Solar cell and preparation method thereof

A technology of solar cells and front electrodes, applied in the field of solar cells, can solve the problems of low conversion efficiency of solar cells, achieve the effects of improving fill factor and conversion efficiency, improving lateral transmission efficiency, and reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

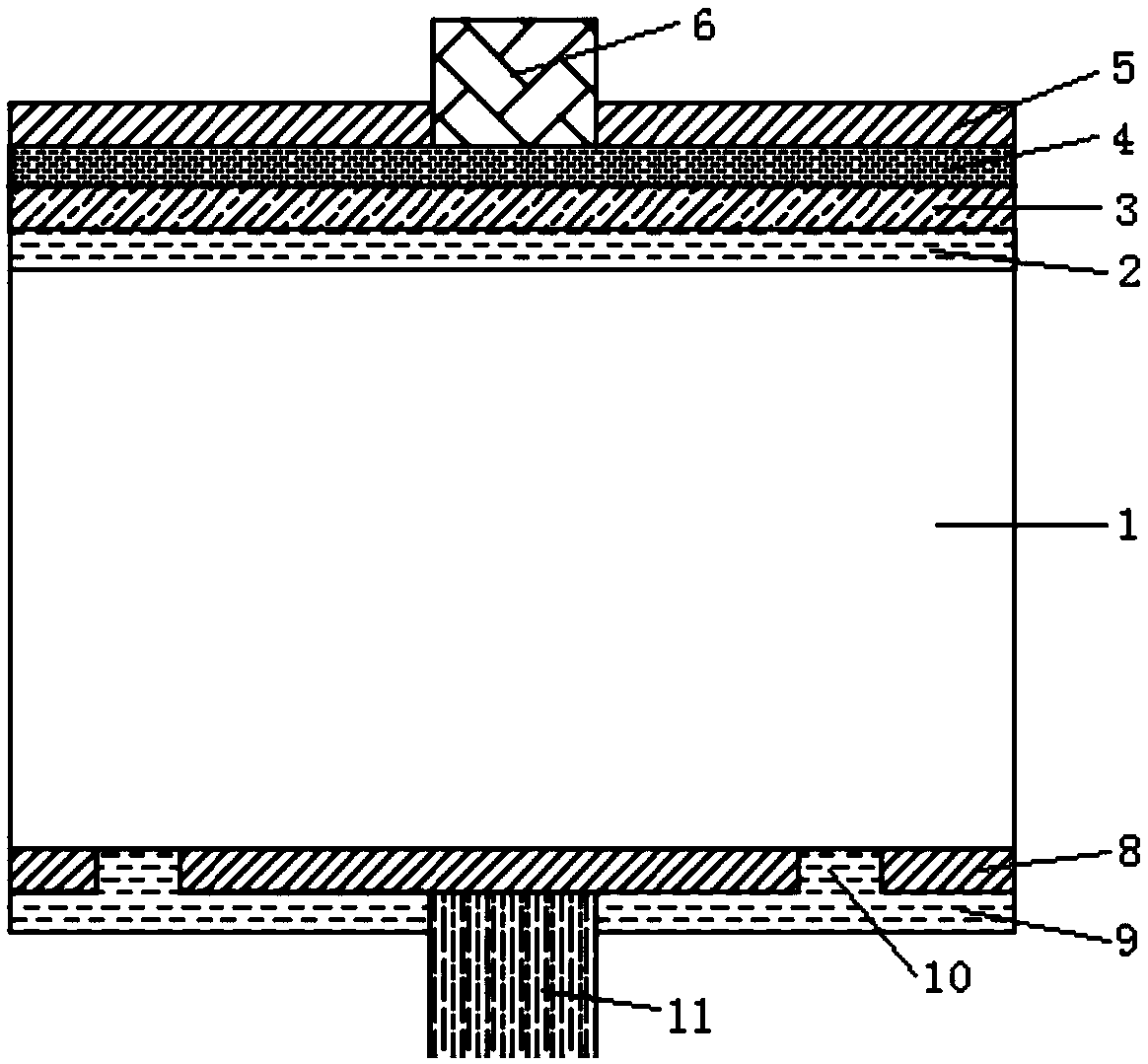

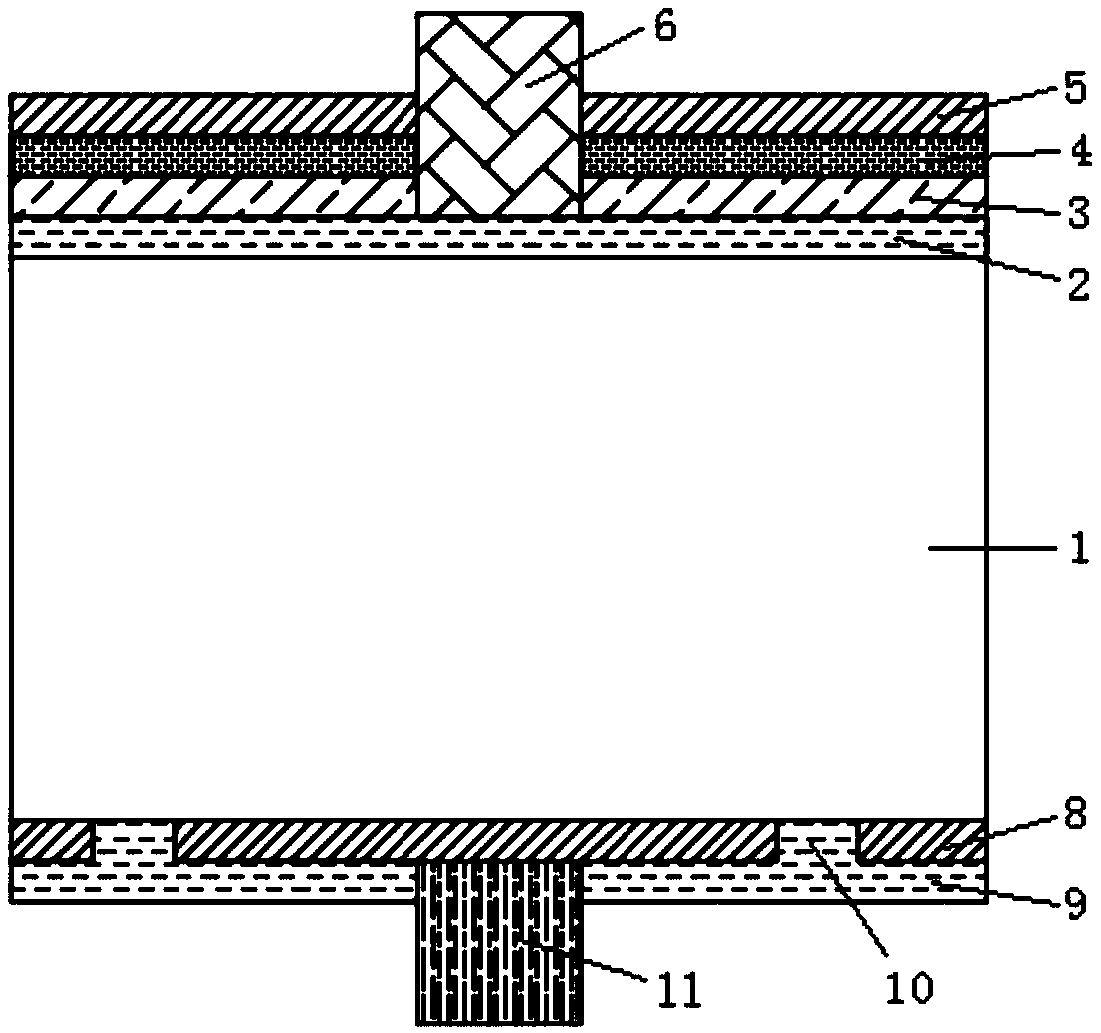

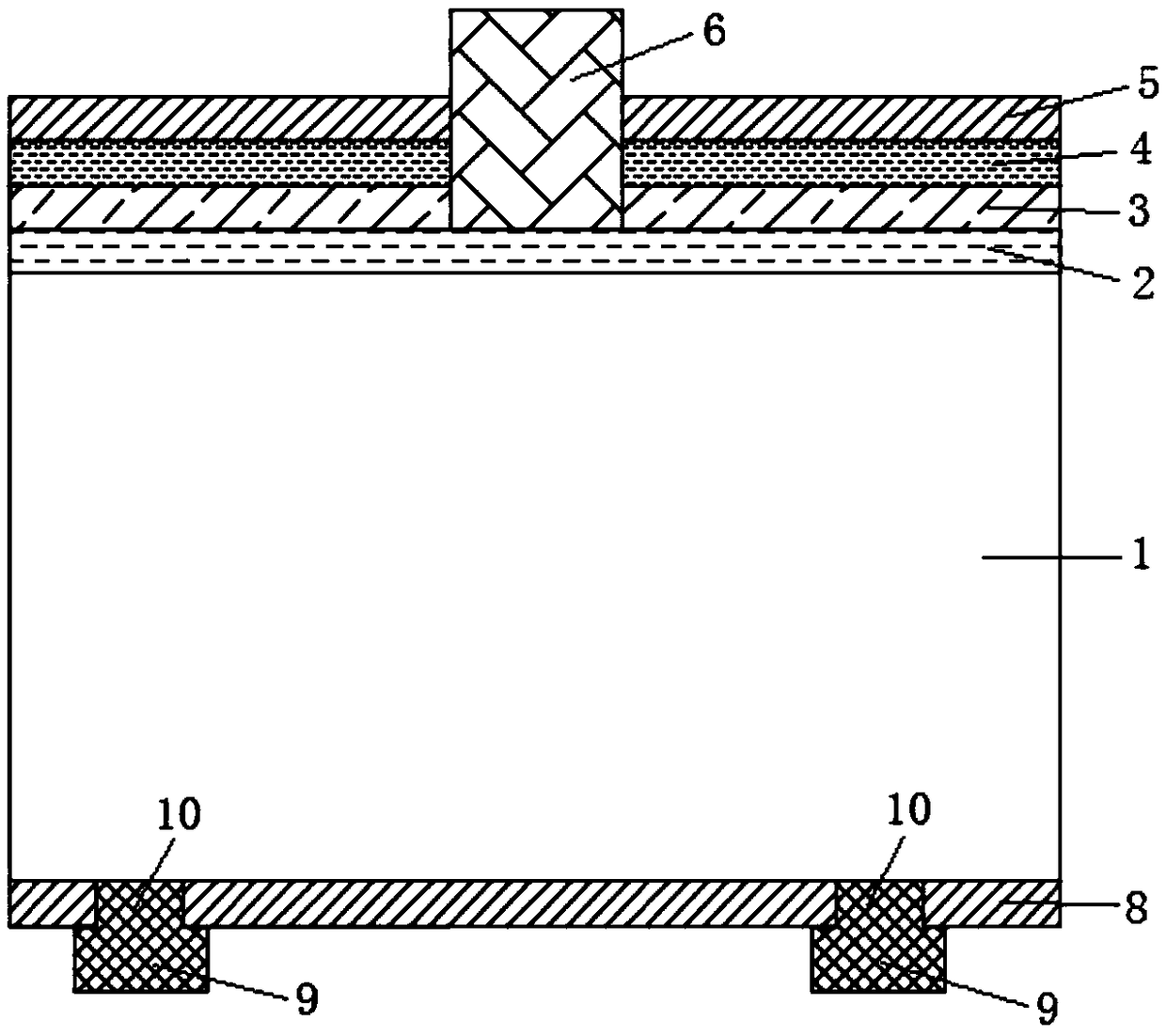

[0056]The embodiment of the present application provides a solar cell, and the structural schematic diagram of the solar cell is as follows Figures 1 to 4 As shown, it includes: a base 1 , a front structure located on the front of the base 1 and a back structure located on the back of the base 1 .

