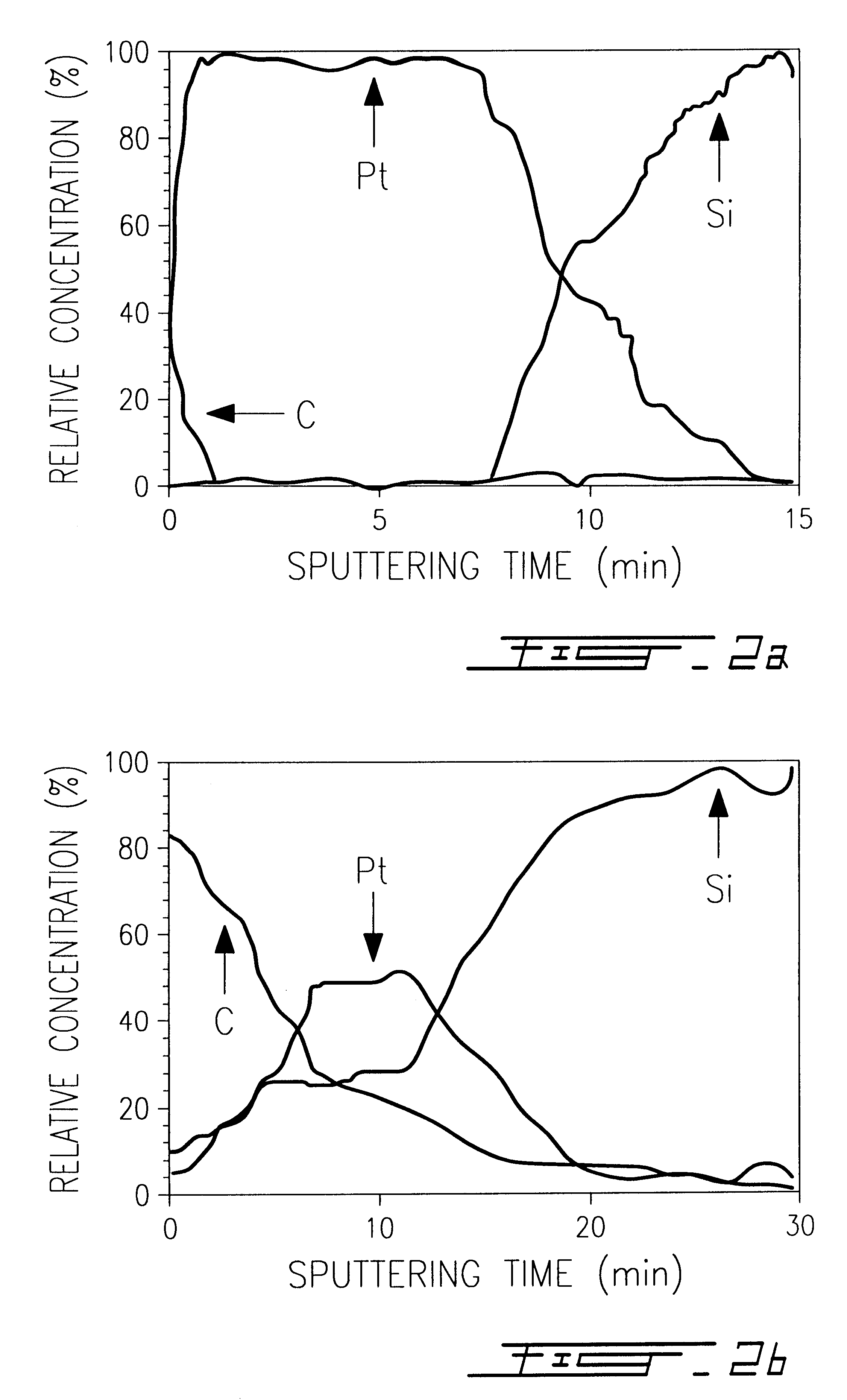

Fabrication of sub-micron etch-resistant metal/semiconductor structures using resistless electron beam lithography

InactiveUS6261938B1NanoinformaticsSemiconductor/solid-state device manufacturingSemiconductor materialsSemiconductor structure

A method for fabricating a sub-micron structure of etch-resistant metal / semiconductor compound on a substrate of semiconductor material comprises the step of depositing onto the substrate a layer of metal capable of reacting with the semiconductor material to form etch-resistant metal / semiconductor compound, and the step of producing a focused electron beam. The focused electron beam is applied to the layer of metal to locally heat the metal and semiconductor material and cause diffusion of the metal and semiconductor material in each other to form etch-resistant metal / semiconductor compound. The focused electron beam is displaced onto the layer of metal to form the structure of etch-resistant metal / semiconductor compound. Finally, the layer of metal is wet etched to leave on the substrate only the structure of metal / semiconductor compound. Following wet etching of the layer of metal, an oxygen plasma etch can be conducted to remove a carbon deposit formed at the surface of the structure of etch-resistant metal / semiconductor compound. Also, the substrate may be subsequently etched to remove a thin layer of metal rich semiconductor material formed at the surface of the substrate by reaction, at room temperature, of the metal and semiconductor material with each other.

Owner:SCOPRA SCI & GENIE SEC

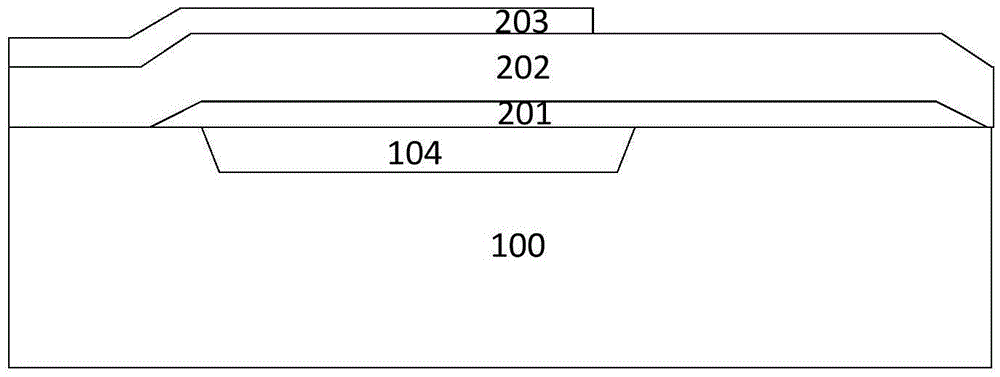

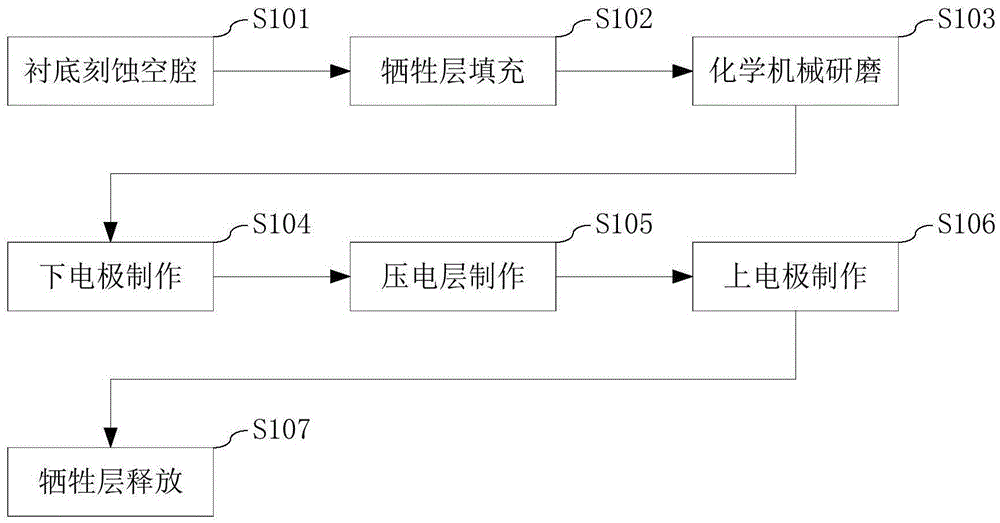

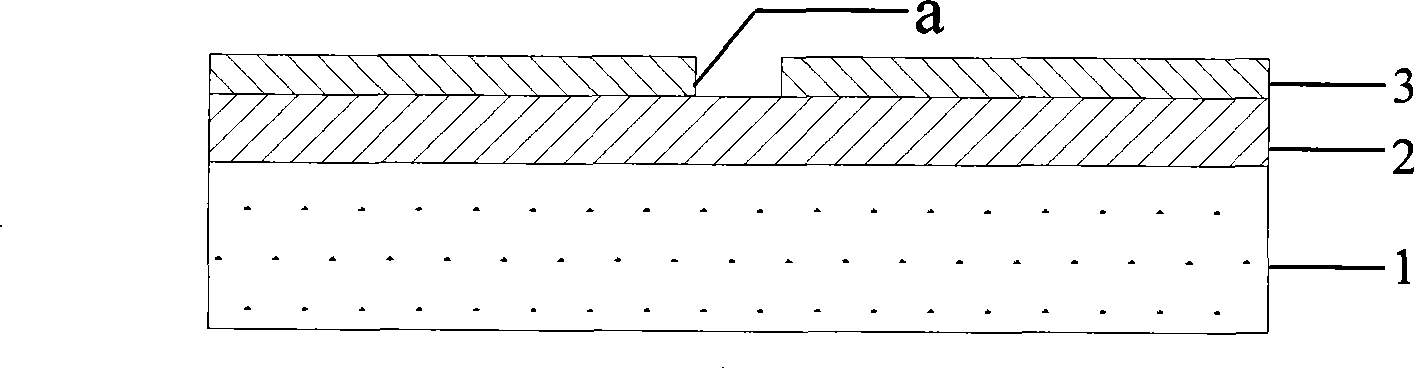

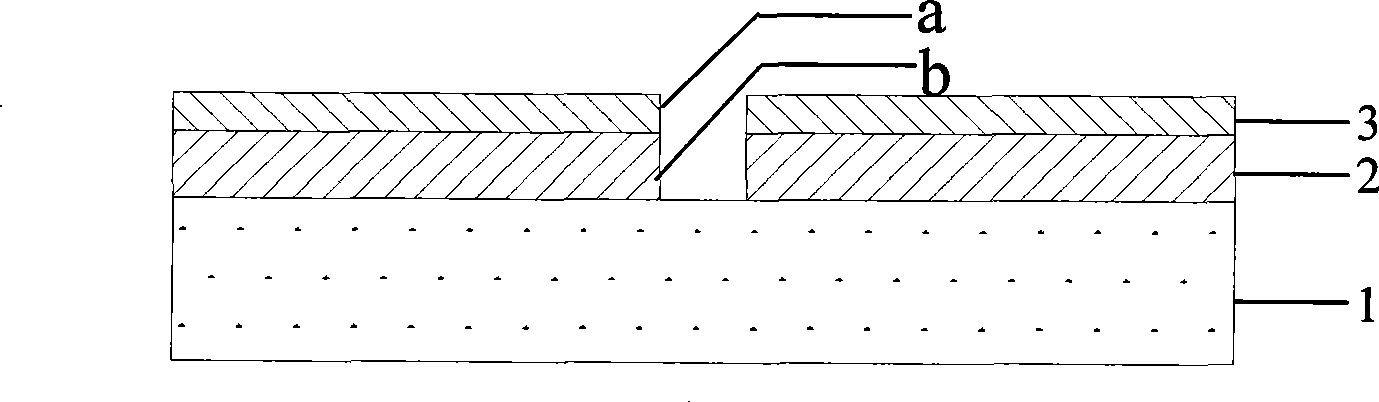

Thin-film bulk acoustic resonator and manufacturing method thereof

ActiveCN105680813AImprove reliabilityAvoid damageImpedence networksThin-film bulk acoustic resonatorOxygen plasma etching

The invention discloses a thin-film bulk acoustic resonator (FBAR); a cavity is formed in a substrate; a lower electrode, an upper electrode, and a piezoelectric layer positioned between the two electrodes are further arranged above the cavity; the cavity is obtained by firstly filling a sacrificial layer and then removing the sacrificial layer, and the sacrificial layer is made of a material which can be removed with an oxygen plasma etching process; and the lower electrode, the upper electrode and / or the electrode leading-out end adopt one or multiple of aluminum, copper or copper aluminum alloy. The invention further discloses a manufacturing method of the FBAR; the aluminum, the copper or the copper aluminum alloy are adopted as an interconnected metal to form the electrode leading-out end; and the oxygen plasma etching (O<2> Plasma) process is adopted to remove the sacrificial layer to form an air gap of the FBAR. According to the invention, the manufacturing cost is reduced, the reliability of the thin-film bulk acoustic resonator is improved, and the environmental friendliness is embodied.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

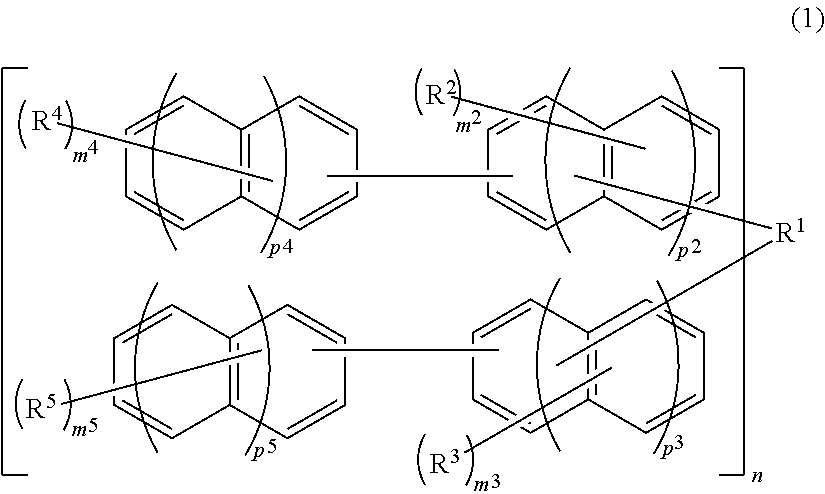

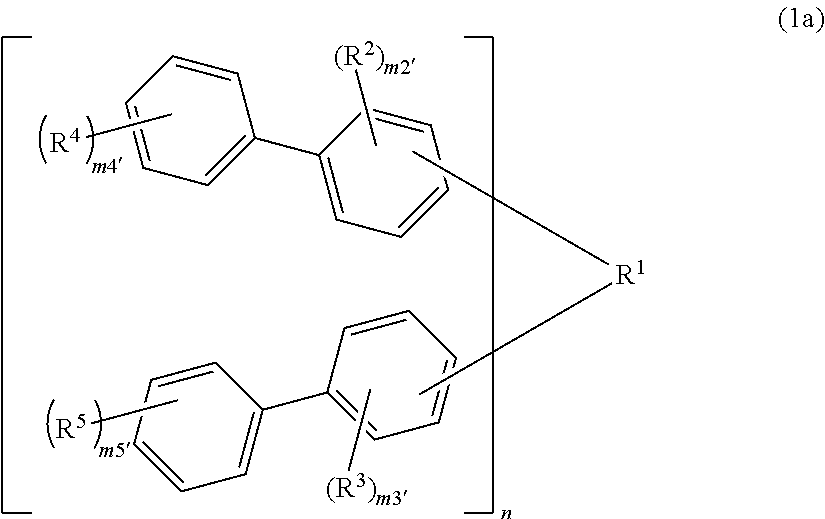

Silicon-containing polymer, resist composition and patterning process

InactiveUS6919161B2High sensitivityImprove heat resistancePhotosensitive materialsConductive materialResistAryl

Silicon-containing polymers comprising recurring units of formula (1) are novel wherein R1 is a single bond or alkylene, R2 is hydrogen or alkyl, R3, R4 and R5 are alkyl, haloalkyl, aryl or silicon-containing group, R6 is hydrogen, methyl, cyano or —C(═O)OR8 wherein R8 is hydrogen, alkyl or acid labile group, R7 is alkyl, —NR9R10 or —OR11 wherein R9, R10 and R11 are hydrogen or alkyl, a and b are positive numbers satisfying 0<a+b≦1. Resist compositions comprising the polymers are sensitive to high-energy radiation and have a high sensitivity and resolution at a wavelength of less than 300 nm and improved resistance to oxygen plasma etching.

Owner:SHIN ETSU CHEM IND CO LTD

Selective electroless-plated copper metallization

InactiveUS20070085213A1Semiconductor/solid-state device detailsSolid-state devicesCopperOxygen plasma etching

Structures and methods are provided which include a selective electroless copper metallization. The present invention includes a novel methodology for forming copper vias on a substrate, including depositing a thin film seed layer of Palladium (Pd) or Copper (Cu) on a substrate to a thickness of less than 15 nanometers (nm). A number of via holes is defined above the seed layer. A layer of copper is deposited over the seed layer using electroless plating to fill the via holes to a top surface of the patterned photoresist layer. The method can be repeated any number of times, forming second, third and fourth layers of copper. The photoresist layers along with the seed layers in other regions can then be removed, such as by oxygen plasma etching, such that a chemical mechanical planarization process is avoided.

Owner:MICRON TECH INC

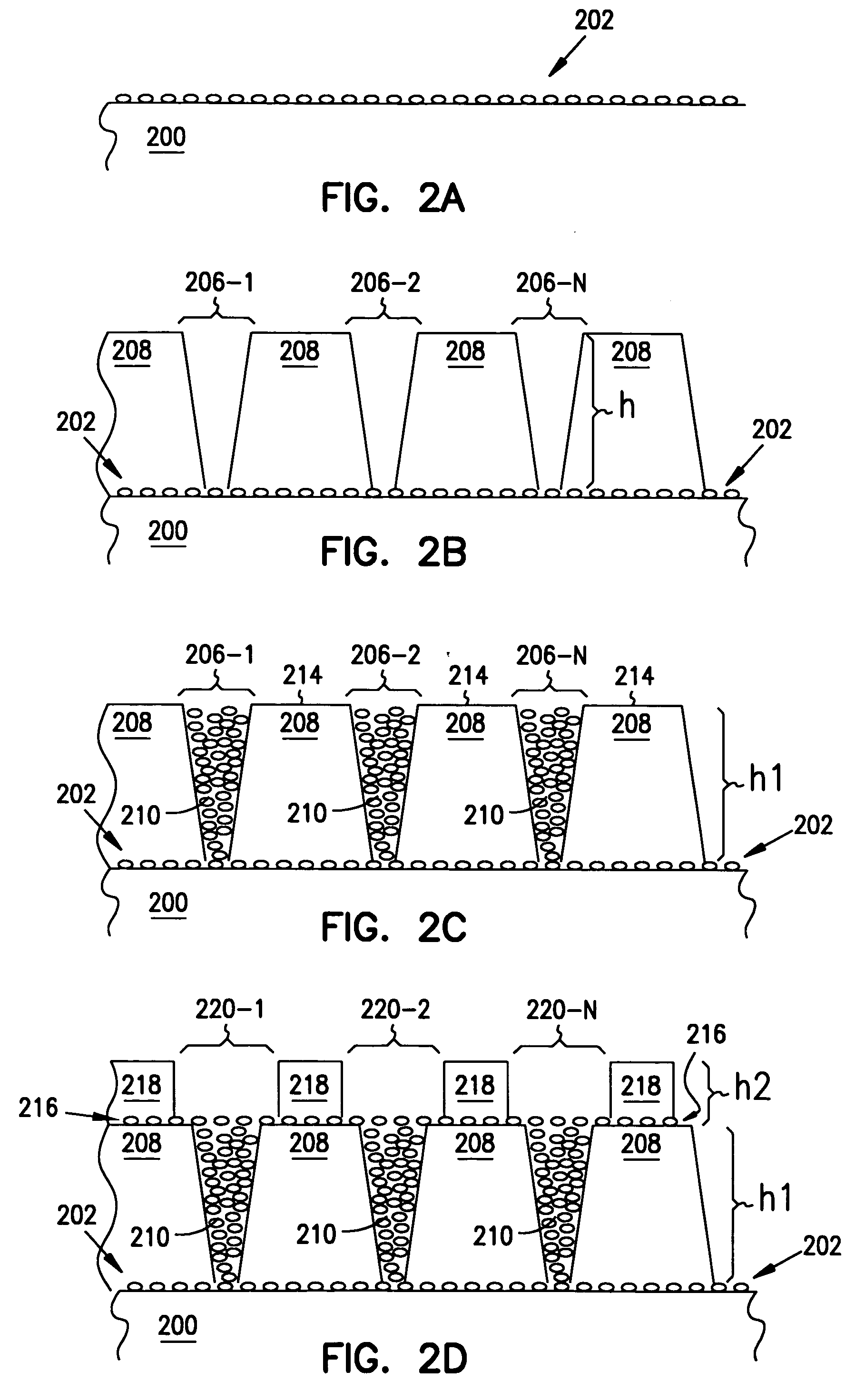

Masking high-aspect aspect ratio structures

InactiveUS20080138581A1Layered productsSemiconductor/solid-state device manufacturingResistOxygen plasma etching

