Patents

Literature

68results about How to "Improve surface passivation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

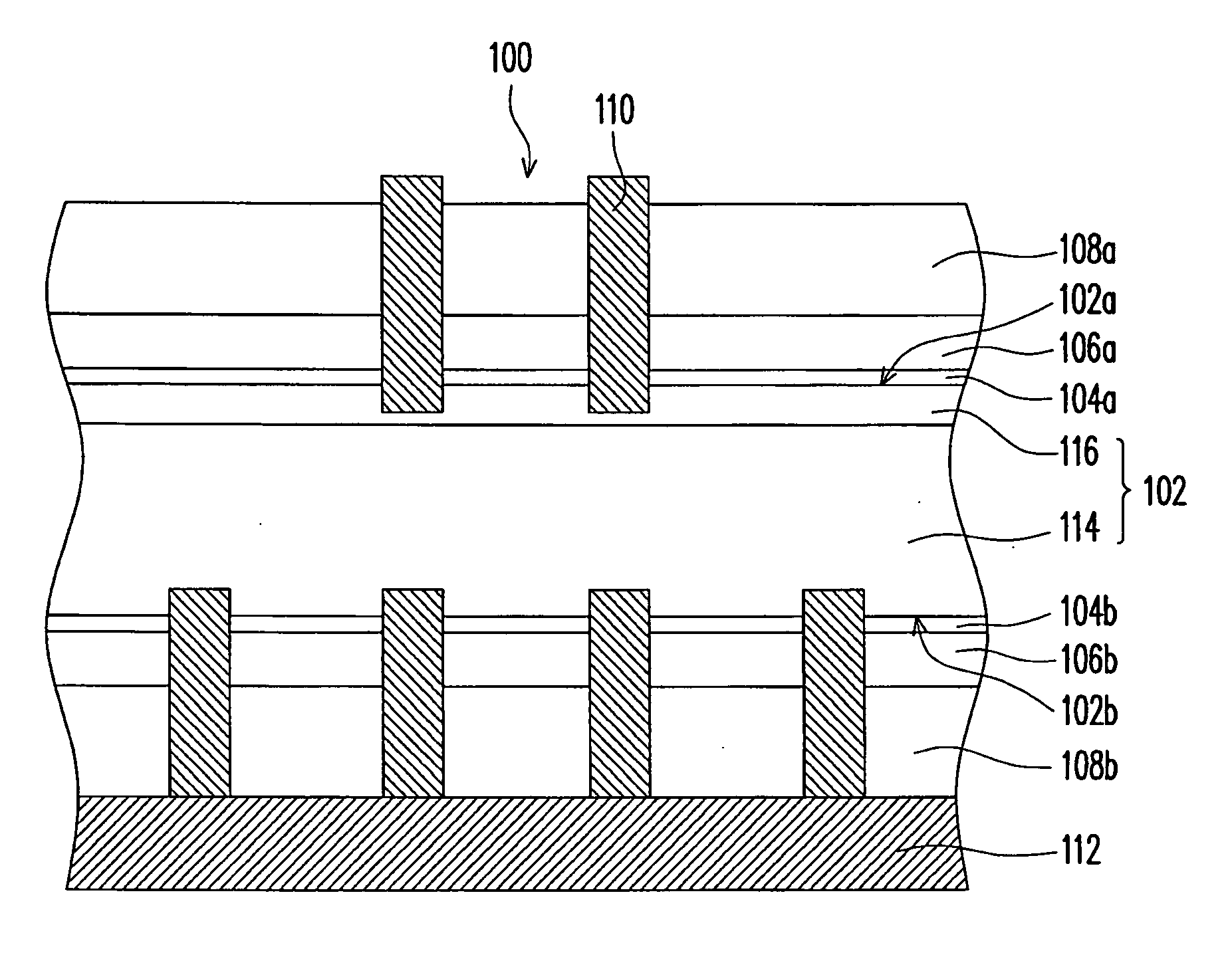

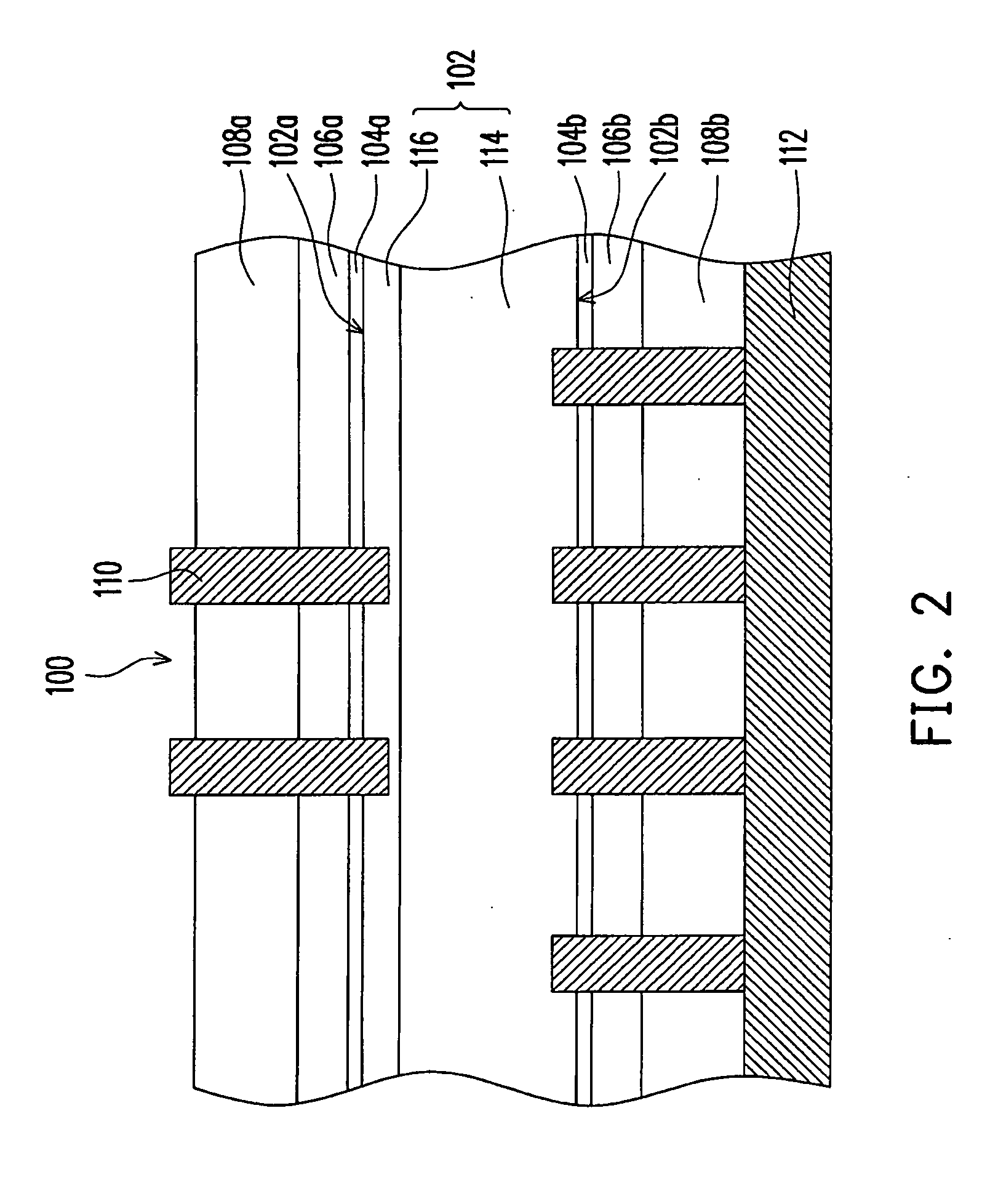

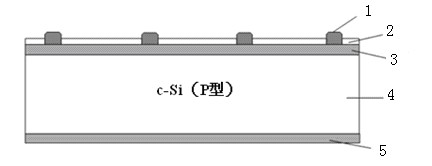

Passivation layer structure of solar cell and fabricating method thereof

InactiveUS20090165855A1Improve passivation effectImprove photoelectric conversion efficiencyFinal product manufactureCoatingsCarrier lifetimePhotoelectric conversion efficiency

A passivation layer structure of a solar cell, disposed on a substrate, is provided. The passivation layer structure has a first passivation layer and a second passivation layer. The first passivation layer is disposed on the substrate. The second passivation layer is disposed between the substrate and the first passivation layer, and the material of the second passivation layer is an oxide of the material of the substrate. Since the second passivation layer is disposed between the substrate and the first passivation layer, the surface passivation effect and carrier lifetime of a photoelectric device are enhanced, and a photoelectric conversion efficiency of the solar cell is increased as well.

Owner:IND TECH RES INST

Silicon solar battery antireflective thin film

InactiveCN101022135AImprove surface passivation effectReduce light absorption lossSemiconductor devicesRefractive indexCompound (substance)

This invention discloses an anti-reflection film of silicon solar cell used in solar cells by depositing a rich silicon SiN film on the positive surface of a silicon chip and a SiN film with ideal match on the rich silicon SiN film, in which, and the film content closing to the Si chip surface is high and the surface pasivation effect is better than the SiN film approaching to the idea match, the surface composition speed is more than one time less than the normal matched SiN film, and the rich Si film is thin and only absorbs 20%-30% short waves with the wavelength about 300nm and does not absorb long-middle lightwaves and other composition approaches to ideal chemical match.

Owner:JIANGSU AIDE SOLAR ENERGY TECH CO LTD

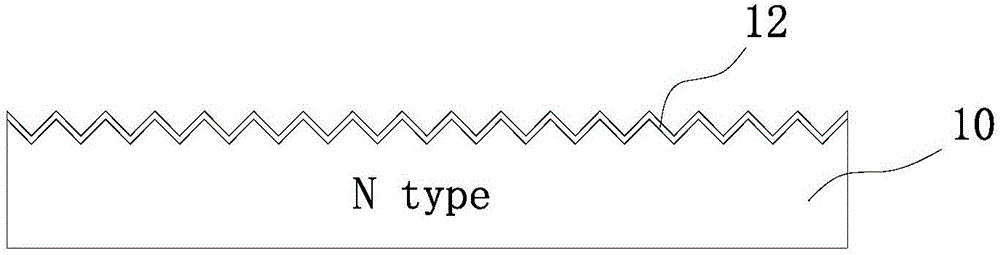

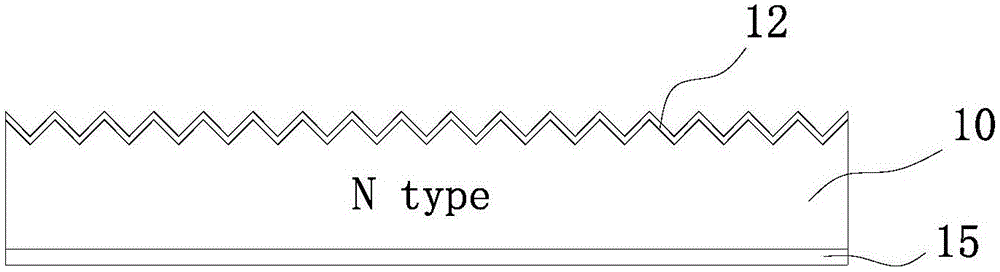

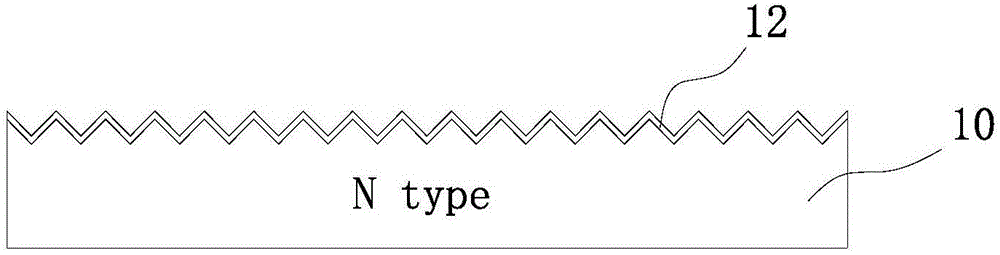

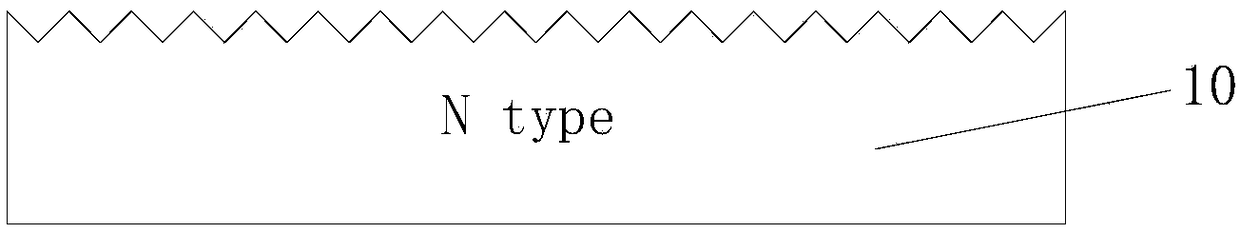

Passivated contact N-type solar cell, preparation method, assembly and system

InactiveCN105895738AGood surface passivation effectExcellent field passivation effectFinal product manufacturePhotovoltaic energy generationCharge carrierAmorphous silicon

The invention relates to a passivated contact N-type solar cell, a preparation method, an assembly and a system. The preparation method for a passivated contact N-type solar cell includes the steps of conducting doping treatment for the front surface of an N-type crystalline silicon substrate to form a p+ doped region; preparing a tunneling oxide layer on the back surface of the N-type crystalline silicon substrate, then preparing a phosphorus-containing amorphous silicon layer or phosphorus-containing polysilicon layer on the tunneling oxide layer, and then conducting annealing; and after preparation of passivated anti-reflection film and a passivated film, printing and sintering metal slurry to obtain a front electrode and a back electrode. The beneficial effects of the invention lie in that the tunneling oxide layer can provide the silicon substrate with an excellent surface passivated effect and achieve selective tunneling of carriers, the n+ doped polysilicon layer can effectively transmit the carriers for the metal electrode on the back surface to collect, the back metal electrode does not destroy the passivated layer on the surface of the crystalline silicon substrate, and thus thereby open-circuit voltage of the cell can be greatly increased.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

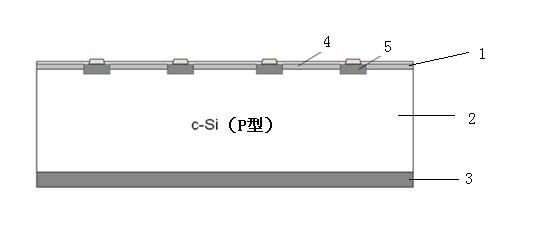

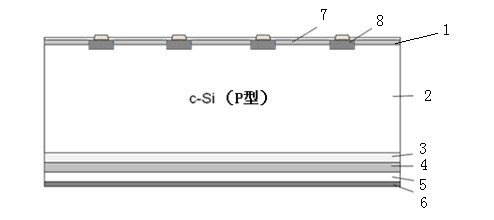

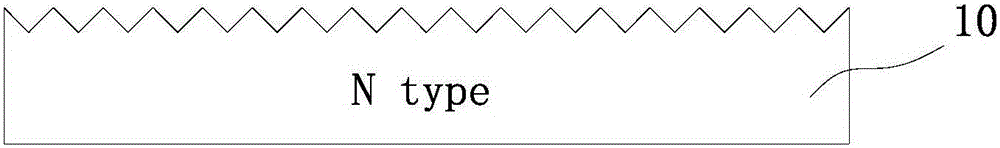

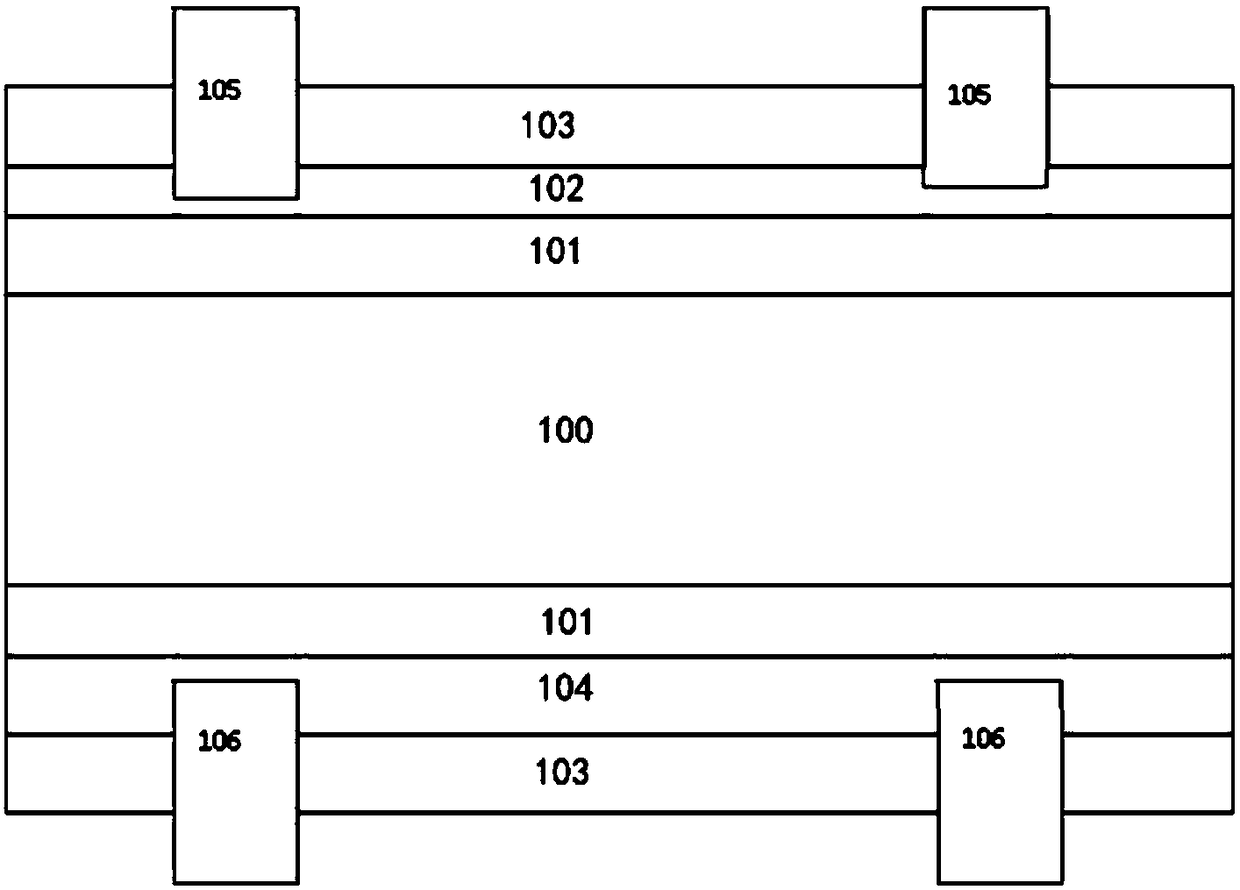

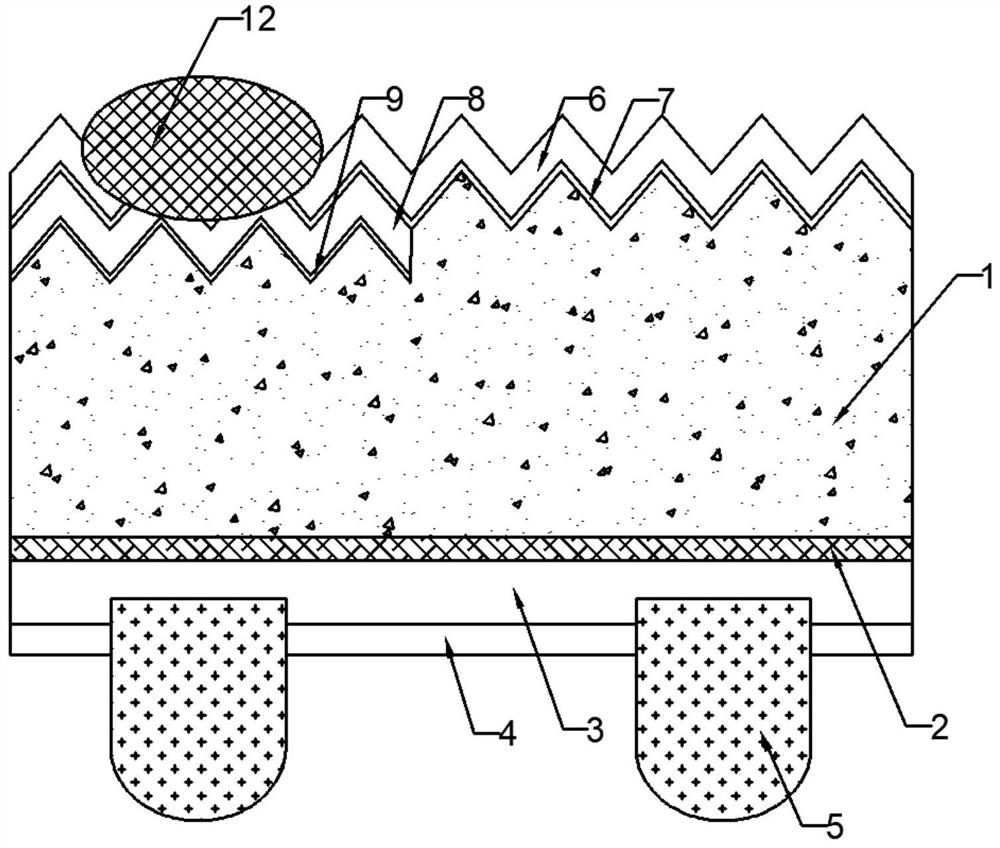

Novel crystalline silicon solar cell and manufacturing method thereof

InactiveCN102064216AImprove surface passivation effectReduce surface recombination rateFinal product manufacturePhotovoltaic energy generationHeterojunctionMaterials science

