Solar cell with passivation contact and preparation method thereof

A solar cell and contact area technology, applied in the field of solar cells, can solve problems such as the large gap between cell efficiency and theoretical efficiency, lowering the power generation efficiency of solar cells, and decreasing current density, achieving good surface passivation effect and improving cell performance. , reduce the effect of surface recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

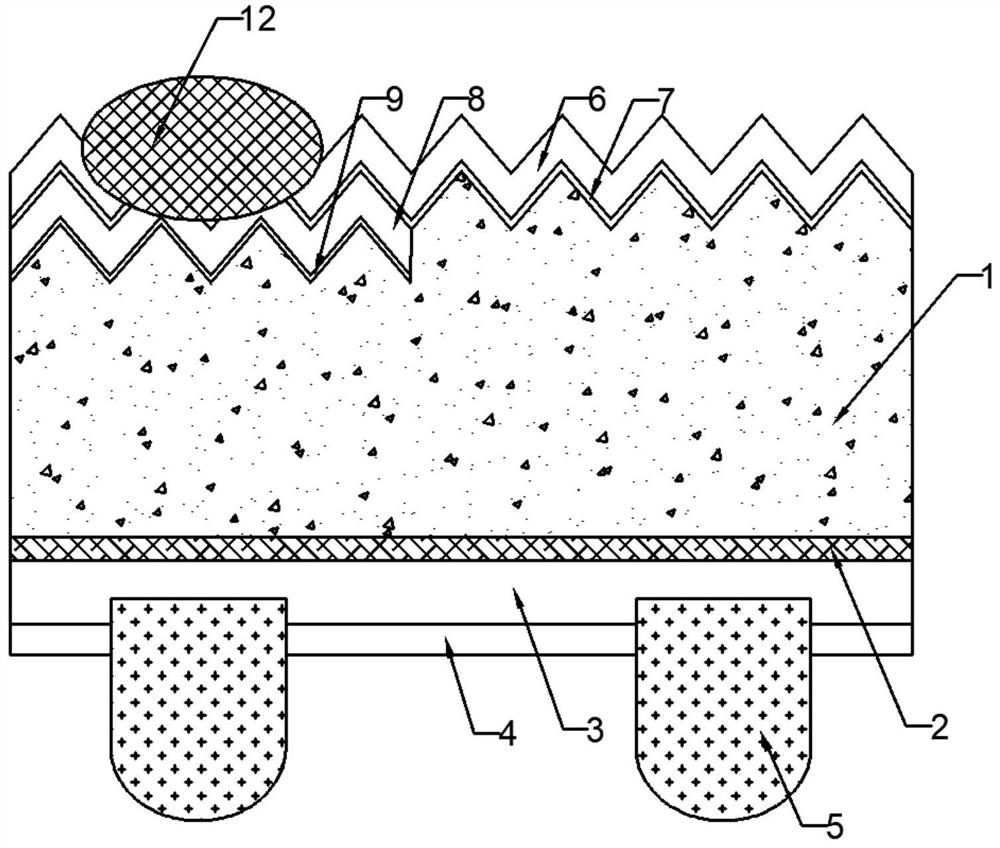

[0071] This embodiment provides a solar cell, the solar cell is as figure 1As shown, including the substrate 1, the metal contact region on the front side of the substrate 1 is sequentially stacked with a front tunnel oxide layer 9 (silicon oxide layer) and a front doped polysilicon layer 8 (phosphorous doped polysilicon layer), and the front tunnel oxide layer Layer 9 has a thickness of 2 nm, and the front doped polysilicon layer 8 has a thickness of 200 nm. The front doped polysilicon layer 8 and the surface of the non-metal contact region are sequentially stacked with a phosphorus diffusion layer-A (front surface field FSF) 7 and a front anti-reflection layer 6, and the thickness of the phosphorus diffusion layer-A (front surface field FSF) 7 is The thickness of the front anti-reflection layer 6 is 50 nm. Front metal grid lines 12 are formed on the surface of the front antireflection layer 6 , and the front metal grid lines 12 are in contact with the front doped polysilico...

