Titanium oxide passivation film preparation method and solar energy cell prepared through utilizing titanium oxide passivation film preparation method

A passivation film and titanium oxide technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of high deposition process requirements, low passivation effect, complex precursor synthesis process, etc., to achieve the operation mode and operation The process is simple, the effect of reducing the surface recombination rate and improving the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a kind of preparation method of titanium oxide passivation film, comprises the following steps:

[0026] Clean the N-type silicon wafer with a thickness of 250um, a resistivity of 5Ω·cm, and a size of 4cm×4cm to remove surface contamination by standard RCA cleaning, that is, first heat it with RCA No.1 solution at 120°C for 10 minutes. The following components form according to the proportioning by volume, sulfuric acid (98%): hydrogen peroxide (30%): deionized water=100ml: 100ml: 600ml; RCA No. solution is heated at 100 ℃ of temperature for 10 minutes after washing with deionized water Minutes, RCA2 solution is formed by the following components according to volume ratio proportioning, hydrochloric acid (68%): hydrogen peroxide (30%): deionized water=100ml: 100ml: 1000ml; rinse with 10% mass fraction hydrogen after deionized water Soak in hydrofluoric acid solution to remove the natural oxide layer on the surface, and test the initial minority ca...

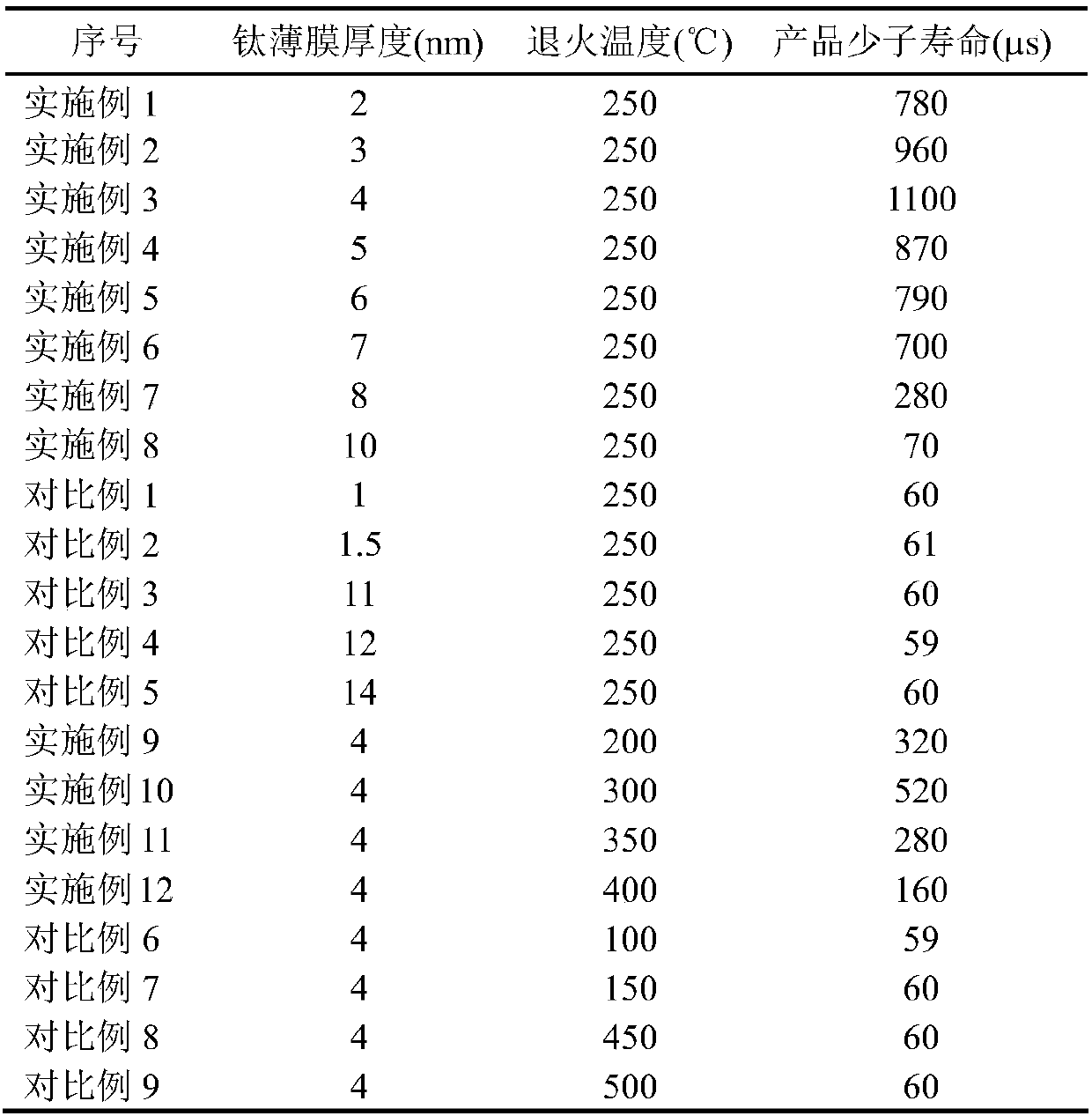

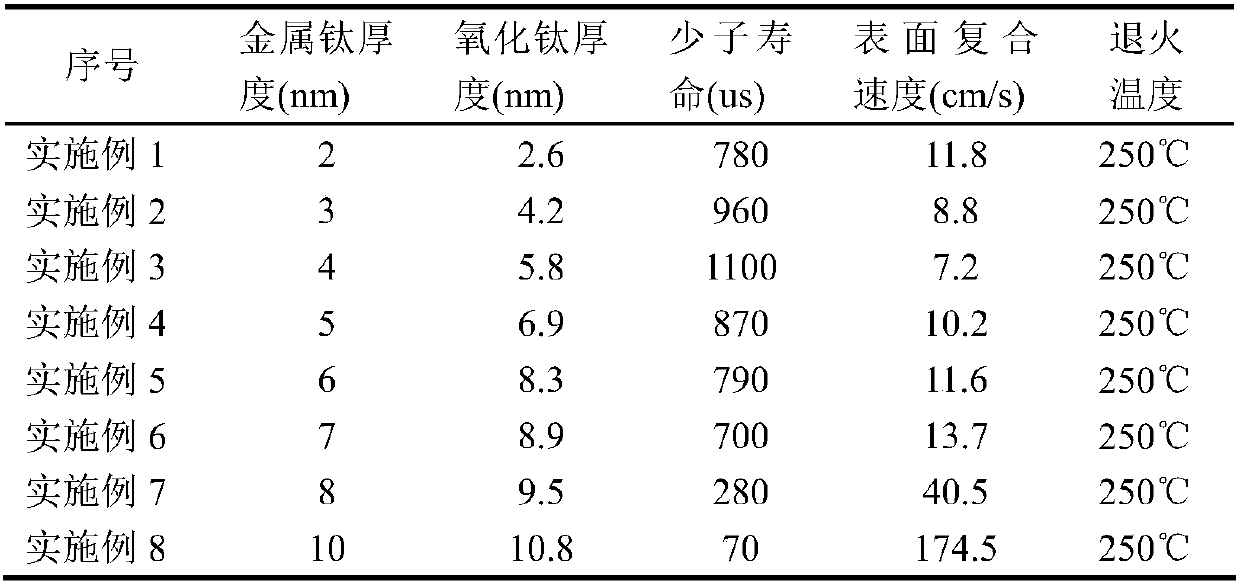

Embodiment 2~8

[0029] Change the thickness of the titanium metal film deposited in Example 1 to 3, 4, 5, 6, 7, 8, and 10 nm respectively, and the others are the same as in Example 1.

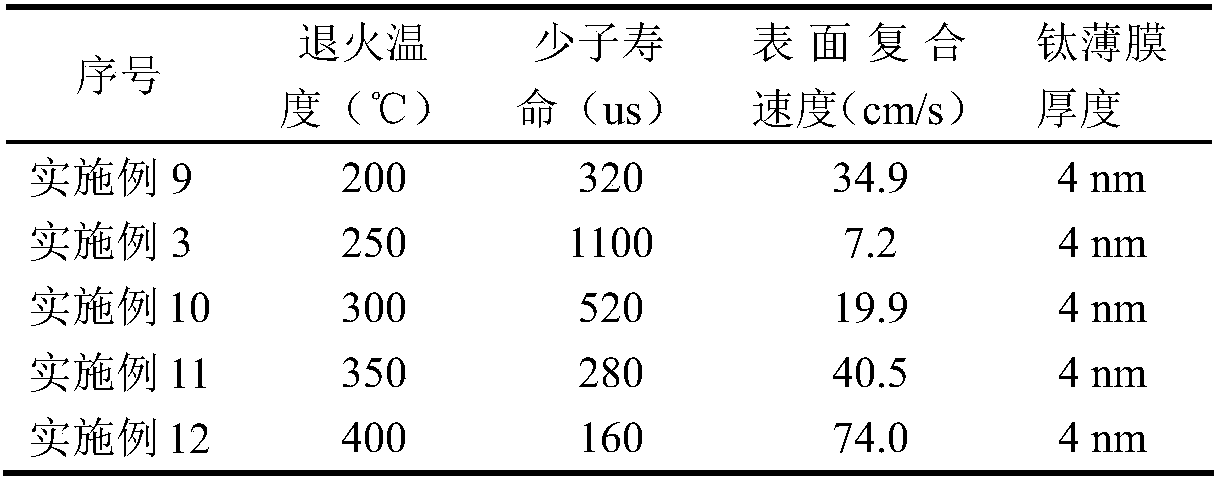

Embodiment 9

[0031] Clean the N-type silicon wafer with a thickness of 250um, a resistivity of 5Ω·cm, and a size of 4cm×4cm to remove surface contamination by standard RCA cleaning, that is, first heat it with RCA No.1 solution at 120°C for 10 minutes. The following components form according to the proportioning by volume, sulfuric acid (98%): hydrogen peroxide (30%): deionized water=100ml: 100ml: 600ml; RCA No. solution is heated at 100 ℃ of temperature for 10 minutes after washing with deionized water Minutes, RCA2 solution is formed by the following components according to volume ratio proportioning, hydrochloric acid (68%): hydrogen peroxide (30%): deionized water=100ml: 100ml: 1000ml; rinse with 8% mass fraction hydrogen after deionized water Soak in hydrofluoric acid solution to remove the natural oxide layer on the surface, and test the initial minority carrier lifetime to be about 60us;

[0032] A metal titanium film with a thickness of 4nm is deposited on both sides of the silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com