The invention discloses a novel crystalline silicon solar cell. The novel crystalline silicon solar cell comprises a crystalline silicon matrix, wherein the front surface of the crystalline silicon matrix has an emitter structure, and the back surface of the crystalline silicon matrix has a heterojunction structure; the heterojunction structure comprises an intrinsically hydrogenated amorphous silicon film, a hydrogenated amorphous silicon film, a transparent conductive oxide film and a metal conductive electrode in turn; the intrinsically hydrogenated amorphous silicon film covers the entire back surface of the crystalline silicon matrix; the hydrogenated amorphous silicon film is heavily doped by using a dopant which has the same conduction type as that of the matrix; and the metal conductive electrode passes through the transparent conductive oxide film and is in ohmic contact with a heavily doped layer. The invention also discloses a manufacturing method of the crystalline silicon solar cell. The crystalline silicon solar cell with the structure can reduce composite loss on the surface; meanwhile, the back surface of the solar cell forms a better light trap structure to improve open-circuit voltage of the solar cell, so that conversion efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

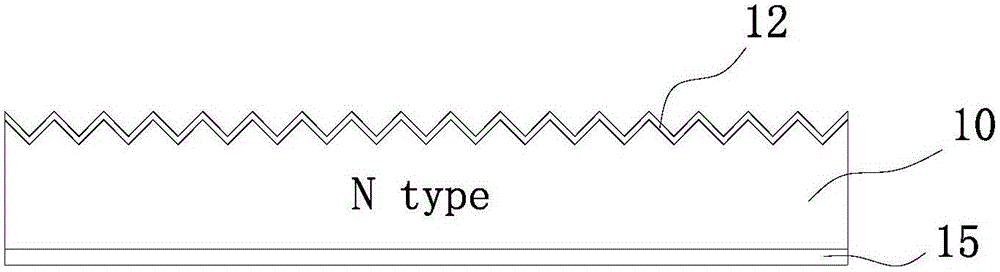

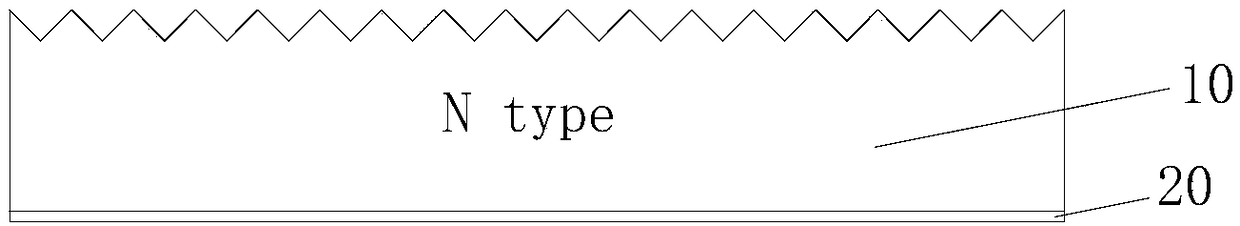

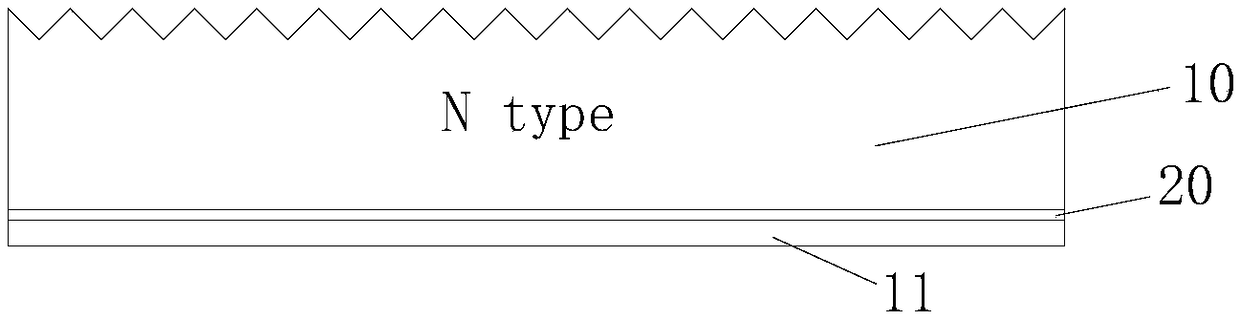

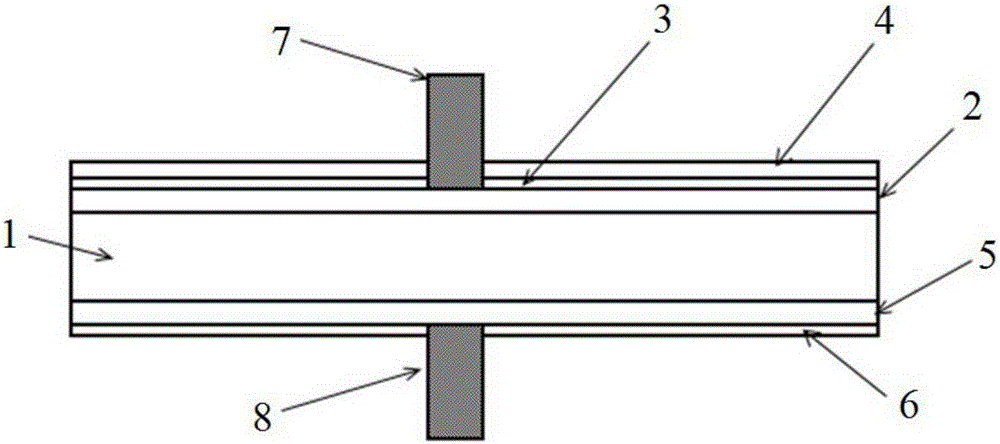

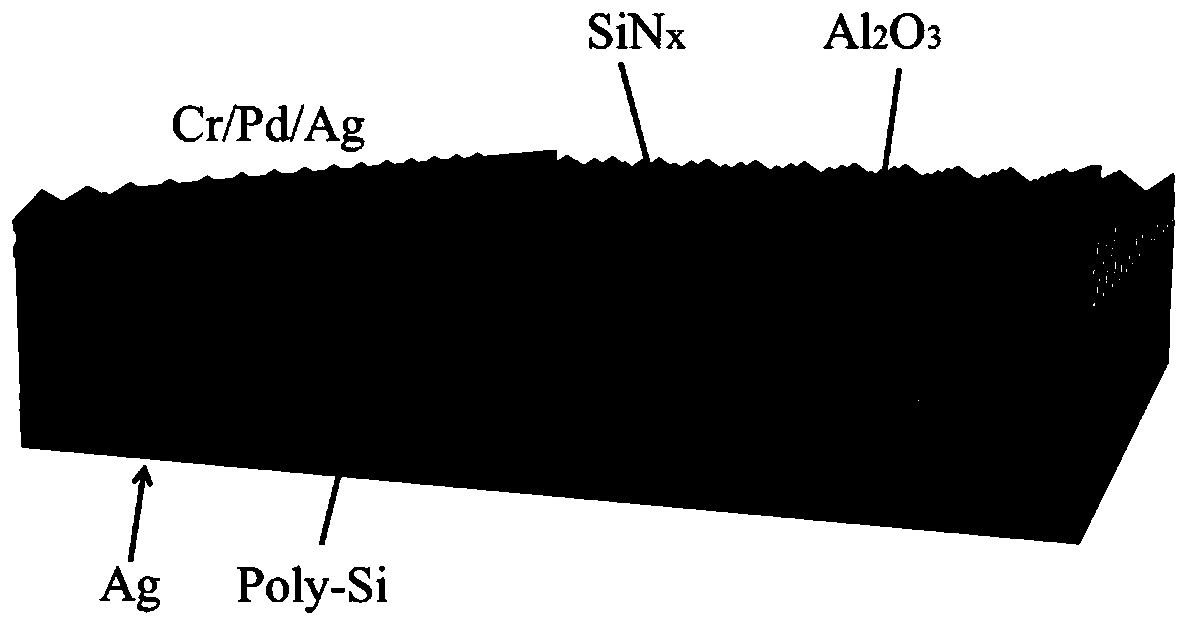

Passivated contact N type crystal silicon cell, preparation method, assembly and system

ActiveCN105826428AGood surface passivation effectReduce compoundingFinal product manufacturePhotovoltaic energy generationSurface electrodeOxide

The invention relates to a passivated contact N type crystal silicon cell, a preparation method thereof, a passivated contact N type crystal silicon cell assembly and a passivated contact N type crystal silicon cell system. The preparation method of the passivated contact N type crystal silicon cell includes the following steps that: a p+ doped region is formed on the front surface of an N-type crystalline silicon base body; a tunnel oxide layer is prepared on the back surface of the N-type crystalline silicon base body, a phosphorus-containing polycrystalline silicon layer is prepared on the tunnel oxide layer, and annealing is carried out; a passive antireflective film and a passive film are prepared; and back-surface silver electrodes and a front-surface electrode comprising metal wires are prepared. According to the preparation method of the passivated contact N type crystal silicon cell, the tunnel oxide layer and an n+ doped polycrystalline silicon layer can realize excellent surface passivation and field passivation, the back-surface silver electrodes do not destroy a passivation layer at the surface of the silicon base body, and carriers can selectively pass through the tunnel oxide layer and are collected by the metal electrode, and therefore, the passivated contact N type crystal silicon cell has high open-circuit voltage, short-circuit current and conversion efficiency; and the metal wires are adopted to form the front-surface electrode, and therefore, the silver slurry consumption of the cell can be reduced, and the production cost of a cell sheet can be reduced.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Austenitic stainless steel cleaning and passivating agent

InactiveCN109487280AAccelerated corrosionLess corrosiveMetallic material coating processesPhosphoric acidYttrium

The invention discloses an austenitic stainless steel cleaning and passivating agent. The austenitic stainless steel cleaning and passivating agent is composed of, by mass, 30%-40% of citric acid, 0.1%-1% of ethylene diamine tetraacetic acid disodium, 1%-5% of 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP), 3%-8% of glycollic acid, 3%-8% of phosphoric acid, 0.1%-2% of a non-ionic surface activeagent, 0.5%-3% of 322H, 0.5%-1% of sodium dodecylbenzenesulfonate, 0%-0.5% of yttrium nitrate, 0.1%-1% of corrosion inhibitor and the balance water. The prepared degreasing, rust removing and passivating agent has the characteristics of being environment-friendly, free of pungent smell and free of toxicity, harm to people and the environment can be remarkably reduced, and the production cost is effectively reduced.

Owner:安徽笃舜智能装备有限公司

Manufacturing method of high-square-resistance solar cell

ActiveCN102629643AHigh power outputImprove surface passivation effectFinal product manufactureSemiconductor devicesSolar cellSilicon dioxide

The invention relates to a manufacturing method of a high-square-resistance solar cell. The manufacturing method is characterized by comprising the following steps of: manufacturing an emitter junction on the surface of a silicon wafer through pre-diffusion treatment; removing an edge junction of the silicon wafer by using wet etching or plasma etching equipment; cleaning the silicon wafer by using RCA solution; placing the silicon wafer in a diffusion furnace for treatment to increase the junction depth and forming a silicon dioxide layer on the surface of the silicon wafer; manufacturing a silicon nitride layer on the silicon dioxide layer on the surface of the emitter junction through PECVD (Plasma Enhanced Chemical Vapor Deposition) equipment; and finally, preparing a front face electrode, a back face electrode and a back face electric field by using screen printing equipment, and co-firing the electrodes and the electric field by using a sintering furnace. Thus, the high-square-resistance solar cell is manufactured by promoting an emitter junction process through secondary high temperature, and the doping concentration of the surface of the junction is reduced. Meanwhile, a proper silicon dioxide film is formed on the surface of the silicon wafer, and the film layer and a silicon nitride film which is manufactured subsequently form a stack layer, so that the surface passivation performance of the cell is improved.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