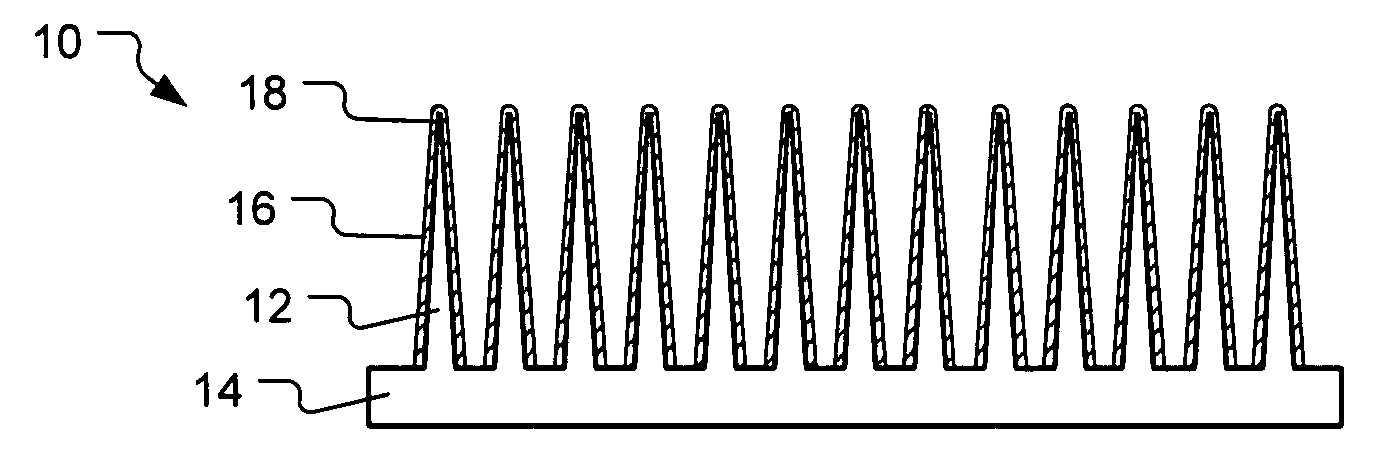

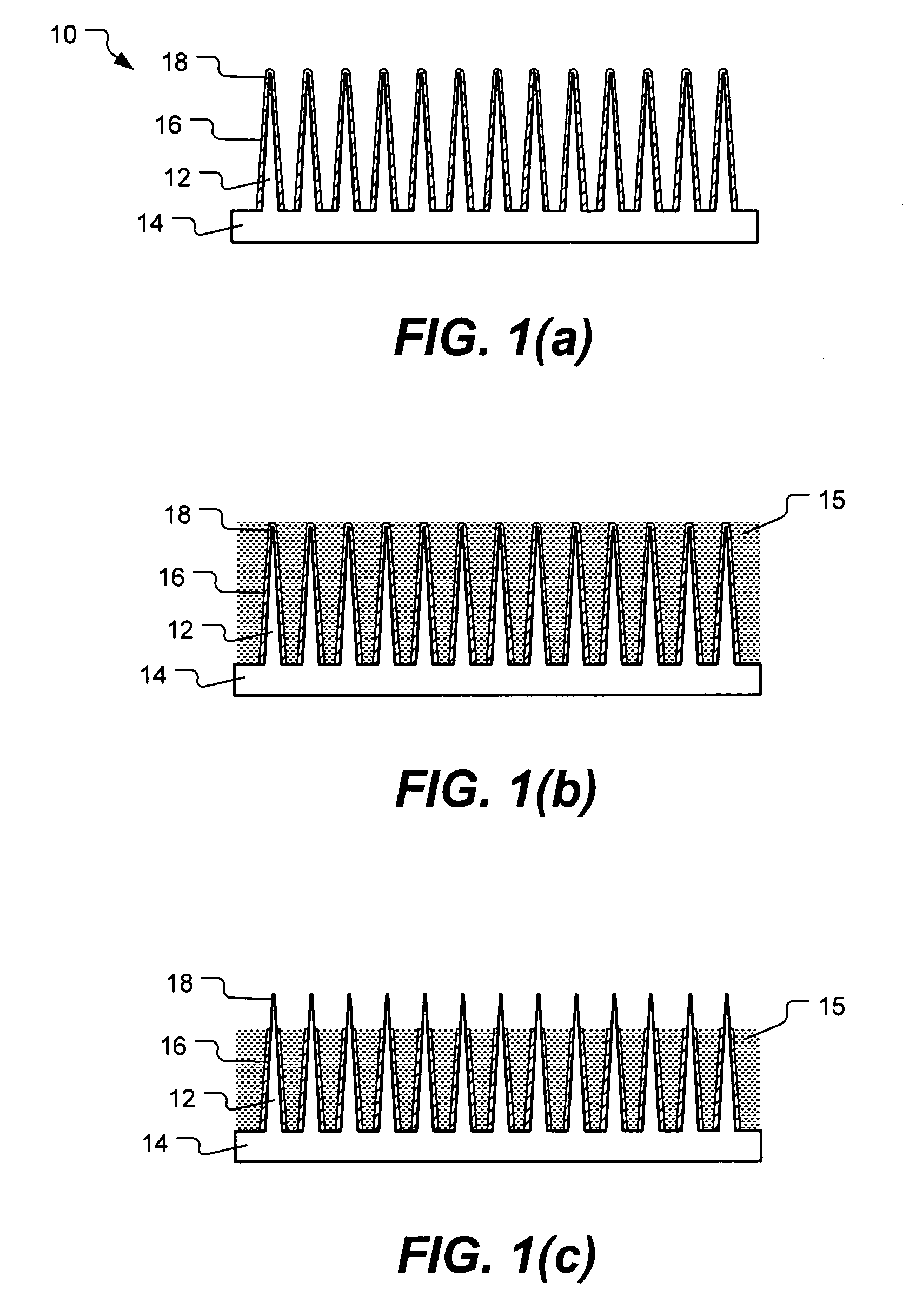

A method of masking high-aspect ratio structures on a wafer includes submerging the wafer in a resist material so that the high-aspect ratio structures are at least partially embedded within the resist material. The resist material is cured and further processing steps, such as for example oxygen plasma etching, are applied, for example to remove portions of the resist material and material from upper portions of the high-aspect ratio structures.

Owner:UNIV OF UTAH RES FOUND

Silicon-containing polymer, resist composition and patterning process

InactiveUS6902772B2High sensitivityImprove heat resistancePhotosensitive materialsPhotomechanical apparatusResistAryl

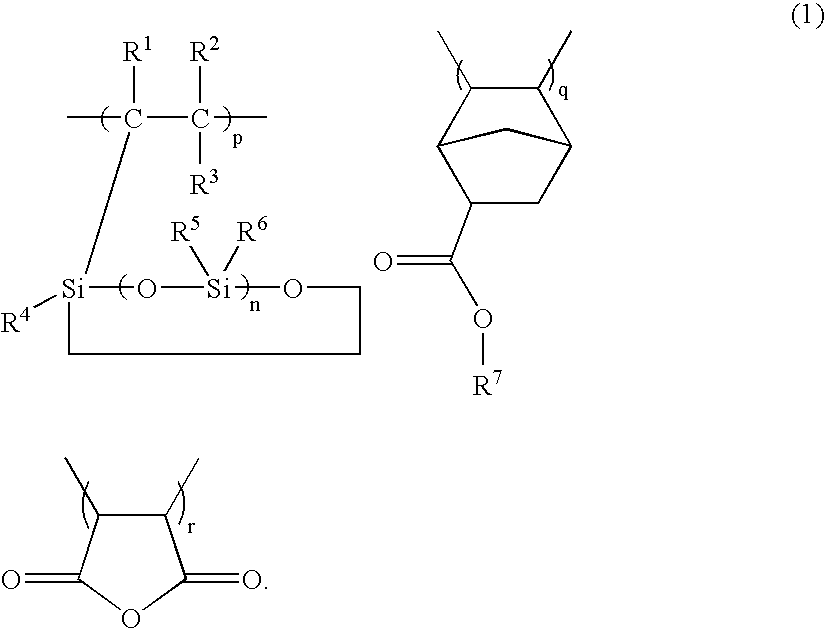

Silicon-containing polymers comprising recurring units of three components represented by the general formula (1) are novel wherein R1, R2 and R3 are hydrogen or C1-10 alkyl, R4, R5 and R6 are hydrogen, C1-20 alkyl or haloalkyl, or C6-20 aryl, R7 is C4-20 alkyl, n is 1 to 5, p, q and r are positive numbers. Resist compositions comprising the polymers are sensitive to high-energy radiation and have a high sensitivity and resolution at a wavelength of less than 300 nm and improved resistance to oxygen plasma etching

Owner:SHIN ETSU CHEM IND CO LTD

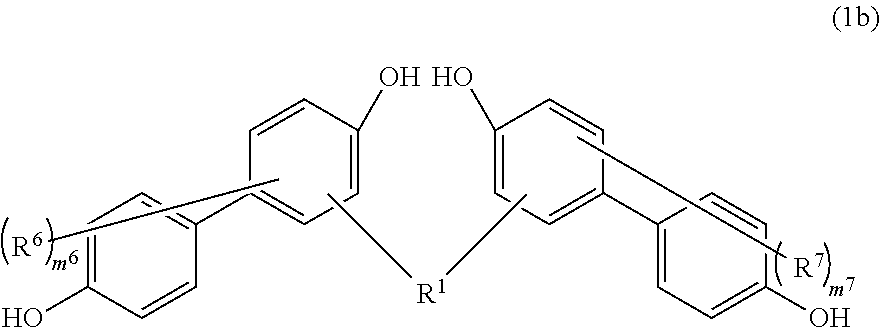

High molecular weight silicone compounds, chemically amplified positive resist compositions, and patterning method

InactiveUS6066433AHigh sensitivity and resolutionHigh aspect ratioPhotosensitive materialsRadiation applicationsPolymer scienceOxygen plasma etching

In a silicone polymer having phenolic hydroxyl groups, the hydrogen atoms of some of the phenolic hydroxyl groups are replaced by acid labile groups of at least one type. The silicone polymer is crosslinked at some of the remaining phenolic hydroxyl groups with crosslinking groups having C-O-C linkages within a molecule and / or between molecules. The silicone polymer has a Mw of 5,000 to 50,000. A chemically amplified positive resist composition comprising the silicone polymer as a base resin has a high sensitivity and resolution so that it is suitable for fine patterning with electron beams or deep UV. Because of improved oxygen plasma etching resistance, the composition is suitable for use in the two-layer resist technique.

Owner:SHIN ETSU CHEM IND CO LTD

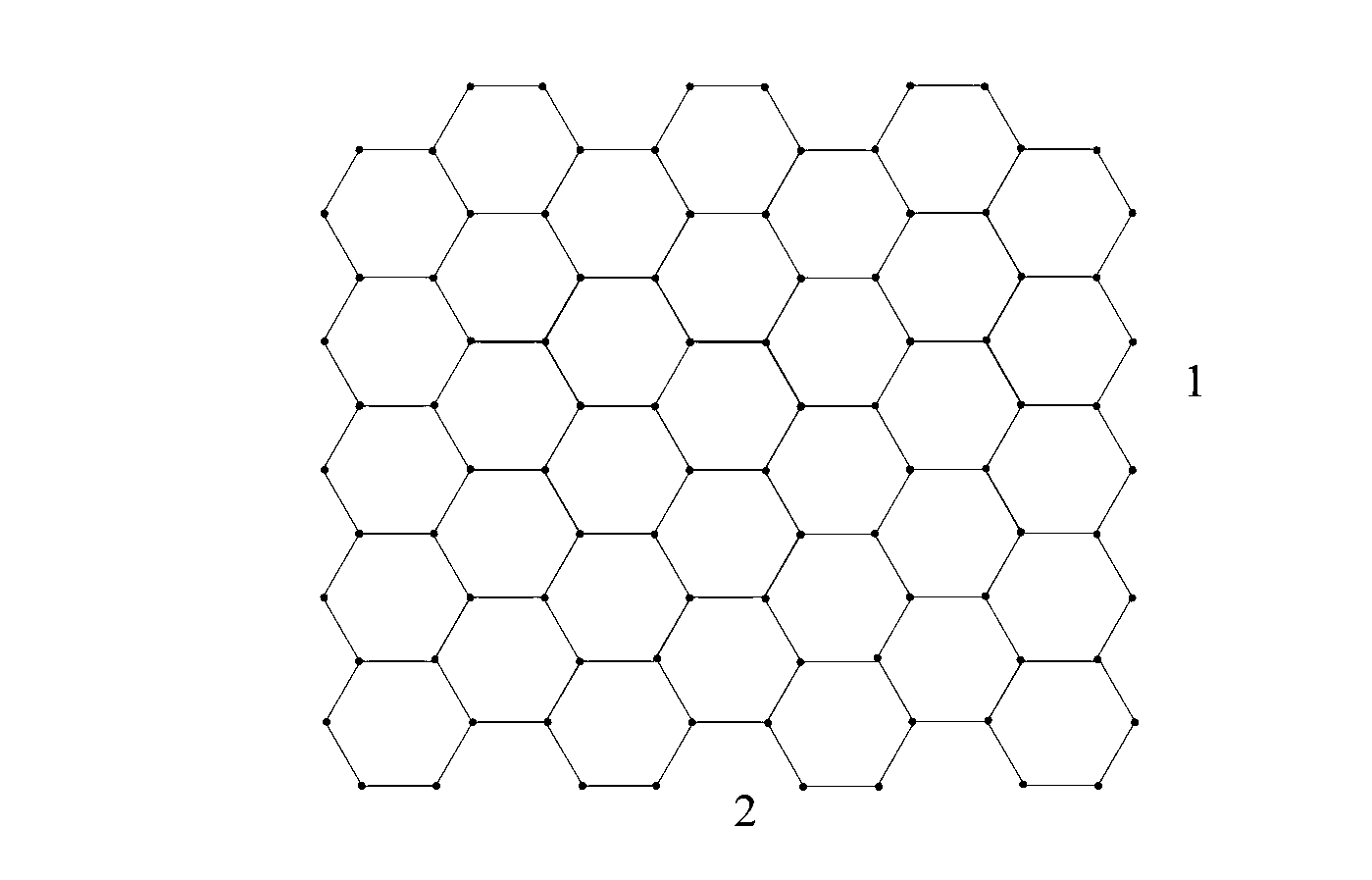

Method for preparing graphene image with specific edge

The invention provides a method for preparing a graphene image with a specific edge. The method comprises the steps of preparing a graphene thin film; forming an artificial defect on the graphene thin film; carrying out anisotropic etching on the graphene thin film by H(hydrogen)-containing plasma and forming a graphene crystal orientation mark image along the artificial defect; aligning the graphene thin film with the graphene crystal orientation mark image to a target substrate and transferring the graphene thin film to the target substrate; and imaging the graphene thin film by using a photoetching technology and an oxygen plasma etching technology in sequence, thus obtaining the graphene image with the specific edge. By the method for preparing the graphene image with the specific edge provided by the invention, the image with the specific edge can be prepared and therefore graphene thin films with different properties are obtained; the application of graphene in different fields is facilitated; and the method is simple and compatible with the conventional CMOS (Complementary Metal-Oxide-Semiconductor Transistor) technology, thus being beneficial to popularization application.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Process for patterning nanocarbon material, semiconductor device, and method for manufacturing semiconductor device

A process for patterning a nanocarbon material includes a step of forming a nanocarbon layer on a substrate; a step of forming a first metal layer on the nanocarbon layer to pattern the first metal layer, the first metal layer containing at least one selected from the group consisting of zinc, tin, indium, aluminum, and titanium; and a step of etching the nanocarbon layer with oxygen plasma using the first metal layer as a positive pattern. Also, a method for manufacturing a semiconductor device including a semiconductor layer containing a nanocarbon material includes a step of patterning a nanocarbon material by the above process; and, a semiconductor device containing a nanocarbon material includes a semiconductor layer including a nanocarbon sub-layer patterned by the process.

Owner:CANON KK

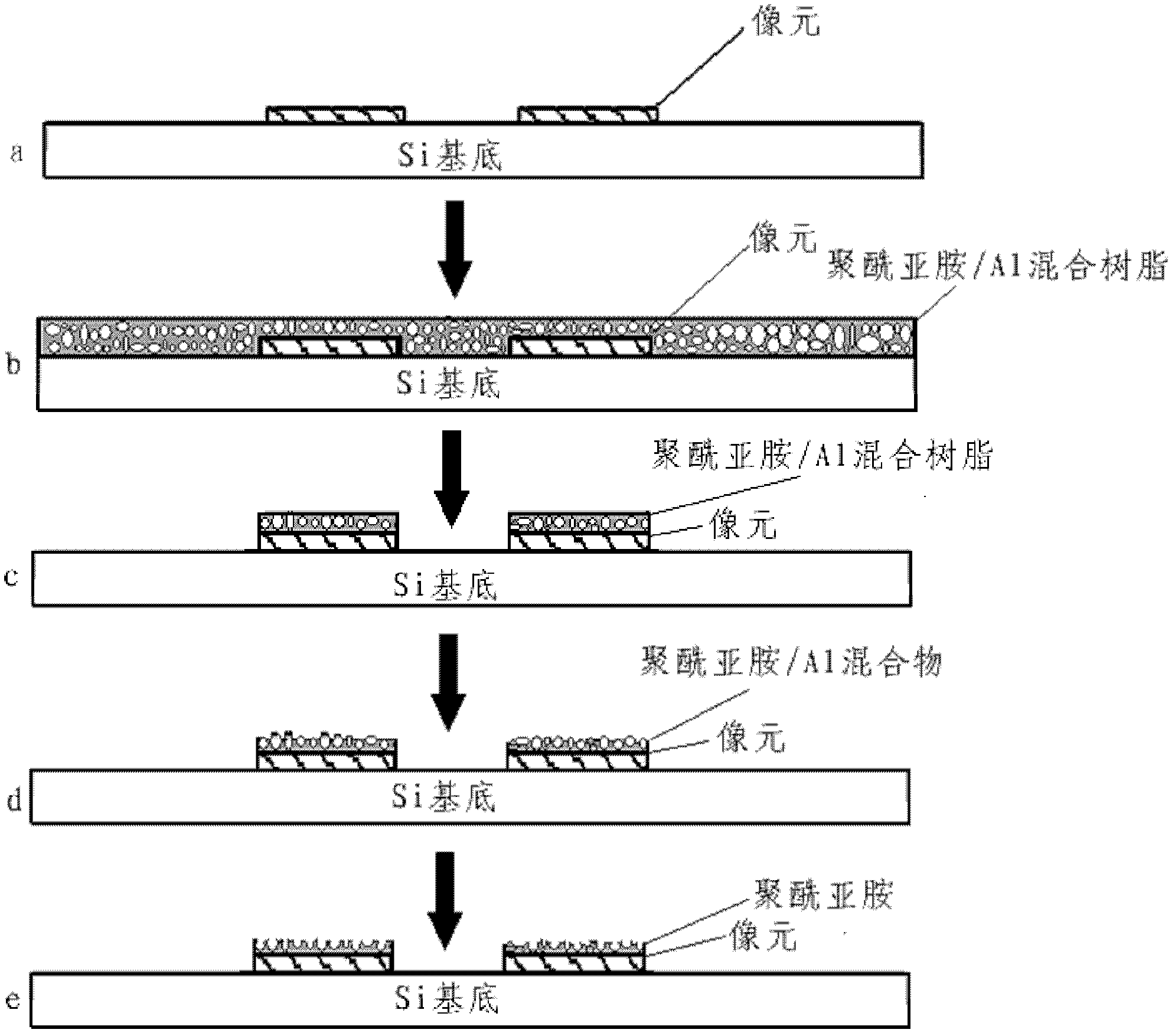

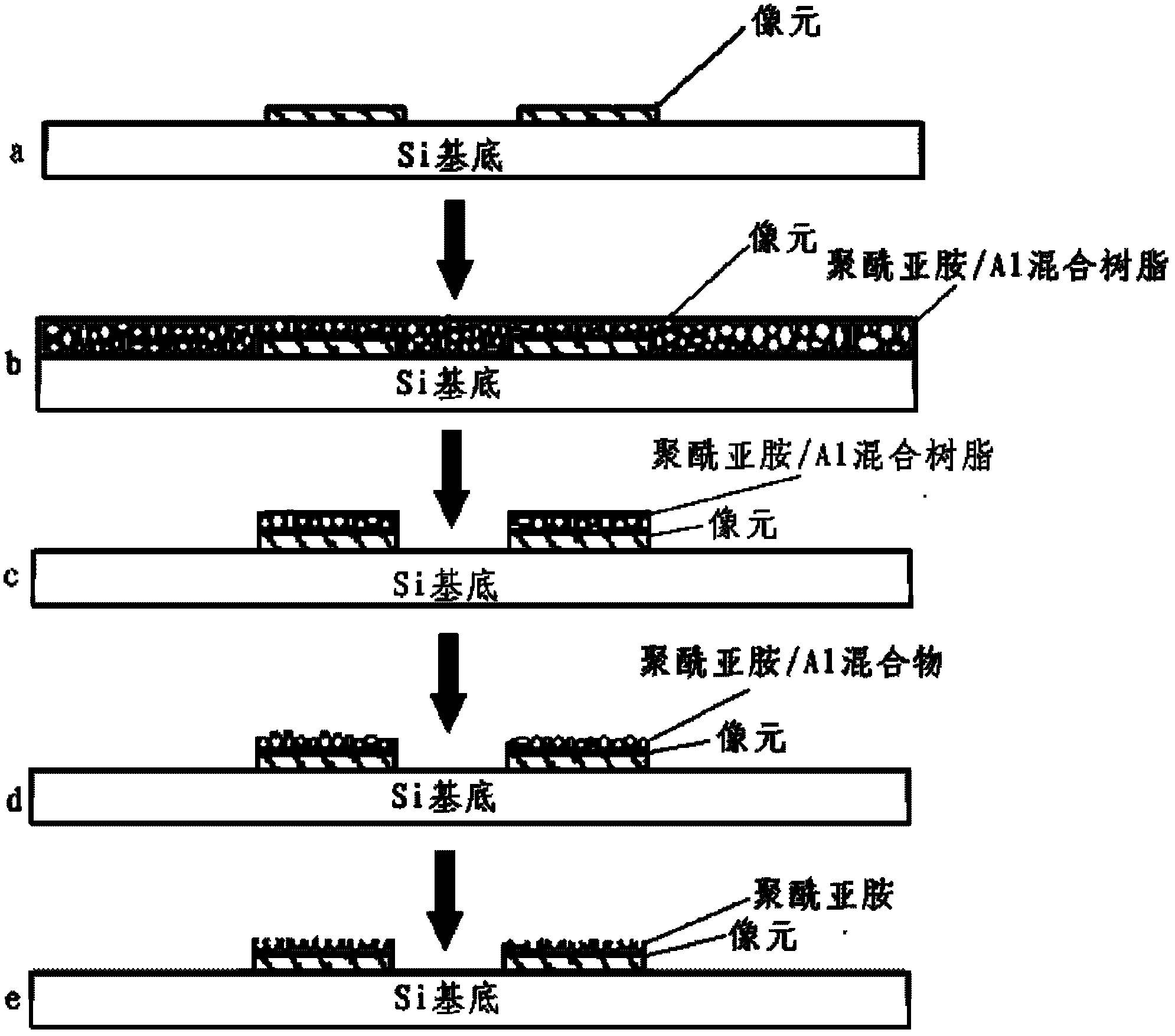

Method for preparing loosened polyimide infrared absorption film

InactiveCN102530843AStrong adhesionImprove visualizationDecorative surface effectsChemical vapor deposition coatingThin metalPhysical chemistry