[0057] In the embodiment of the present application, the front structure includes: a first doped layer 2, a passivation tunneling layer 3, a second doped layer 4, a passivation anti-reflection layer 5, and a front electrode 6 (negative electrode thin grid line); A doped layer 2 , a passivated tunneling layer 3 , a second doped layer 4 and a passivated anti-reflection layer 5 are arranged in sequence, and the front electrode 6 passes through the passivated anti-reflection layer 5 and contacts the second doped layer 4 .

[0058] Compared with the prior art, the embodiment of the present application adds a passivation tunneling layer 3 to provide better passivation, which can effecti...

Embodiment 2

[0090] Based on the same inventive concept, an embodiment of the present application provides a method for preparing a solar cell. The schematic flow chart of the method is shown in Figure 9 shown, including:

[0091] S1, pretreating the substrate 1 .

[0092] Optionally, step S1 specifically includes: performing damage removal treatment and surface texturing treatment on the substrate 1 to form a pyramid texture on the front surface of the substrate 1 .

[0093] Taking p-type monocrystalline silicon as the substrate of the battery as an example, first, use a 60°C solution containing KOH for damage removal treatment, and use a solution containing KOH for surface texturing at 80°C to form a pyramid texture. The scale of the pyramid can reach 2-5um (micrometer); then, the substrate 1 is cleaned with a mixed solution containing hydrofluoric acid and hydrochloric acid and deionized water in sequence, and then dried.

[0094] S2 , performing doping treatment on the front surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com