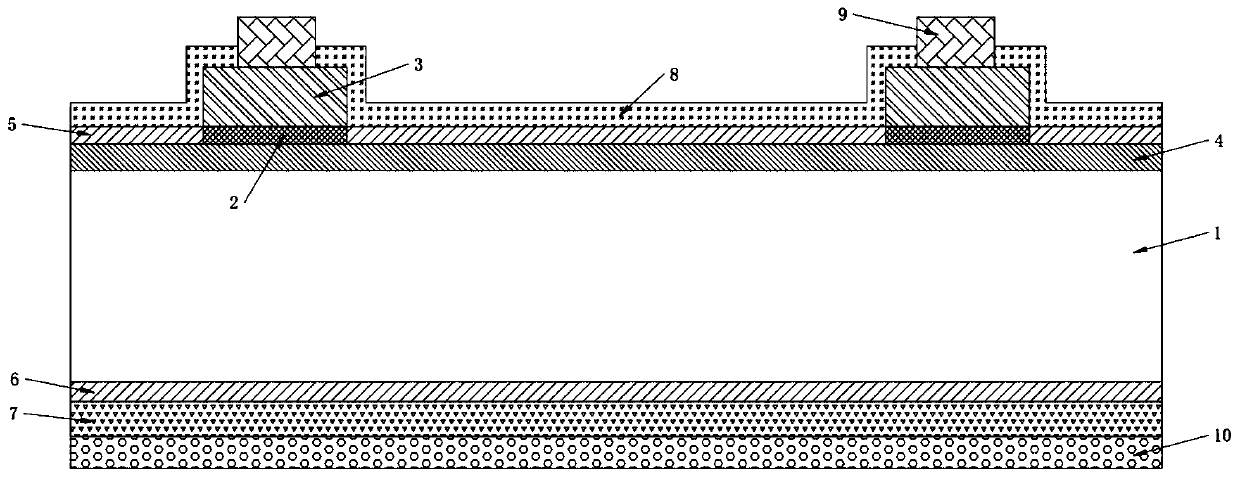

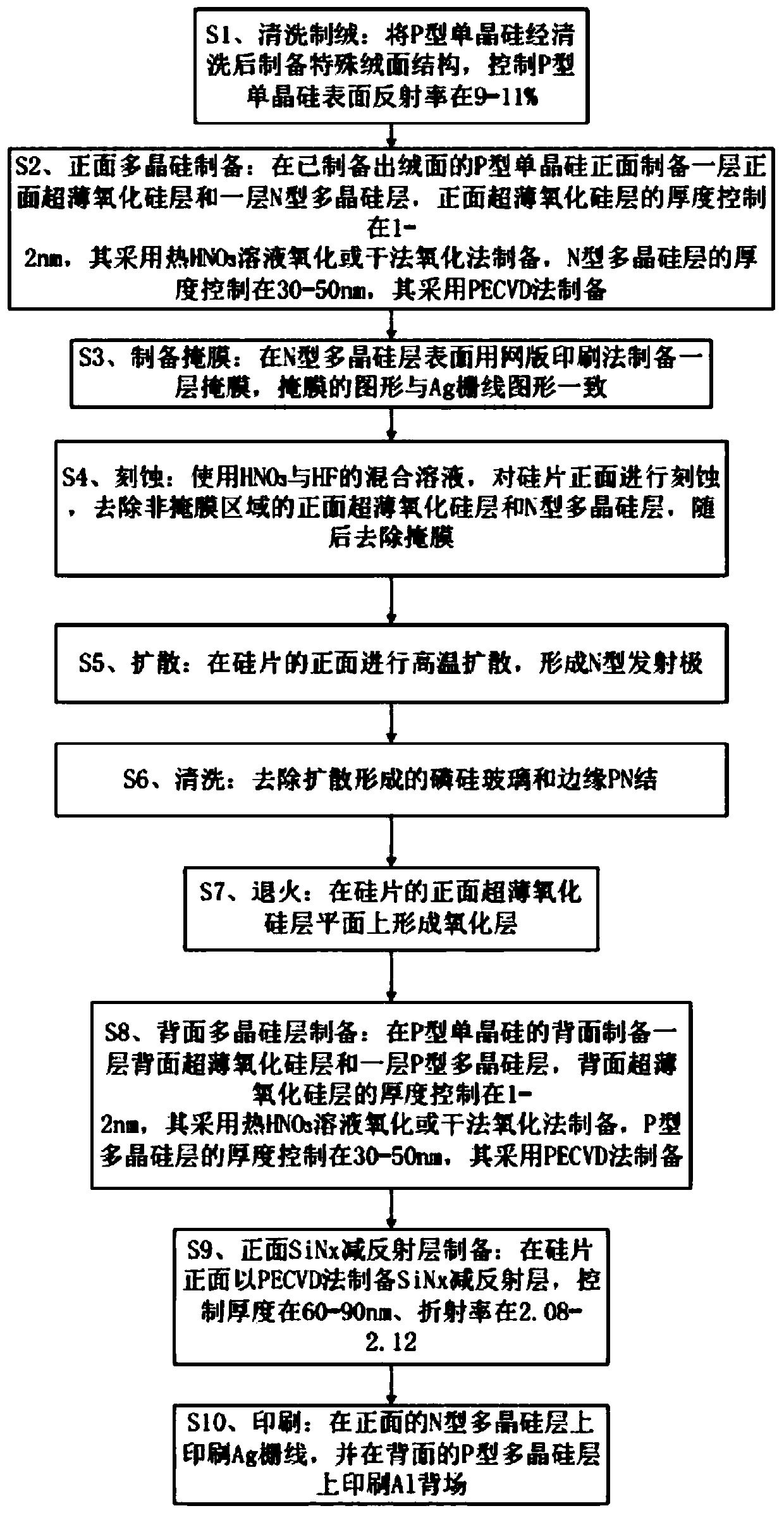

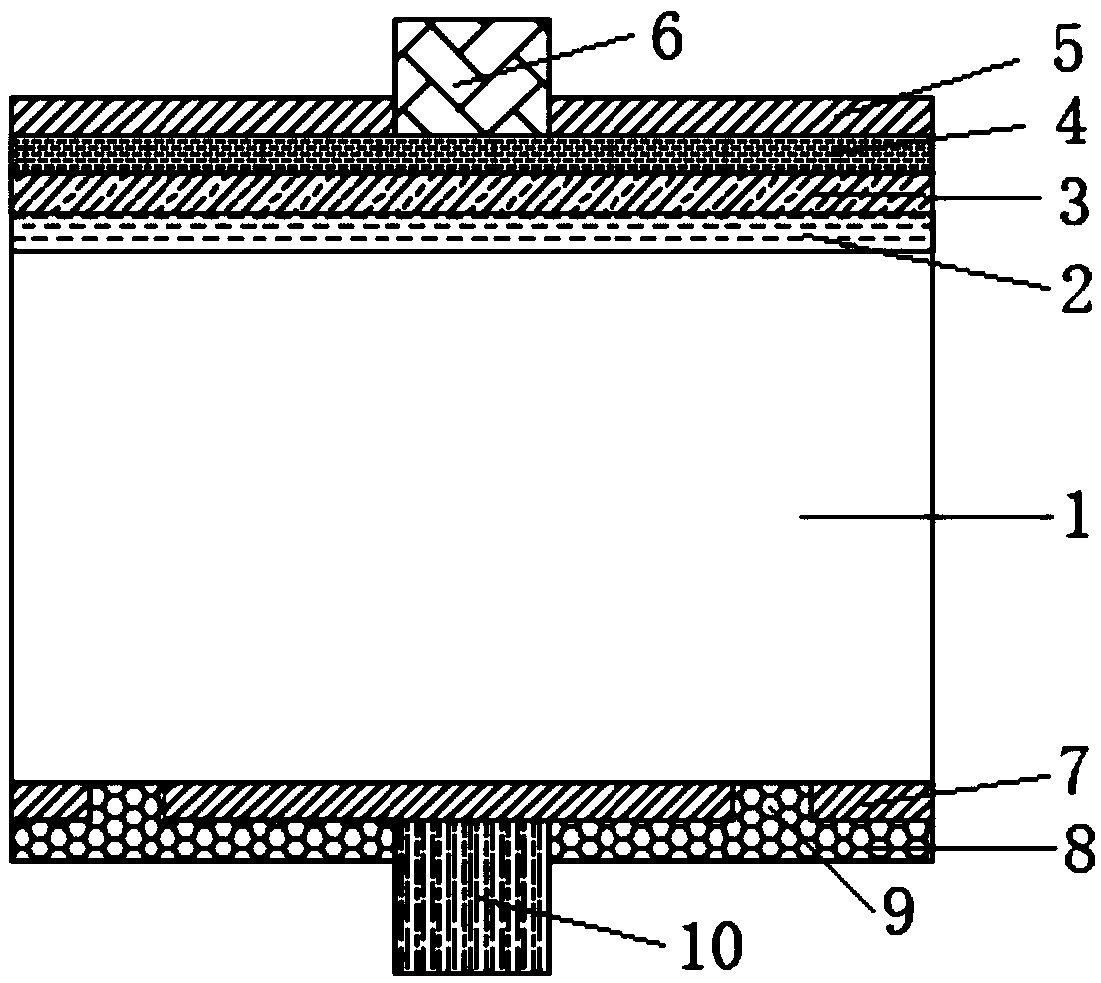

Double-sided passivation contact P-type high-efficiency battery and preparation method thereof

PendingCN110137274AAvoid direct contactGood chemical passivation effectFinal product manufactureSemiconductor devicesSilicon oxideMetal

The invention discloses a preparation method of a double-sided passivation contact P-type high-efficiency battery. The preparation method comprises the following steps: S1, cleaning and texturing; S2,preparing frontal polysilicon; S3, preparing a mask; S4, etching; S5, diffusion; S6, cleaning; S7, annealing; S8, preparing a back polysilicon layer; S9, preparing a front SiNx antireflection layer;and S10. Printing. The invention also discloses the double-sided passivation contact P-type high-efficiency battery comprising P-type monocrystalline silicon. An N-type emitter is provided with a front ultra-thin silicon oxide layer far from the P-type monocrystalline silicon. A back ultra-thin silicon oxide layer is arranged on the back surface of the P-type monocrystalline silicon. The contact structure is passivated by using the tunnel oxide layer on the front and back surfaces of the battery so as to have great surface passivation effect. The silicon surface is passivated exactly under thefront metal gate line and the back aluminum back field so as to avoid direct contact between the metal and the silicon base, reduce the surface recombination and improve the conversion efficiency ofthe battery.

Owner:TONGWEI SOLAR (ANHUI) CO LTD +1

Passivation contact IBC battery and preparation method thereof, assembly and system

InactiveCN106374009AIncrease the open circuit voltageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationSurface oxidationElectrical battery

The invention relates to a passivation contact IBC battery and a preparation method thereof, an assembly and a system. According to the preparation method of the passivation contact IBC battery, a doping treatment method of the back surface of an N-type crystalline silicon substrate comprises the steps of growing a back surface oxide layer on the back surface of the N-type crystalline silicon substrate, growing an intrinsic polysilicon layer or an intrinsic amorphous silicon layer on the back surface oxide layer and then selectively injecting boron ions and phosphorus ions on the intrinsic polysilicon layer or the intrinsic amorphous silicon layer; and then carrying out degradation and coating treatment. The passivation contact IBC battery has the beneficial effects that a passivation contact technology is combined with a back contact structure; the oxide layer is arranged on the back surface of the N-type crystalline silicon substrate and p+ and n+ doped regions which are alternately arranged are arranged on the oxide layer; the oxide layer disclosed by the invention can bring a better surface passivation effect for the back surface of the N-type crystalline silicon substrate; meanwhile, current carriers can be freely transmitted through the oxide layer; and the prepared battery has higher open-circuit voltage and conversion efficiency.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

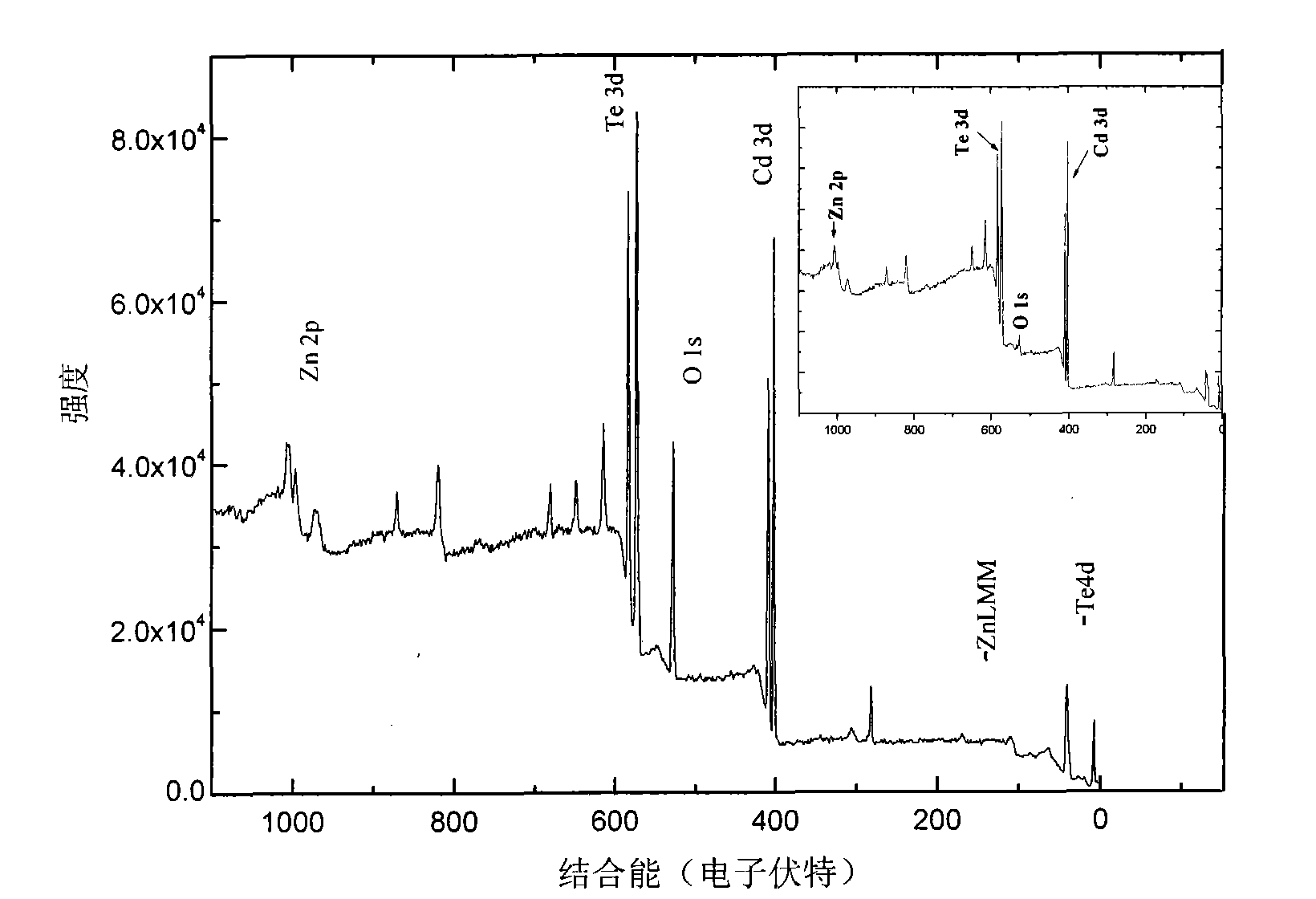

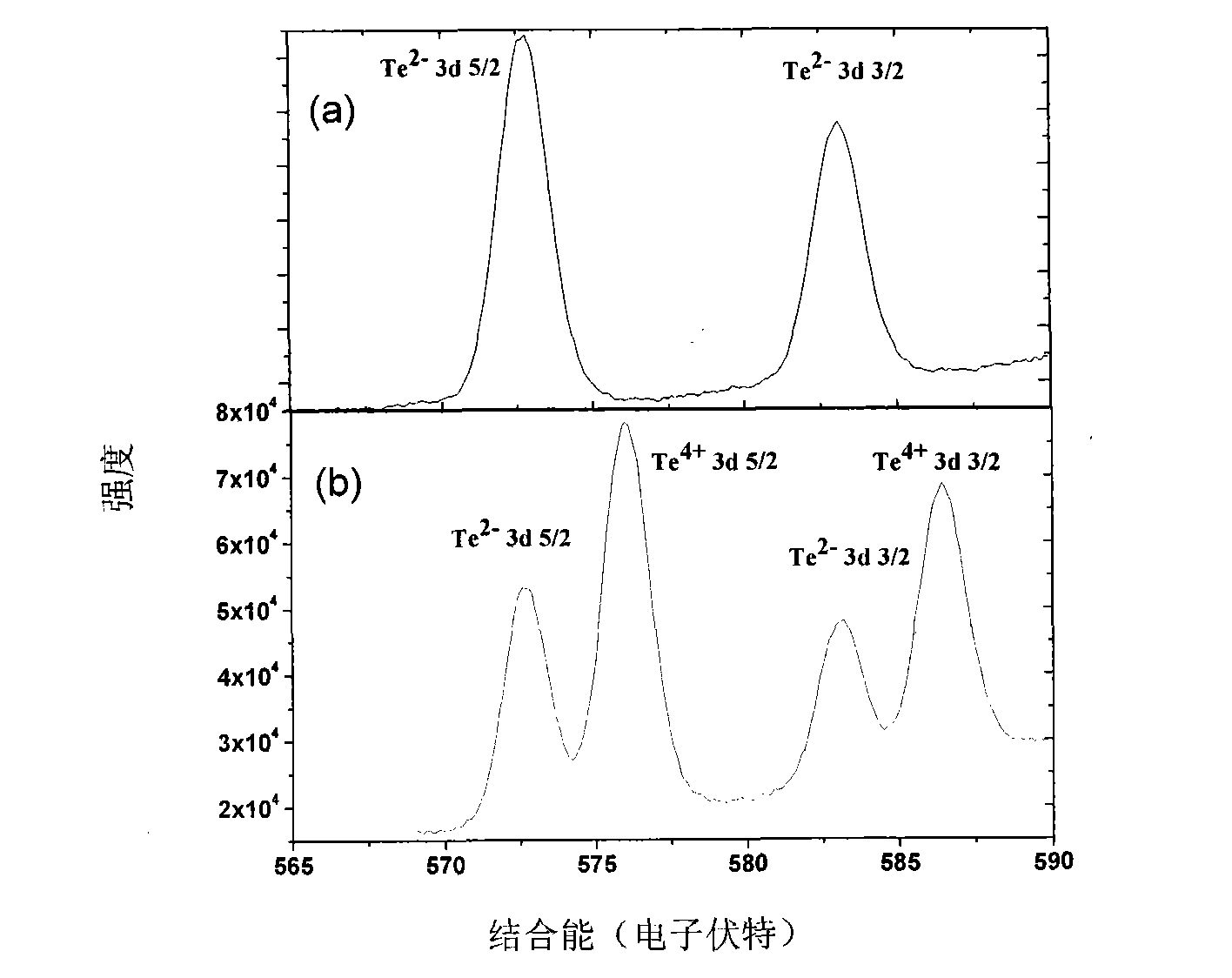

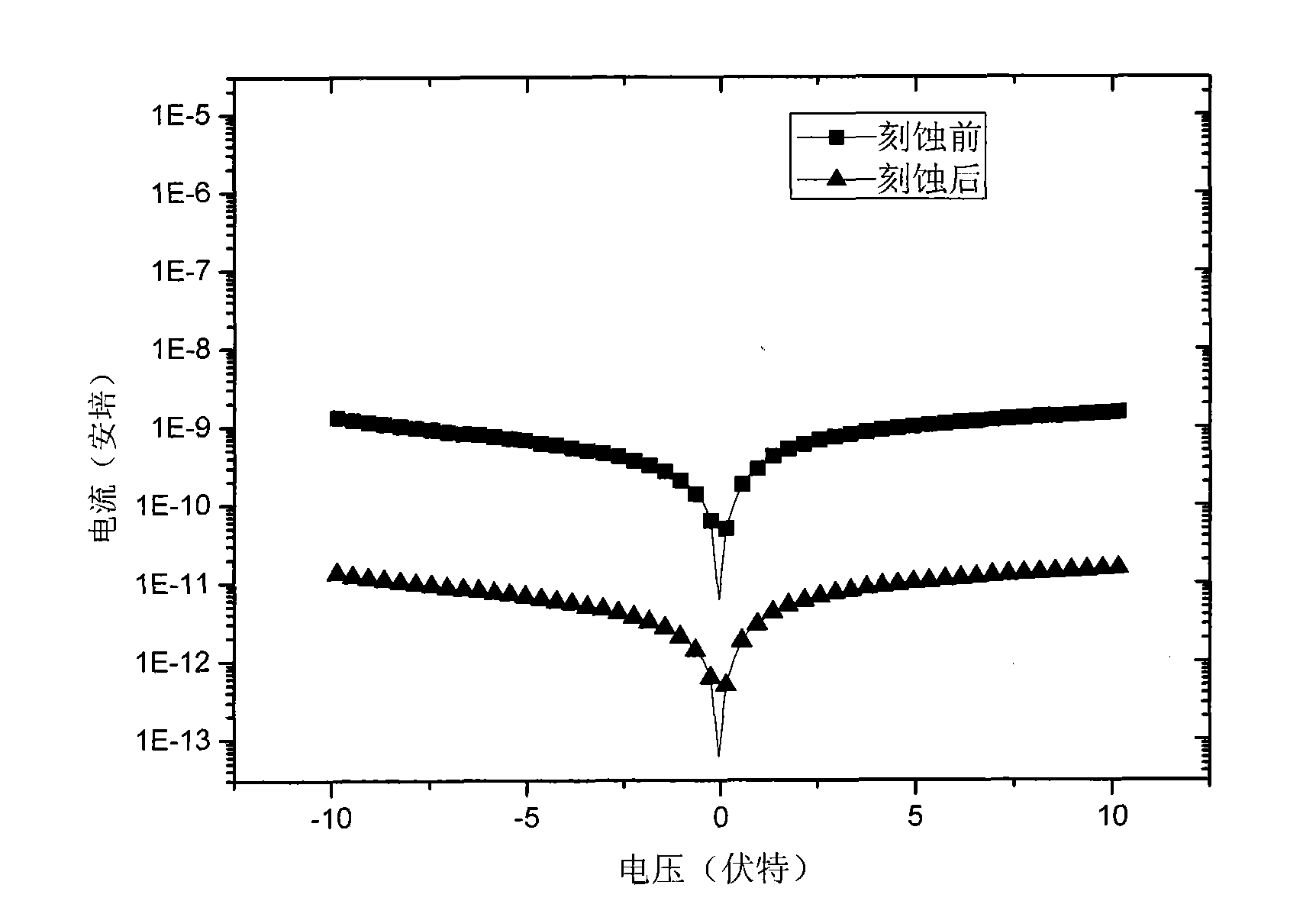

Method for inactivating tellurium-zinc-cadmium pixel detector electrodes

InactiveCN101783373AReduce leakage currentEffective leakage currentFinal product manufactureSemiconductor devicesWaferingDrain current

The invention discloses a method for inactivating tellurium-zinc-cadmium pixel detector electrodes, which is used for inactivating the tellurium-zinc-cadmium pixel detector electrodes to reduce current leakage. The method comprises the following steps of: firstly carrying out linear cutting, grinding, mechanical polishing and cleaning on cadmium-zinc-tellurium (CdZnTe) crystals, then chemically polishing in 2% of Br-MeOH to obtain standby CdZnTe chips; carrying out the processes of cleaning, gluing, drying, exposure, development, vacuum electrode evaporation, peeling and the like on the mechanically and chemically polished CdZnTe chips to prepare pixel detector electrodes; then putting the pixel detector electrodes in a RIE-3 reactive ion etcher for evacuation, wherein the vacuum degree is 0.3333-0.3999 Pa, the oxygen flow is regulated to 70-80 cm<3> / min, the working air pressure is regulated to 0.5-1.0 Pa, the radio-frequency power is regulated to 8-12 W, and the etching time is 35-50 min. The CdZnTe surfaces between the CdZnTe pixel detector electrodes prepared through the steps generate compact oxide films, the current leakage is reduced by one order of magnitude, and therefore, the invention achieves the purpose of inactivation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