The invention discloses a method for preparing loosened polyimide infrared absorption film, which includes steps that: a piece of polyimide film is prepared by coating photosensitive polyimide resin on the surface of a substrate in rotating mode and then performing imine processing; imine processing leads the polyimide film to be well adhered to the substrate; photo-etching and developing processes are adopted to lead the polyimide film to form on surfaces of image elements; loosening is conducted, and the polyimide film is corroded to remove aluminum powder particles mixed in the polyimide film; and the thickness of polyimide film can be controlled with an oxygen plasma etching method, thermal mass can be reduced, and simultaneously surfaces of the aluminum powder particles can be ensured to be partially or totally exposed so that the aluminum powder particles can be totally removed. The loosened polyimide infrared absorption film prepared with the method overcomes defects that black gold absorption film is poor in mechanical strength, not apt to form images and high in thermal mass, improves infrared absorption efficiency compared with thin metal absorption film, is favorable for improving performance of non-refrigerating detectors, and has practical application value.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

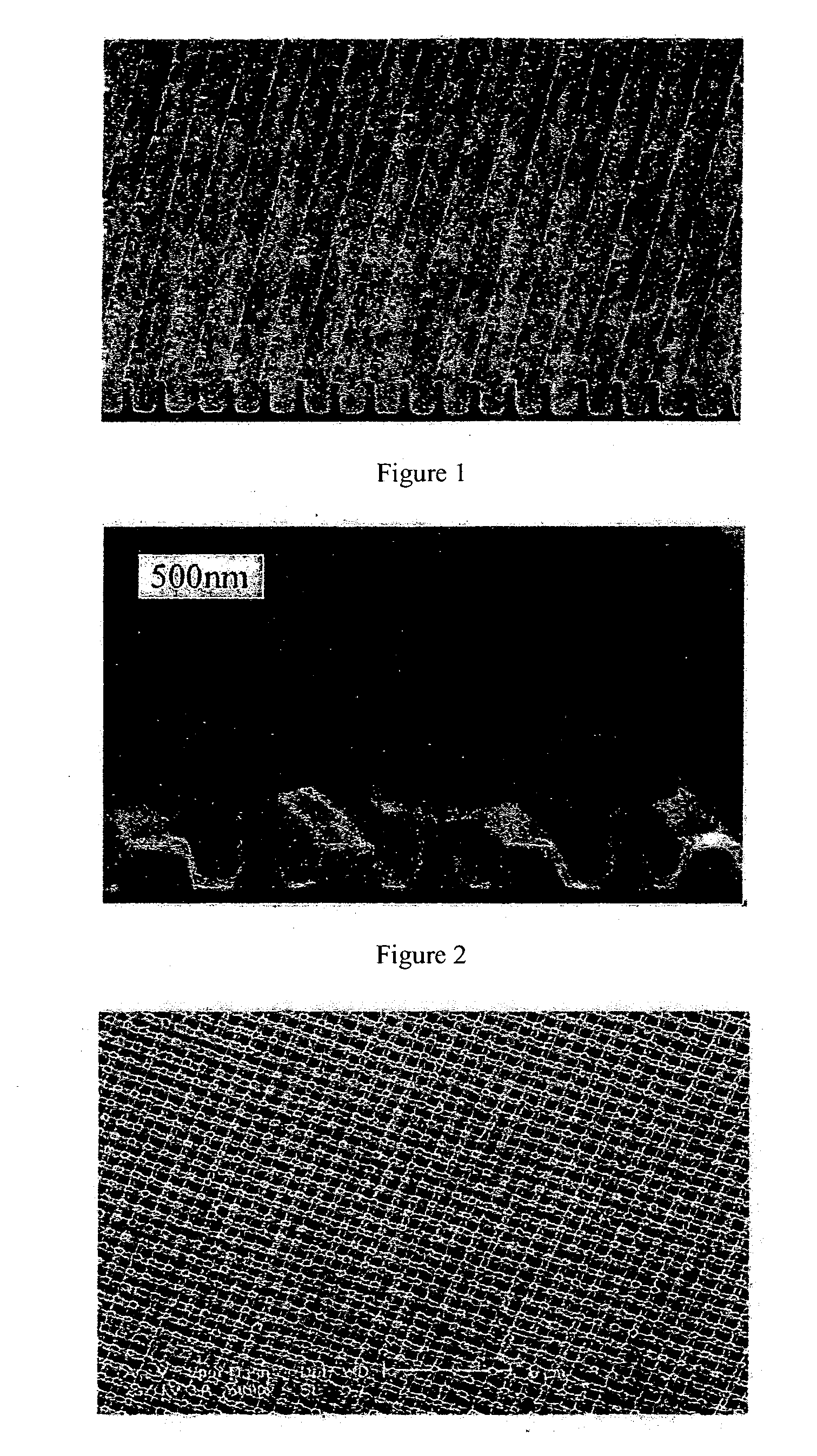

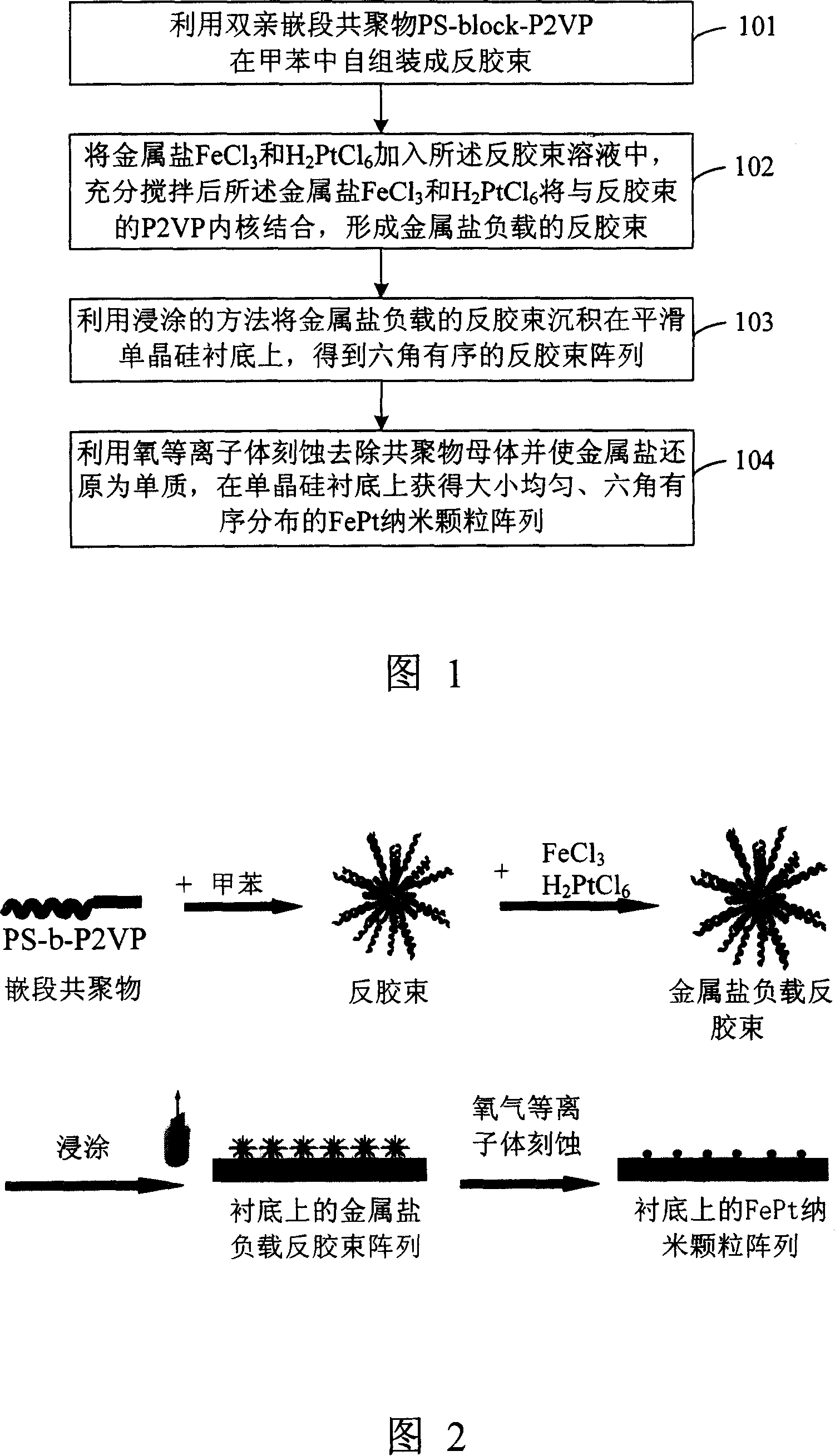

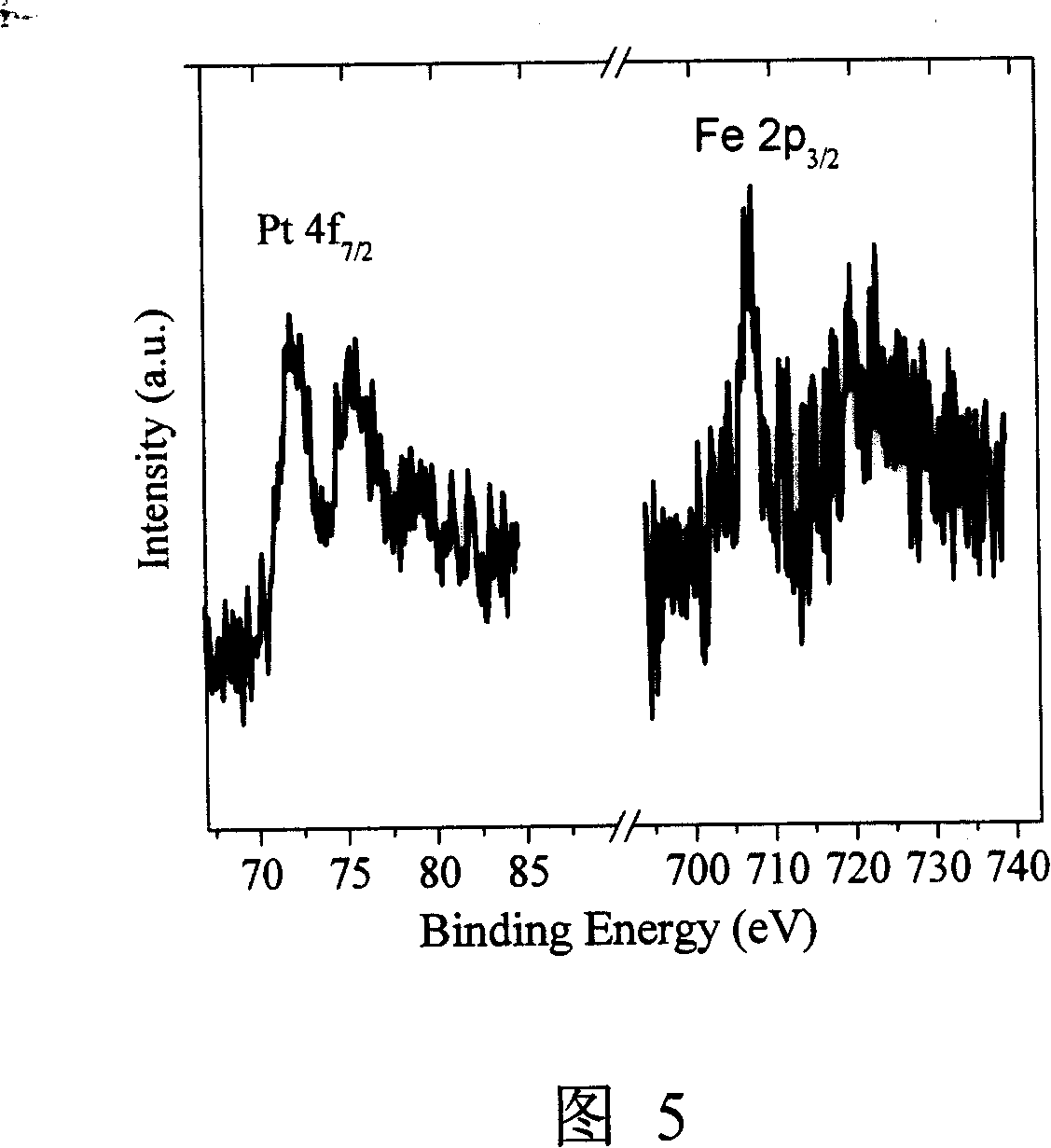

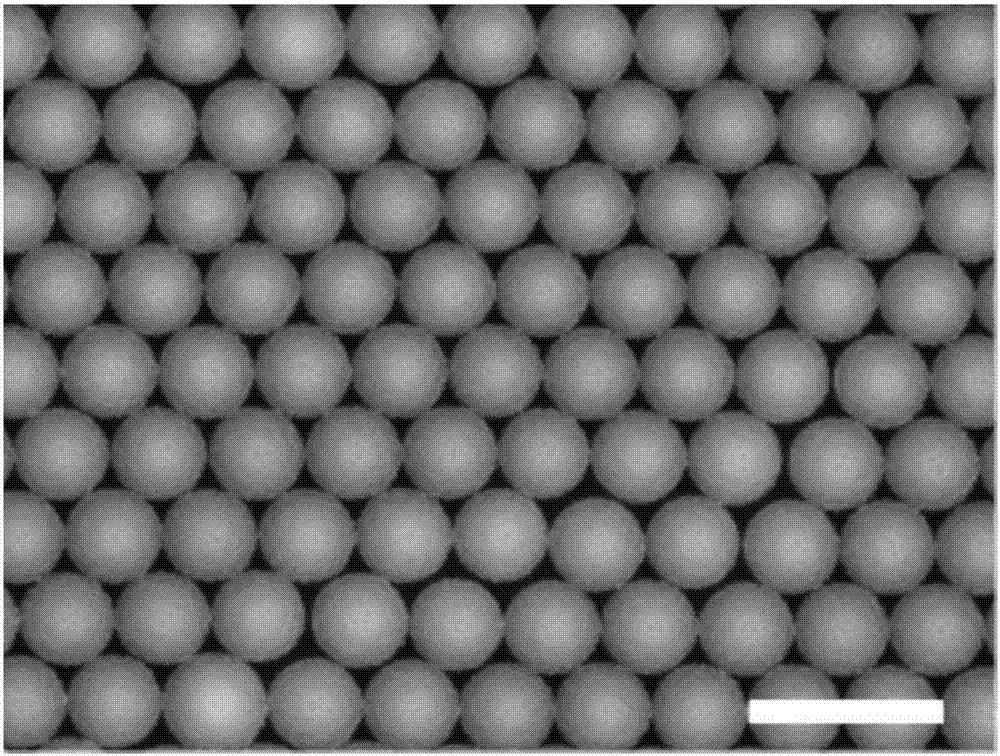

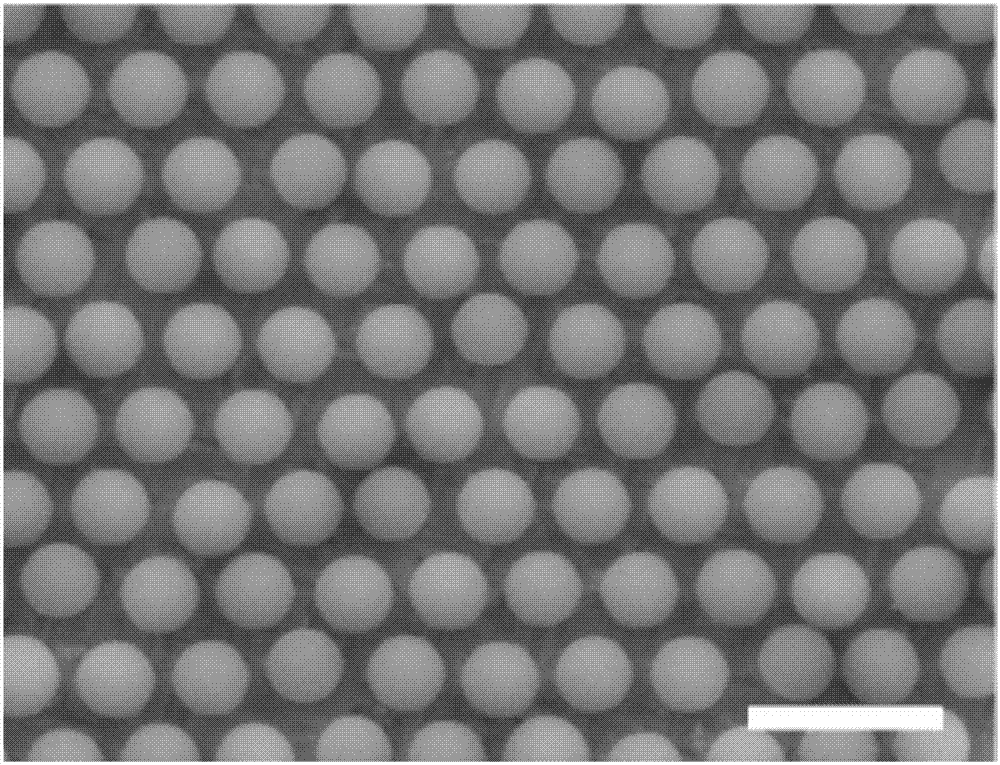

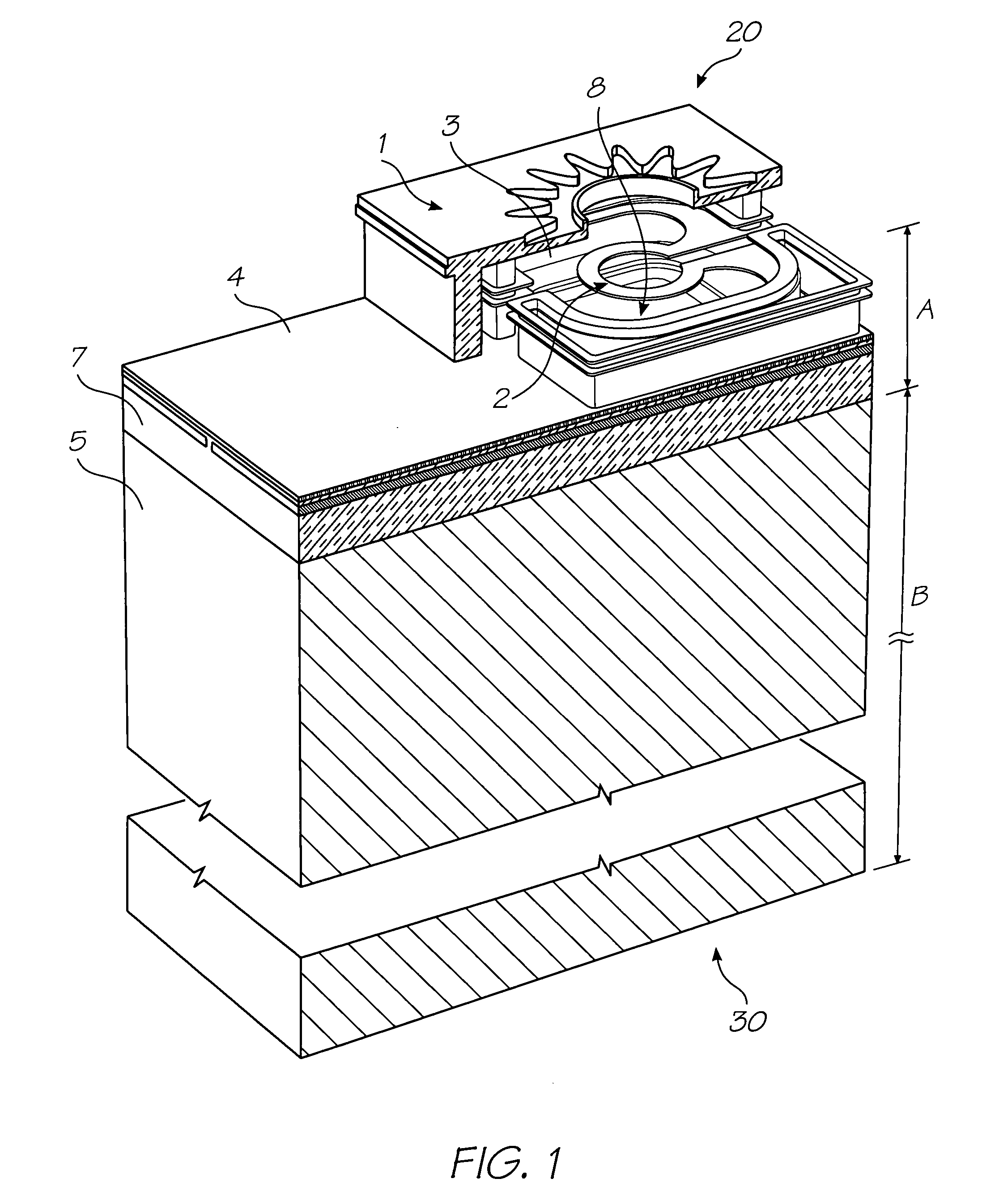

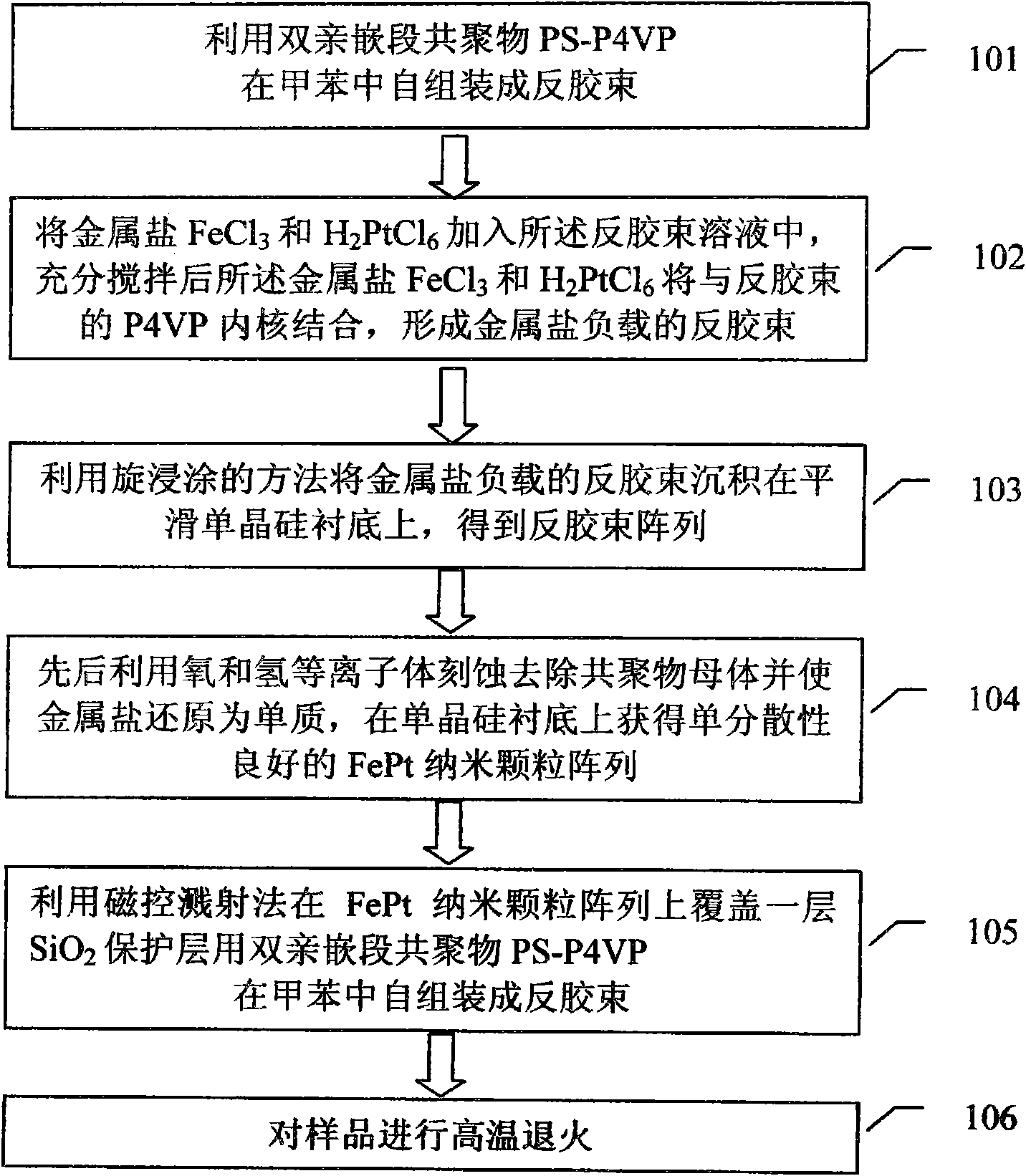

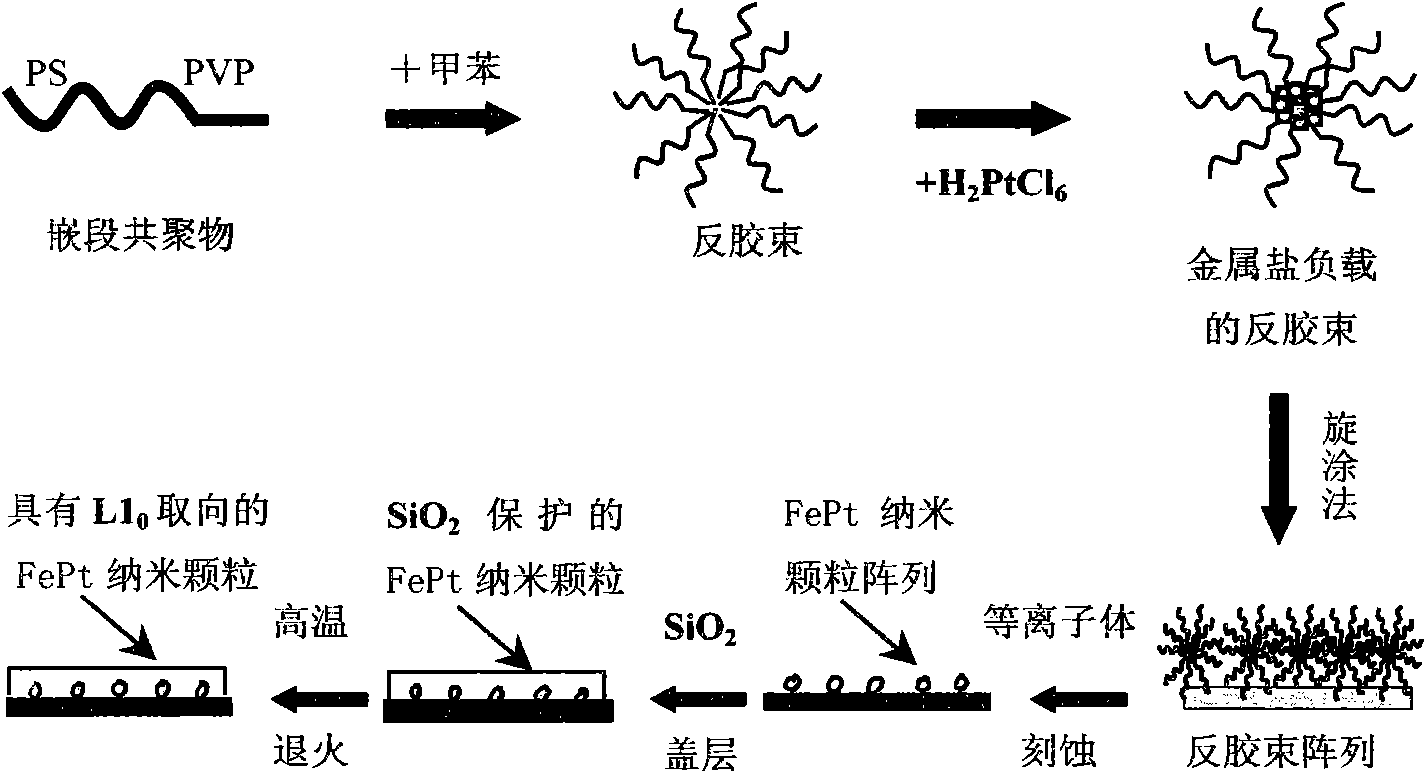

Method for preparing hexangular ordered FePt nano particle array

InactiveCN101148710AEvenly distributedParticle size is easy to controlInductances/transformers/magnets manufactureNanoparticleDip-coating

The process of preparing ordered hexagonal nanometer FePt particle array includes the following steps: 1. self-assembling inverse micelle with amphiphilic block copolymer PS-block-P2VP intoluene; 2. adding metal salts FeCl3 and H2PtCl6 into the inverse micelle solution through stirring for the metal salts FeCl3 and H2PtCl6 to be combined with the P2VP kernel of the inverse micelle to form inverse micelle with supported metal salts; 3. depositing the inverse micelle with supported metal salts onto smooth monocrystalline substrate through dip coating to obtain ordered hexagonal inverse micelle array; and 4. oxygen plasma etching to eliminate copolymer substrate and reduce metal salt into simple substance so as to obtain homogeneous ordered hexagonal nanometer FePt particle array on the monocrystalline substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

