Metal nanoparticles and preparation method thereof, qled device

A technology of metal nanoparticles and seeds, applied in metal processing equipment, nanotechnology, electrical solid devices, etc., can solve the problems of poor surface passivation effect and stability, uneven particle size distribution, etc., and achieve good surface passivation effect and stability, the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

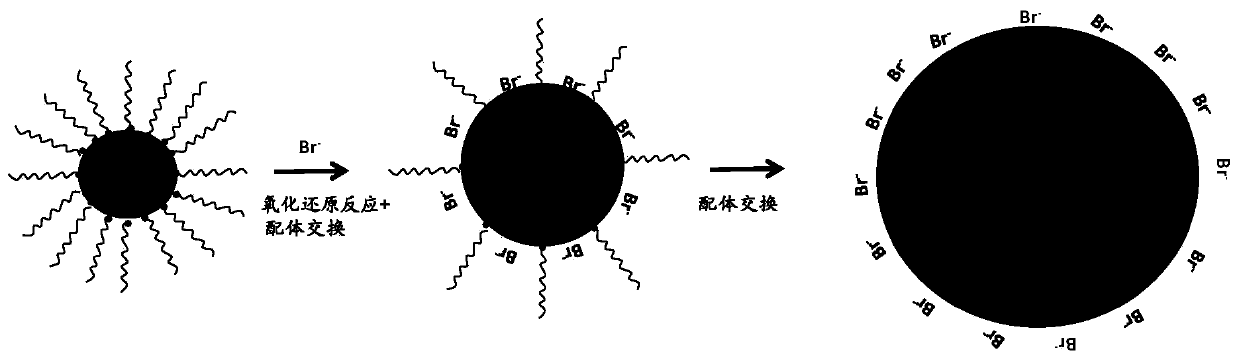

[0017] The embodiment of the present invention provides a method for preparing metal nanoparticles, comprising the following steps:

[0018] S01. Provide metal nanoparticle seeds, configured as a metal nanoparticle seed solution;

[0019] S02. After dispersing the metal nanoparticle seed solution, add mercaptan for mixing reaction, then use extractant to centrifuge from the mixed solution to obtain metal nanoparticle seeds containing thiol ligands, and form thiol-containing Ligand metal nanoparticles seed solution;

[0020] S03. Add halide quaternary ammonium salts and trihaloacetic acid to the metal nanoparticle seed solution containing thiol ligands, stir and react under an inert atmosphere, add a quencher after the reaction, and obtain halogen-passivated metal nanoparticles particles.

[0021] Specifically, in the above step S01, the source of the metal nanoparticle seeds is not clearly defined, and can be purchased or obtained through preparation. In the embodiment of t...

Embodiment 1

[0042] A halogen-passivated gold nanoparticle made by the following steps:

[0043] S11. Preparation of gold nanoparticles seeds: get 0.5ml of sodium hydroxide solution (containing 0.2mmol NaOH) and 0.3ml of tetrakis hydroxymethyl phosphorus chloride solution {(HOCH 2 ) 4 PCl} (purity grade: HPLC) was fully mixed, and then the mixed solution was diluted to 1.2ml to obtain an aqueous solution with a mass fraction of hydroxymethylphosphorus chloride of 80wt%, fully stirred for 10min, and the mass fraction of 0.6ml was 1wt%. Hypochloroauric acid (HAuCl 4 ) was added dropwise to the above mixture at a certain rate with stirring, and then stirred for 15 minutes to obtain gold nanoparticles. Finally, solid gold nanoparticles were obtained by high-speed centrifugation and then separated by size selection. Gold nanoparticle seeds with smaller size are produced, and finally dispersed in ethanol to prepare a 15-20 mg / ml solution and stored in the dark and low temperature for later use...

Embodiment 2

[0049] A QLED device prepared by the following method:

[0050] After filtering the PEDPOT:PSS (AI4083) solution with a 0.45 micron filter head, spin-coat the cleaned ITO glass sheet at a speed of 4000rpm for 60s, and then anneal at 150°C for 15min; Hole transport layer and electron blocking layer (wherein electron blocking layer is made by PVK chlorobenzene solution, and the concentration of PVK chlorobenzene solution is 6mg / ml), then the gold nanoparticle solution of the chlorine atom passivation that embodiment 1 is prepared In the glove box, the spin-coating deposition was carried out at a speed of 2000rpm for 60s, and then the quantum dot luminescent layer was spin-coated at a speed of 1000rpm for 30s, and finally in a high vacuum 2x10 4 Under Pa pressure, 40nm-thick TPBI and 150nm-thick aluminum electrodes are deposited by thermal evaporation through a mask, and the area of the prepared QLED device is 4cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com