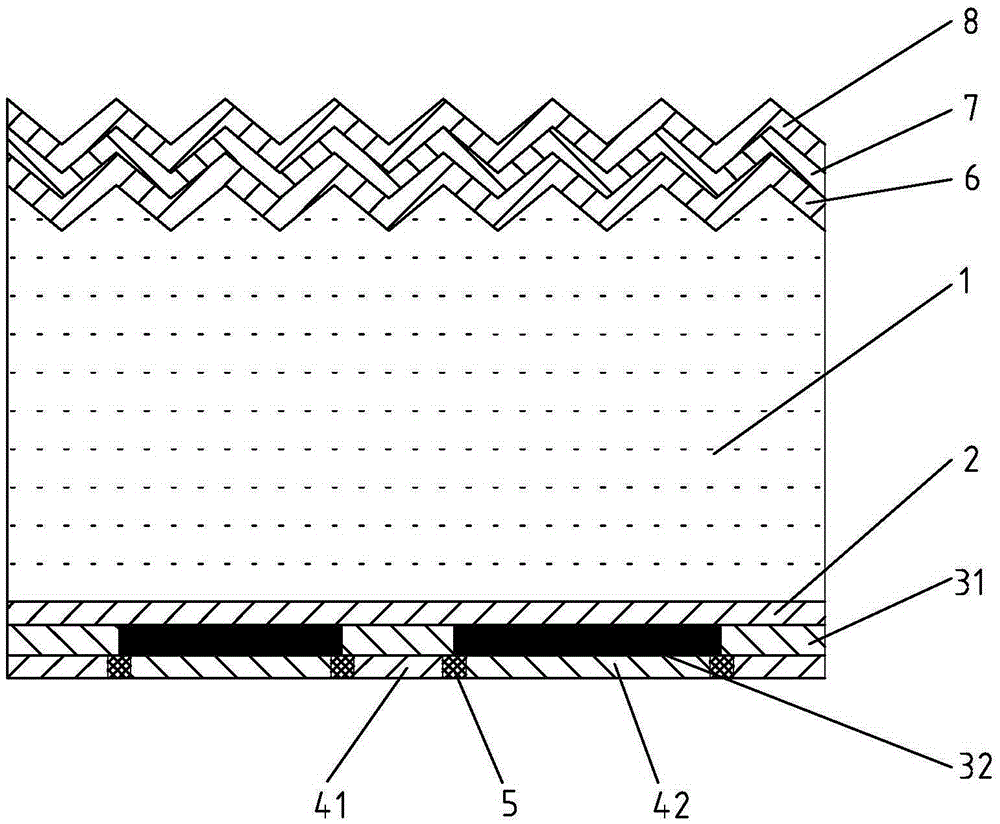

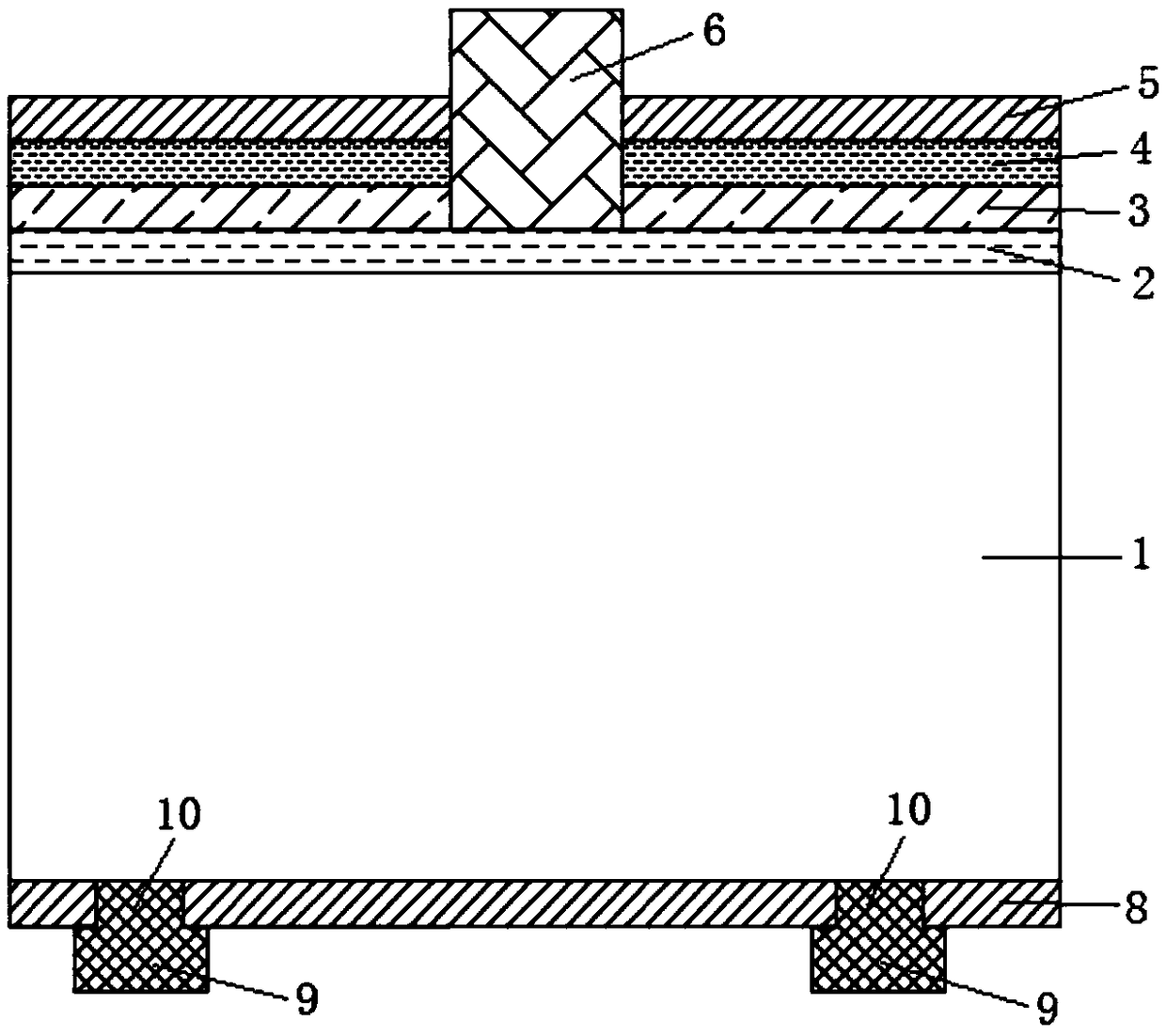

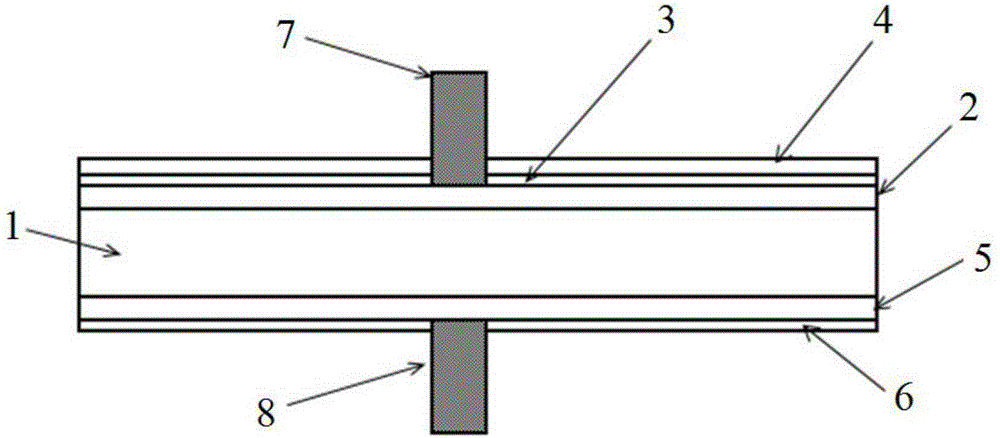

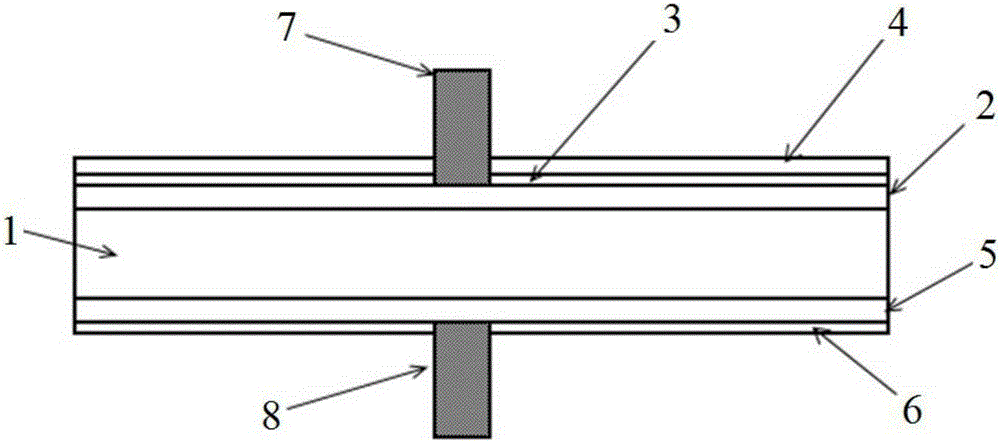

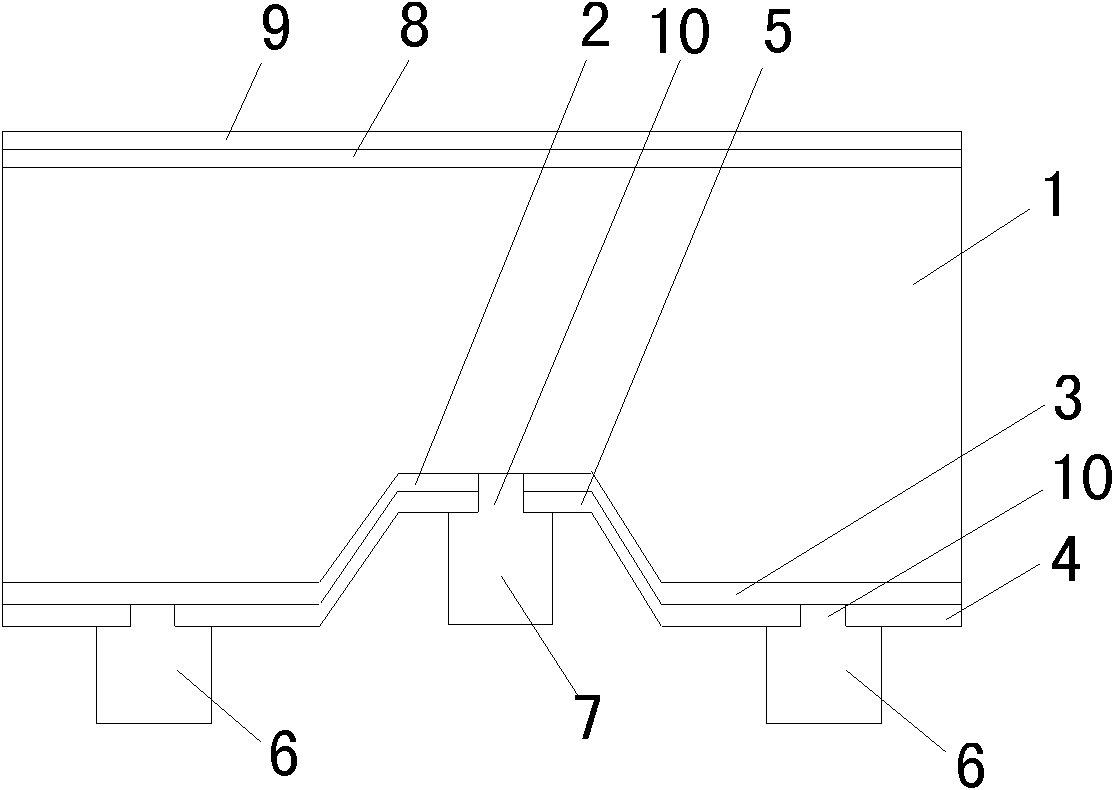

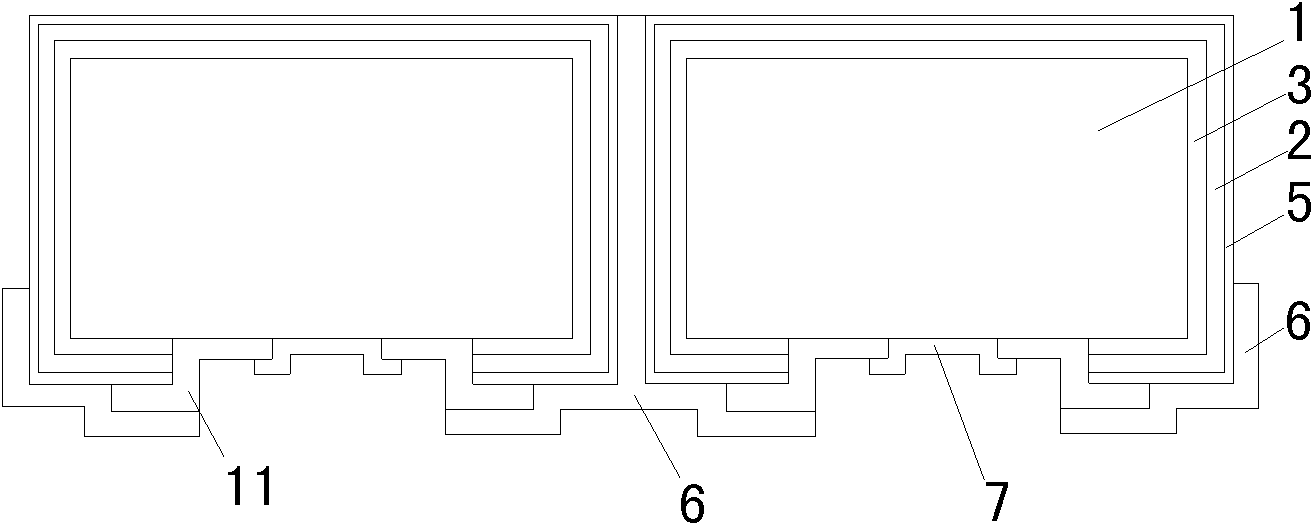

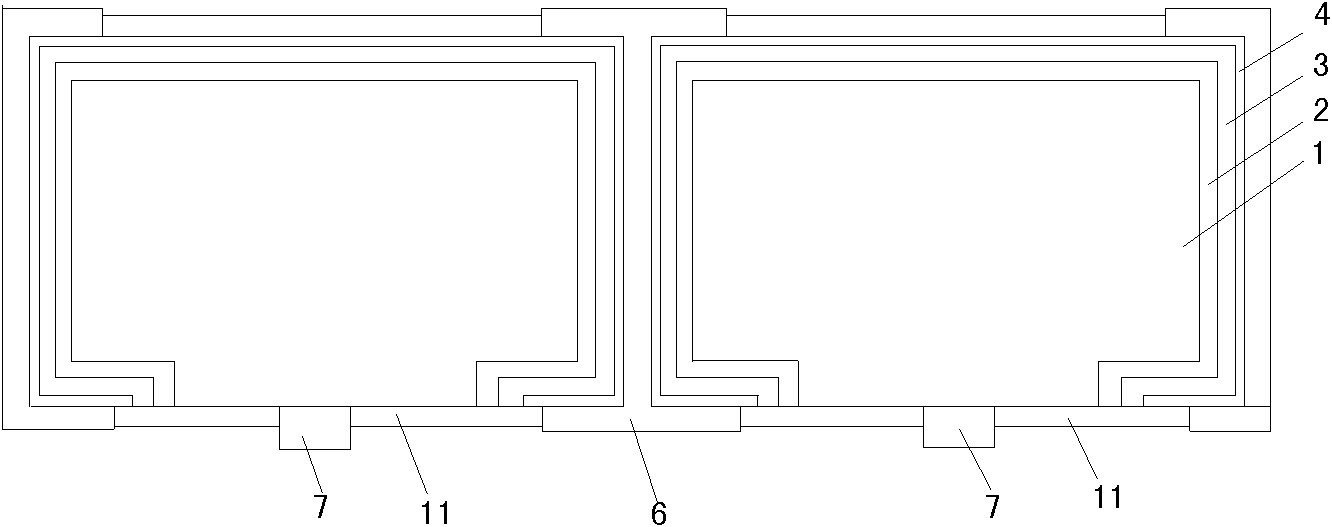

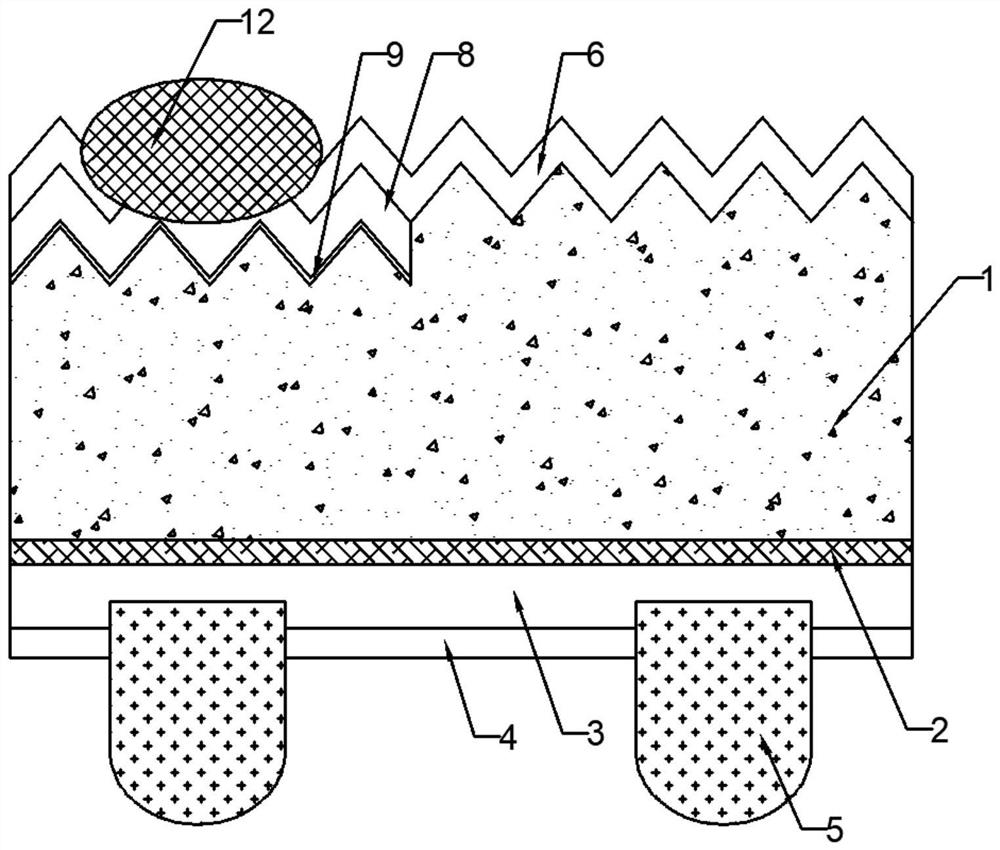

Full-back-electrode solar cell structure and preparation method therefor

InactiveCN105390555AImprove surface passivation effectAvoid recombinationFinal product manufacturePhotovoltaic energy generationSolar cellPolycrystalline silicon

The invention discloses a full-back-electrode solar cell structure and a preparation method therefor. The full-back-electrode solar cell structure comprises a cell substrate, a tunneling passivation layer, and a polycrystalline silicon layer, wherein the tunneling passivation layer is arranged on the back surface of the cell substrate; the polycrystalline silicon layer is arranged on the lower surface of the tunneling passivation layer; and the polycrystalline silicon layer is provided with an N type heavily-doped polycrystalline silicon layer and a P type polycrystalline silicon layer that are arranged side by side. According to the full-back-electrode solar cell structure, the silicon body is good in the surface passivation effect, and carriers can be selectively output, so that the efficiency of the full-back-electrode solar cell is improved.