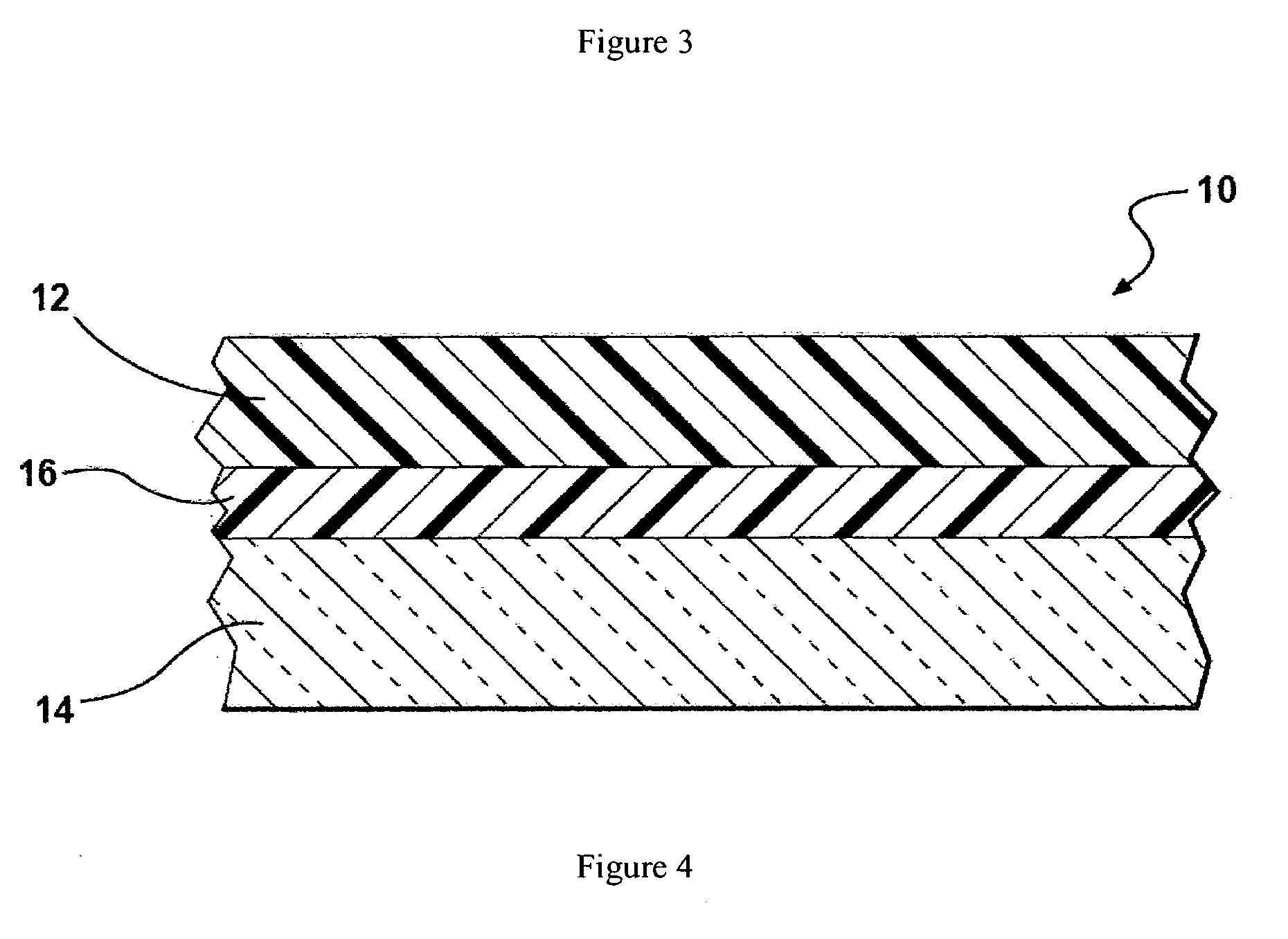

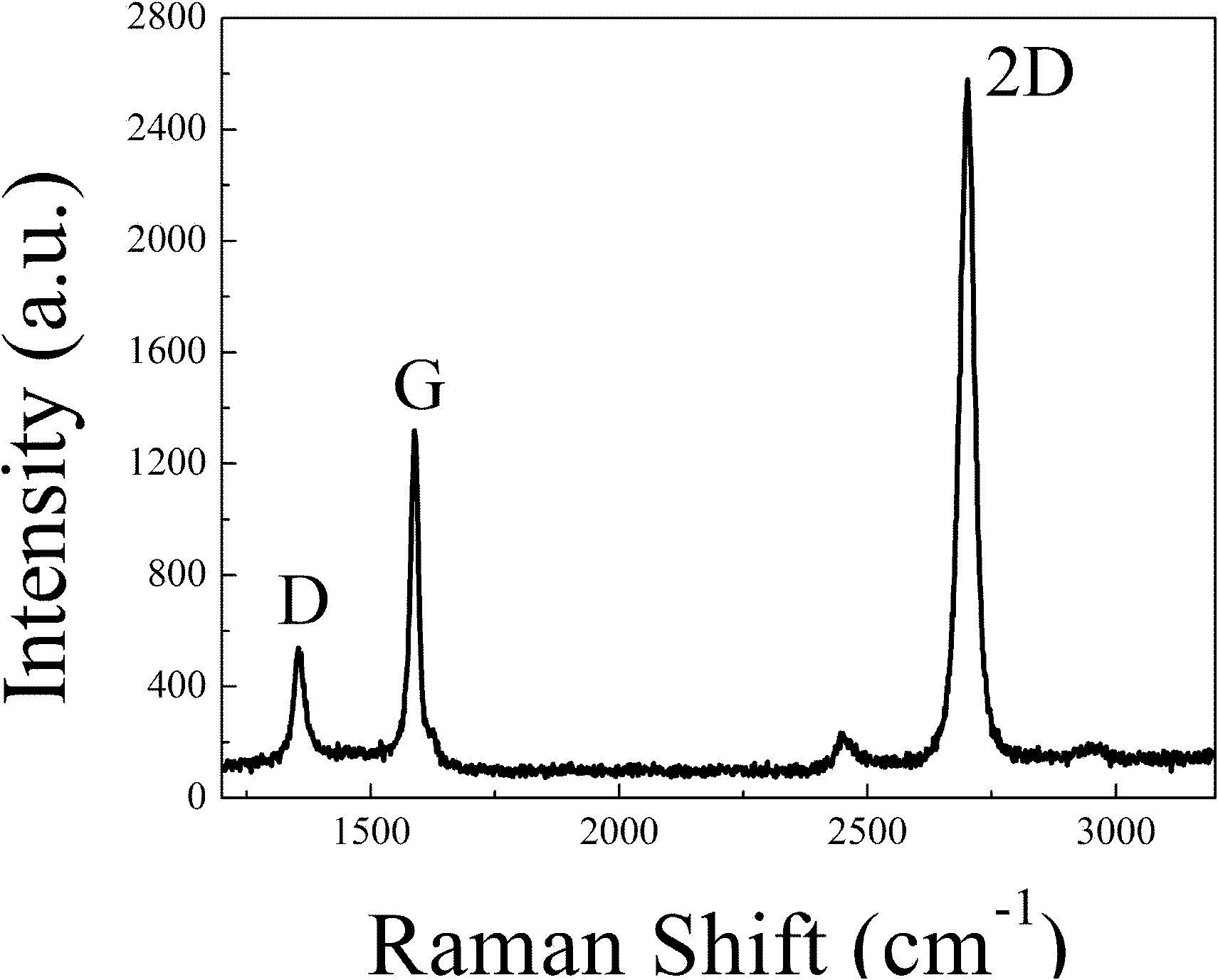

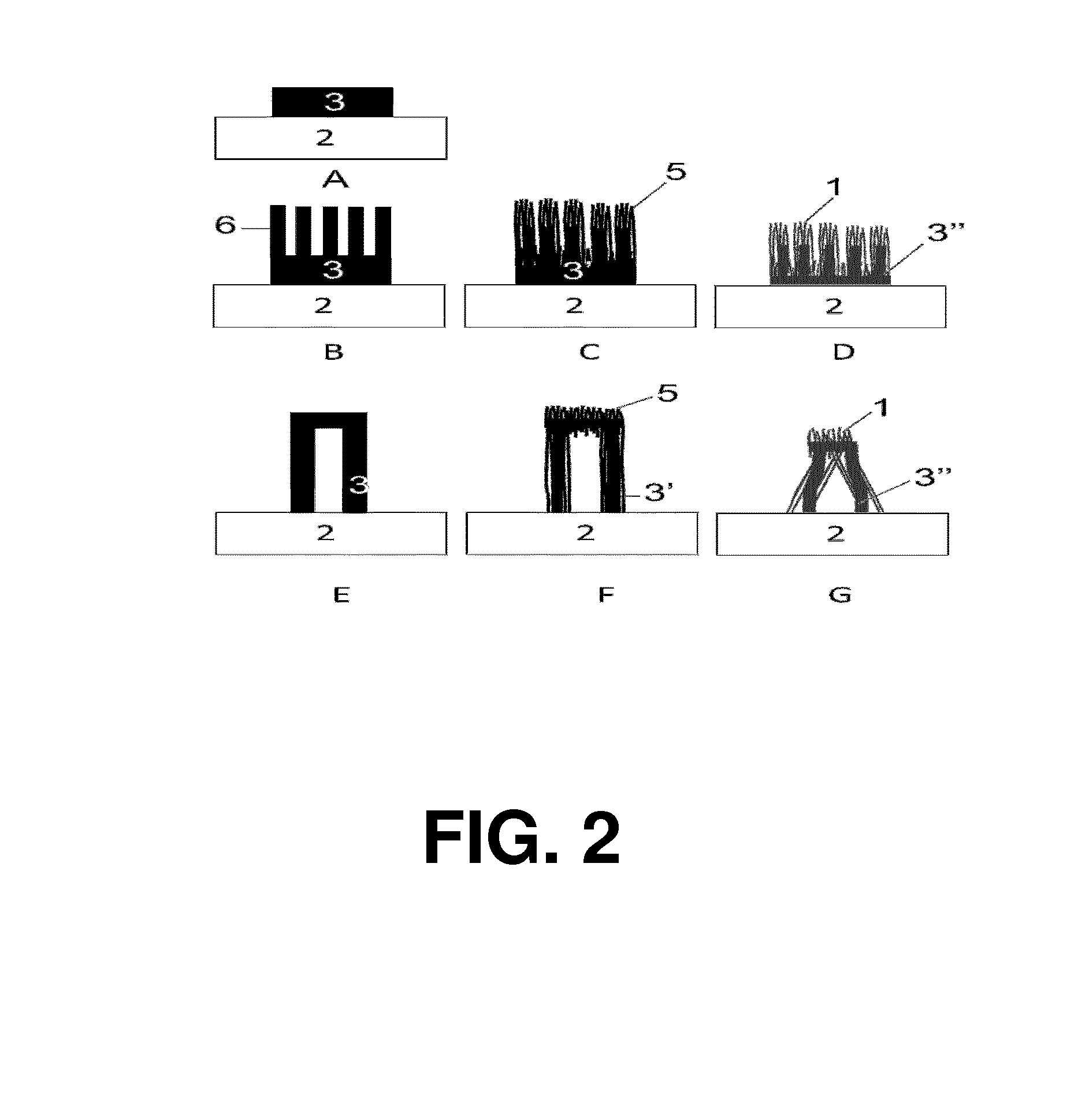

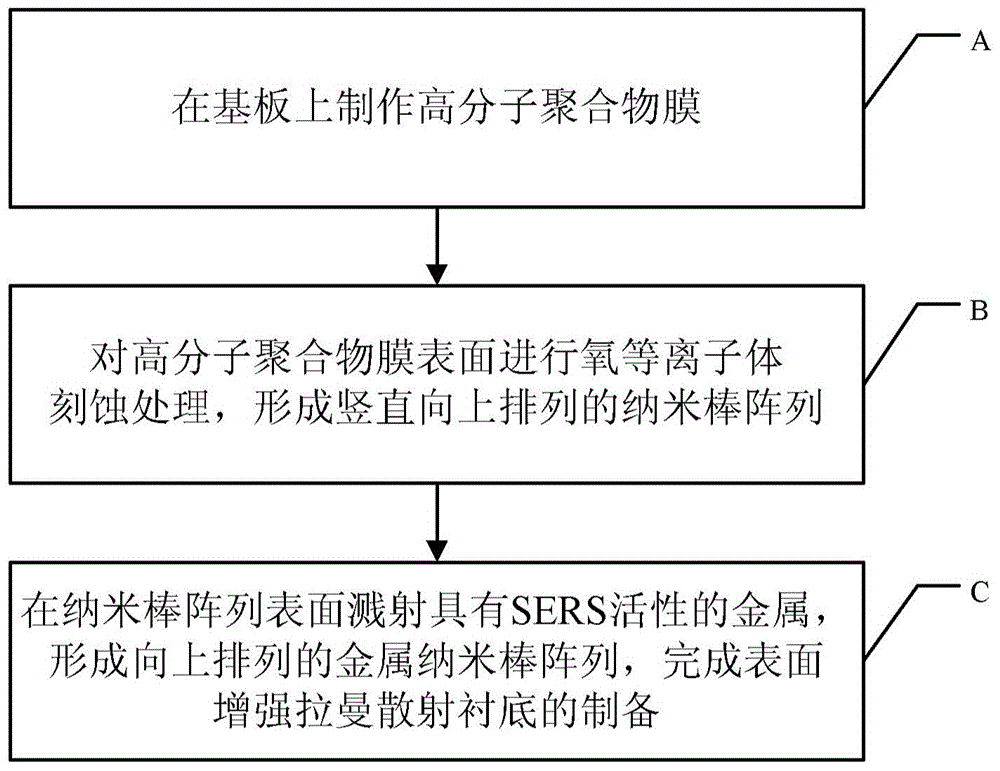

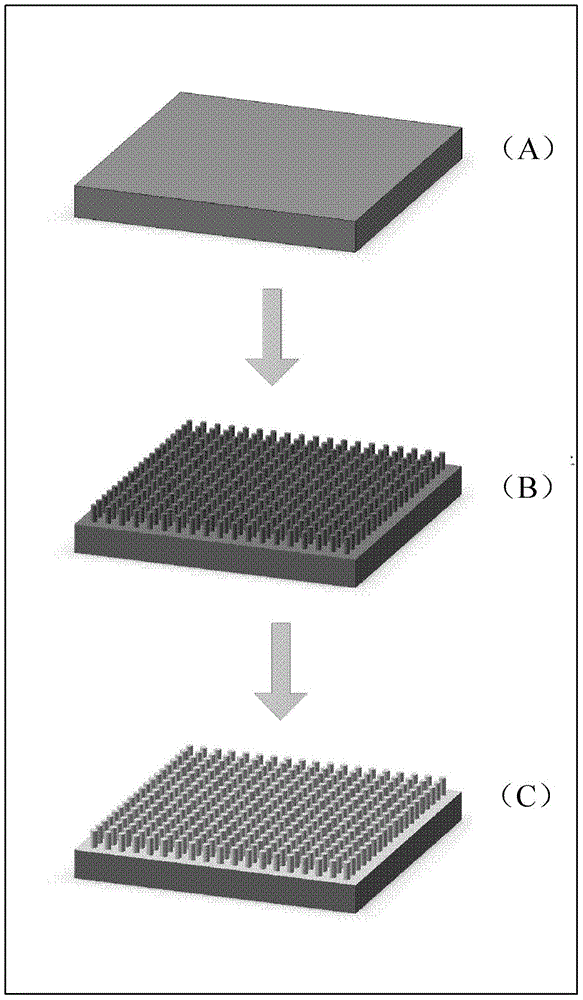

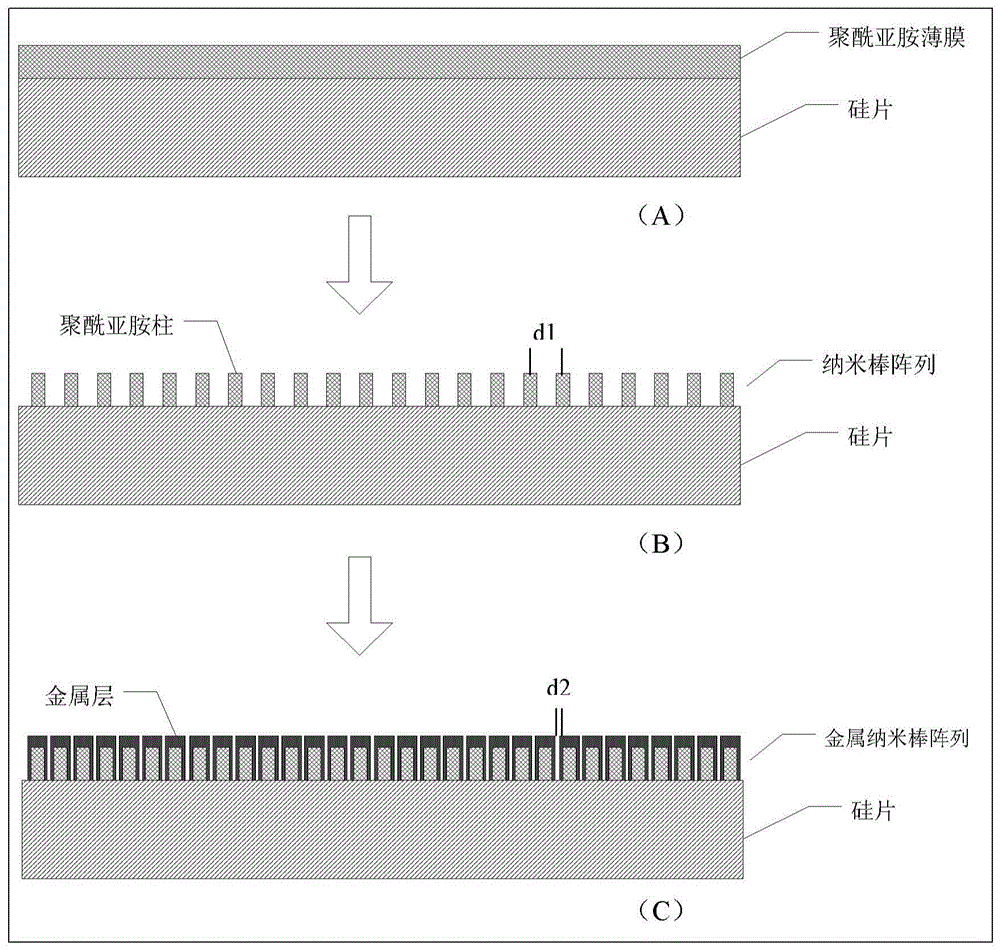

Manufacturing method of surface-enhanced Raman scattering (SERS) substrate

InactiveCN105129724AScatter enhancement effect increasedLarge specific surface areaDecorative surface effectsChemical vapor deposition coatingOxygen plasma etchingNanoscopic scale

The invention provides a manufacturing method of a surface-enhanced Raman scattering (SERS) substrate. The manufacturing method comprises the following steps: A, acquiring a high-molecular polymer film, wherein the high-molecular polymer film is made of a high-molecular polymer material which can be subjected to oxygen plasma etching; B, performing oxygen plasma etching treatment on the high-molecular polymer film to form nanorod arrays which are arranged vertically upwards; and C, covering the surfaces of the nanorod arrays with a metal layer having SERS activity to form metal nanorod arrays which are arranged upwards in order to finish manufacturing of the SERS substrate. In the method, the sizes and gaps of metal nanorods can be controlled at a nanoscale, so that the manufactured SERS substrate has a large specific surface area; the adsorption of molecules to be tested is facilitated; and the reduction of luminous reflectance and intercoupling of electric fields among the metal nanorods are facilitated. Thus, the Roman scattering enhancing effect can be enhanced greatly through the SERS substrate.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

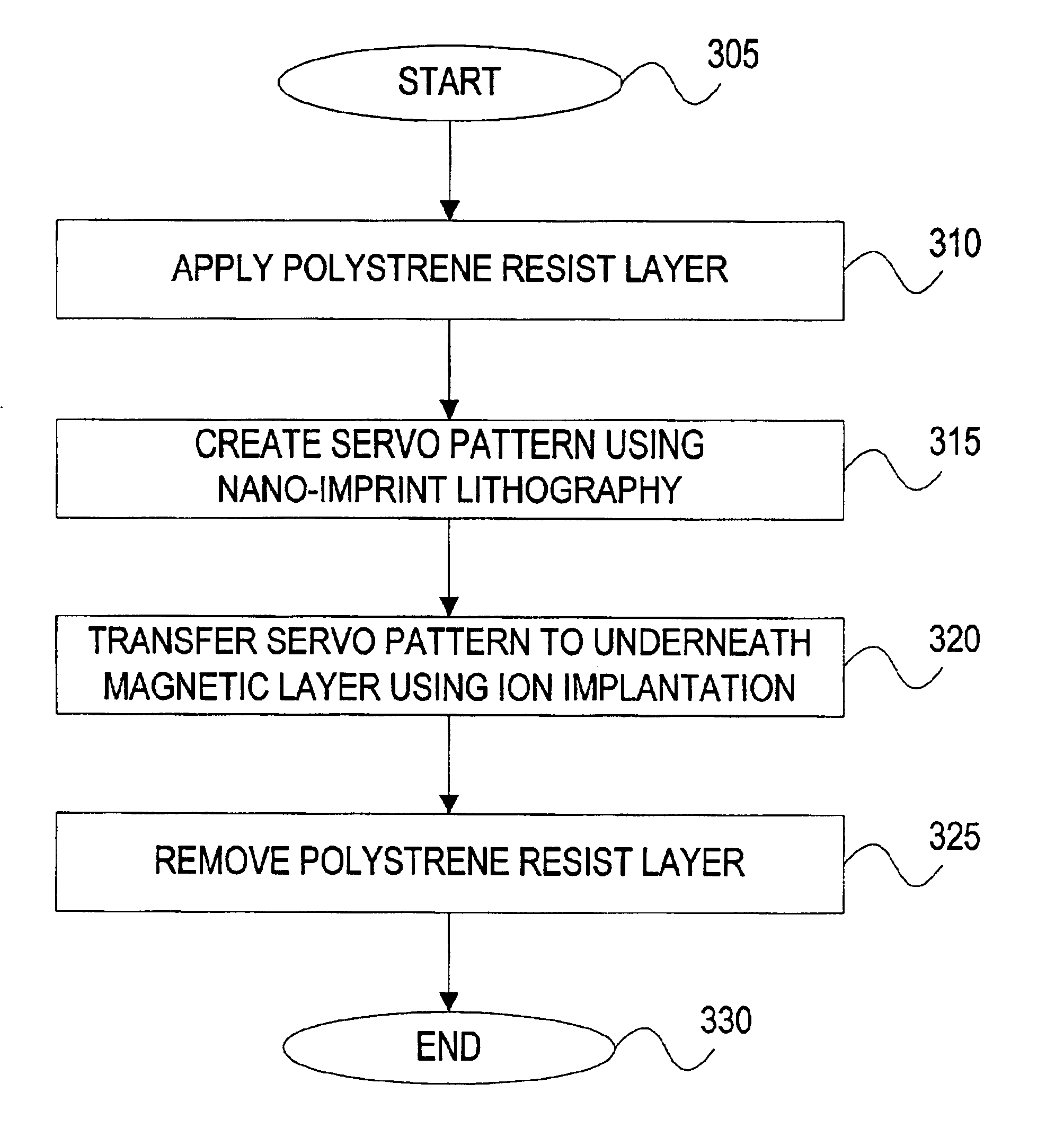

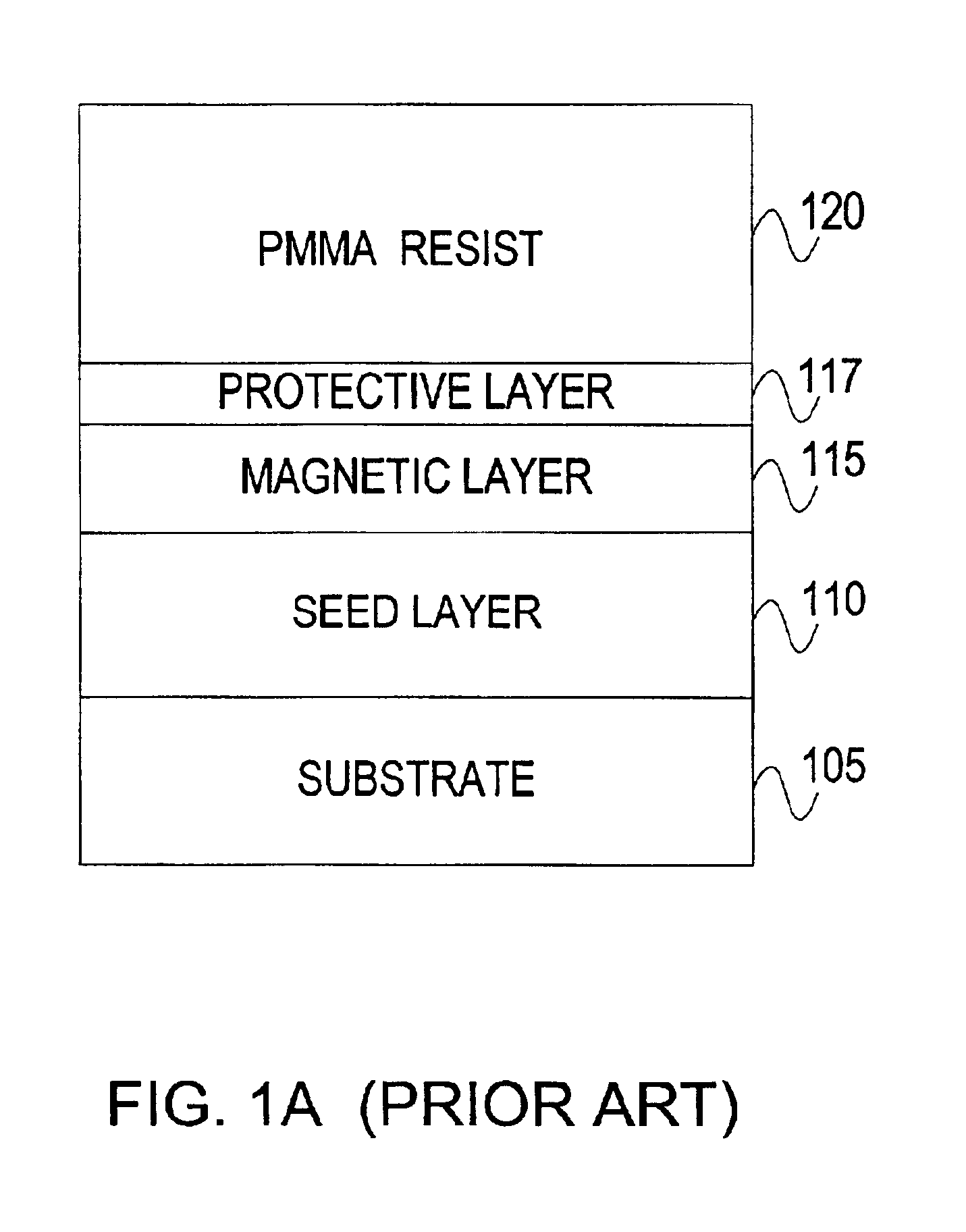

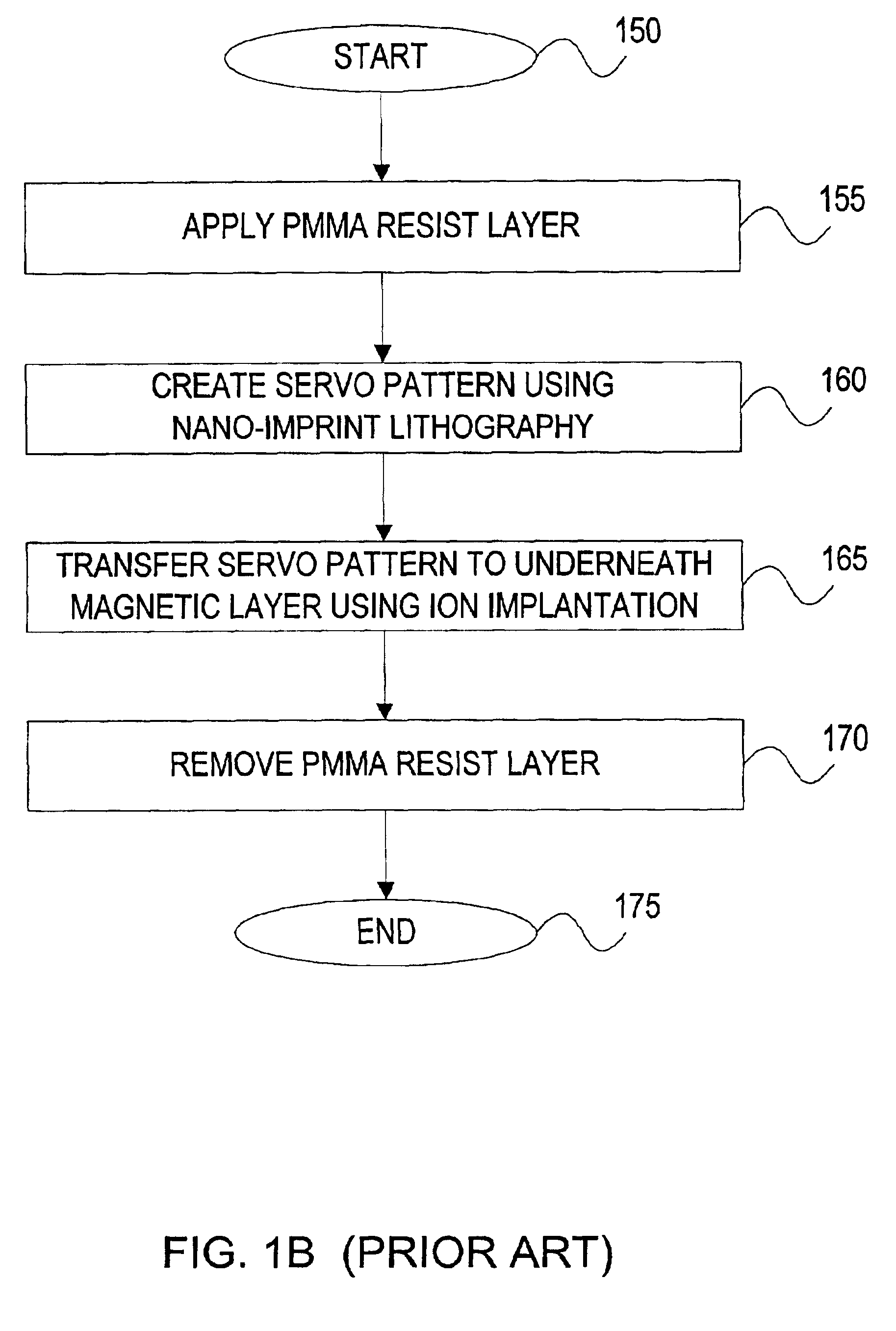

Polystyrene as a resist for making patterned media

InactiveUS6838227B2Excellent ion stopping propertyLow coercivityNanoinformaticsPretreated surfacesResistMagnetic media

