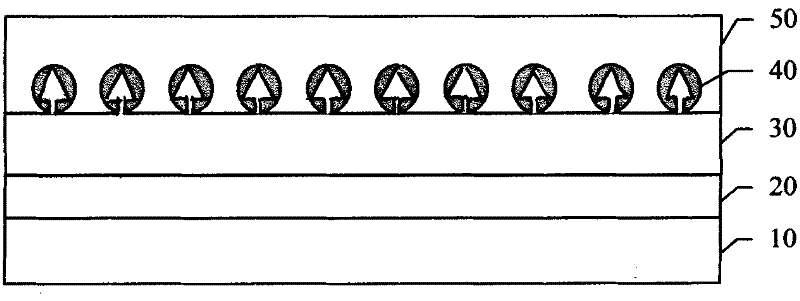

Method for preparing c-axle vertical alignment patterned magnetic recording medium

A magnetic recording medium and vertical orientation technology, which is applied in the direction of coating with magnetic layer, disc carrier manufacturing, coating coating by sputtering method, etc., can solve the problems of poor particle orientation effect, unsuitable for industrial production, and high difficulty in preparation, and achieve The effect of small size dispersion, promotion of orientation growth and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] According to the method for preparing c-axis vertically oriented BPM described in the specific embodiment, the method will be described below in conjunction with specific examples:

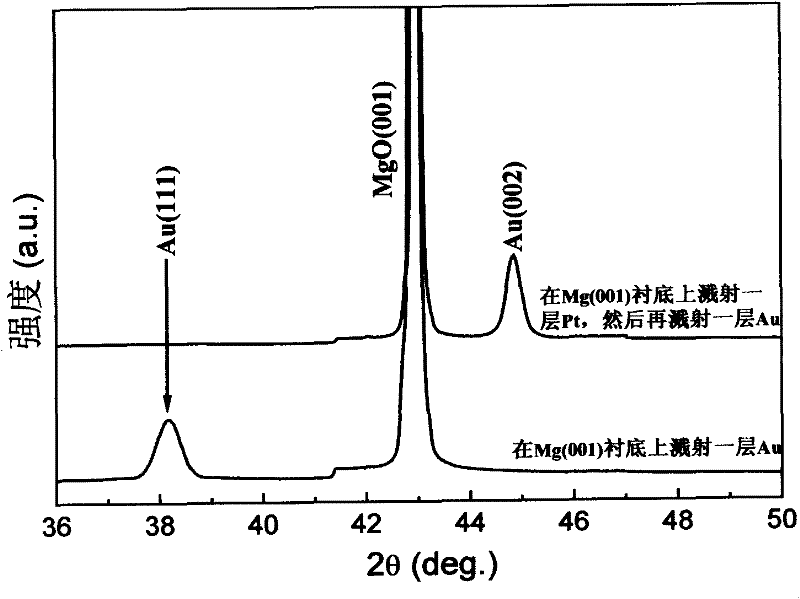

[0034] 1) Place the cleaned and dried MgO(100) single crystal substrate in the magnetron sputtering chamber, and sputter a layer of Pt(002) film with a thickness of 2nm. The sputtering conditions used are: the target distance is 7cm, and the working environment is 0.4Pa under Ar atmosphere, the sputtering temperature is 400°C, and the working power of radio frequency magnetron sputtering is 5W;

[0035] 2) Then sputter a layer of 40nm thick Au(002) film on it, the sputtering conditions used are: the target distance is 7cm, the working environment is 0.4Pa under Ar atmosphere, the sputtering temperature is 400°C, radio frequency magnetron The working power of sputtering is 5W;

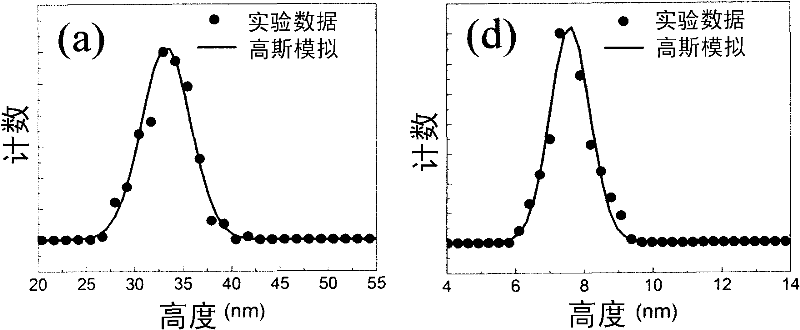

[0036] 3) Add the amphiphilic block copolymer PS(1762)-P4VP(308) into toluene and stir thoroughly, the concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com