Owner:TRINA SOLAR CO LTD

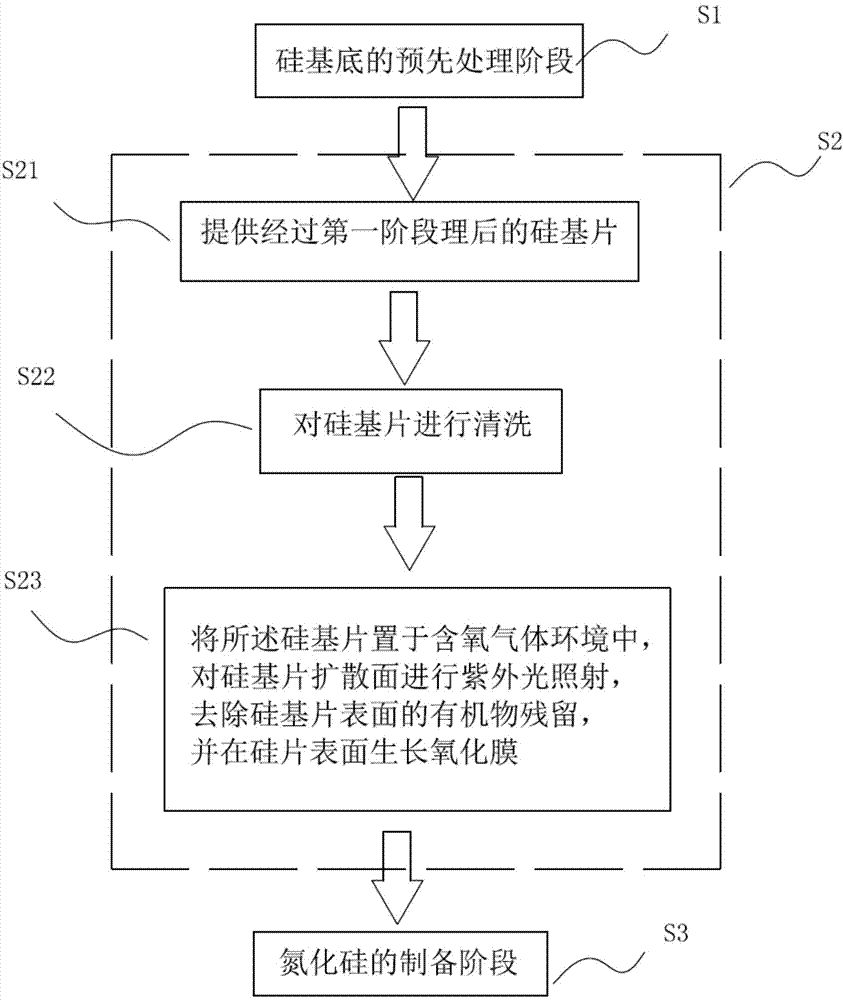

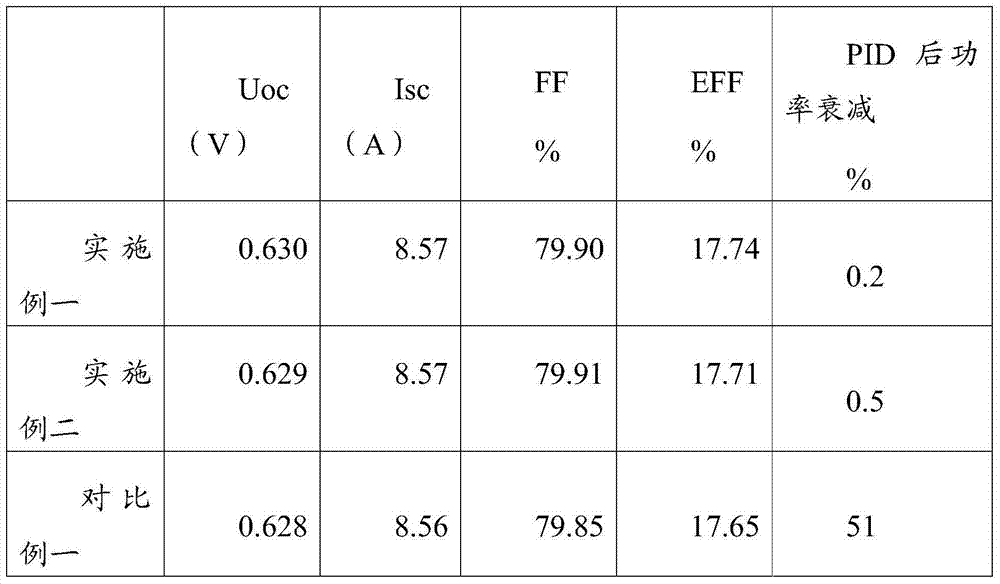

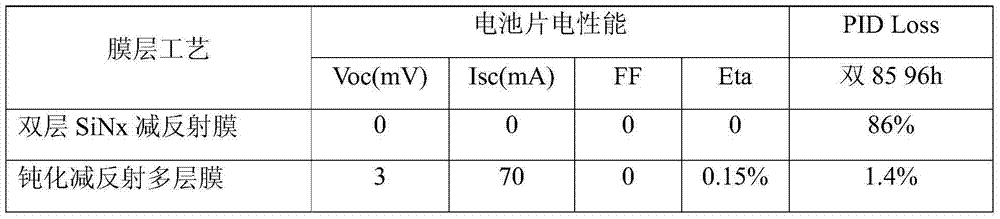

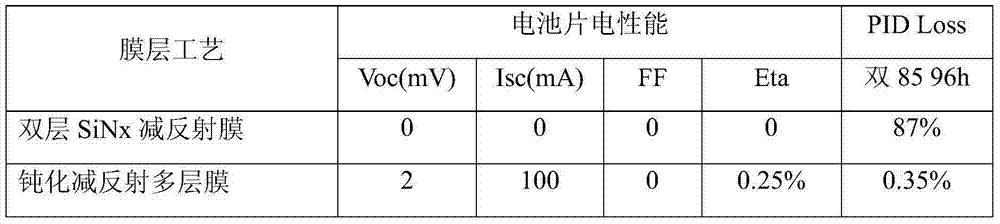

PID-resistant solar cell manufacturing method

ActiveCN103943722AAnti-reflection effectGood surface passivation effectFinal product manufactureSemiconductor/solid-state device manufacturingAutomatic controlUltraviolet lights

Owner:CSI CELLS CO LTD

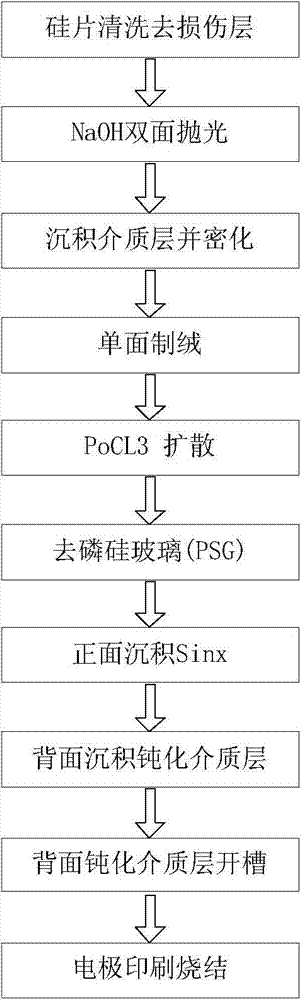

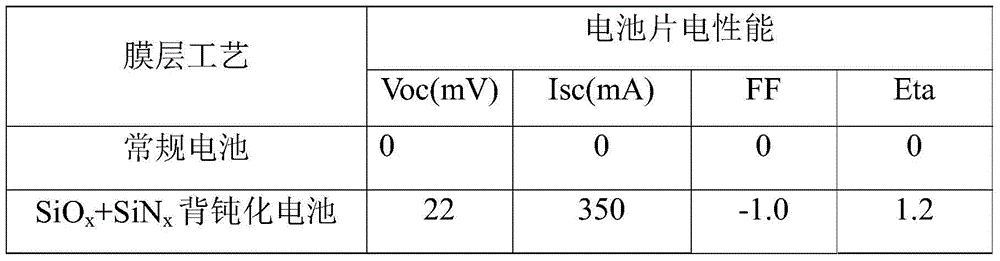

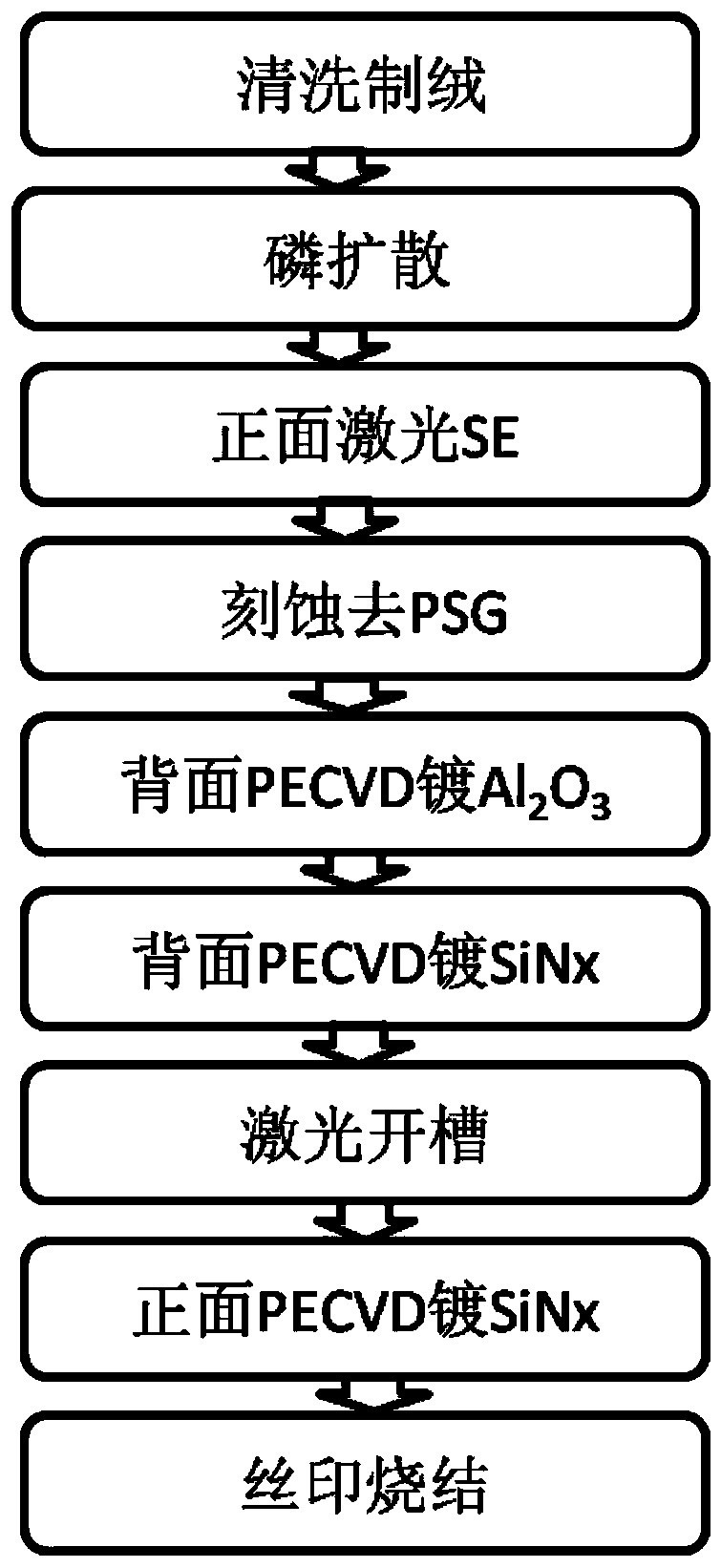

Back-passivation efficient PERL battery technology

InactiveCN104716224AReduce dosageSimple processFinal product manufactureSemiconductor devicesAluminium pasteEngineering

The invention relates to a back-passivation efficient PERL battery technology. The back-passivation efficient PERL battery technology comprises the steps that a silicon wafer is cleaned in a HF / HNO3 mixed solution, a surface damaged layer is removed, double-side polishing is carried out, a SiOx film layer is deposited on a single-side, a suede face is made, POCl3 single-side deposition and diffusion are carried out in a high-temperature furnace, surface phosphorosilicate glass is removed, SiNx with a thickness of 80 nm is deposited on the front side of the silicon wafer, SiOx with a thickness ranging from 10 nm to 20 nm is deposited on the back side of a polished surface of the silicon wafer, an SiNx layer with a thickness ranging from 100 nm to 200 nm is deposited in a pipe-type or a plate-type PECVD equipment, slots and holes are formed in a back-passivation layer, and silk-screen printing and sintering are carried out on back aluminium paste, a back electrode and a positive electrode. Compared with the prior art, the technology is simplified, and therefore the large-scale mass production is facilitated.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Laser grooving gate-buried electrode solar cell and method for preparing the same

InactiveCN104505407AThe grid line shadow area is smallReduce contact resistanceFinal product manufacturePhotovoltaic energy generationAcid etchingSolar cell

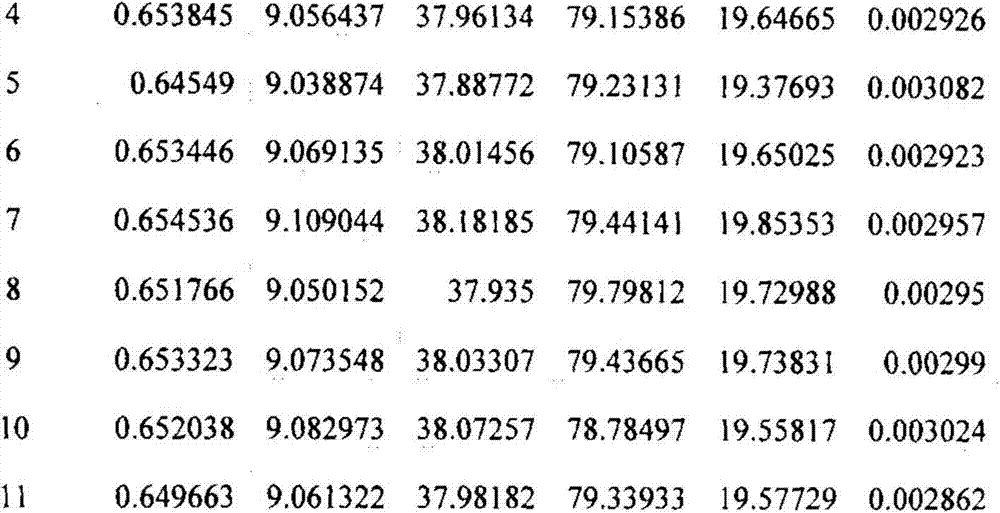

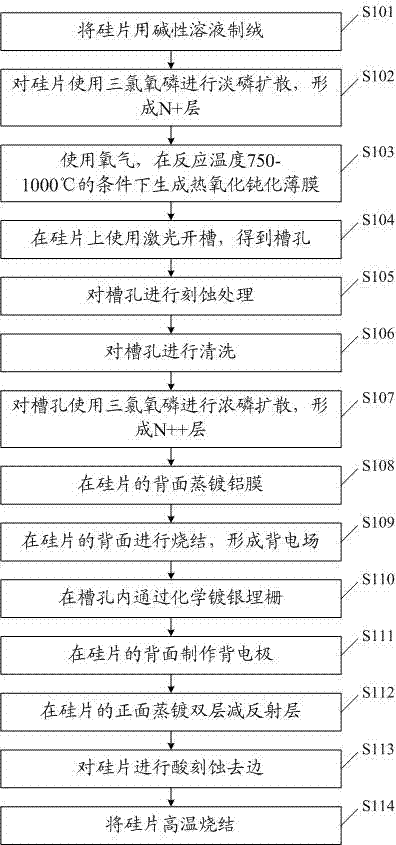

The present invention discloses a method for preparing a laser grooving gate-buried electrode solar cell, comprising: a) texturing a silicon wafer by an alkaline solution; b) performing light phosphorous diffusion to form a N+ layer; c) generating a thermal oxidation passivated film; d) grooving by a laser so as to obtain a slot; e) etching the slot; f) cleaning the slot; g) performing heavy phosphorous diffusion to form a N++ layer; h) evaporating and plating an aluminum film on the back surface; i) sintering the back surface to form an electric field; j) chemically plating silver to bury a gate; k) making a back electrode; l) evaporating and plating two antireflection layers on the front surface, the two antireflection layers comprising an MgF2 layer and a ZnS layer; m) acid etching to remove the edge; and n) sintering at a high temperature to form a laser grooving gate-buried electrode solar cell. Accordingly, the present invention further provides a laser grooving gate-buried electrode solar cell prepared by the aforementioned preparation method. The method of the present invention can simultaneously achieve the purposes of improving the passivation effect for the front and back surface, reducing contamination of the surfaces caused by metallic impurities, improving the bonding strength between the plated layers and the substrate and greatly decreasing the reflectance and the like.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

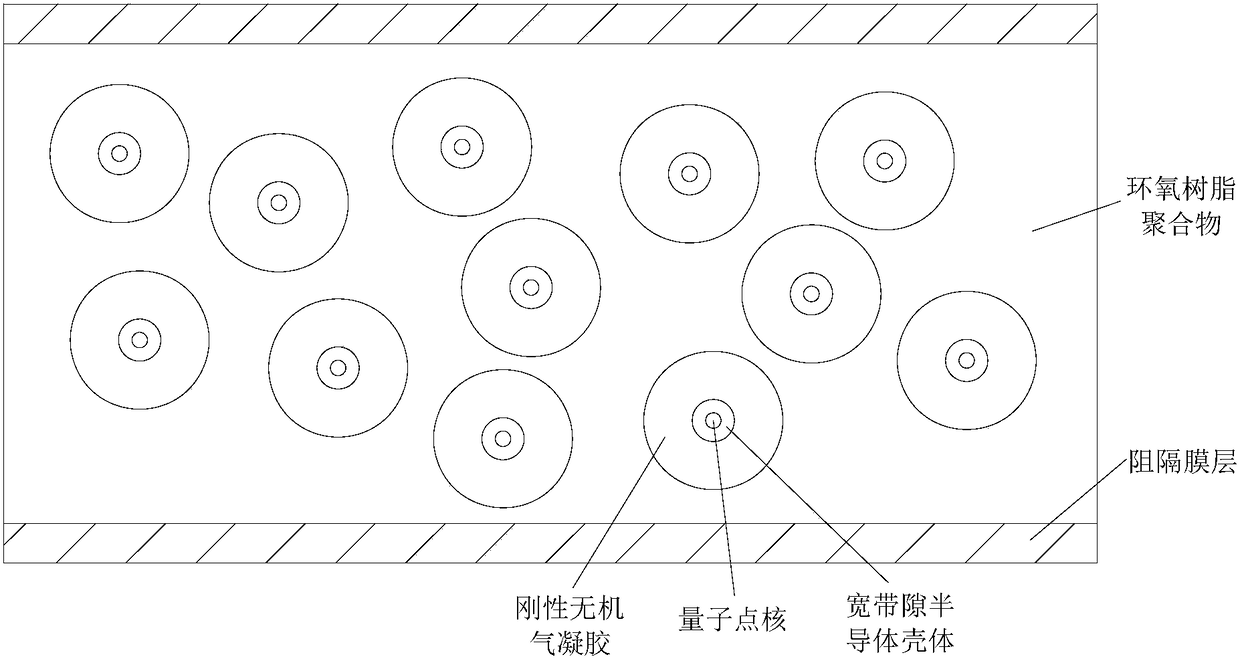

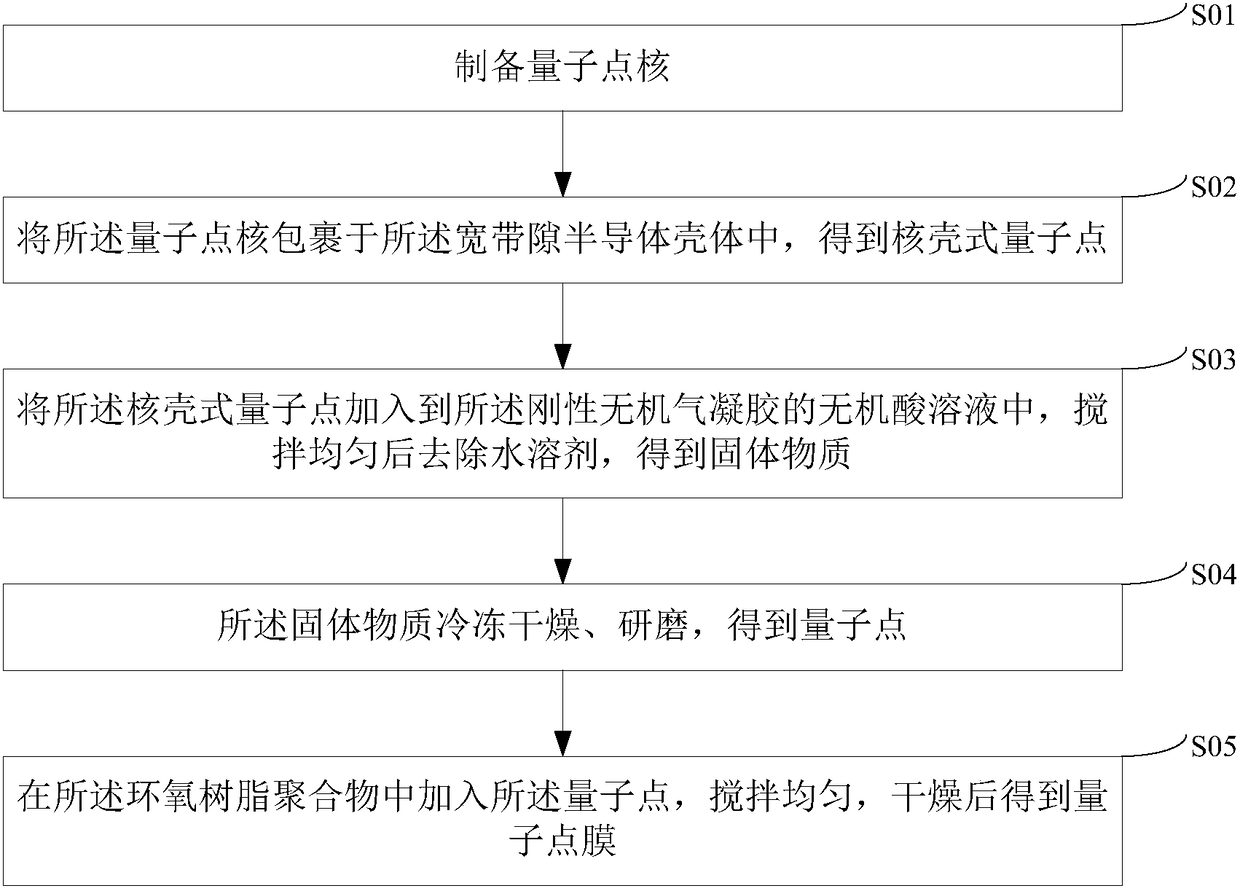

Quantum dot film, preparation method thereof, backlight module and display device

ActiveCN108264734AImprove luminous efficiencyGood fluorescence propertiesSelenium/tellurium compundsZinc sulfidesEpoxyDispersity

The invention provides a quantum dot film, a preparation method thereof, a backlight module and a display device. In the quantum dot film, broad-band gap semiconductor shell can fill the defects of the core surfaces of quantum dots and improve the luminous efficiency of the quantum dots, the influence of the surface state of naked quantum dots on fluorescence can be reduced, and the fluorescence characteristic of the quantum dots can be improved. The bonding strength between a rigid inorganic aerogel and the broad-band gap semiconductor shell is much higher than the bonding strength between organic molecular ligands and the quantum dots, so that the quantum dot film has high stability. The rigid inorganic aerogel can form rigid epitaxial frameworks on the surfaces of core-shell quantum dots, and the dispersity of the quantum dots is increased, so that the quantum dots are not agglomerated in an epoxy resin polymer, and the luminous efficiency of the quantum dots is improved. The rigidepitaxial frameworks can also improve the surface passivation effect of the quantum dots, reduce the defect density, reduce the probability of nonradiative recombination and enhance the mobility of excitons in the quantum dots, so that the luminous efficiency of the quantum dots is improved, and finally the luminous efficiency of the quantum dot film is improved.