A system and method for forming servo patterns on magnetic media is disclosed. A magnetic film coated with a layer of polystyrene is stamped with a nickel stamper reproducing the negative image of the stamped pattern on the polystyrene. Ions are then accelerated towards the surface of the polystyrene, which stopps the ions in the areas where the polystyrene is thick and allows the ions to penetrate through to the magnetic layer in the areas where the polystyrene is thin. The ions, which penetrate through to the magnetic layer, interact with the magnetic layer altering the magnetic layer's structure reducing its coercivity (Hc) and remnant moment (Mrt). This reproduces the stamped polystyrene pattern on the magnetic layer. The polystyrene is then removed by oxygen plasma etching the surface leaving behind a patterned magnetic media.

Owner:SEAGATE TECH LLC

Polymer plane nano-channel production method

InactiveCN101477096AEasy to makeShort cyclePhotomechanical apparatusMaterial analysisMicro nanoLine width

The invention relates to a making method of a polymer planar nano channel, which belongs to the technical field of making micro-nano flow-control chip and is used in the fields of life science, medicine, analytical chemistry, and the like. The making method comprises the following steps: firstly, making a metal masking figure with micron-sized line width on a polymer substrate on the basis of standard ultraviolet lithography and chemical wet method erosion technology; then, carrying out oxygen plasma etching on exposed polymer by means of a plasma cleaning machine and accurately controlling the etching depth of a polymer nano channel through setting etching time; and finally, removing the metal masking figure by means of chemical wet method erosion to obtain the polymer planar nano channel. The making method does not need to purchase reactive ion etching or inductive coupling plasma etching equipment with complex operation and high price in order to realize polymer etching. Moreover, the entire making process of the nano channel has simplicity, short cycle and low cost.

