A method to enhance the optical absorption of cdin2s4

A technology of optical absorption and cdin2s4, which is applied in the field of semiconductor optoelectronic materials, can solve the problems of unfavorable carrier separation, disconnection, and affecting the photoelectric conversion performance of semiconductors, and achieve the goal of enhancing optical absorption capacity, enhancing optical absorption capacity, and improving photoelectric conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

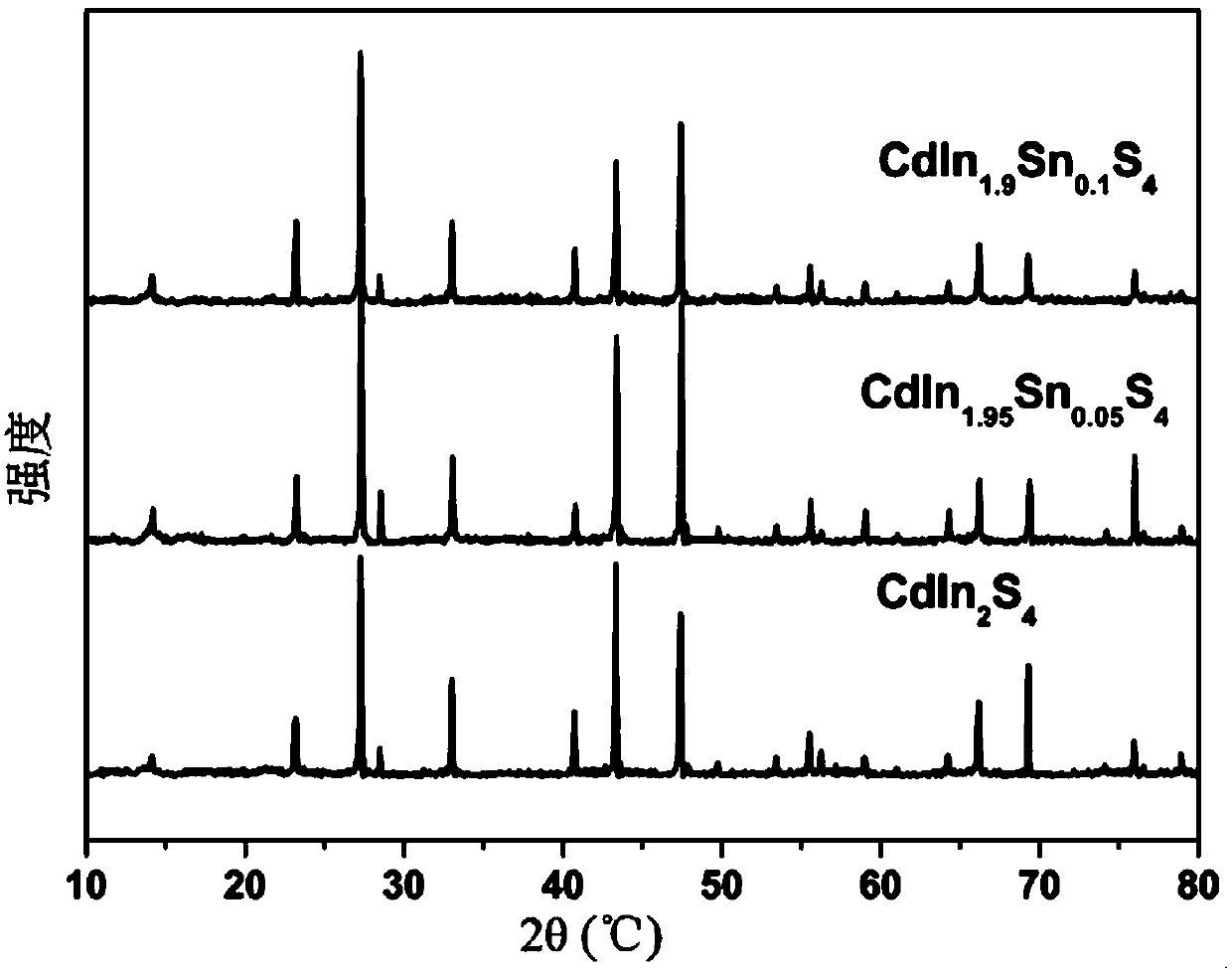

[0031] Example 1CdIn 2-x sn x S 4 (x=0,0.05,0.1) Preparation of materials

[0032] Cd powder (purity: 99.99%), In particles (purity: 99.999%), S powder (purity: 99.999%) and Sn powder (purity: 99.99%) according to CdIn 2-x sn x S 4Weigh the stoichiometric ratio of (x=0,0.05,0.1), put it into a quartz glass tube, and seal the quartz glass tube with a hydrogen-oxygen flame; put the fused quartz glass tube into a programmable temperature-controlled muffle furnace , slowly heated up to 750°C at a rate of 2°C / min and held for 24 hours, then cooled to room temperature with the furnace; after opening the tube again, the obtained sample was ground in an agate mortar, vacuum-packed in a quartz glass tube, and placed in a program control In a warm muffle furnace, slowly raise the temperature to 750°C at a rate of 2°C / min and then sinter and hold for 48 hours. The sample is cooled to room temperature with the furnace, and then ground again after opening the tube.

Embodiment 2

[0033] Example 2CdIn 2-x sn x S 4 (x=0,0.05,0.1) Preparation of materials

[0034] Binary compounds of Cd, In, S and Sn with a purity of not less than 99.99% are classified as CdIn 2-x sn x S 4 (x=0,0.05,0.1) stoichiometric ratio weighing, put into a quartz glass tube, and seal the quartz glass tube with a hydrogen-oxygen flame; put the fused quartz glass tube into a programmed temperature control muffle furnace , slowly heated up to 700°C at a rate of 5°C / min and held for 48 hours, then cooled to room temperature with the furnace; after opening the tube again, the obtained sample was ground in an agate mortar, vacuum-packed in a quartz glass tube, and controlled by the program In a warm muffle furnace, the temperature was slowly raised to 700°C at a rate of 5°C / min and then sintered and held for 24 hours. The sample was cooled to room temperature with the furnace, and then ground again after opening the tube.

Embodiment 3

[0035] Example 3CdIn 2-x sn x S 4 (x=0,0.05,0.1) Preparation of materials

[0036] Cd powder (purity: 99.99%), In particles (purity: 99.999%), S powder (purity: 99.999%) and Sn powder (purity: 99.99%) according to CdIn 2-x sn x S 4 Weigh the stoichiometric ratio of (x=0,0.05,0.1), put it into a quartz glass tube, and seal the quartz glass tube with a hydrogen-oxygen flame; put the fused quartz glass tube into a programmable temperature-controlled muffle furnace , slowly heated up to 750°C at a rate of 3°C / min and held for 24 hours, then cooled to room temperature with the furnace; after opening the tube again, the obtained sample was ground in an agate mortar, vacuum-packed in a quartz glass tube, and controlled by the program In a warm muffle furnace, the temperature was slowly raised to 800°C at a rate of 3°C / min and then sintered and held for 24 hours. The sample was cooled to room temperature with the furnace, and then ground again after opening the tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com