Owner:HISENSE VISUAL TECH CO LTD

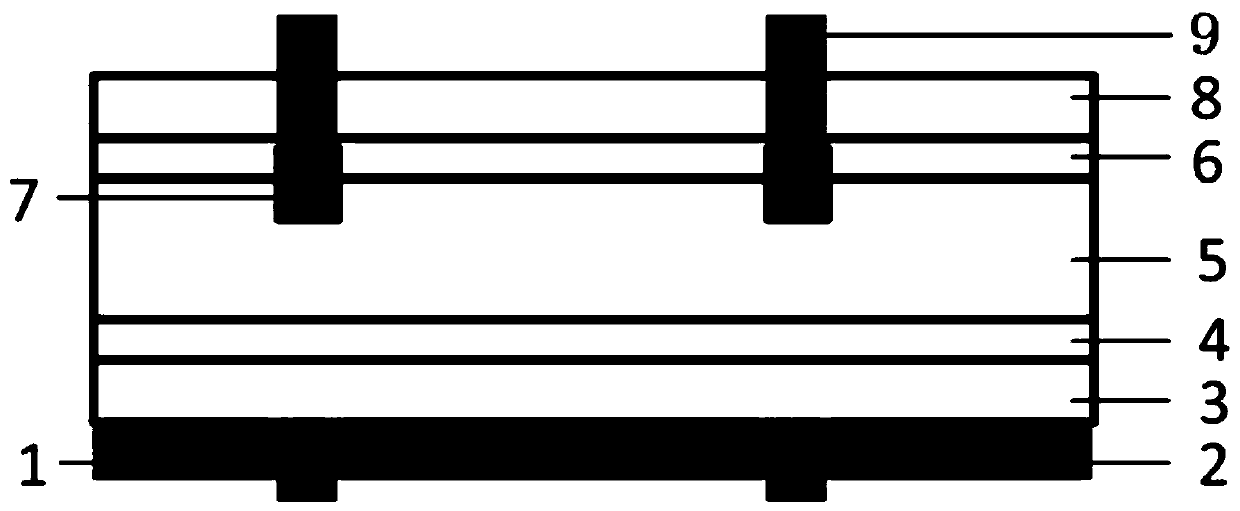

Passivating antireflection film of high PID resistance type polycrystalline cell and preparation process thereof

ActiveCN104752526AReduce surface interface stateImprove the anti-PID decay characteristicsFinal product manufacturePhotovoltaic energy generationRefractive indexMedia layer

The invention relates to a passivating antireflection film of a high PID resistance type polycrystalline cell and a preparation process thereof. The passivating antireflection film comprises a first SiOx layer used as a bottom layer, a second SiOx layer used as a medium layer, and a third SiNx layer used as a top layer, wherein the first SiOx layer, the second SiOx layer and the third SiNx layer are sequentially deposited on the front surface of a monocrystalline chip substrate, and the total film thickness of the first SiOx layer, the second SiOx layer and the third SiNx layer is 65 to 120nm; the refraction rate is 1.9 to 2.25; the film thickness of the SiNx layer used as the medium layer is 10 to 50nm, and the refraction rate is 2.2 to 2.4; the film thickness of the SiNx layer used as the top layer is 30 to 80nm, and the refraction rate is 1.9 to 2.2; one or a plurality of SiNx layers are arranged as the top layer. The passivating antireflection film can reduce the reflecting rate and improve the passivating effect, so that the solar cell efficiency can be increased; the passivating antireflection film is outstanding in PID attenuating resisting characteristic.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

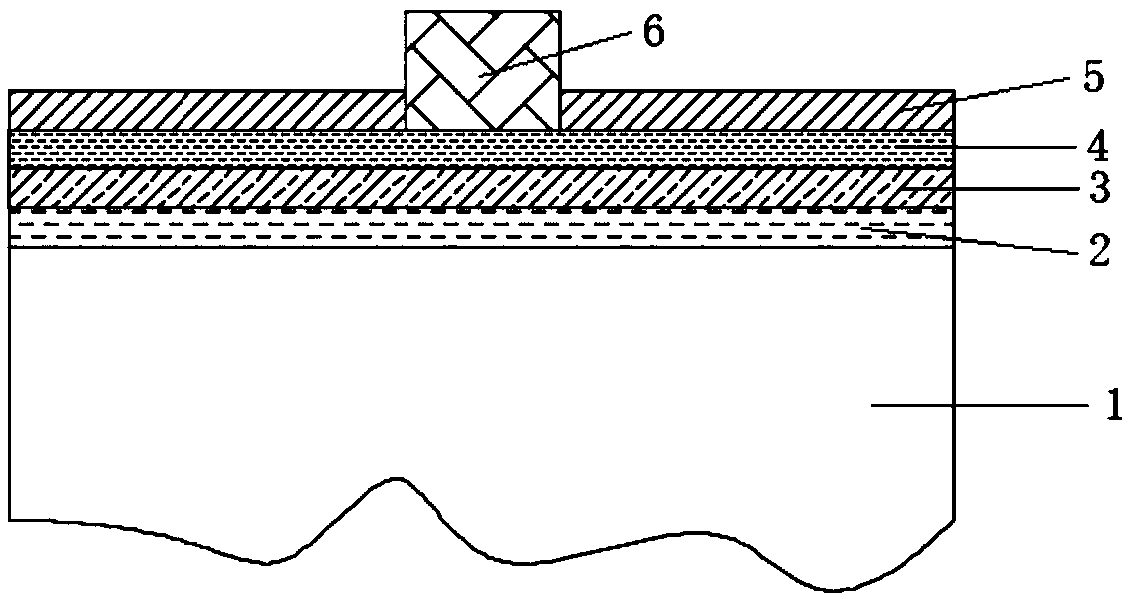

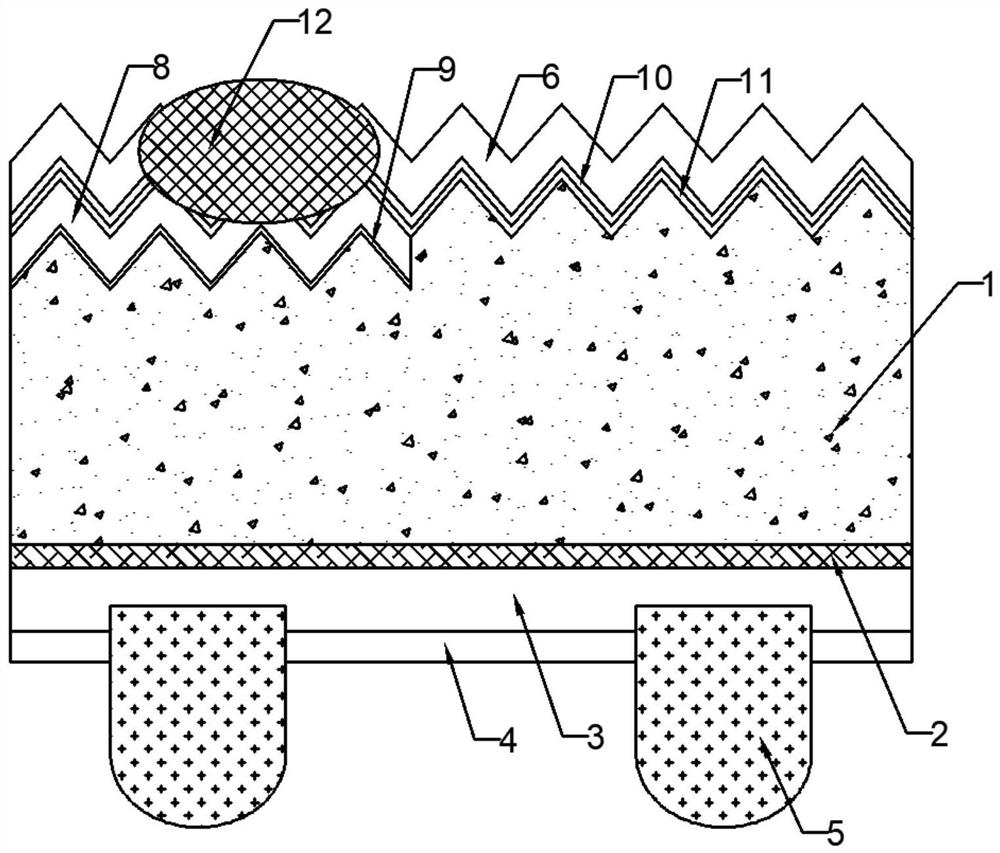

Solar cell and preparation method thereof

PendingCN109216491AReduce surface recombination rateImprove surface passivation effectFinal product manufacturePhotovoltaic energy generationFill factorFilling factor

The invention provides a solar cell and a preparation method thereof. The solar cell comprises a substrate, a front structure located on the front side of the substrate and a back structure located onthe back side of the substrate; The front structure comprises a first doping layer, a passivation tunneling layer, a second doping layer, a passivation antireflection layer and a front electrode. Thefirst doping layer, the passivation tunnel layer, the second doping layer and the passivation antireflection layer are arranged in sequence, and the front electrode is in contact with the second doping layer through the passivation antireflection layer; The backside structure comprises a backside passivation film and a backside electrode; The back electrode is in contact with the substrate through a contact area of the back passivation film. In the invention, a passivation tunneling layer is added, the surface recombination rate of the battery is effectively reduced, and the surface passivation performance of the battery is improved; The contact between the front electrode and the second doping layer can effectively improve the lateral transfer efficiency of the positive surface of the battery, reduce the series resistance of the battery, and thus improve the fill factor and conversion efficiency of the battery.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

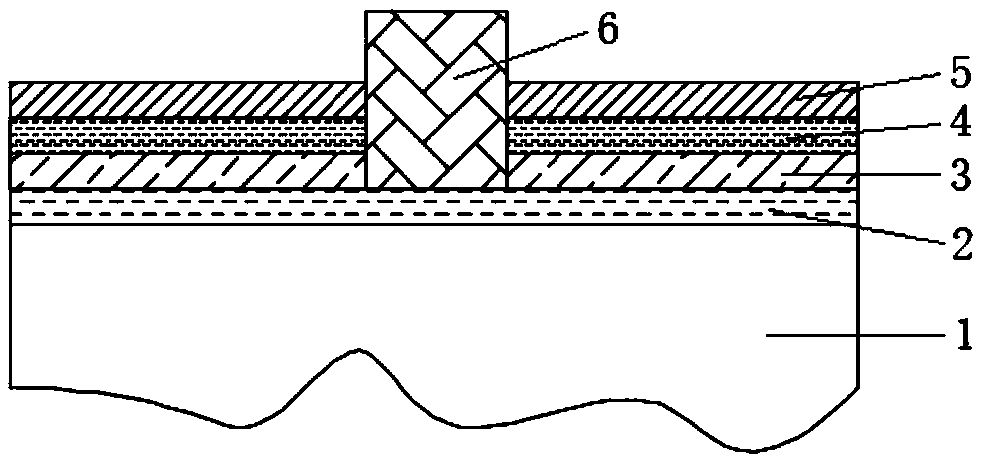

Heterogeneous emitting electrode structure of solar cell and solar cell

PendingCN109301005AReduce surface recombination rateImprove surface passivation performancePhotovoltaic energy generationSemiconductor devicesFilling factorSolar cell

The present invention provides a heterogeneous emitting electrode structure of a solar cell and a solar cell. The heterogeneous emitting electrode structure of the solar cell comprises a substrate, afirst doping layer, a passivation tunnelling layer, a second doping layer, a passivation antireflection layer and a front electrode. The substrate, the first doping layer, the passivation tunnelling layer, the second doping layer and the passivation antireflection layer are arranged in order, and the front electrode passes through the passivation antireflection layer and is in contact with the second doping layer. In the invention, the passivation tunnelling layer is added to effectively reduce the surface recombination rate of the cell so as to improve the surface passivation performance of the cell; and the front electrode is in contact with the second doping layer to effectively improve the transverse transmission efficiency of the front surface of the cell and reduce the serial resistance of the cell so as to improve the cell filling factor and conversion efficiency and improve the solar cell conversion efficiency.

Owner:TAIZHOU LERRISOLAR TECH CO LTD

Preparation method of passivation contact type IBC (interdigitated back contact) cell

InactiveCN108538962AGood surface passivation effectIncrease the open circuit voltageFinal product manufactureSemiconductor devicesSurface oxidationSlurry

The invention relates to a preparation method of a passivation contact type IBC (interdigitated back contact) cell. A doping processing method for the back surface of an N-type crystalline silicon substrate comprises the following steps: a back surface oxidation layer grows on the back surface of the N-type crystalline silicon substrate, then an intrinsic polycrystalline silicon layer or an intrinsic amorphous silicon layer grows on the back surface oxidation layer, and phosphorus ions are injected into the intrinsic polycrystalline silicon layer or the intrinsic amorphous silicon layer; thena mask grows, an n+ zone is protected by barrier slurry, interdigitated p+ and n+ zones are formed by printing the barrier slurry, the mask in the p+ zone is removed, annealing in the n+ zone and doping in the p+ zone are performed once by boron diffusion finally, and accordingly, alternate p+ and n+ doped zones are formed on the back surface. The preparation method of the passivation contact typeIBC cell has the following beneficial effects: the surface passivation effect is good, and open-circuit voltage and conversion efficiency are high; high-temperature procedures are reduced, and production cost is saved; damage to silicon chips due to laser ablation is reduced, and realization of cells with high conversion efficiency is more facilitated.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Method for achieving passivation of tunneling oxide layer of N-type double-sided battery

InactiveCN106486554AReduce concentrationGood surface passivationFinal product manufactureSemiconductor devicesDiffusion methodsBoron

The invention relates to a method for achieving passivation of a tunneling oxide layer of an N-type double-sided battery. The method comprises six steps of texturing treatment, front PN junction manufacturing, tunneling oxide layer preparation, back phosphorus doping, passivation layer manufacturing and electrode printing. Compared with the prior art, the method has the advantages that a boron-doped ultrathin oxide layer is prepared on the surface of a silicon wafer through a diffusion method by adopting a tunneling oxide layer passivation contact technology, and the oxide layer forms a passivation contact structure on the surface of the silicon wafer, so that the production efficiency of the N-type double-sided battery is improved.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Rapid annealing method for preparing tunneling oxygen passivation contact structure

ActiveCN110165017AShort processing timeShorten the annealing timeFinal product manufactureSemiconductor devicesTemperature controlOxygen

The invention provides a rapid annealing method for preparing a tunneling oxygen passivation contact structure, and the method comprises the following steps: (1) preheating: increasing the temperatureof a sample to be annealed to 150-250 DEG C in process gas, and performing the heat preservation for 1-2min; (2) hydrogen release: increasing the temperature to 300-600 DEG C, and performing heat preservation for 3-10min; (3) crystallization: increasing the temperature to 780-1100 DEG C, and performing heat preservation for 1-15min; (4) cooling: reducing the temperature to 600 DEG C or less within 5 minutes. Through temperature control, the method effectively avoids the phenomenon of film explosion of the sample, and prolongs the body service life of a silicon substrate through hydrogen passivation; meanwhile, doped atoms in a thin film are fully activated; in addition, due to the fact that the annealing time is relatively short, the diffusion degree of doped atoms to the silicon substrate is weakened, the surface auger recombination is effectively reduced, the surface passivation performance of the tunneling oxygen passivation contact structure is improved; meanwhile, the contact resistivity is low; in addition, the annealing time is shortened, the production efficiency is improved, the productivity is improved, and the production cost is saved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method adopting PECVD for preparing back passivation film layer of solar back passivation battery

InactiveCN104576833AImprove conversion efficiencyReduce production processFinal product manufacturePhotovoltaic energy generationRefractive indexEngineering

The invention relates to a method adopting PECVD for preparing a back passivation film layer of a solar back passivation battery. The back passivation film layer adopts a bottom layer of PECVD equipment as a SiOx layer, the refraction index of the SiOx layer is 1.48-1.8, and the thickness of the SiOx layer is 20-90 nm; a top layer of the back passivation film layer is a SiNx layer, the SiNx layer can be single-layer SiN and multi-layer SiN different in refractive index, the refractive index ranges from 1.9 to 2.25, and the thickness is 50-200 nm; the total film thickness of the back passivation film layer is 100-290 um, and the refraction index is 1.8-2.2. According to the method, the back interface state of a battery piece can be reduced, the passivation effect is improved, reflection of incident light can be improved, the light path is prolonged, the long wave response of a crystal silicon battery is improved, short-circuit currents are increased, and therefore the efficient back passivation battery is prepared.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

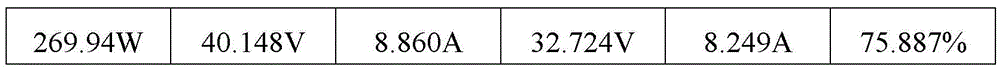

Preparation method for efficient solar cell

ActiveCN105529381AReduce consumption costReduce process complexityFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionScreen printing

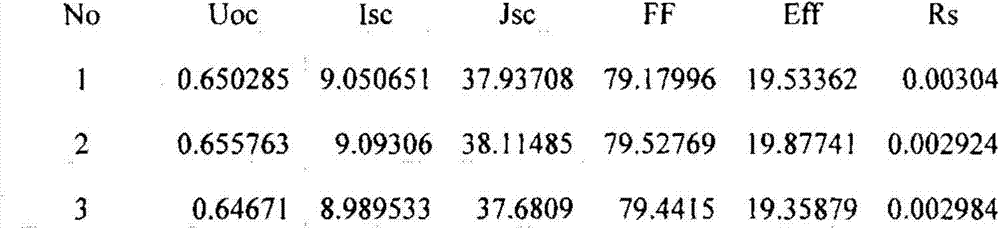

The invention discloses a preparation method for an efficient solar cell. The preparation method comprises the steps of performing texturing, diffusing and polishing on a raw material silicon wafer, and manufacturing a selective emitting electrode, plating an anti-reflection film, performing silk-screen printing, and sintering to obtain the efficient solar cell. According to the preparation method, the step of polishing is performed before the step of manufacturing the selective emitting electrode; a selective emitting electrode preparing technology and a back polishing technology are combined, so that a large amount of cost consumption for HNO3 and HF can be saved; the preparation method is simple and easy to implement; compared with an IBC cell, a heterojunction cell, and other efficient solar cells, the efficient solar cell prepared by the invention can reduce complexity of process, and the large-scale production can be realized; and in addition, the Uoc, Isc and Eff of the solar cell prepared by the preparation method are greatly improved.

