Etching-technology-based silicon science (SIS) junction solar cell

A solar cell and technology technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low conversion efficiency of SIS junction solar cells, and achieve the effects of reducing surface recombination rate, balancing photocurrent, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

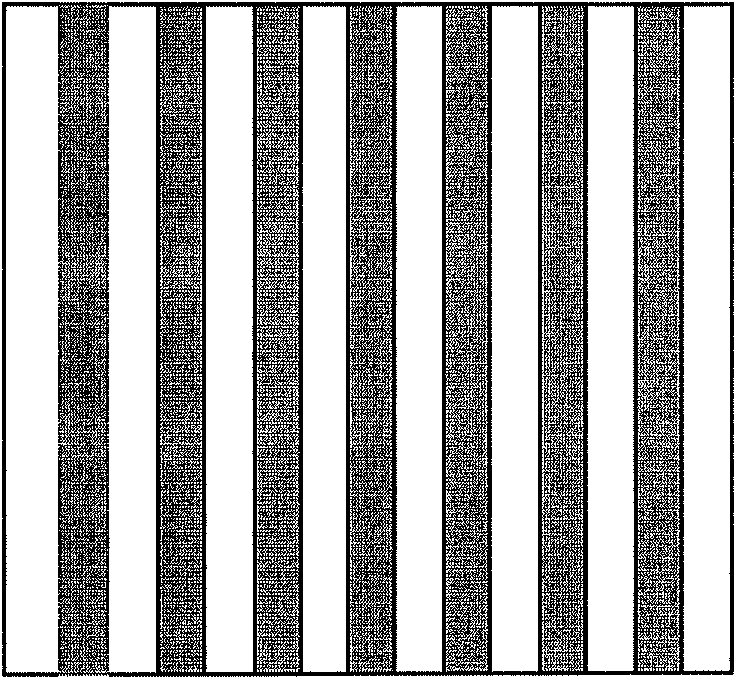

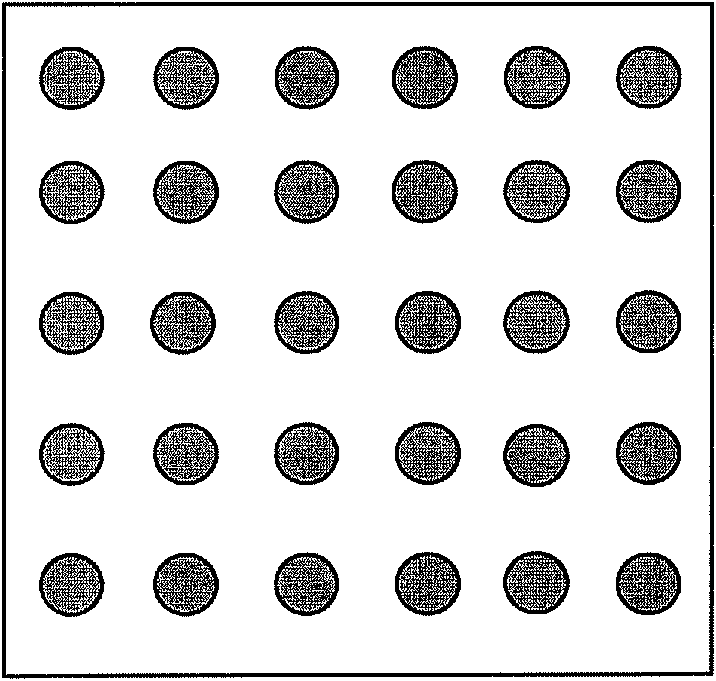

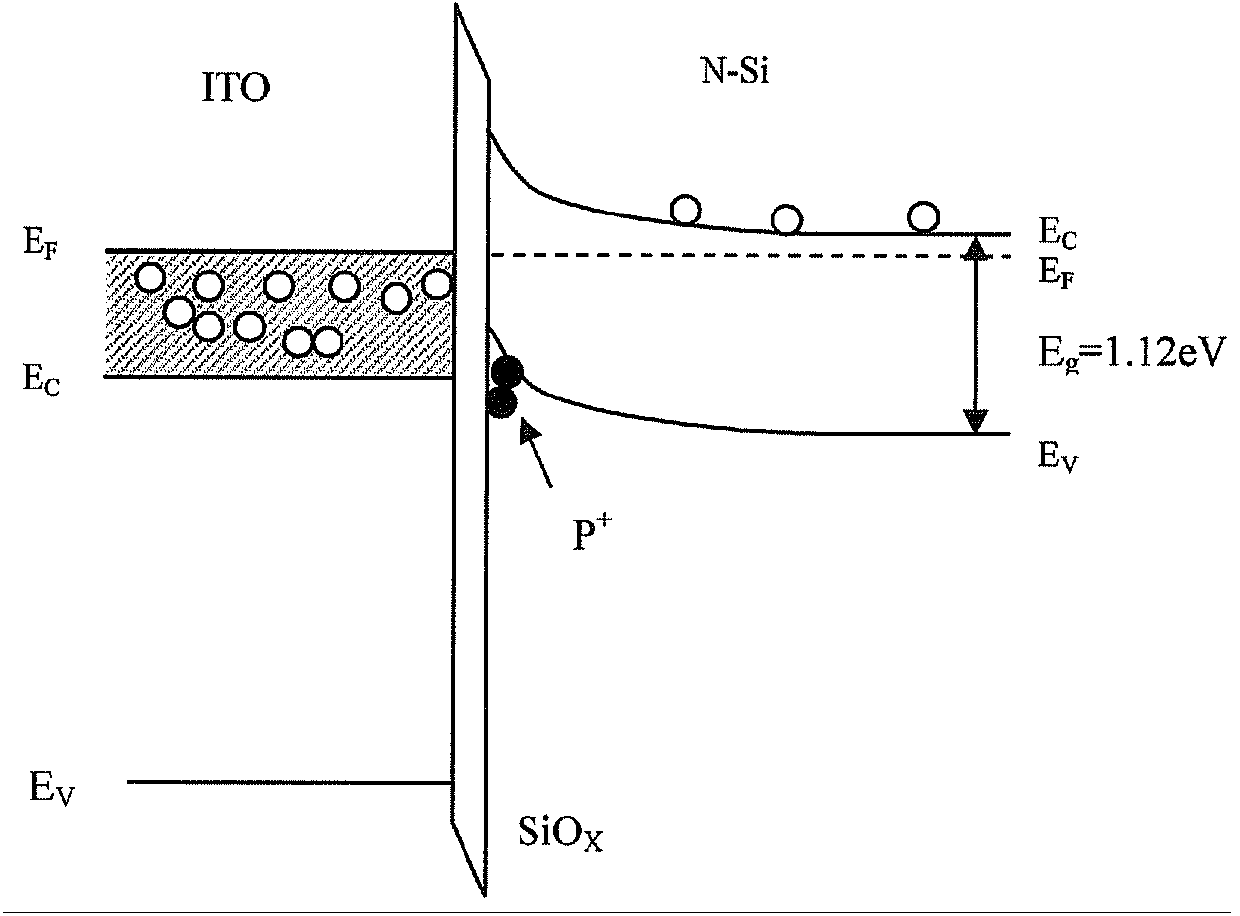

[0040] In this embodiment, the lower electrode 10 is Ti / Au. In order to improve the carrier collection efficiency and realize the ideal ohmic contact between the electrode and the light-absorbing material layer 20, the surface in contact with the lower electrode 10 needs to be heavily doped; optical absorption The material layer 20 is N-type single crystal Si with a band gap of 1.12eV and a thickness of 100 microns. The surface etching structure is a one-dimensional strip type, which is realized by photolithography and ICP etching. The specific parameters can be selected as a strip width of 10 microns , the period is 20 microns, the etching depth is 50 microns; the oxide insulating layer 30 passes through the H 2 o 2 Formed by corrosion, the thickness is about ten angstroms. The insulating layer can effectively reduce surface defects and improve the Schottky barrier; the TCO thin film layer 40 is selected as ITO, with a thickness of about 80nm, and is deposited on the oxide in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com