Method for preparing parallel-oriented FePt magnetic nano-composite film

A technology of magnetic nanometer and composite film, applied in the field of magnetic nanometer, can solve the problems of oxygen oxidation and FePt nanoparticle not having good magnetic orientation, and achieve the effect of reducing magnetic storage energy, easy control of particle size and spacing, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

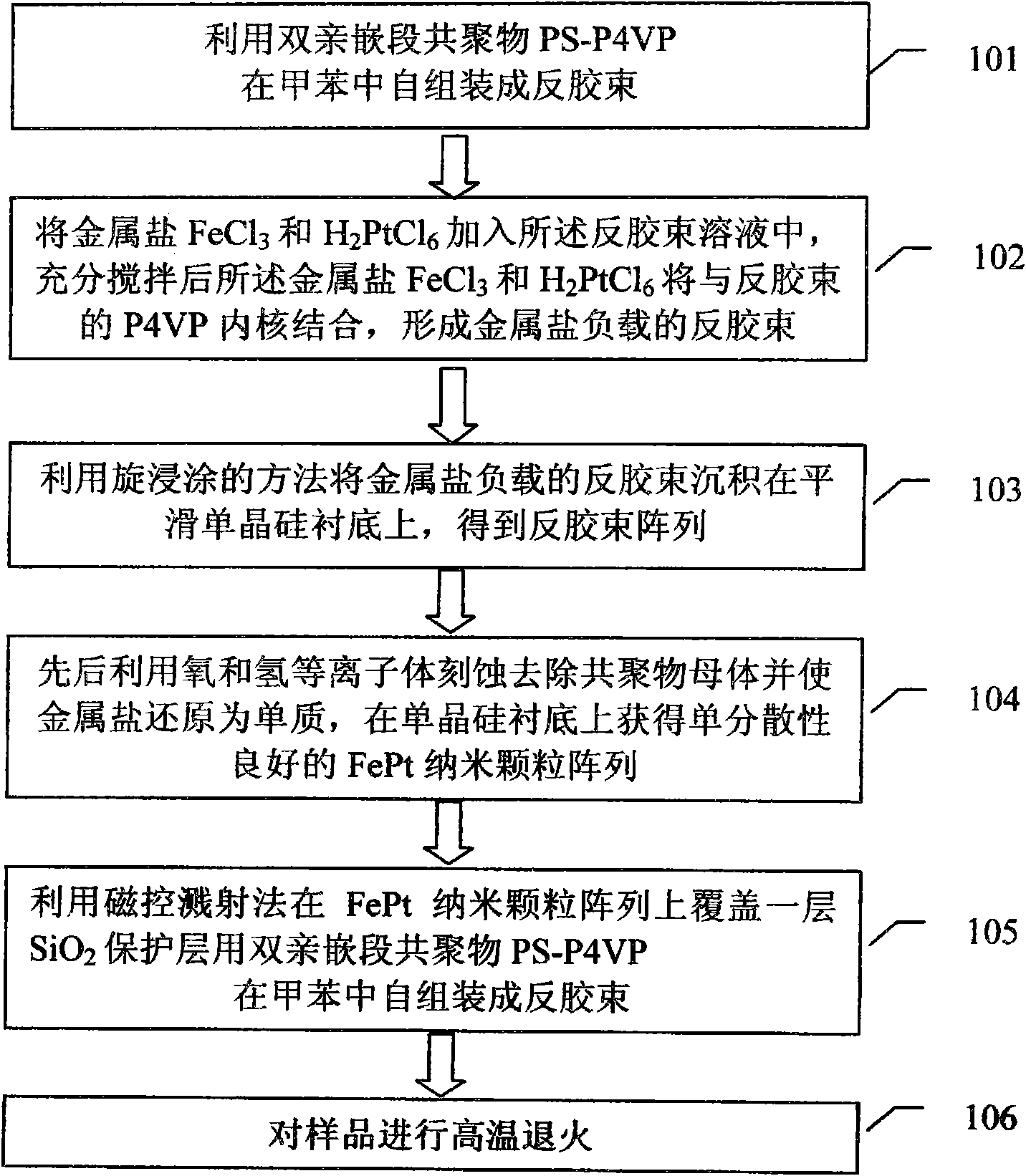

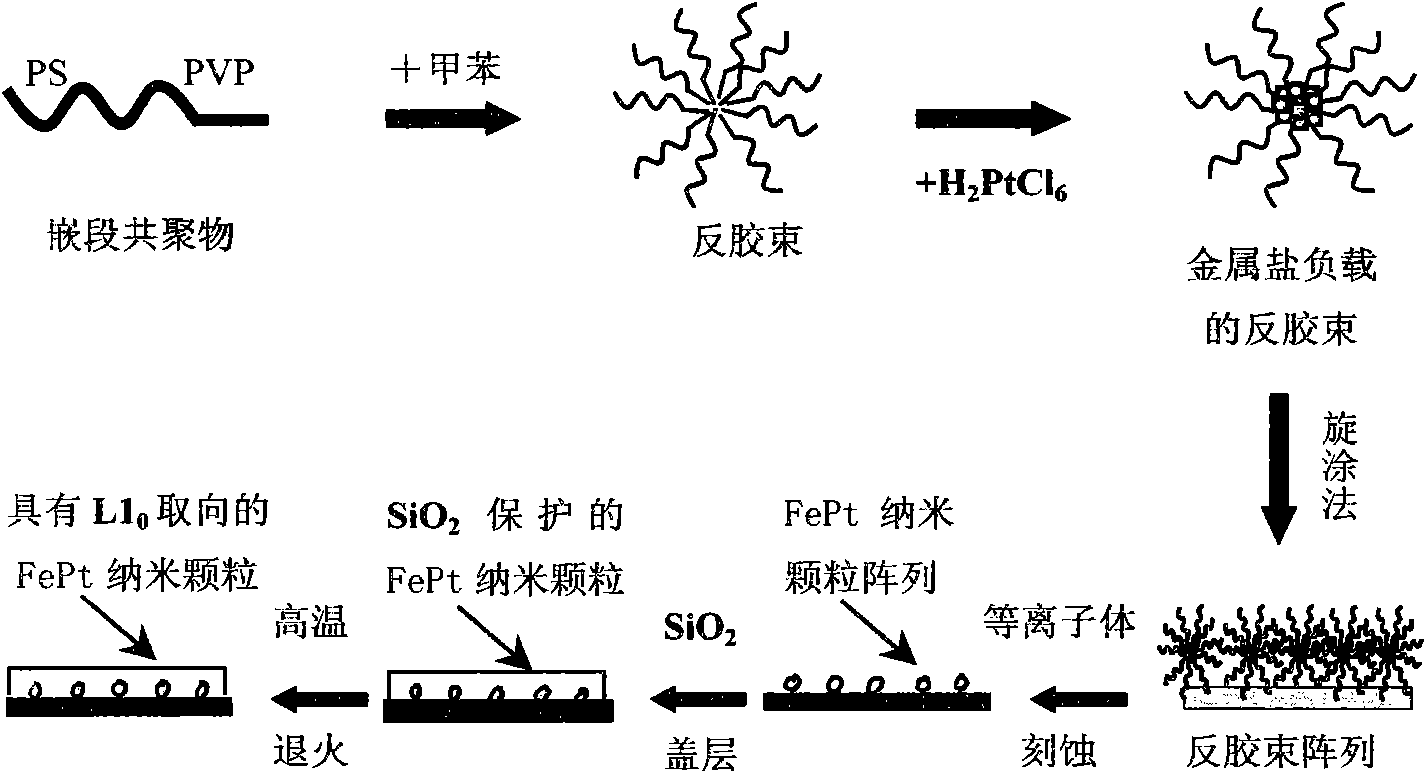

[0033] figure 2 According to the embodiment of the present invention, the process flow schematic diagram of preparing parallel-oriented FePt magnetic nanocomposite films specifically includes the following steps:

[0034] 1) Add 5 mg of amphiphilic block copolymer PS(306)-P4VP(125) into 5 mL of toluene. After sufficient stirring (more than 24 hours), the copolymer will self-assemble into uniformly sized, monodisperse reverse micelles in toluene.

[0035] 2) Add metal salt 2.58mg FeCl to the above reverse micellar solution 3 and 9.70 mg H 2 PtCl 6 , after fully stirring, the metal salt will occupy the inner core of the reverse micelles to form metal salt-loaded reverse micelles.

[0036] 3) Put the cleaned and dried (100) silicon substrate on the horizontal stage of the spin coater, start the engine and make it rotate at a constant and controllable rate along the vertical film surface at a speed of 100r / min; , a layer of monodisperse and evenly distributed metal salt-load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com