Owner:TRINA SOLAR CO LTD +1

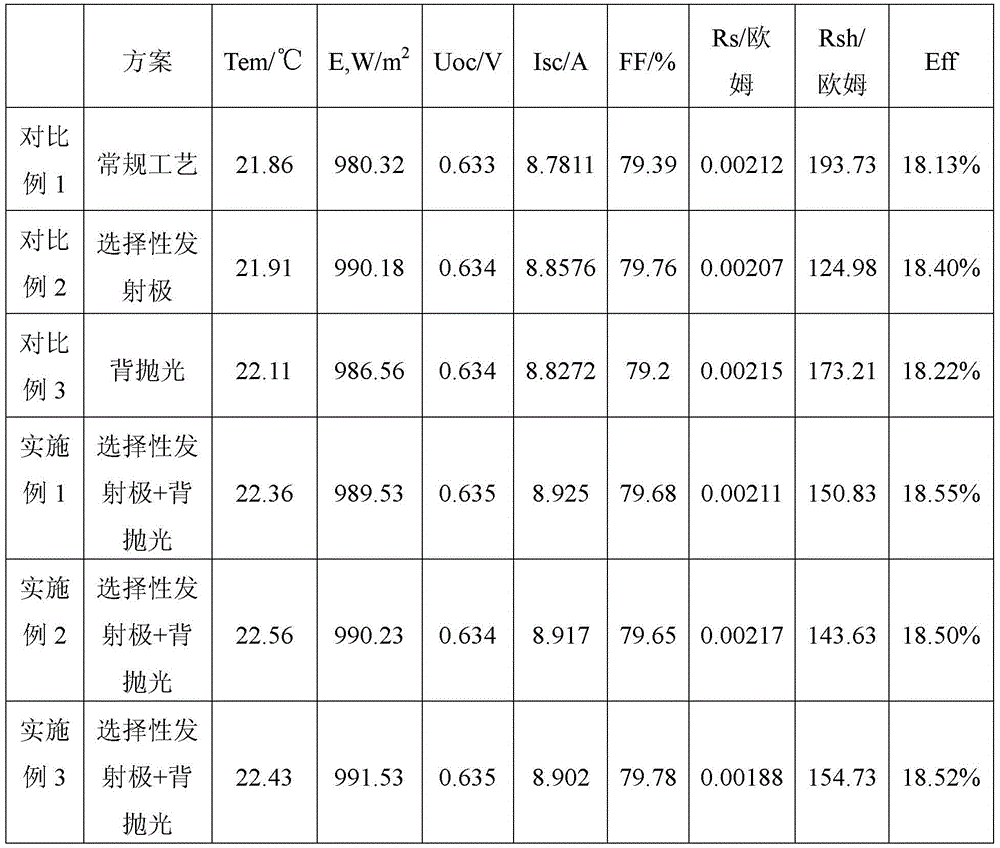

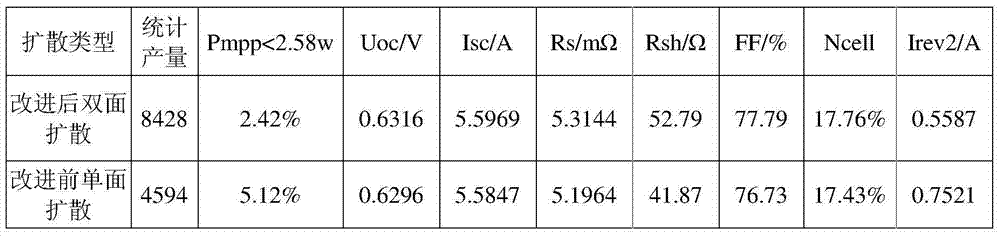

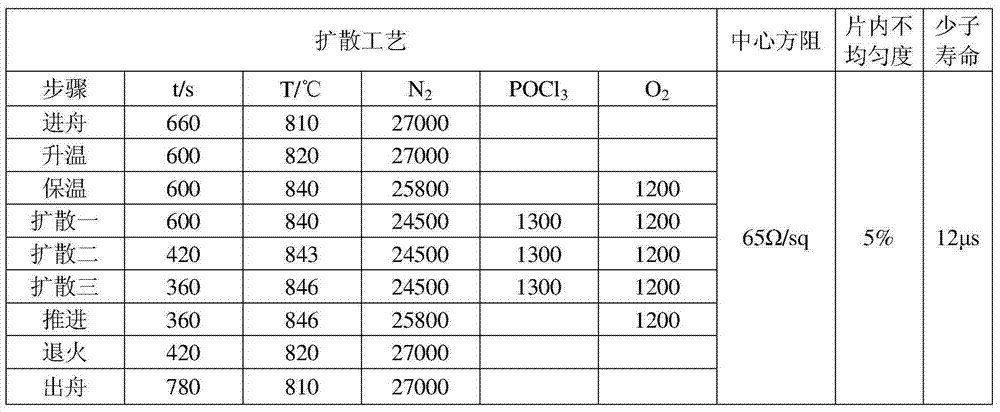

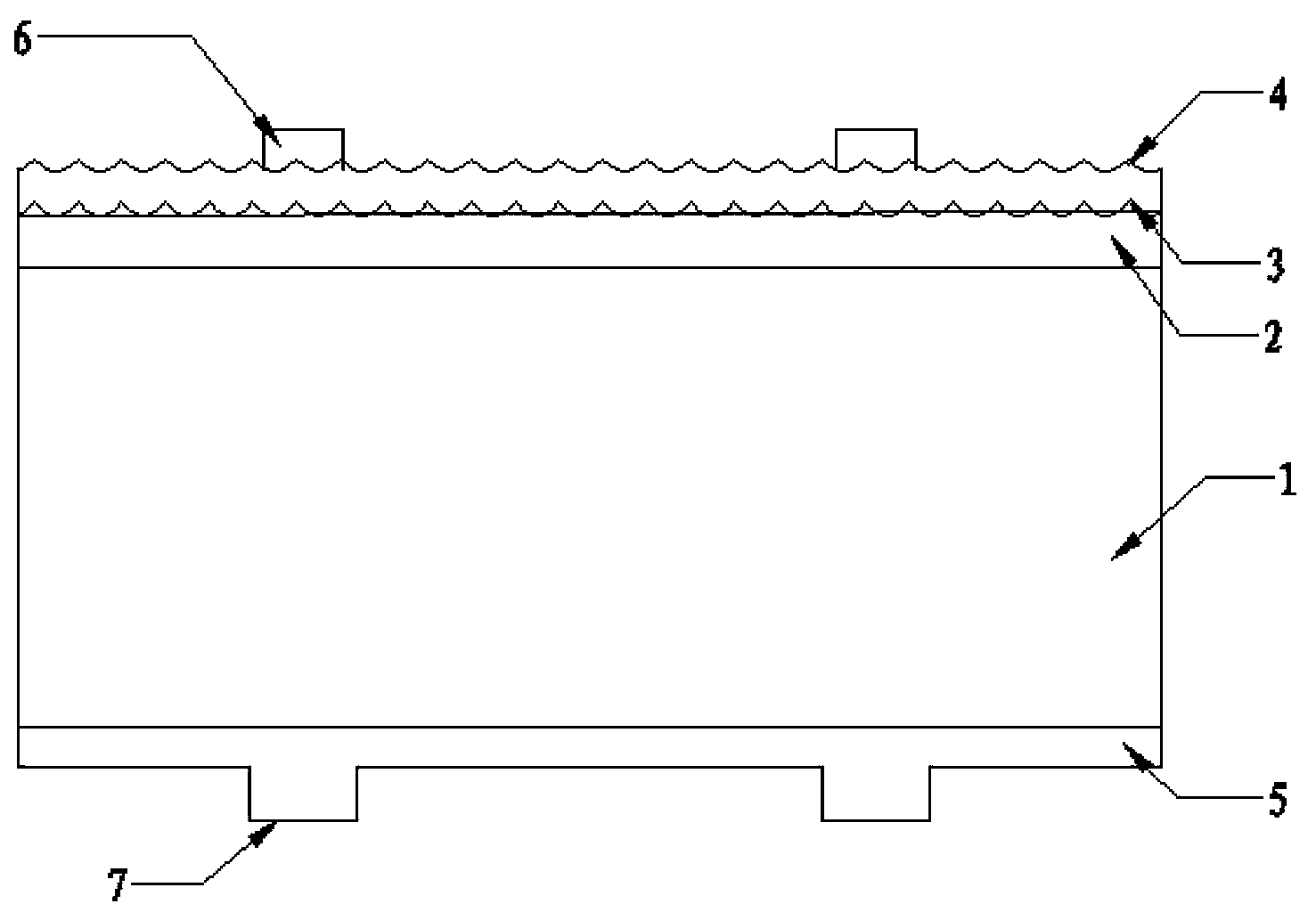

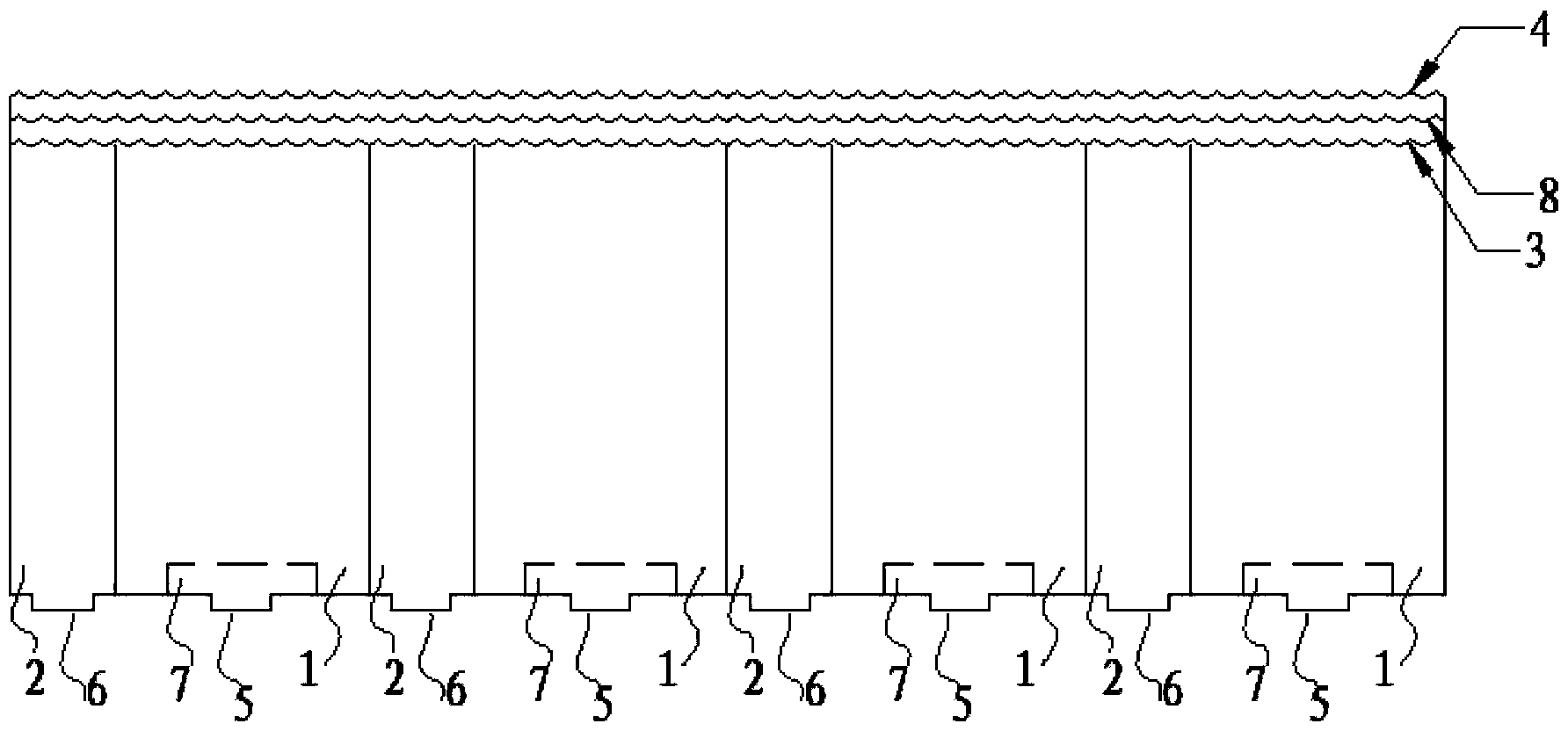

Diffusion technology for prolonging minority carrier lifetime of metallurgical silicon wafer

ActiveCN103531449AImprove conversion efficiencyImprove yieldFinal product manufactureSemiconductor/solid-state device manufacturingSilicon solar cellOxygen

The invention relates to a diffusion technology adopted in the process of manufacturing a physical metallurgical silicon solar cell, in particular to a diffusion technology for prolonging the minority carrier lifetime of a metallurgical silicon wafer. The diffusion technology is characterized by comprising the following steps: (1) propelling a quartz boat at the low temperature and raising the temperature preliminarily; (2) introducing nitrogen carried with phosphorus oxychloride and diffusing generated phosphorus atoms; (3) advancing at the constant temperature; (4) cooling and withdrawing the quartz boat. The technology has the benefits as follows: 1, spraying type diffusion is adopted, so as to save the phosphorus source as well as improve the uniformity of diffusion junction depth, and the technology is suitable for high sheet resistance; 2, according to the characteristics of physical metallurgical silicon, two-sided phosphorus is adopted in gettering to enhance the gettering effect and prolong the minority carrier lifetime of the silicon wafer; 3, the diffusion technology is effectively improved via the coordination of temperature and time; 4, the proportions of introduced oxygen and introduced raw material are controlled to reduce the defects caused by direct diffusion and improve the junction depth of a PN junction, the surface passivation effect can be further improved, and the short-circuit current and the open-circuit voltage are increased, so that the conversion efficiency and the yield of the metallurgical silicon solar cell are further improved.

Owner:NINGXIA YINXING ENERGY

Crystalline silicon solar cell and manufacturing method thereof

InactiveCN103390660AReduce incident light lossIncrease short circuit currentFinal product manufacturePhotovoltaic energy generationFill factorP–n junction

The invention discloses a crystalline silicon solar cell. The crystalline silicon solar cell comprises a crystalline silicon slice substrate. A plurality of transverse PN junctions perpendicular to the end faces of a silicon slice are arranged on the two opposite end faces of the crystalline silicon slice substrate respectively, the PN junctions are composed of P type layers and N type layers respectively, a suede surface and an antireflection layer are sequentially arranged on the front surface of the crystalline silicon slice substrate, and metal electrodes and / or P+ layers are arranged on the back surface of the crystalline silicon slice substrate. A manufacturing method of the crystalline silicon solar cell includes the steps of silicon slice pretreatment, vertical structure treatment, transverse PN junction manufacture, suede surface manufacture, antireflection layer deposition, insulating layer deposition and metallization. According to the crystalline silicon solar cell, incident light loss can be effectively reduced, electrode resistance and contact resistance are reduced, short circuit current, open circuit voltage and fill factors of the solar cell are effectively increased, and conversion efficiency of the solar cell is improved. The crystalline silicon solar cell is high in output voltage and can be used for special occasions.

Owner:上海太阳能工程技术研究中心有限公司

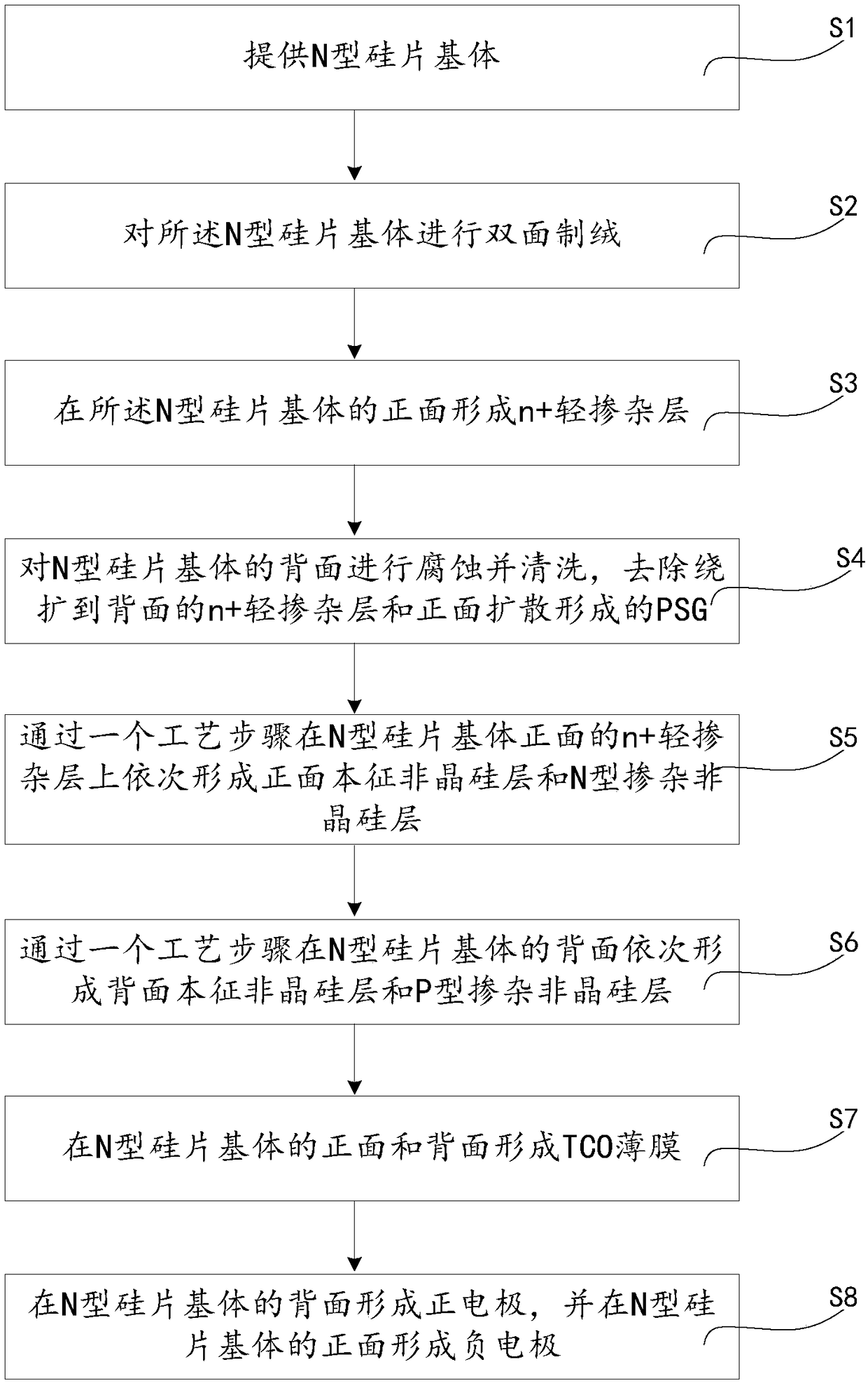

Preparation method of N type heterojunction two-sided solar battery

ActiveCN108172658AImprove current efficiencyImprove battery efficiencyPhotovoltaic energy generationSemiconductor devicesHeterojunctionIntrinsics

The invention discloses a preparation method of an N type heterojunction two-sided solar battery. The preparation method comprises the following steps of S1, providing an N type silicon wafer substrate; S2, performing two-sided texturing on the N type silicon wafer substrate; S3, forming an n+ lightly doped layer on the front surface of the N type silicon wafer substrate; S4, performing corrosionand cleaning on the back surface of the N type silicon wafer substrate; S5, forming a front surface intrinsic amorphous silicon layer and an N type doped amorphous silicon layer on the n+ lightly doped layer on the front surface of the N type silicon wafer substrate through a process step in sequence; S6, forming a back surface intrinsic amorphous silicon layer and a P type doped amorphous siliconlayer on the back surface of the N type silicon wafer substrate through a process step in sequence; S7, forming TCO thin films on the front surface and the back surface of the N type silicon wafer substrate; and S8, forming a positive electrode on the back surface of the N type silicon wafer substrate, and forming a negative electrode on the front surface thereof. By adoption of the method, a high surface passivation effect can be obtained, the problem that utilization of a window layer of a solar battery front surface is suppressed in the prior art can be solved, and the conversion efficiency of the battery can be improved.