Owner:DALIAN UNIV OF TECH

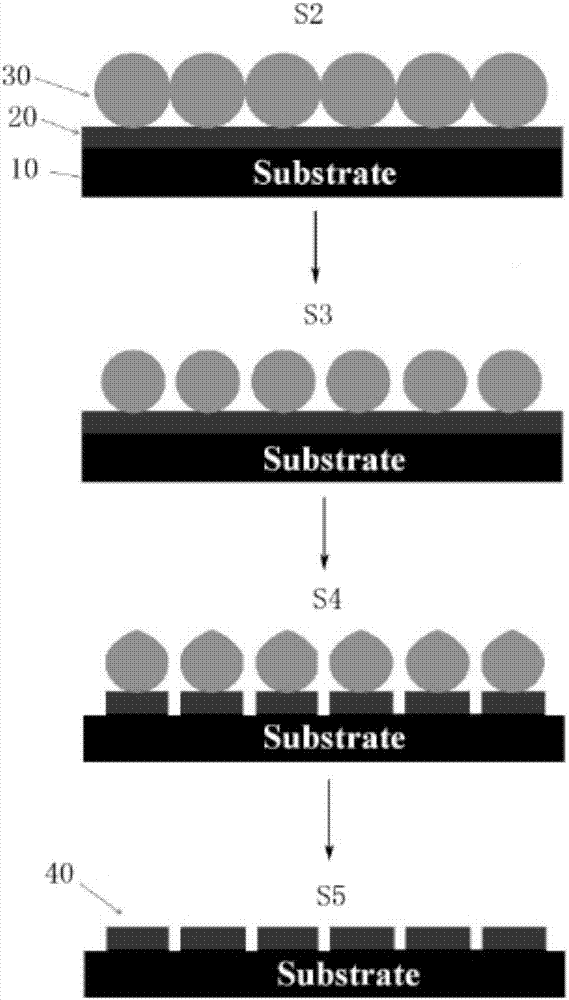

Method using one-step template method to prepare ordered ferroelectric nanodot array

InactiveCN107244649AImprove securityEasy to extendSpecific nanostructure formationOxygen plasma etchingPulsed laser deposition

The invention relates to a method using a one-step template method to prepare an ordered ferroelectric nanodot array. The method includes the steps of S1, using a pulsed laser deposition method to deposit a high-performance epitaxy ferroelectric film on a substrate; S2, transferring single-layer PS small spheres to the surface of the ferroelectric film to serve as the mask plate; S3, performing oxygen plasma etching on the substrate with the mask plate to obtain a to-be-etched sample; S4, etching the to-be-etched sample in an ion beam etching machine; S5, removing the residual mask plate to obtain the ordered ferroelectric nanodot array. The method has the advantages that the method is simple, convenient in template removing and suitable for large-scale preparation, and the prepared ferroelectric nanodot array keeps the excellent epitaxy and ferroelectric performance of the ferroelectric film.

Owner:SOUTH CHINA NORMAL UNIVERSITY

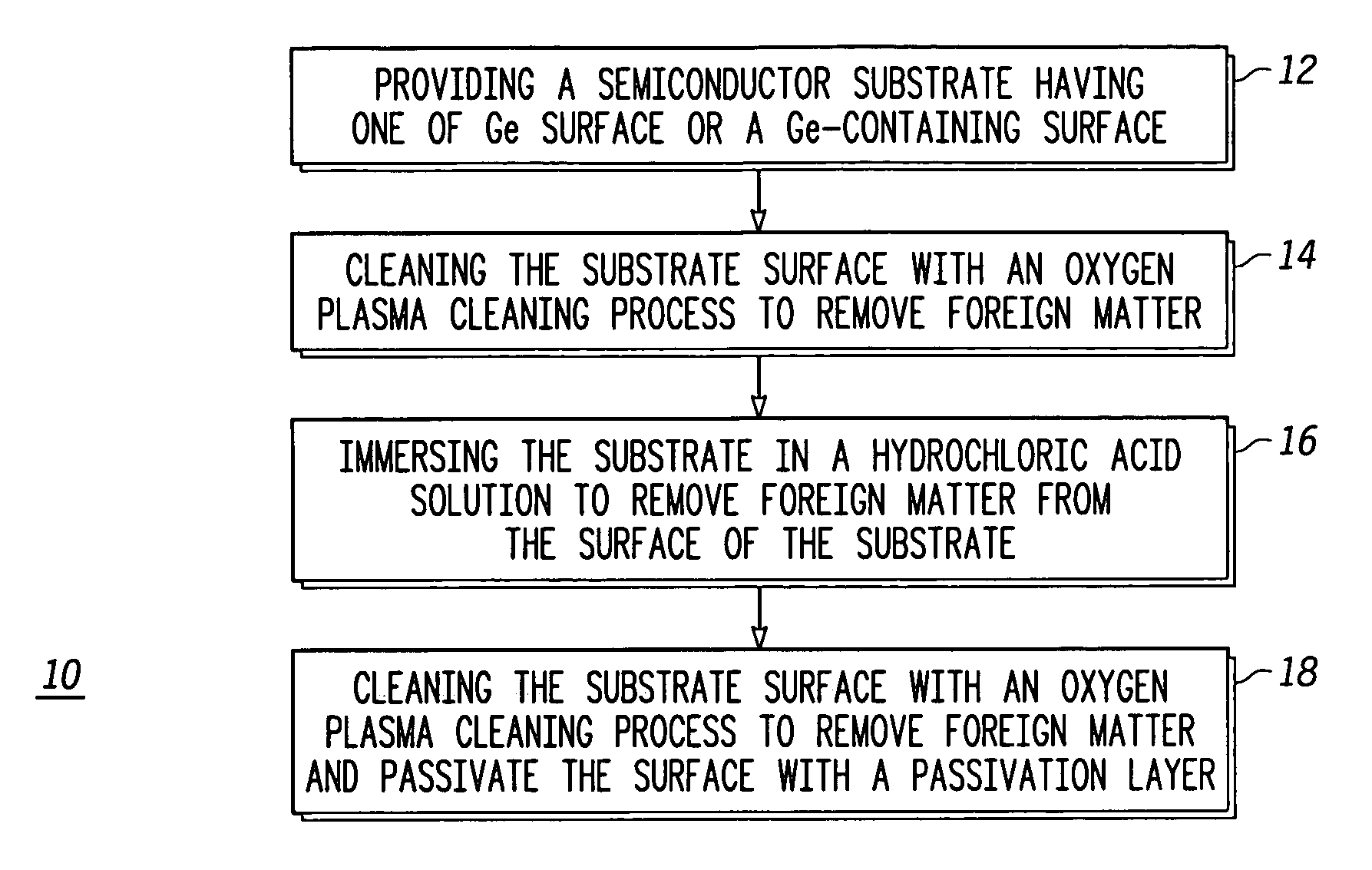

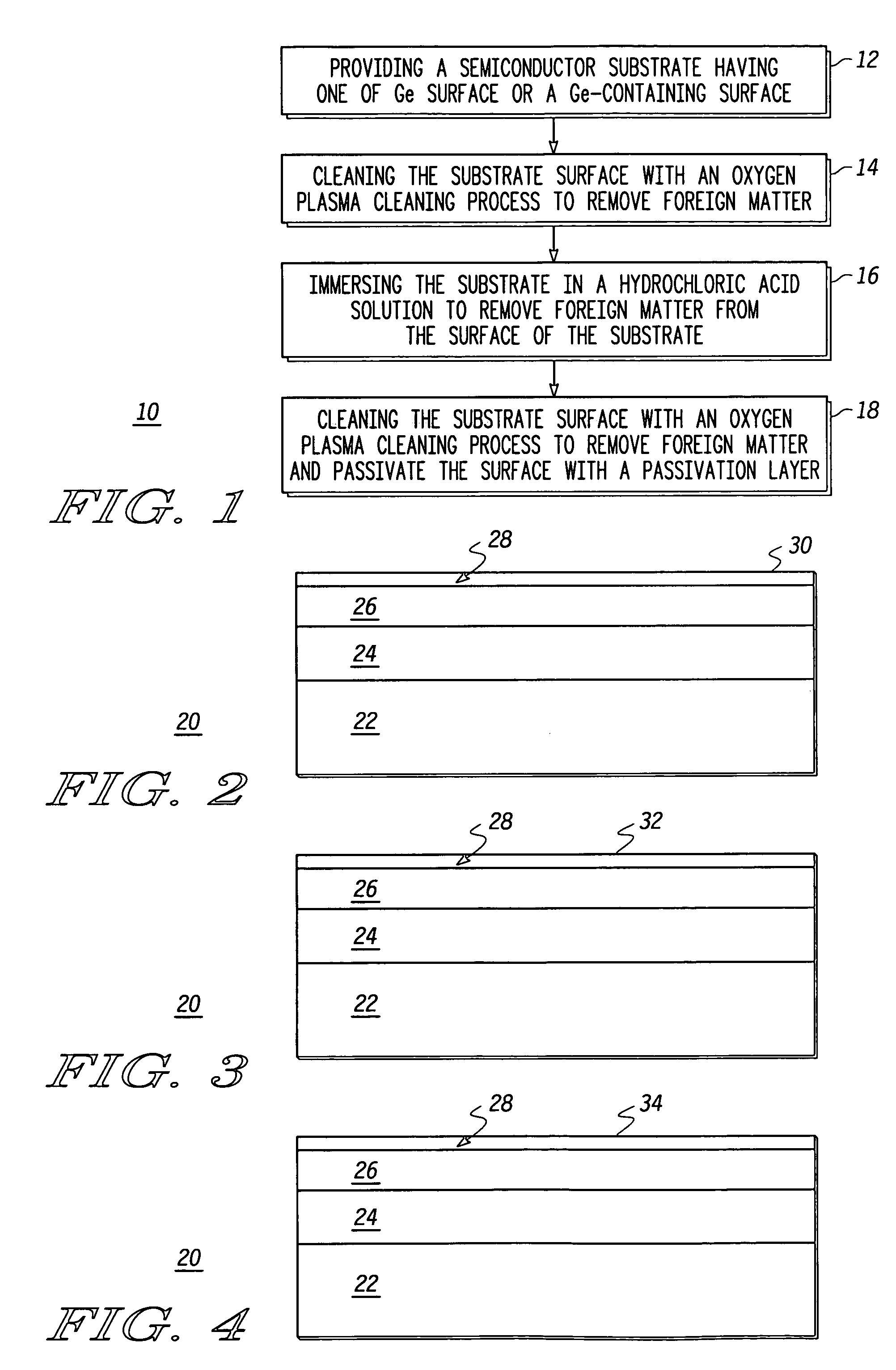

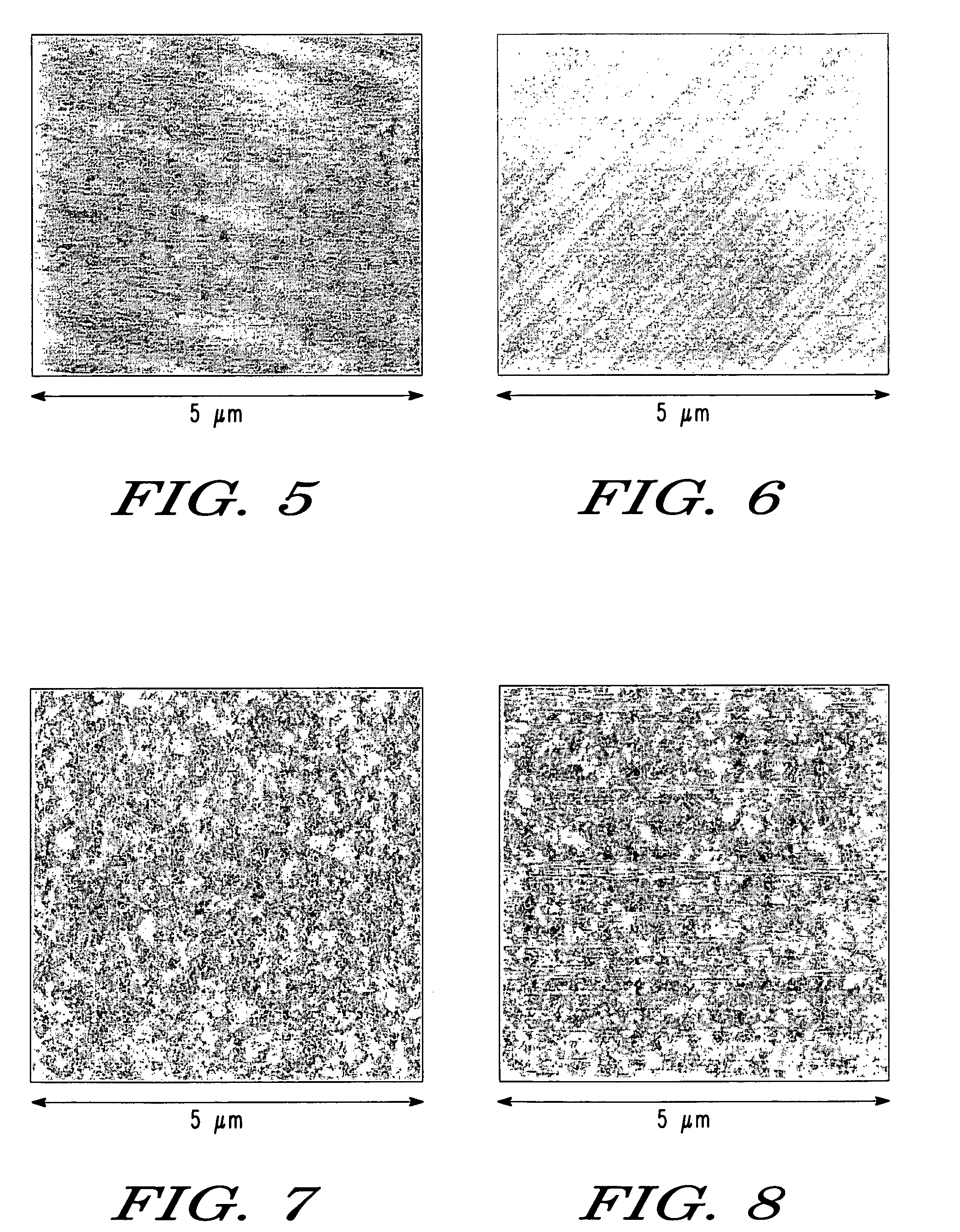

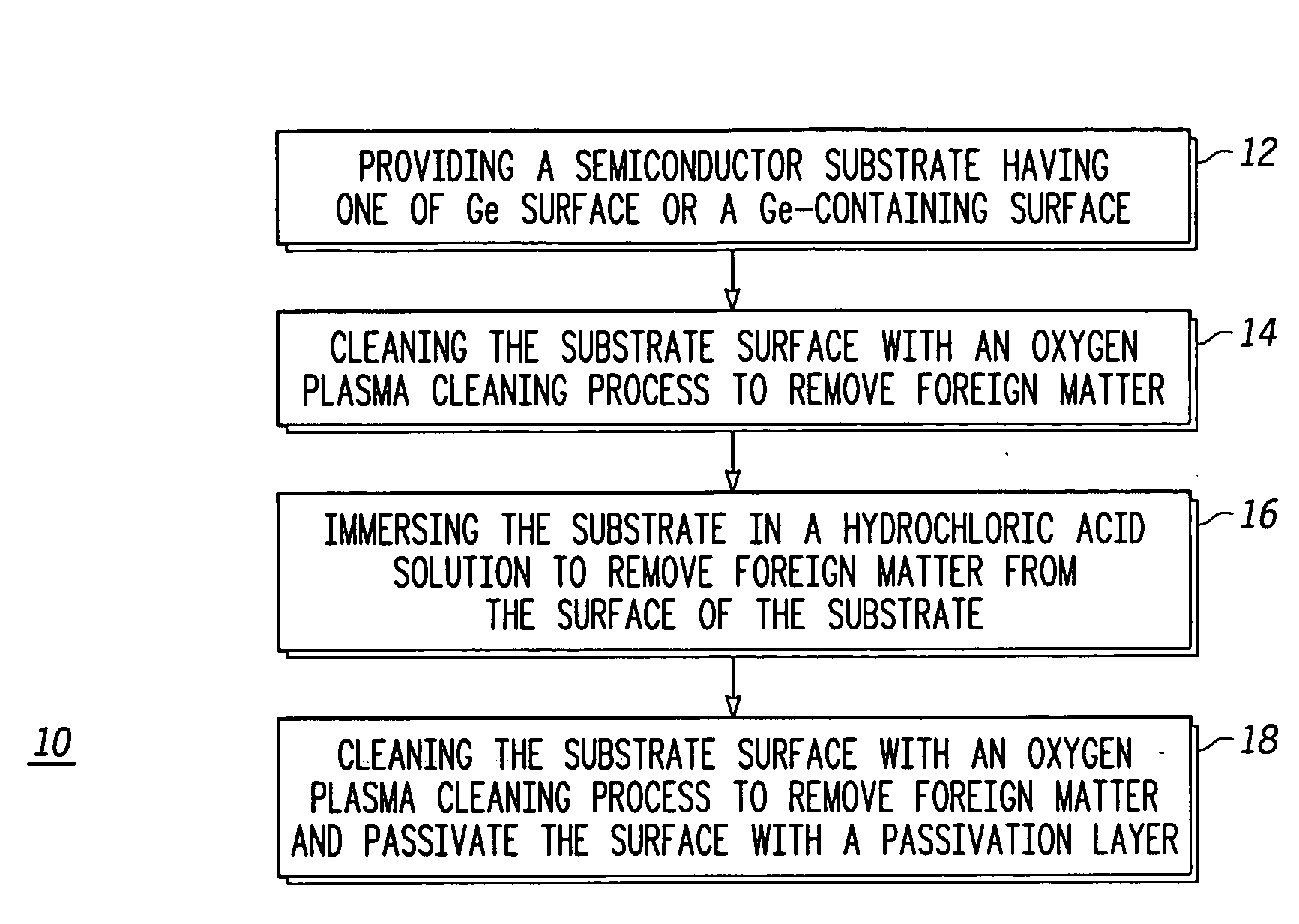

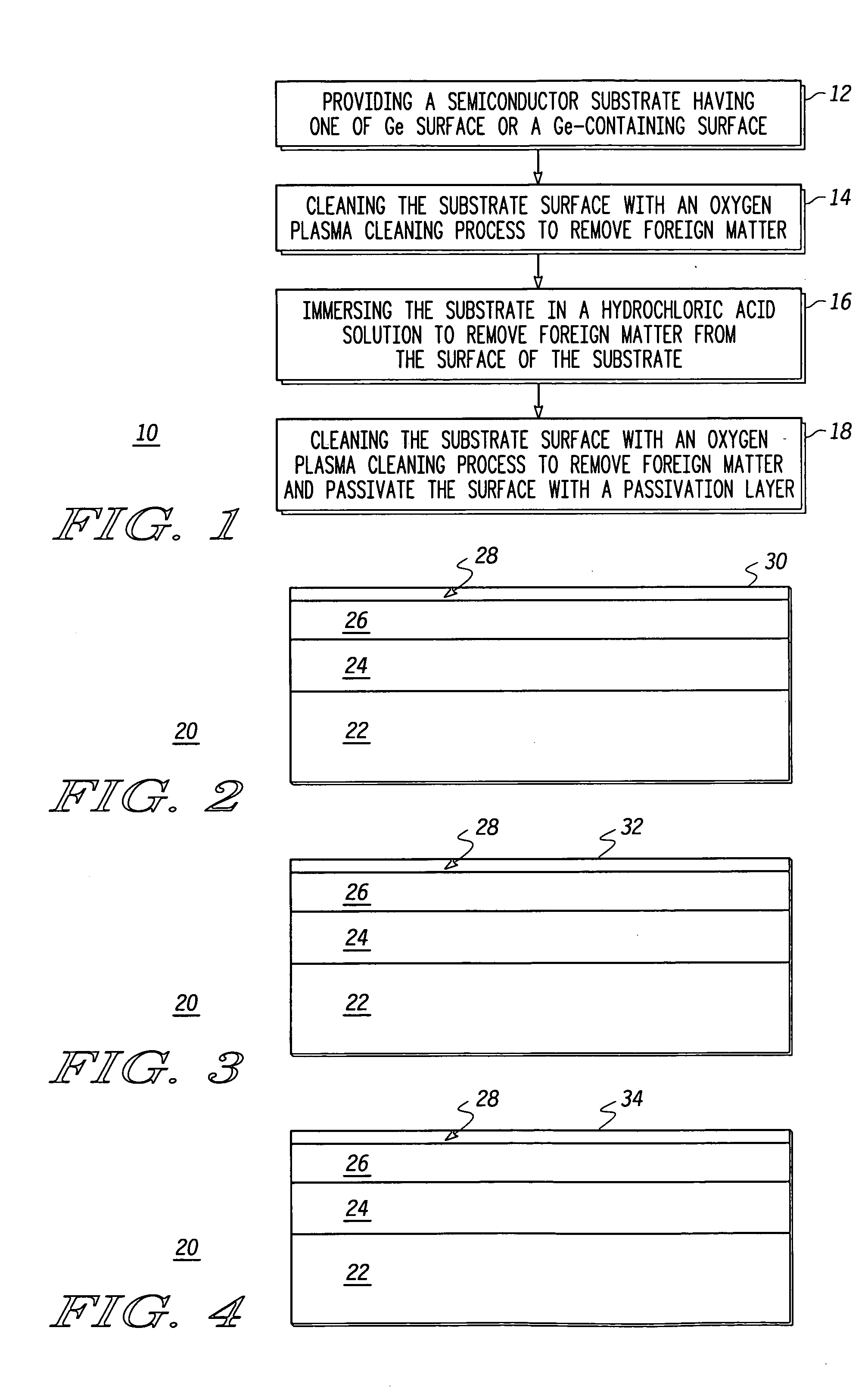

Method for preparing a semiconductor substrate surface for semiconductor device fabrication

