A high-efficiency polycrystalline multilayer passivation anti-reflection coating structure with high PID resistance

A passivation reduction and reflection film technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of battery conversion efficiency reduction, attenuation, low PID, etc., to achieve the effect of reducing reflectivity, increasing short-circuit current, and easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Pretreatment of the original silicon wafer, the pretreatment includes processes such as texturing, diffusion and etching in the battery process;

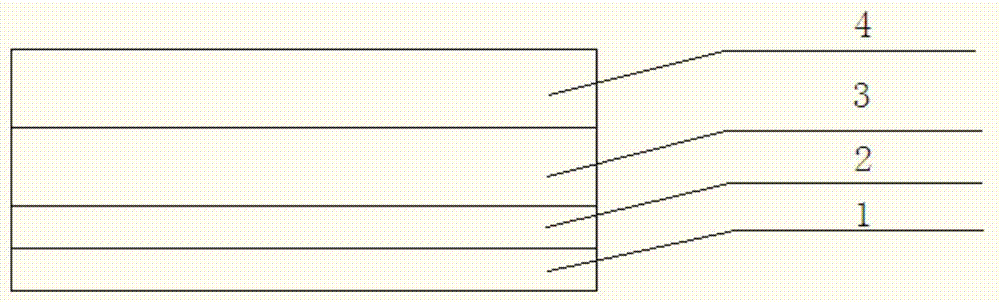

[0024] 2) Use PECVD equipment to sequentially deposit multi-layer SiN whose refractive index decreases according to a certain rule on the surface of the polycrystalline silicon wafer after etching x layer, where the underlying SiN x layer, the refractive index is 2.25, and the film thickness is 10nm; the middle layer SiN x layer, the refractive index is 2.2, and the film thickness is 20nm; single-layer SiN x layer, the refractive index is 2.15, and the film thickness is 30nm;

[0025] 3) Use PECVD equipment to plate remaining SiO on the diffusion surface x Ny layer, the refractive index is 1.75, and the film thickness is 30nm;

[0026] 4) Print the back electrode, aluminum back field, positive grid line and positive electrode using the traditional battery printing process, and sinter them.

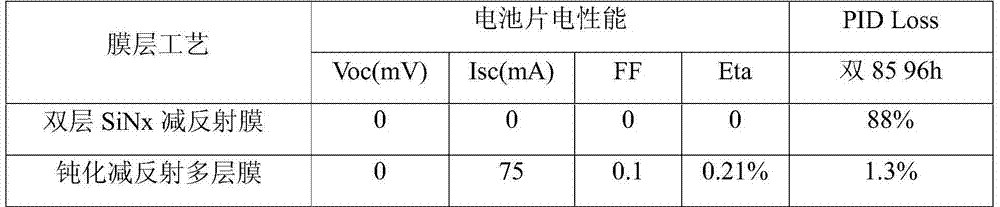

[0027] After testing, it i...

Embodiment 2

[0032] 1) Pretreatment of the original silicon wafer, the pretreatment includes processes such as texturing, diffusion and etching in the battery process;

[0033] 2) Use PECVD equipment to sequentially deposit multi-layer SiN whose refractive index decreases according to a certain rule on the surface of the polycrystalline silicon wafer after etching x layer, where the underlying SiN x layer, the refractive index is 2.25, and the film thickness is 5nm;

[0034] Intermediate SiN x layer, the refractive index is 2.20, and the film thickness is 15nm; double-layer SiN x layer, the first layer of SiN x The refractive index is 2.15, and the film thickness is 15nm; the second layer of SiN x The refractive index is 2.05, and the film thickness is 25nm;

[0035] 3) Use PECVD equipment to plate remaining SiO on the diffusion surface x N y layer, the refractive index is 1.8, and the film thickness is 35nm;

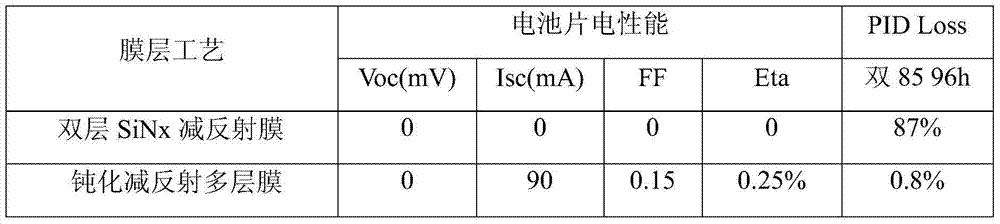

[0036] 4) Print the back electrode, aluminum back field, positive grid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com