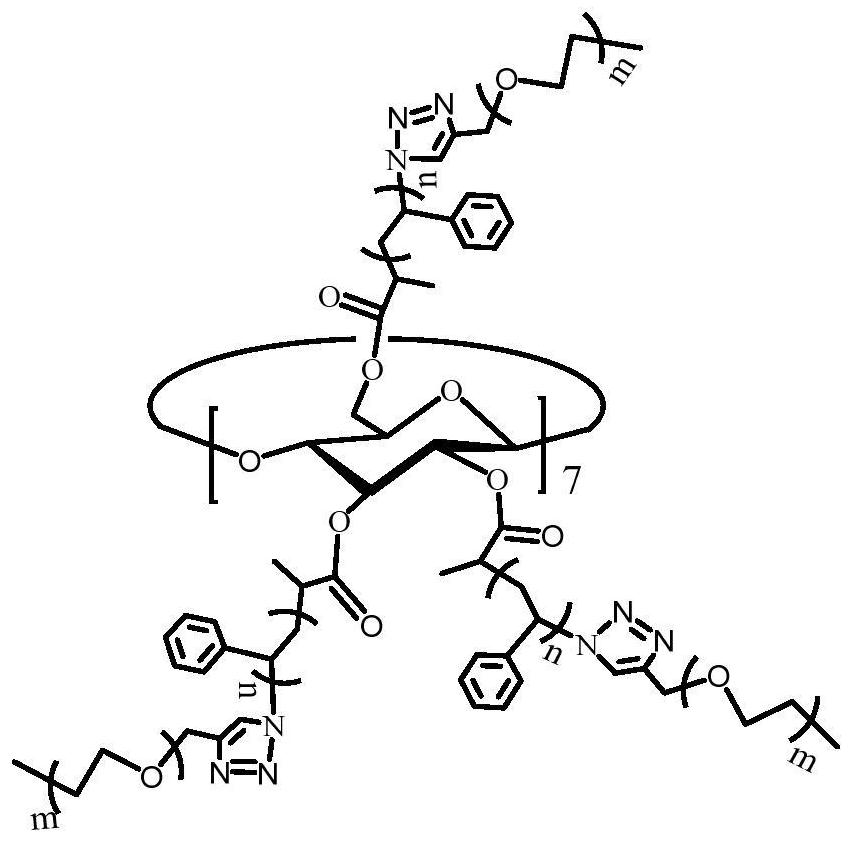

Multi-arm star-shaped polymer assembled micelle and preparation method thereof

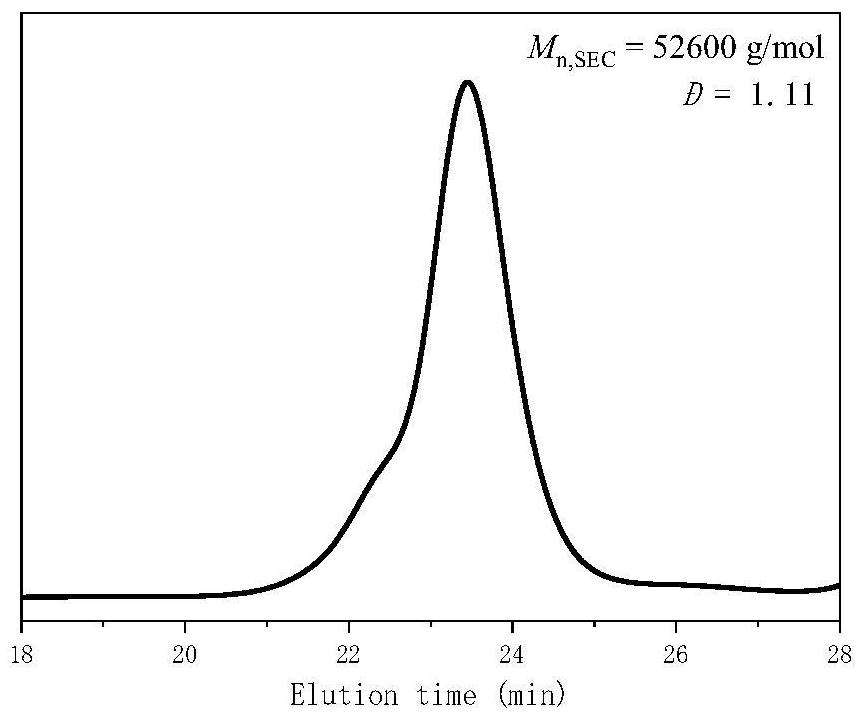

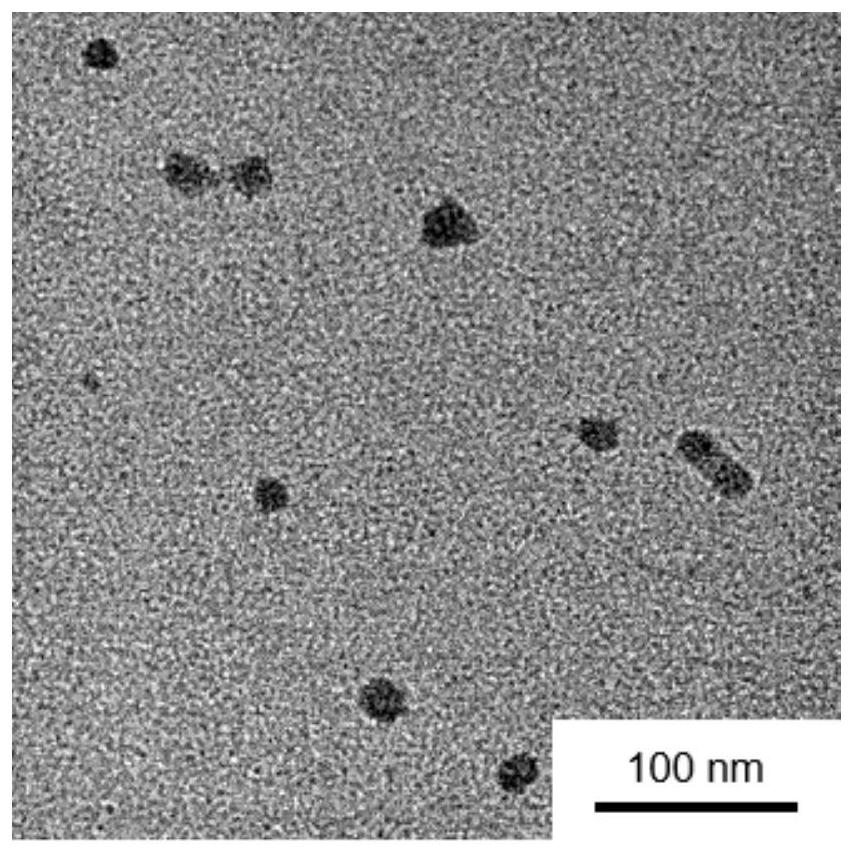

A multi-armed star polymer technology, applied in the field of multi-armed star-shaped polymer assembly micelles and its preparation, can solve the problems of low yield and slow preparation rate, and achieve small size, small size dispersion, and expanded concentration range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of 12-arm star amphiphilic block copolymer (PtBA-b-PHEMA) 12 polymer solution;

[0045] Take 20mg of copolymer (PtBA-b-PHEMA) 12 Dissolved in 10 mL of co-solvent THF, sonicated for 30 min and allowed to stand overnight to prepare a 2 mg / mL polymer solution.

Embodiment 2

[0047] Preparation of 16-arm star amphiphilic block copolymer (PS-b-PEG) 16 polymer solution

[0048] Take 100mg of polymer (PS-b-PEG) 16 Dissolved in 10 mL of co-solvent DMF, ultrasonicated for 30 min and allowed to stand overnight to prepare a 10 mg / mL polymer solution.

Embodiment 3

[0050] Preparation of 21-arm star amphiphilic block copolymer (PS-b-PEG) 21 polymer solution

[0051] Take 20mg of polymer (PS-b-PEG) 21 Dissolved in 10 mL of co-solvent DMF, sonicated for 30 min and allowed to stand overnight to prepare a 2 mg / mL polymer solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com