Embodiment 2

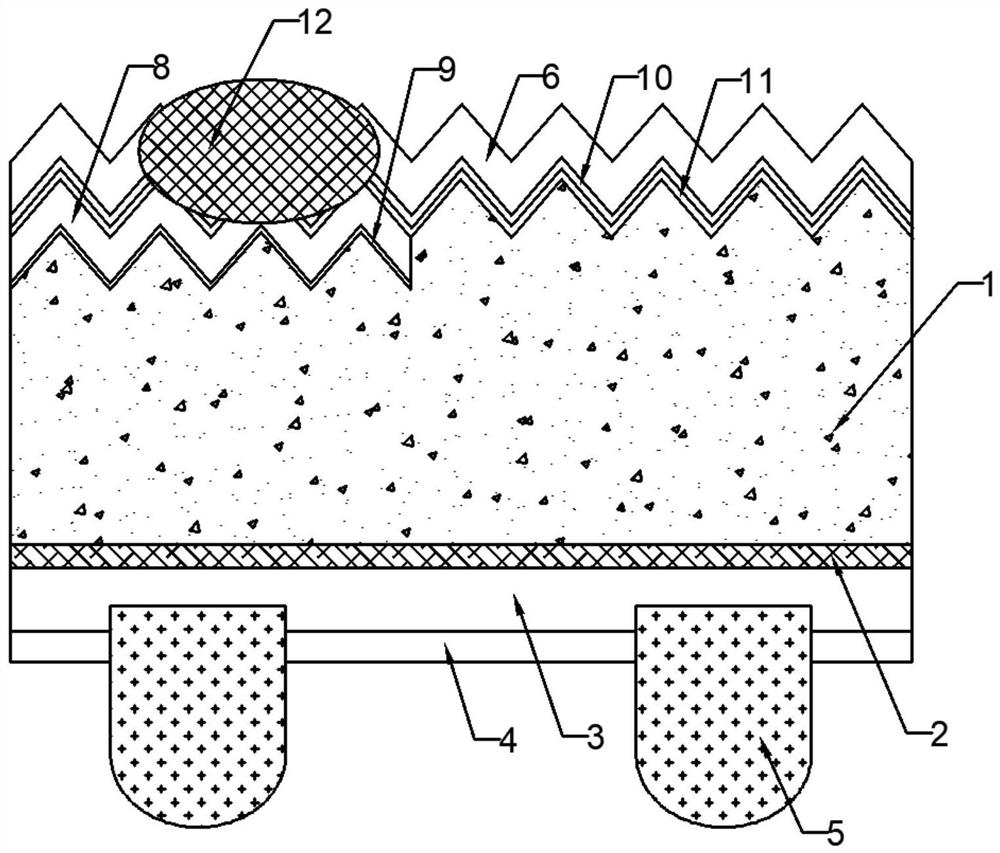

[0085] This embodiment provides a solar cell, the solar cell is as figure 2 As shown, including the substrate 1, the metal contact region on the front side of the substrate 1 is sequentially stacked with a front tunnel oxide layer 9 (silicon oxide layer) and a front doped polysilicon layer 8 (phosphorous doped polysilicon layer), and the front tunnel oxide layer Layer 9 has a thickness of 3nm and front doped polysilicon layer 8 has a thickness of 200nm. The front doped polysilicon layer 8 and the surface of the non-metal contact area are sequentially stacked with a phosphorus diffusion layer-B 11, an oxide layer 10, and a front anti-reflection layer 6. The thickness of the oxide layer 10 is 3 nm, and the thickness of the front anti-reflection layer 6 is 100 nm. . Front metal grid lines 12 are formed on the surface of the front antireflection layer 6 , and the front metal grid lines 12 are in contact with the front doped polysilicon layer 8 .

