Passivating antireflection film of high PID resistance type polycrystalline cell and preparation process thereof

A preparation process, passivation reduction technology, applied in the field of solar cells, can solve the problems of reduced conversion efficiency, low PID, attenuation, etc., and achieve the effects of reducing reflectivity, improving attenuation characteristics, and increasing short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

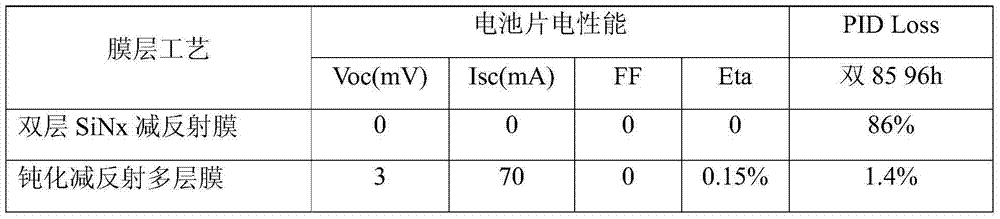

Embodiment 1

[0022] 1). Pretreatment of the original silicon wafer, the pretreatment includes the processes of texturing, diffusion and etching in the battery process;

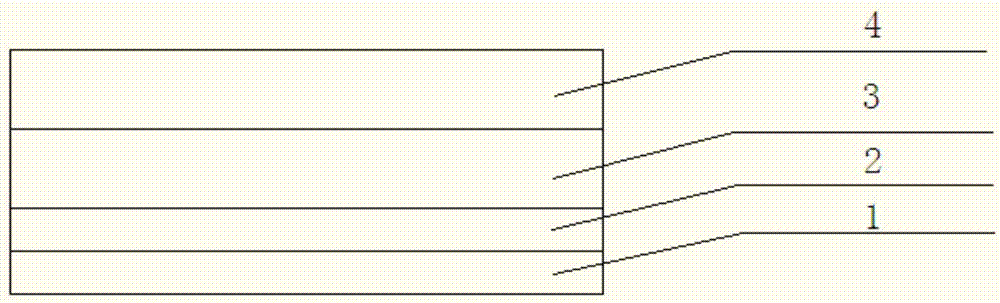

[0023] 2).Oxygen produced by high-voltage ionization or ultraviolet ionization oxygen or compressed air 3 Or free O atoms form a thin layer of dense SiO on the surface of the polysilicon wafer after etching x Layer 1, the refractive index is 1.65, and the film thickness is 0.8nm;

[0024] 3). Use PECVD equipment to coat the remaining film layer on the diffusion surface, cancel the pre-deposition step when coating the film, and coat SiO first x Layer 2, the refractive index is 1.65, and the film thickness is 2nm; then coat high refractive index SiN x Layer 3, the refractive index is 2.20, and the film thickness is 20nm; finally, a single layer of SiN is plated x layer, the refractive index is 2.05, and the film thickness is 60nm;

[0025] 4).Use the traditional battery printing process to print the back electrode, alumi...

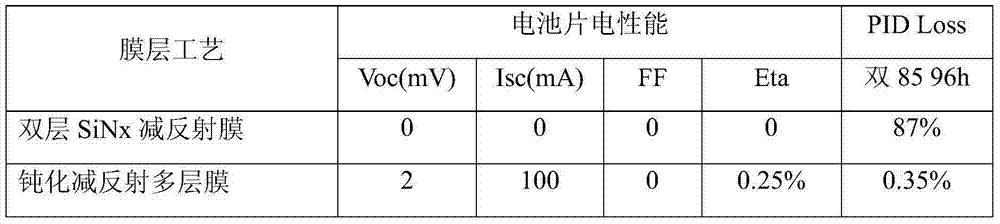

Embodiment 2

[0031] 1). Pretreatment of the original silicon wafer, the pretreatment includes the processes of texturing, diffusion and etching in the battery process;

[0032] 2).Oxygen produced by high-voltage ionization or ultraviolet ionization oxygen or compressed air 3 Or free O atoms form a thin layer of dense SiO on the surface of the polysilicon wafer after etchingx Layer 1, the refractive index is 1.65, and the film thickness is 0.8nm;

[0033] 3). Use PECVD equipment to coat the remaining film layer on the diffusion surface, cancel the pre-deposition step when coating the film, and coat SiO first x Layer 2 has a refractive index of 1.65 and a film thickness of 10nm; the third layer is a high refractive index SiNx layer 3 with a refractive index of 2.20 and a film thickness of 20nm; the top layer is a double-layer SiNx layer 3 and the bottom layer SiN has a refractive index of 2.15. The thickness of the film layer is 20nm, the refractive index of the upper layer SiN is 2.05, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com