Owner:青海黄河上游水电开发有限责任公司西宁太阳能电力分公司 +2

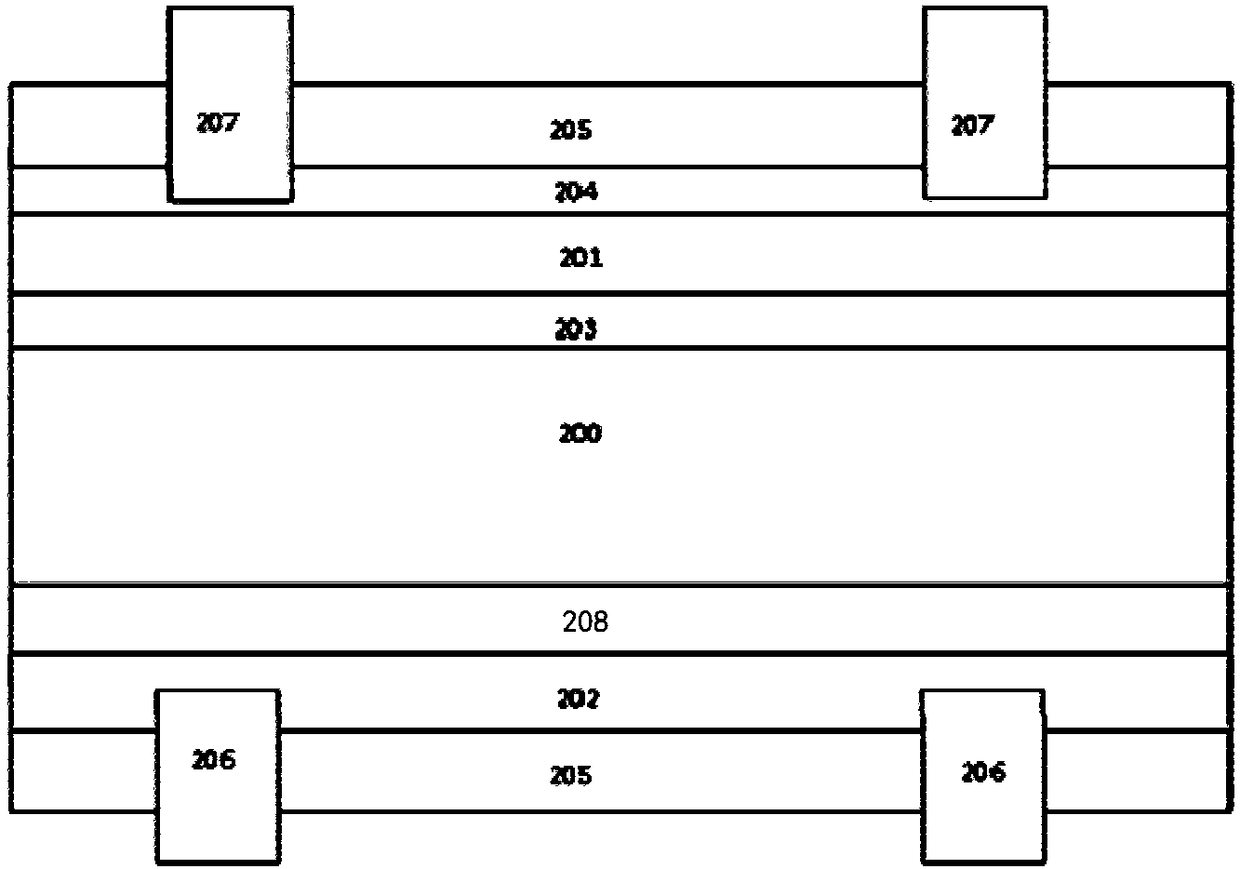

Heterojunction solar cell and manufacturing method thereof

ActiveCN102738289AAvoid damageReduced life expectancyFinal product manufacturePhotovoltaic energy generationHeterojunctionUltraviolet lights

The invention relates to a heterojunction solar cell and a manufacturing method thereof. The heterojunction solar cell comprises a crystal silicon substrate. An N-type silicon thin layer and a P-type silicon thin layer are deposited on the substrate respectively. Transparent conducting films are deposited on the N-type silicon thin layer and / or P-type silicon thin layer. Back contact structure electrodes are arranged on the transparent conducting films or / and a substrate body. The manufacturing method comprises the following steps: depositing the N-type silicon thin layer and the P-type silicon thin layer on a substrate surface; depositing the transparent conducting films on the N-type silicon thin layer and / or P-type silicon thin layer; making the electrodes; sintering so as to generate a product and so on. According to the invention, excellent surface passivation performance of a back contact cell and a low temperature technology advantage of the heterojunction cell are effectively combined; reduction of minority-carrier lifetime of a silicon material and a diffusion length is effectively avoided; a short wave response of the cell to ultraviolet light is increased and loss of a substrate resistance is decreased; light loss caused by a surface grid line is effectively reduced or eliminated.

Owner:上海太阳能工程技术研究中心有限公司

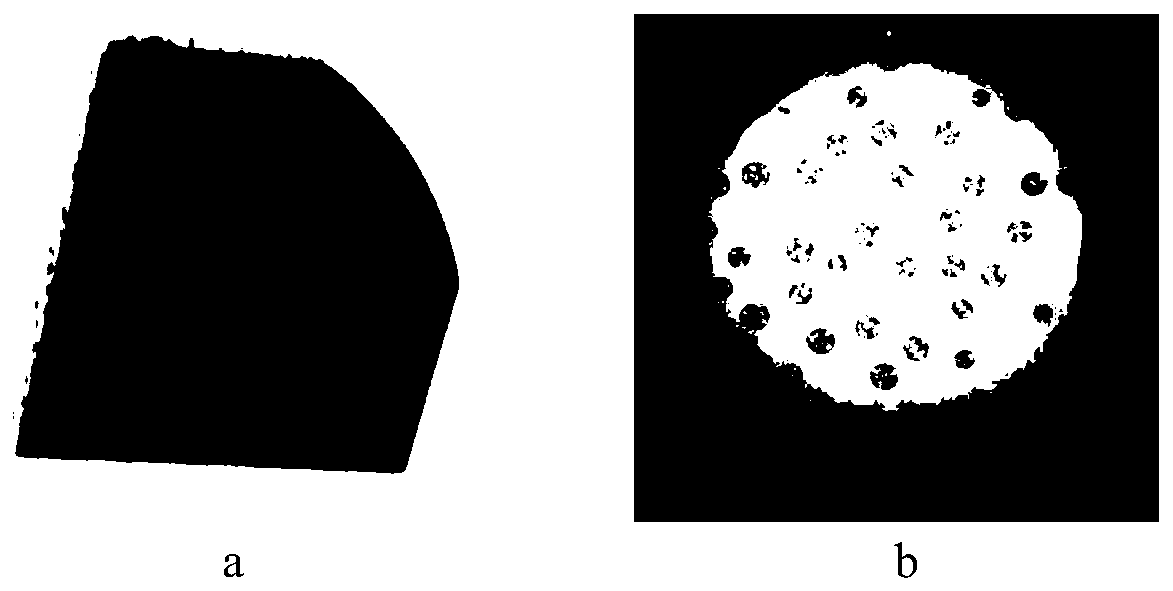

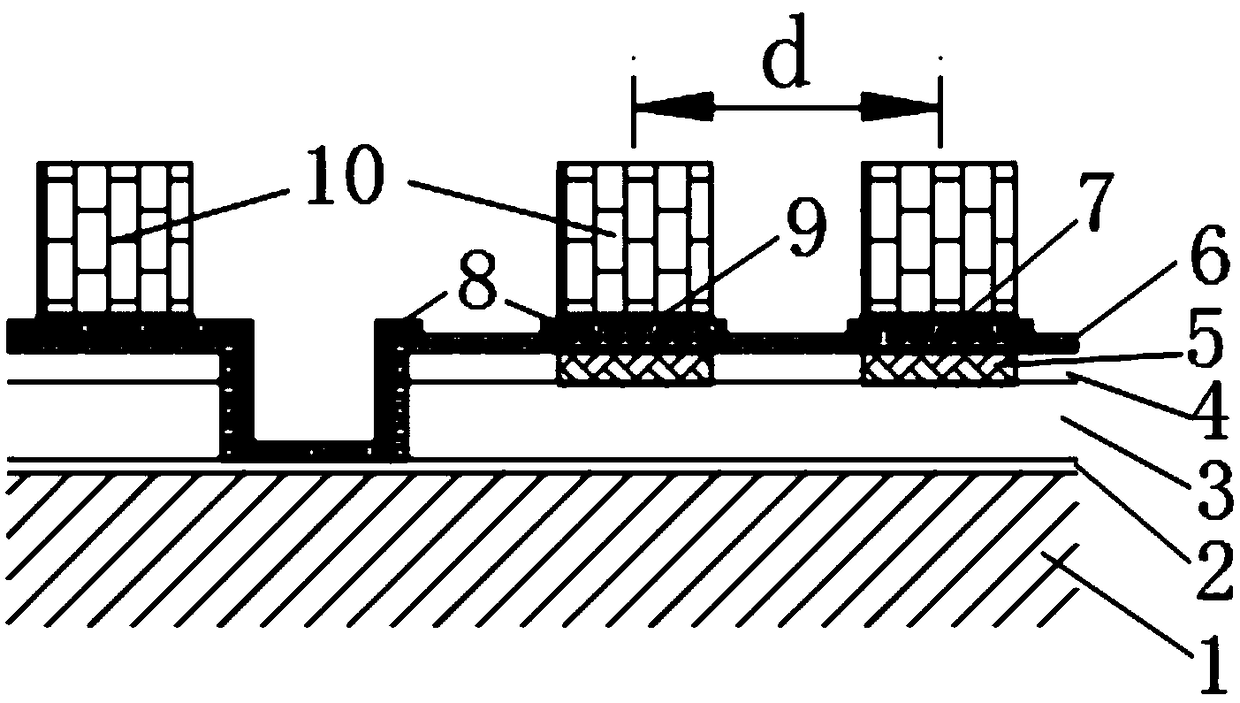

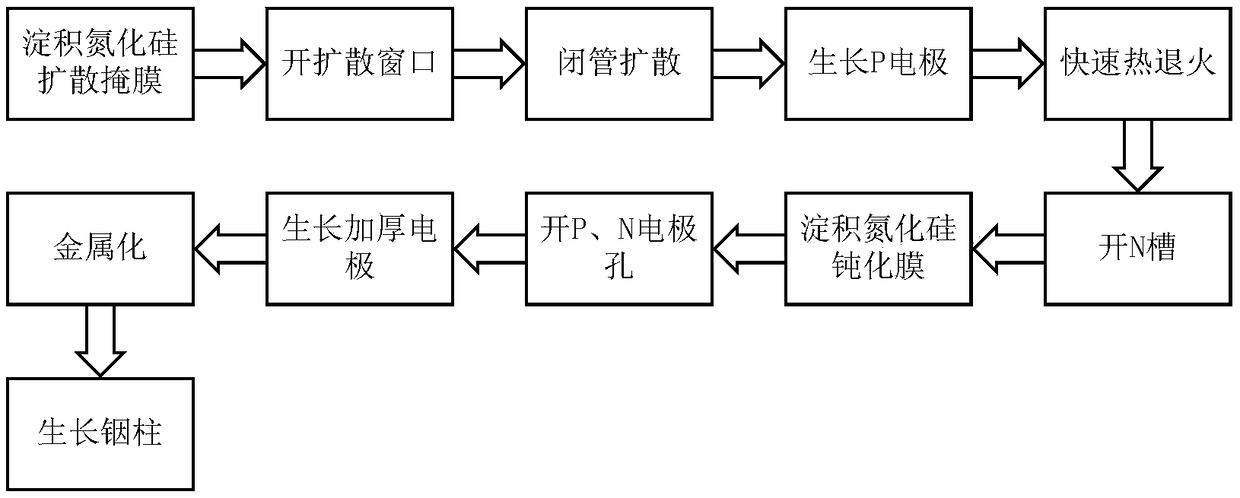

Method for preparing large-scale small-pixel indium gallium arsenide focal plane detector

InactiveCN109449238AReduce the risk of conductionAvoid damageFinal product manufactureSemiconductor devicesLithographic artistIndium bump

The invention discloses a method for preparing a large-scale small-pixel indium gallium arsenide focal plane detector. The method comprises the specific steps as follows: 1) depositing a silicon nitride diffusion mask, 2) opening a diffusion window, 3) performing closing-tube diffusion, 4) growing a P electrode, 5) performing rapid thermal annealing, 6) opening an N groove, 7) depositing the silicon nitride passivation film, 8) opening P and N electrode holes, 9) growing a thickened electrode, 10) metallizing, and 11) growing an indium bump. The invention has the advantages that: 1, the preparation process is simpler, and the technique of first growing the P-region electrode is used to reduce the risk of conduction between the P-region electrode and the N-region InP material caused by lithography deviation and over-etching; 2, the inductively coupled plasma chemical vapor deposition (ICPCVD) technology is used to grow the low-temperature silicon nitride passivation film, and the surface passivation layer of the chip is dense, which reduces the damage caused by the process to the surface of the material and improves the surface passivation effect; and 3, the lithographic growth technique is adopted for the metalized region and the indium bump region to reduce the contact resistance of the device.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Solar cell with passivation contact and preparation method thereof

PendingCN113644142AImprove conversion efficiencyImprove performanceFinal product manufacturePhotovoltaic energy generationFill factorEngineering

The invention provides a solar cell with passivation contact and a preparation method thereof. The solar cell comprises a substrate, a back tunneling oxide layer, a back passivation film and a back anti-reflection layer are sequentially arranged on the back face of the substrate in a stacked mode, a back metal grid line is formed on the surface of the back anti-reflection layer, and the back metal grid line is in contact with the back passivation film; the front surface of the substrate is divided into a metal contact region and a non-metal contact region, the metal contact region is sequentially provided with a front tunneling oxide layer, a front passivation film and a front anti-reflection layer in a stacked manner, and a front metal grid line is formed on the surface of the front anti-reflection layer and is in passivation contact with the front passivation film. According to the solar cell, the recombination of a metal-semiconductor interface in a contact region is effectively reduced, and the surface passivation performance is improved, so that the open-circuit voltage and the fill factor of the cell are greatly improved, and the cell performance is improved.

Owner:TRINA SOLAR CO LTD

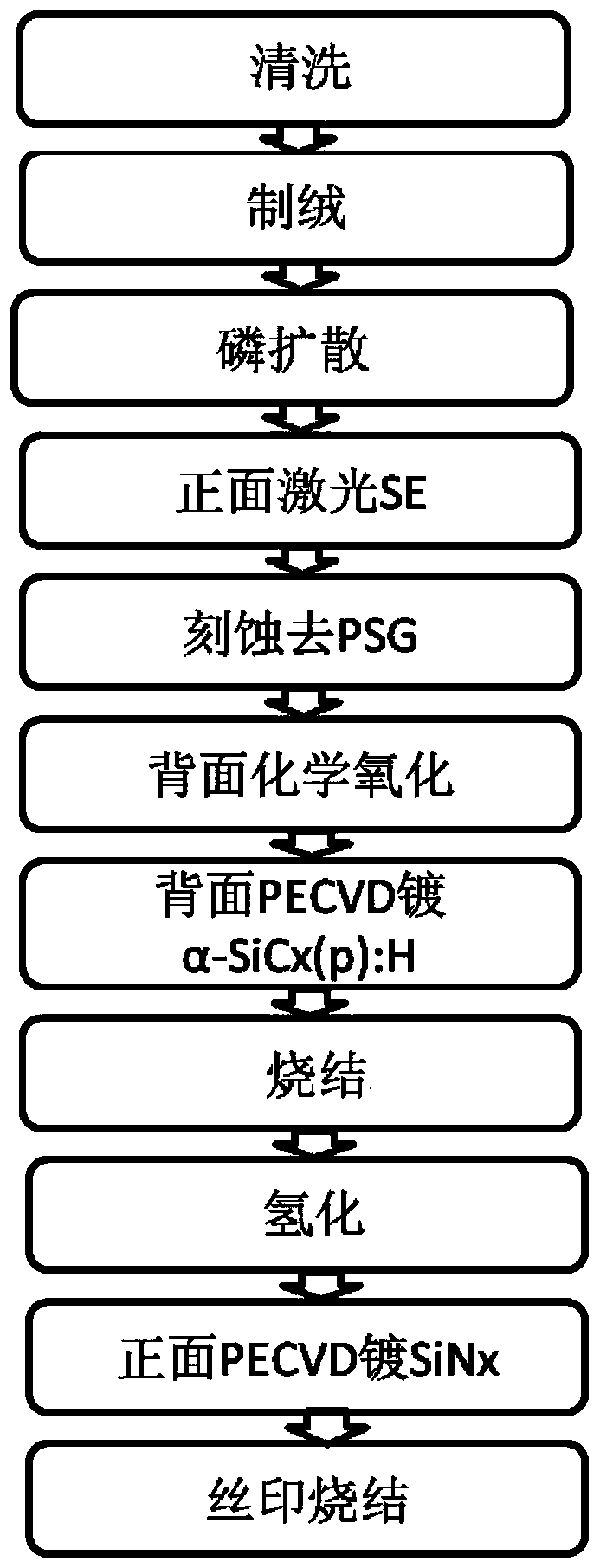

Back full-passivation contact solar cell and preparation method thereof

InactiveCN109860324AImprove efficiencyLow densityFinal product manufacturePhotovoltaic energy generationSilicon oxideP type silicon

The invention discloses a back full-passivation contact solar cell and a preparation method thereof. The cell comprises an all-aluminum back electric field, a nanocrystalline boron hydride doped silicon carbide layer, a silicon oxide layer, P-type silicon, an n+ emitter electrode layer, a silicon nitride layer, a back electrode, a heavily-doped n+ emitter electrode and a front electrode, wherein the all-aluminum back electric field, the nanocrystalline boron hydride doped silicon carbide layer, the silicon oxide layer, the P-type silicon, the n+ emitter electrode layer and the silicon nitridelayer are sequentially connected from the bottom to the top. One end of the heavily-doped n+ emitter electrode is connected with the front electrode, and the other end of the heavily-doped n+ emitterelectrode passes through the n+ emitter electrode layer to be embedded in the P-type silicon. The preparation method comprises the steps of cleaning, texturing, diffusion, front laser SE, secondary cleaning, surface chemical oxidation, passivation layer deposition, sintering, hydrogenation, silicon nitride layer preparation, silk-screen printing and sintering. The cell has the advantages of largeshort-circuit current, high open-circuit voltage, high photoelectric conversion efficiency and the like. The preparation method is simple in process, is low in mass production threshold, is low in preparation cost, is good in compatibility, is high in production efficiency, meets the requirements of large-scale preparation, facilitates the industrial utilization, and has very important significance.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com