[0086] The back side of the su...

Embodiment 3

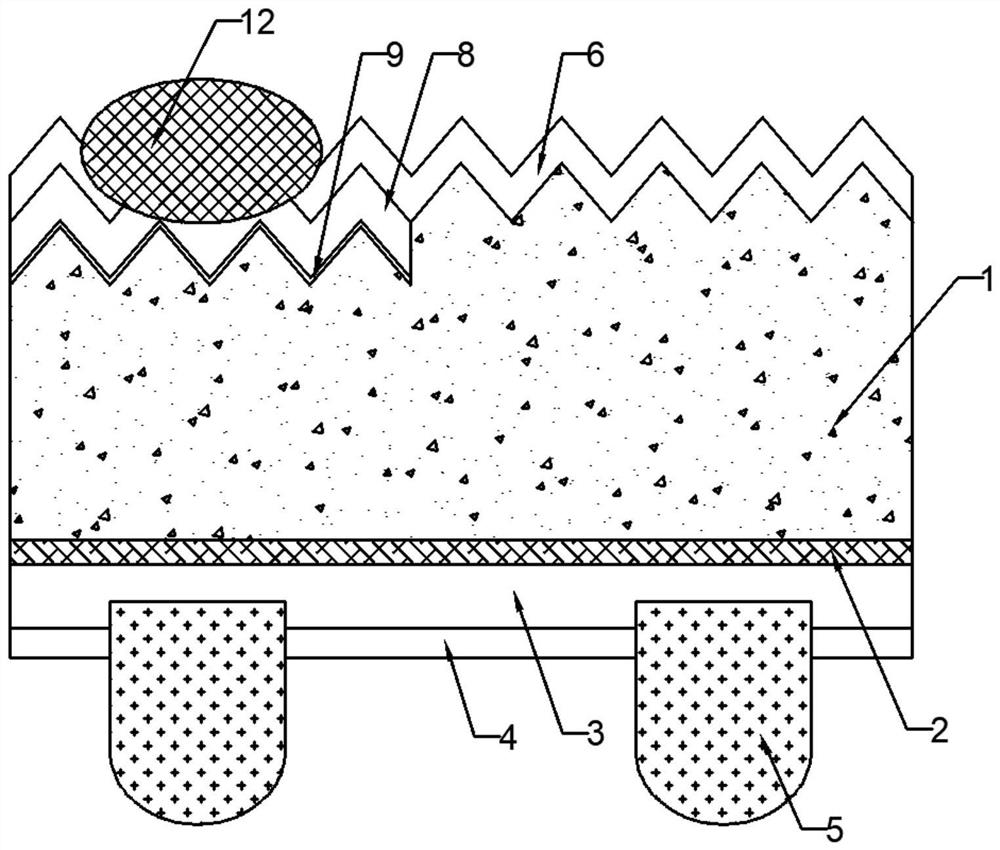

[0100] This embodiment provides a solar cell, the solar cell is as image 3 As shown, including the substrate 1, the metal contact region on the front side of the substrate 1 is sequentially stacked with a front tunnel oxide layer 9 (silicon oxide layer) and a front doped polysilicon layer 8 (phosphorous doped polysilicon layer), and the front tunnel oxide layer Layer 9 has a thickness of 2 nm, and the front doped polysilicon layer 8 has a thickness of 400 nm. The surface of the front doped polysilicon layer 8 and the non-metal contact area is provided with a front anti-reflection layer 6, and the thickness of the front anti-reflection layer 6 is 200nm. Front metal grid lines 12 are formed on the surface of the front antireflection layer 6 , and the front metal grid lines 12 are in contact with the front doped polysilicon layer 8 .

[0101] The back side of the substrate 1 is sequentially stacked with a back tunneling oxide layer 2 (silicon oxide layer), a back doped polysili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com