InactiveUS7132372B2Semiconductor/solid-state device manufacturingSemiconductor devicesForeign matterSurface layer

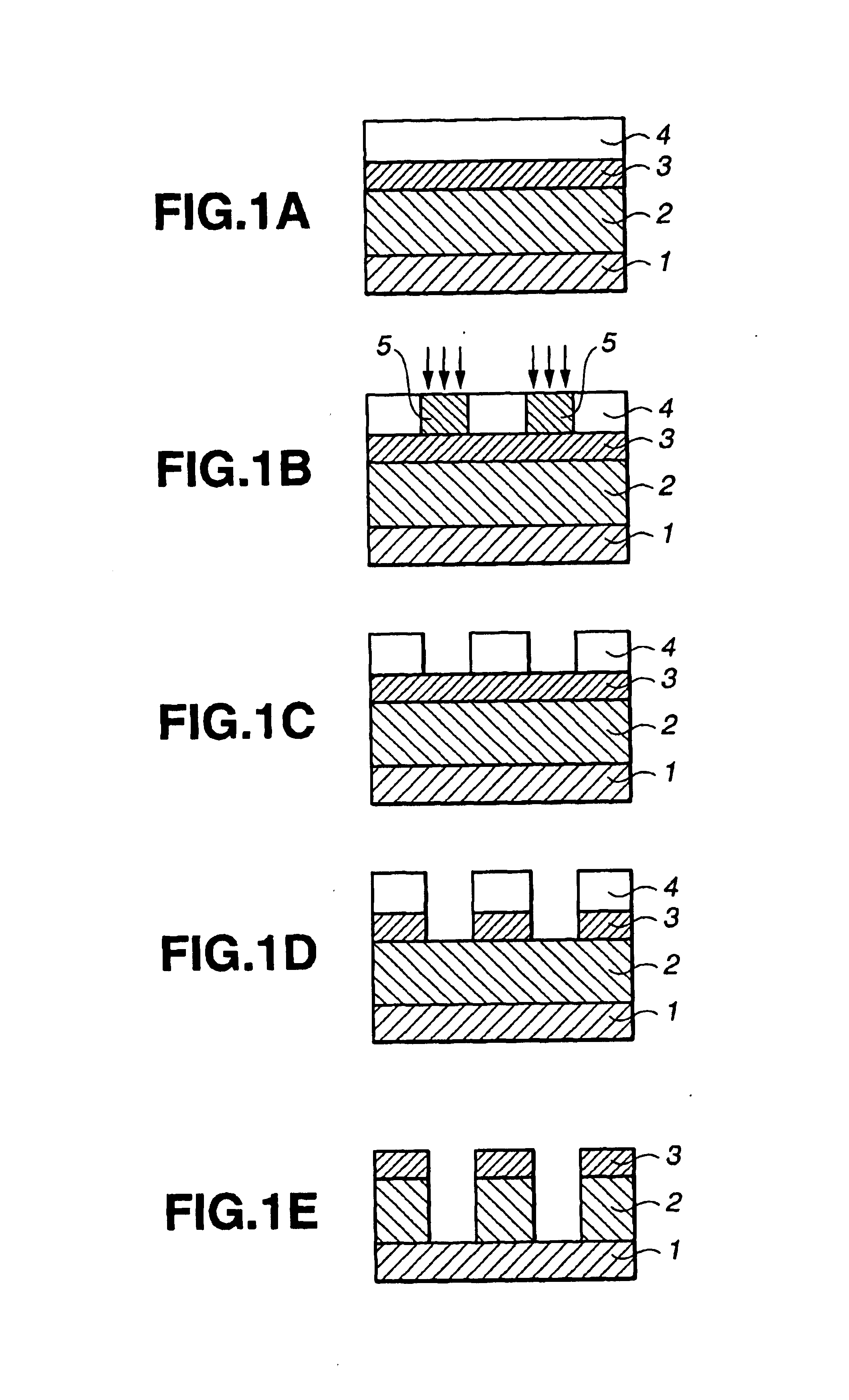

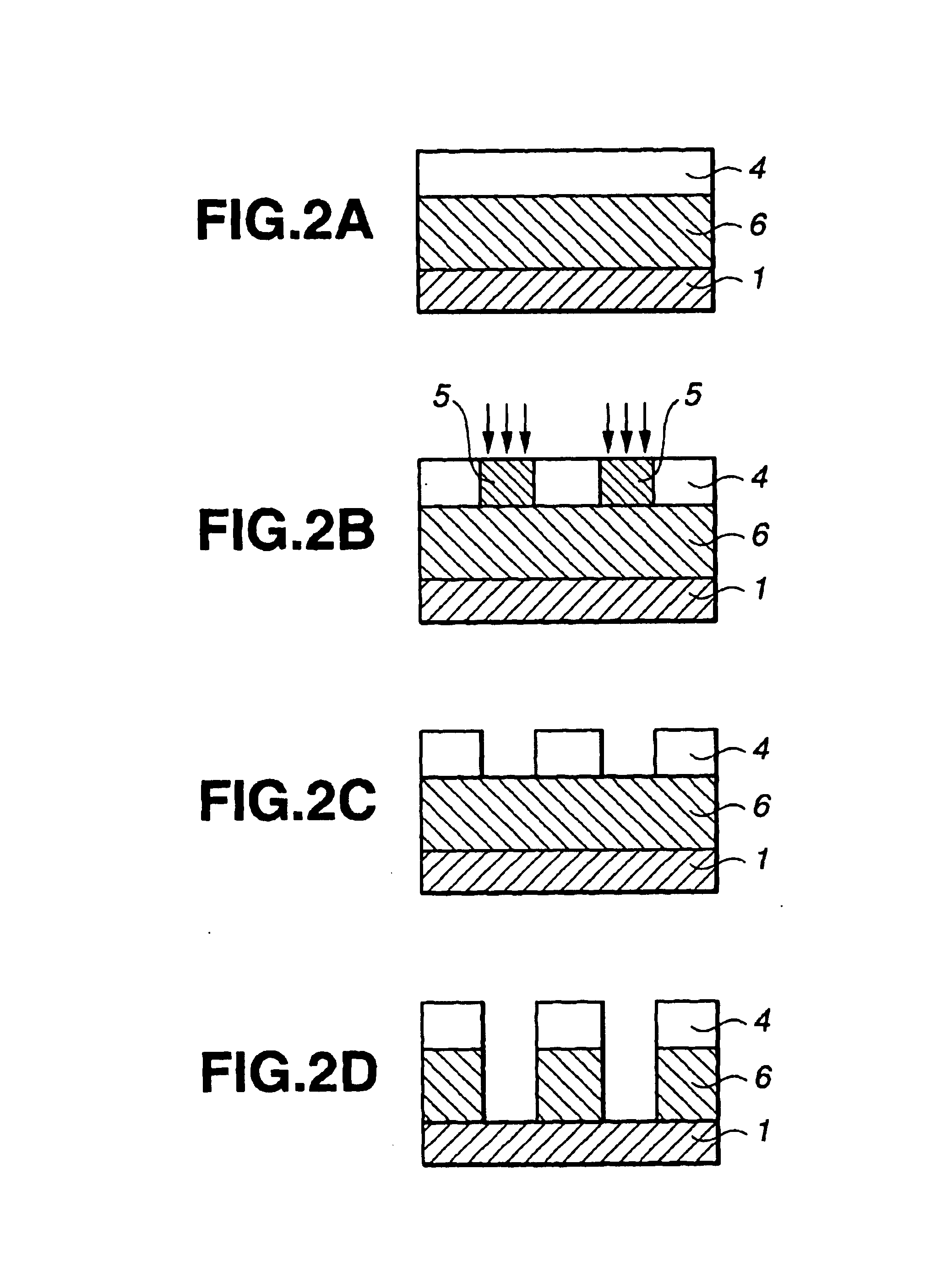

A method for preparing a semiconductor substrate surface (28) for semiconductor device fabrication, includes providing a semiconductor substrate (20) having a pure Ge surface layer (28) or a Ge-containing surface layer (12), such as SiGe. The semiconductor substrate (20) is cleaned using a first oxygen plasma process (14) to remove foreign matter (30) from the surface (28) of the substrate (20). The substrate surface (28) is next immersed in a hydrochloric acid solution (16) to remove additional foreign matter (30) from the surface (28) of the substrate (20). The immersion step is followed by a second oxygen plasma etch process (18), passivate the surface with a passivation layer (34), and provide for an atomically smooth surface for subsequent epitaxial or gate dielectric growth.

Owner:NORTH STAR INNOVATIONS

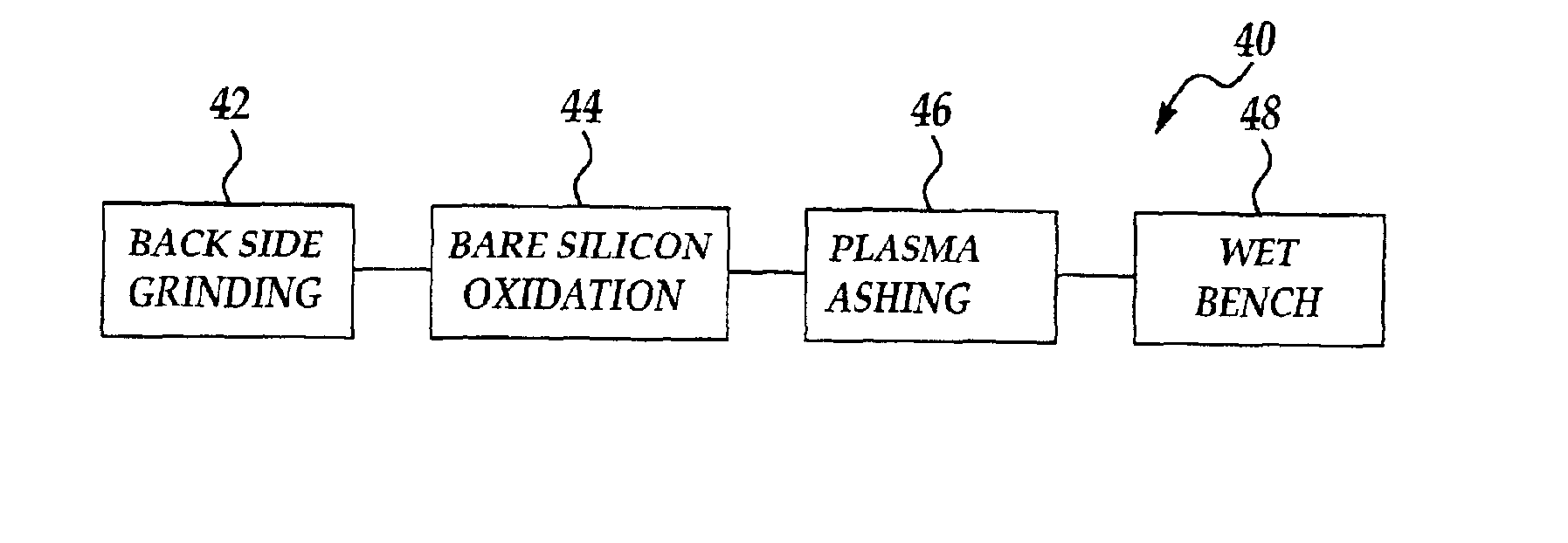

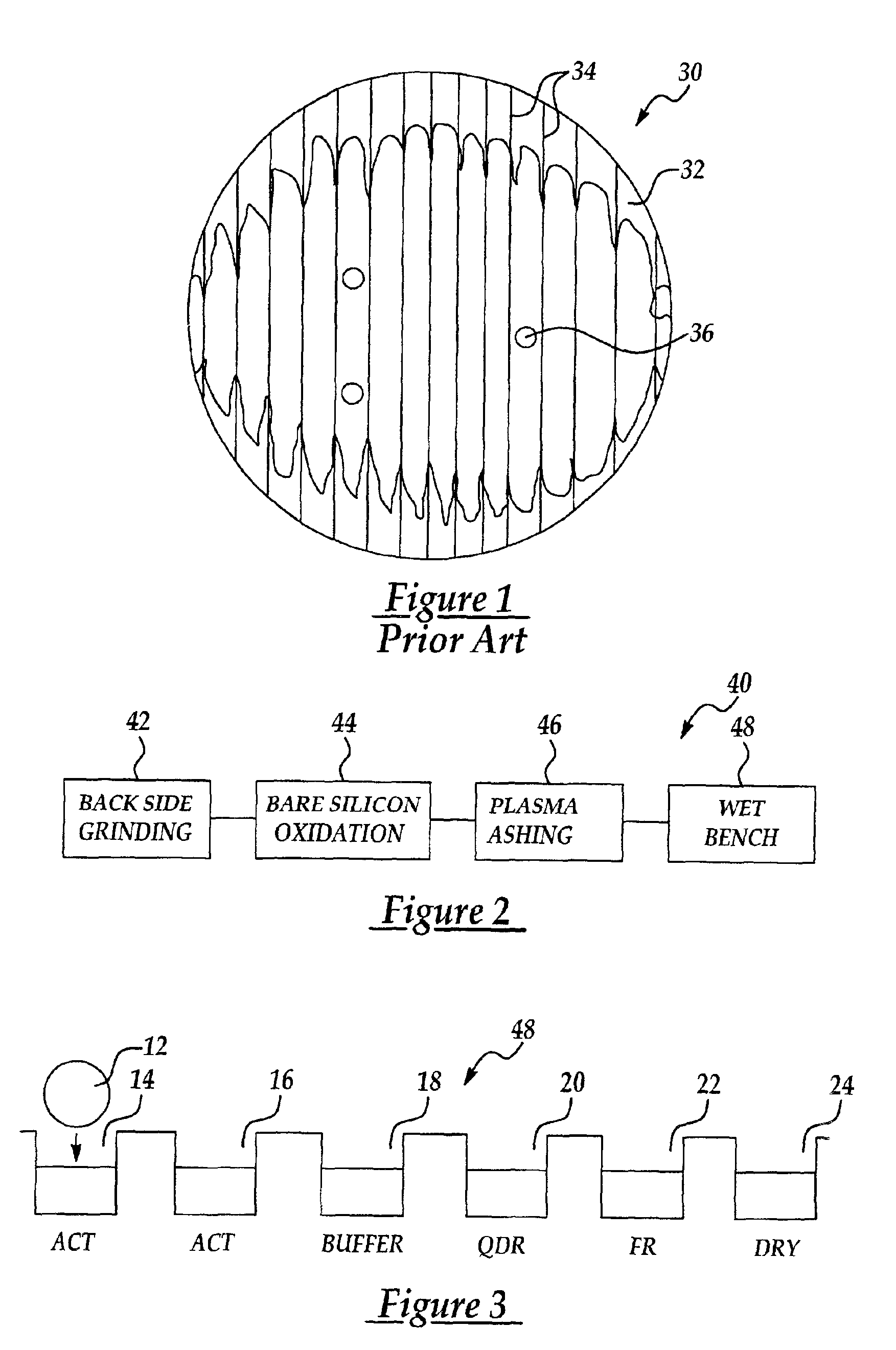

Method for plasma etching a wafer after backside grinding

InactiveUS6887793B2Preventing wafer backside non-uniform oxidationPrevent oxidationSemiconductor/solid-state device manufacturingEffective surfaceWafering

A method for plasma etching a wafer after a backside grinding process which incorporates an oxidation pretreatment step is disclosed. The method includes the step of first grinding a backside of a wafer to expose a bare silicon surface. The bare silicon surface is then oxidized in an oxidation chamber to form a substantially uniform silicon oxide layer of at least 50 Å thick, and preferably at least 100 Å thick. The wafer is then positioned in a plasma etch chamber with an active surface of the wafer exposed, and a surface layer etched away by an oxygen plasma without causing any further silicon oxide formation on the backside of the wafer. The present invention novel plasma etching method can be advantageously used for removing an organic material layer, such as a photoresist layer from a wafer surface.

Owner:TAIWAN SEMICON MFG CO LTD

Resist composition and patterning process

InactiveUS7232638B2High sensitivityHigh resolutionPhotosensitive materialsSemiconductor/solid-state device manufacturingOrganic solventPhotoacid

Chemically amplified positive resist compositions comprising a polymer obtained by copolymerizing a silicon-containing monomer with a polar monomer having a value of LogP or cLogP of up to 0.6 and optionally hydroxystyrene, a photoacid generator and an organic solvent are sensitive to high-energy radiation and have a high sensitivity and resolution at a wavelength of less than 300 nm and improved resistance to oxygen plasma etching.

Owner:SHIN ETSU CHEM IND CO LTD

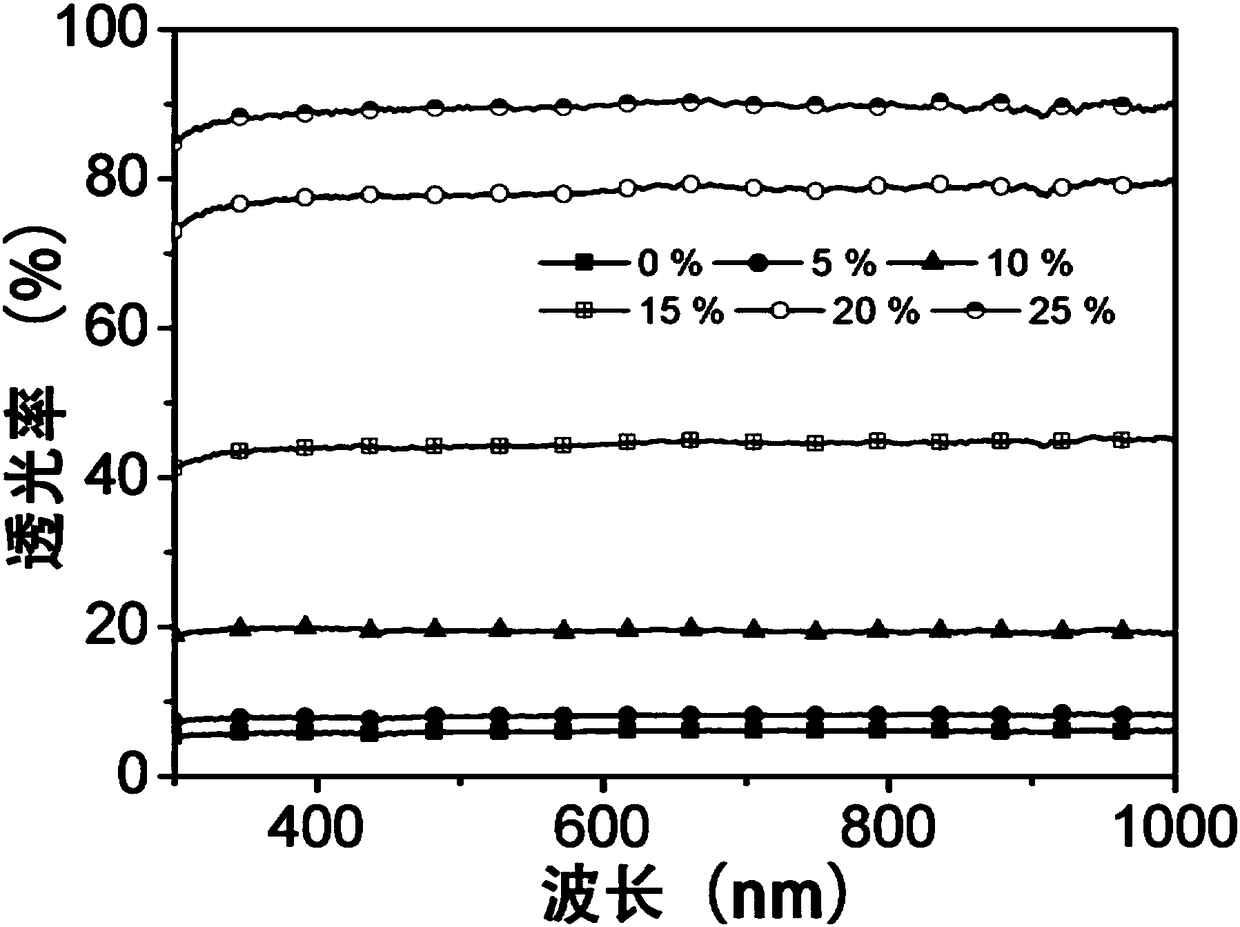

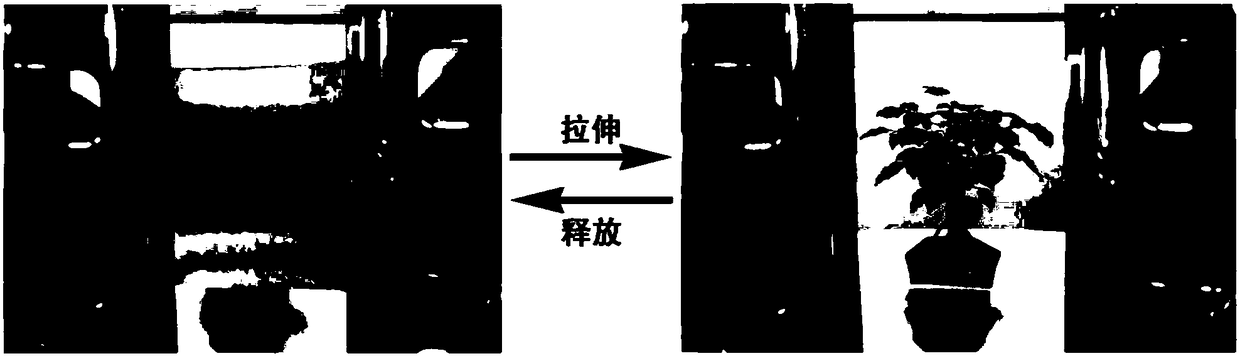

Preparation method of force response type surface folds with adjustable light transmittance

ActiveCN108424543AAchieve reversible transformationEasy to operateCoatingsComposite filmElastic substrate

The invention relates to a preparation method of force response type surface folds with adjustable light transmittance. The method comprises the steps as follows: performing oxygen plasma etching on atransparent elastic substrate to form a hydrophilic layer; coating the surface of the etched elastic substrate with a rigid composite film solution, and drying the surface to form a film; releasing stress after stretching the prepared double-layer film. Regular folds on the surface of a material are obtained with the method. The hydrophilic property of the elastic substrate is changed through ionetching, the folds with regular shapes are formed through pre-stretching after the surface is coated with the rigid molecular solution and the film is formed, the transmittance of the folds for visible light is measured by applying different strains to the folds, and reversible transformation of regulating the light transmittance of the fold surfaces in the large range of 6%-90% is realized. Theoperation method is wide in application range, simple to operate, good in reversibility and capable of realizing large-area preparation and has potential application value in the intelligent window field.

Owner:SHANDONG UNIV

Compound, resin, material for forming underlayer film for lithography, underlayer film for lithography, pattern forming method, and method for purifying the compound or resin

ActiveUS20170073288A1Improve heat resistanceExcellent etch resistanceOrganic chemistryOrganic compound preparationOxygen plasma etchingOrganic chemistry

The compound according to the present invention is represented by a specific formula. The compound according to the present invention has a structure according to the specific formula, and therefore can be applied to a wet process and is excellent in heat resistance and etching resistance. In addition, the compound according to the present invention has such a specific structure, and therefore has a high heat resistance, a relatively high carbon concentration, a relatively low oxygen concentration and also a high solvent solubility. Therefore, the compound according to the present invention can be used to form an underlayer film whose degradation is suppressed at high-temperature baking and which is also excellent in etching resistance to oxygen plasma etching or the like. Furthermore, the compound is also excellent in adhesiveness with a resist layer and therefore can form an excellent resist pattern.

Owner:MITSUBISHI GAS CHEM CO INC

Method for preparing a semiconductor substrate surface for semiconductor device fabrication

InactiveUS20060024970A1Enhancement of GeO formationSemiconductor/solid-state device manufacturingSemiconductor devicesForeign matterGate dielectric

A method for preparing a semiconductor substrate surface (28) for semiconductor device fabrication, includes providing a semiconductor substrate (20) having a pure Ge surface layer (28) or a Ge-containing surface layer (12), such as SiGe. The semiconductor substrate (20) is cleaned using a first oxygen plasma process (14) to remove foreign matter (30) from the surface (28) of the substrate (20). The substrate surface (28) is next immersed in a hydrochloric acid solution (16) to remove additional foreign matter (30) from the surface (28) of the substrate (20). The immersion step is followed by a second oxygen plasma etch process (18), passivate the surface with a passivation layer (34), and provide for an atomically smooth surface for subsequent epitaxial or gate dielectric growth.

Owner:NORTH STAR INNOVATIONS

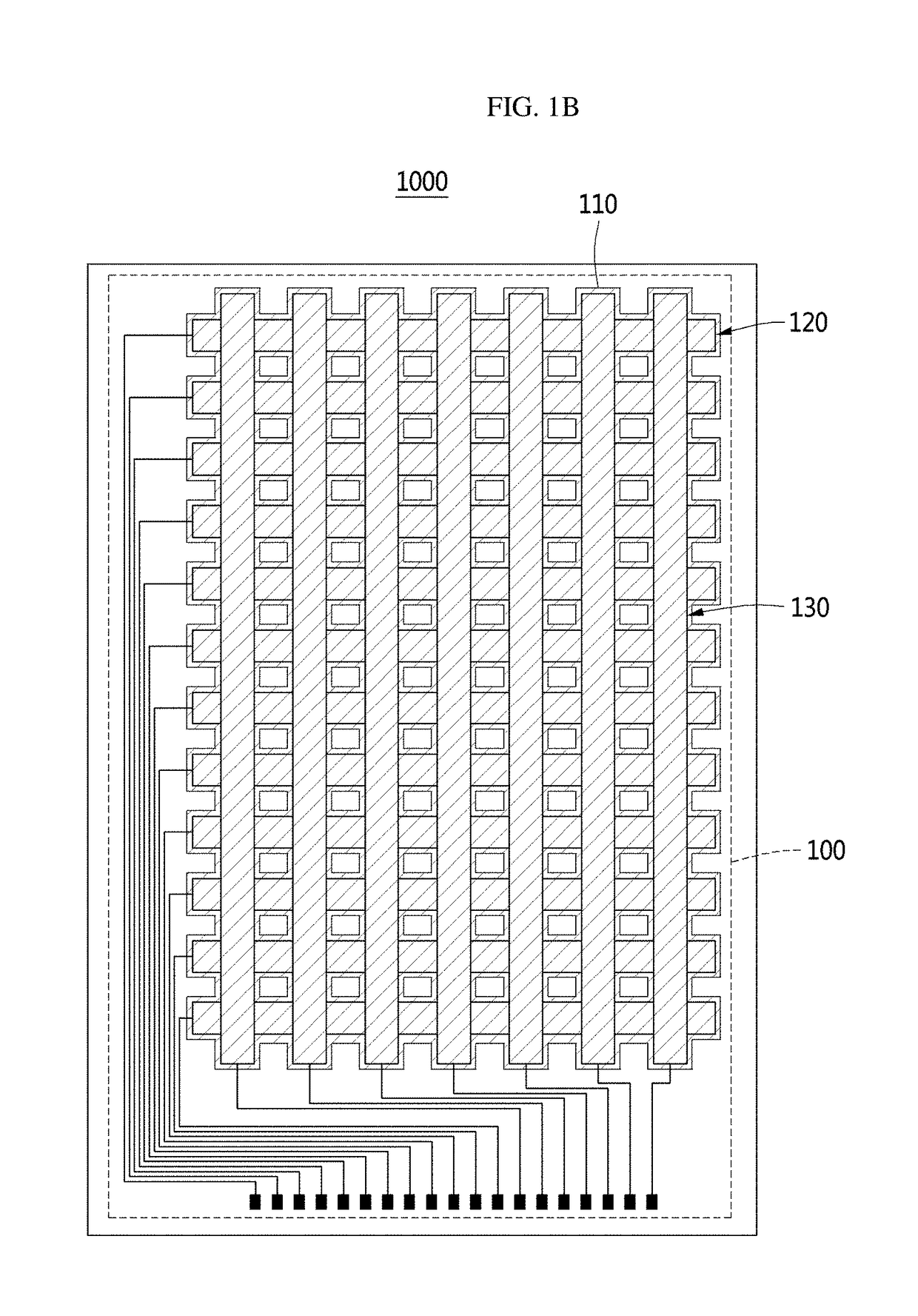

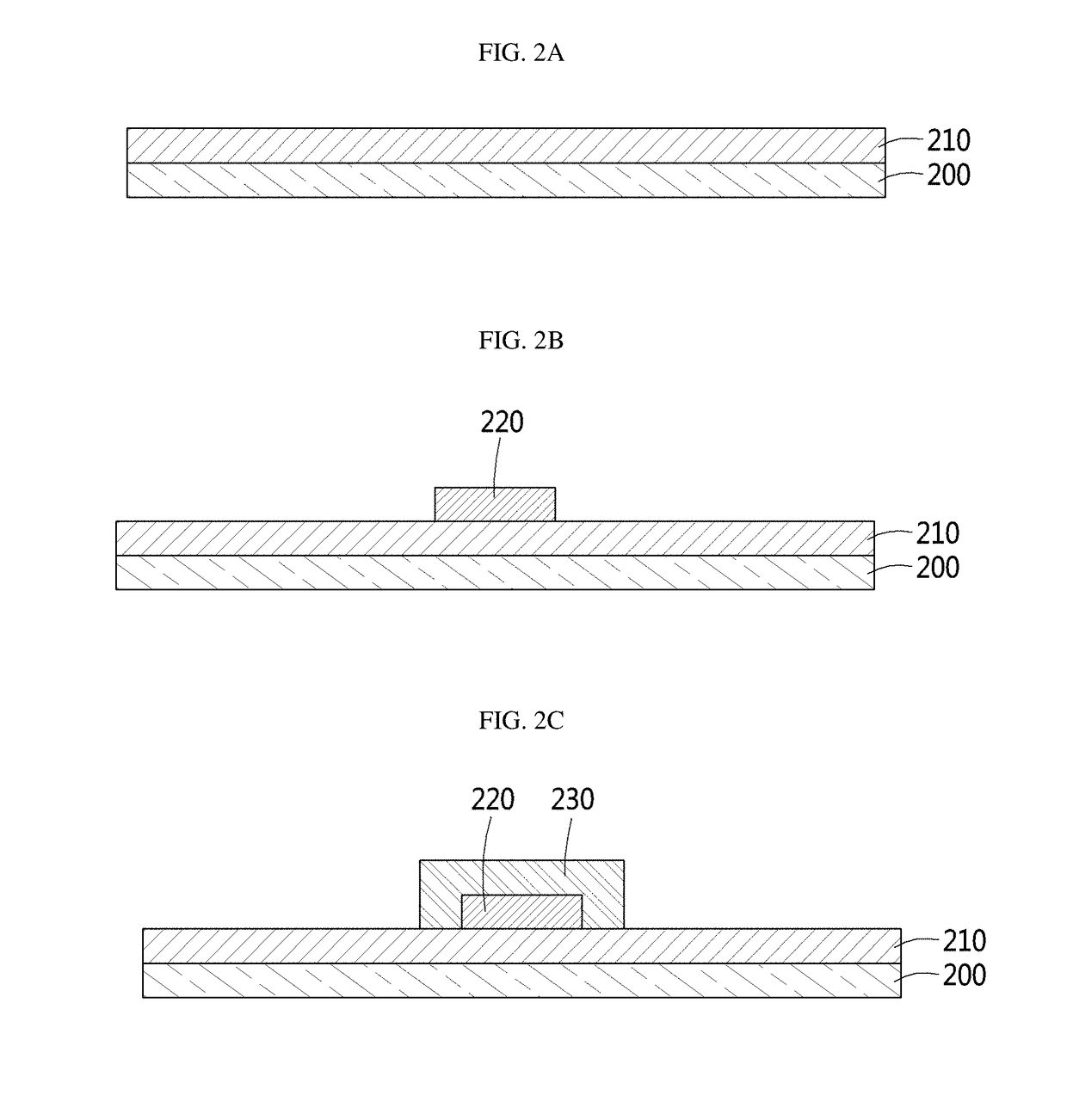

Ultra-thin touch panel and method of fabricating the same

ActiveUS20190073057A1Increase flexibilityGood stretchabilityConductive layers on insulating-supportsDetails for portable computersEngineeringOxygen plasma etching

Disclosed are an ultra-thin touch panel and a method of fabricating the same. Particularly, the ultra-thin touch panel according to an embodiment of the present disclosure includes a flexible substrate, a plurality of first sensing electrodes arranged in a first direction on the flexible substrate, an adhesive insulating layer formed on the flexible substrate and the first sensing electrodes, and a plurality of second sensing electrodes arranged in a second direction, which intersects the first direction, on the flexible substrate and the adhesive insulating layer using a wet transfer method, wherein the flexible substrate is patterned in a shape corresponding to the first and second sensing electrodes by oxygen plasma etching to form a polygonal mesh structure.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Method of modifying an etched trench

InactiveUS20060076312A1Sufficient energyReduce the angleRecording apparatusDecorative surface effectsPolymer scienceOxygen plasma etching

A process for facilitating modification of an etched trench is provided. The process comprises: (a) providing a wafer comprising an etched trench, the trench having a photoresist plug at its base; and (b) removing a portion of the photoresist by subjecting the wafer to a biased oxygen plasma etch. The process is particularly suitable for preparing a trench for subsequent argon ion milling. Printhead integrated circuits fabricated by a process according to the invention have improved ink channel surface profiles and / or surface properties.

Owner:MEMJET TECH LTD

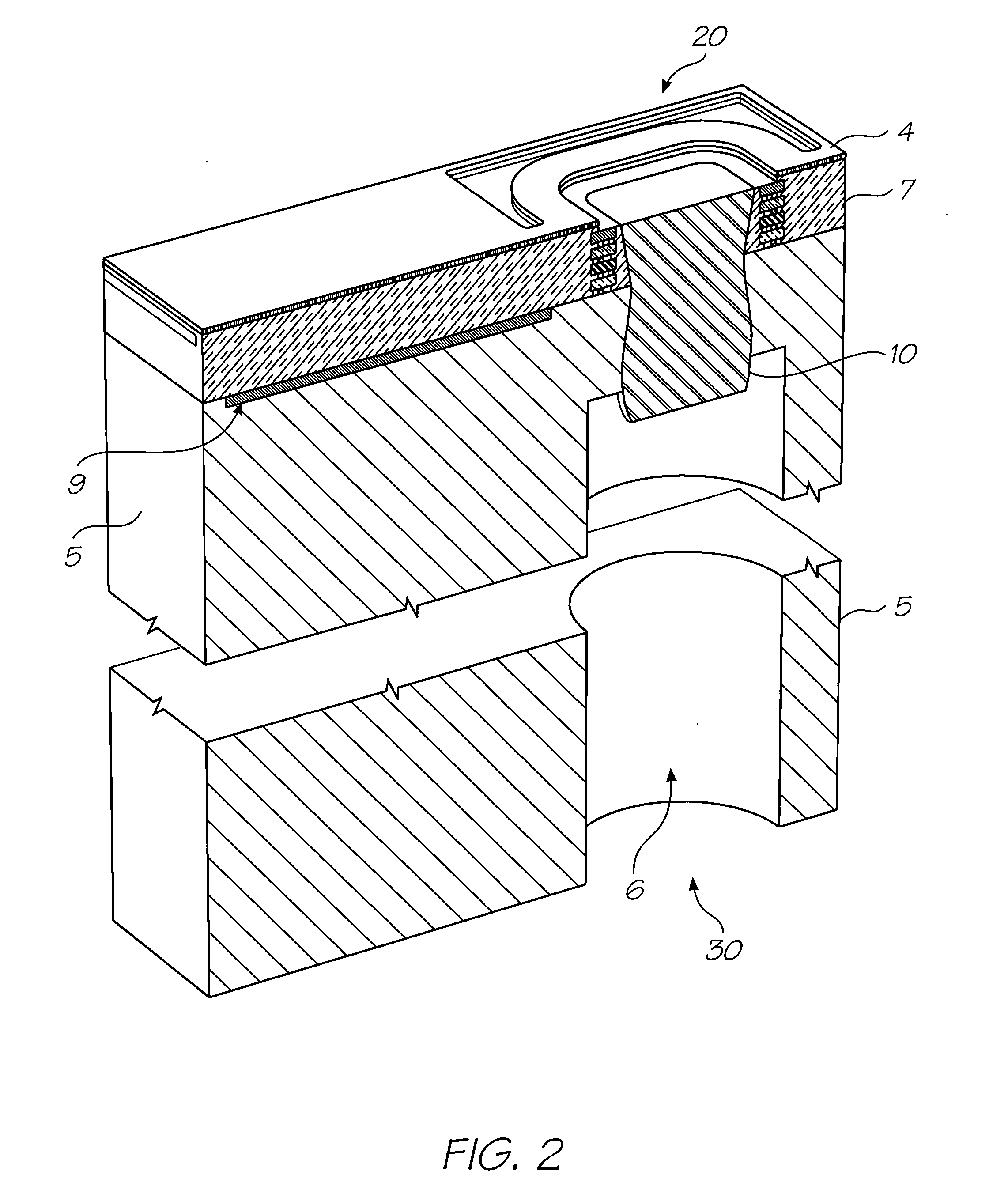

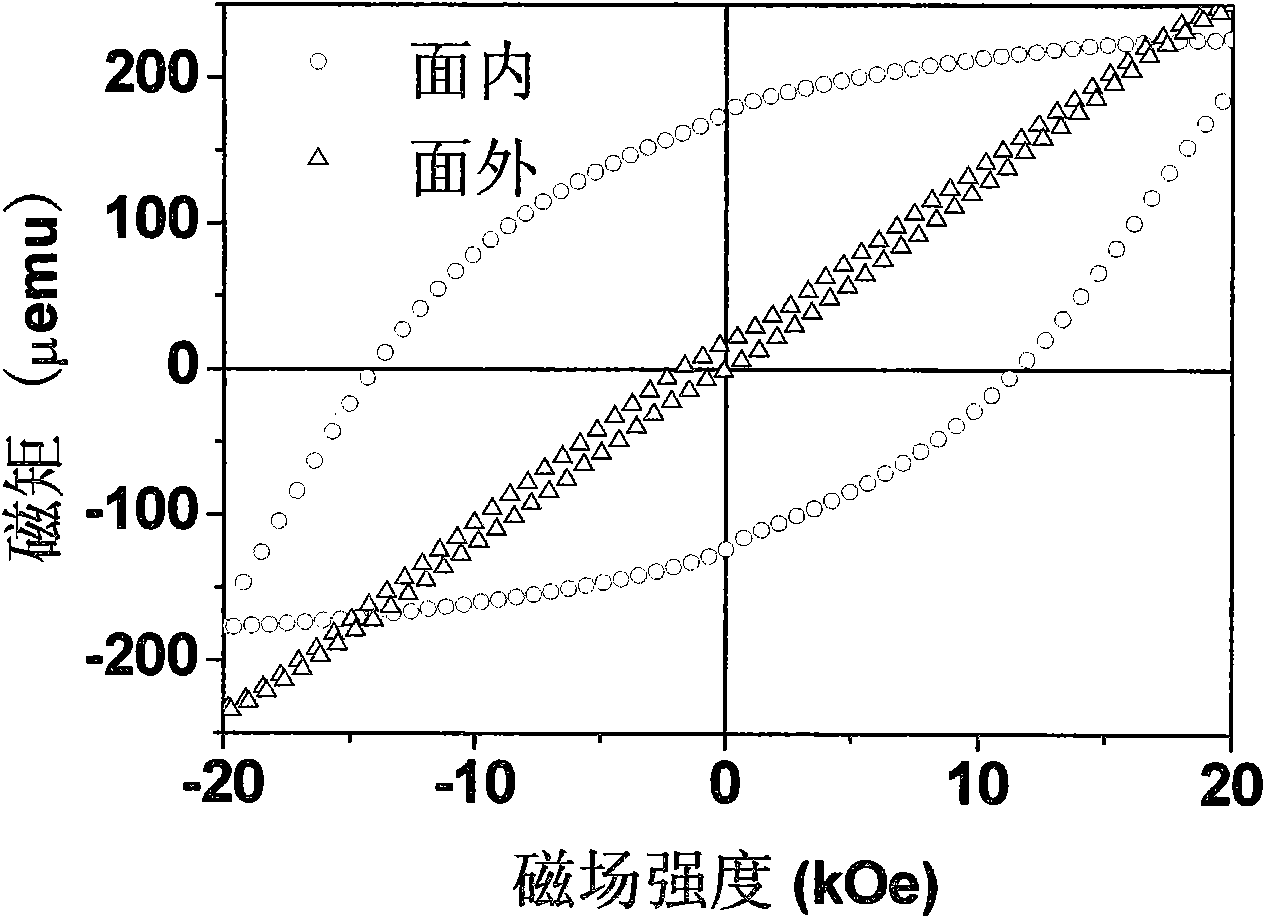

Method for preparing parallel-oriented FePt magnetic nano-composite film

InactiveCN101609743ASmall size dispersionEvenly distributedMagnetic film to substrate applicationMagnetic layersComposite filmCopolymer

The invention discloses a method for preparing a parallel-oriented FePt magnetic nano-composite film, which is characterized by comprising the following steps: 1, utilizing an amphiphilic block copolymer PS-P4VP to self-assemble into a reverse micelle in methylbenzene, and then adding metal salt, namely FeCl3 and H2PtCl6 into reverse micelle solution to form a metal salt supported reverse micelle; 2, utilizing a spin-coating method to obtain a reverse micelle array on a silicon substrate, and obtaining an FePt nano-particle array with good monodispersity through oxygen plasma etching and hydrogen plasma etching; 3, using a magnetic control sputtering method to cover an SiO2 protective layer on the FePt nano-particle array; and 4, performing high-temperature annealing on a sample under protective atmosphere to finish the production of the parallel-oriented FePt magnetic nano-composite film.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com