Heterojunction solar cell and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult control of boron diffusion process, battery grid line shielding, and high diffusion temperature, so as to avoid the reduction of minority carrier lifetime and diffusion length, The effect of avoiding damage and eliminating light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

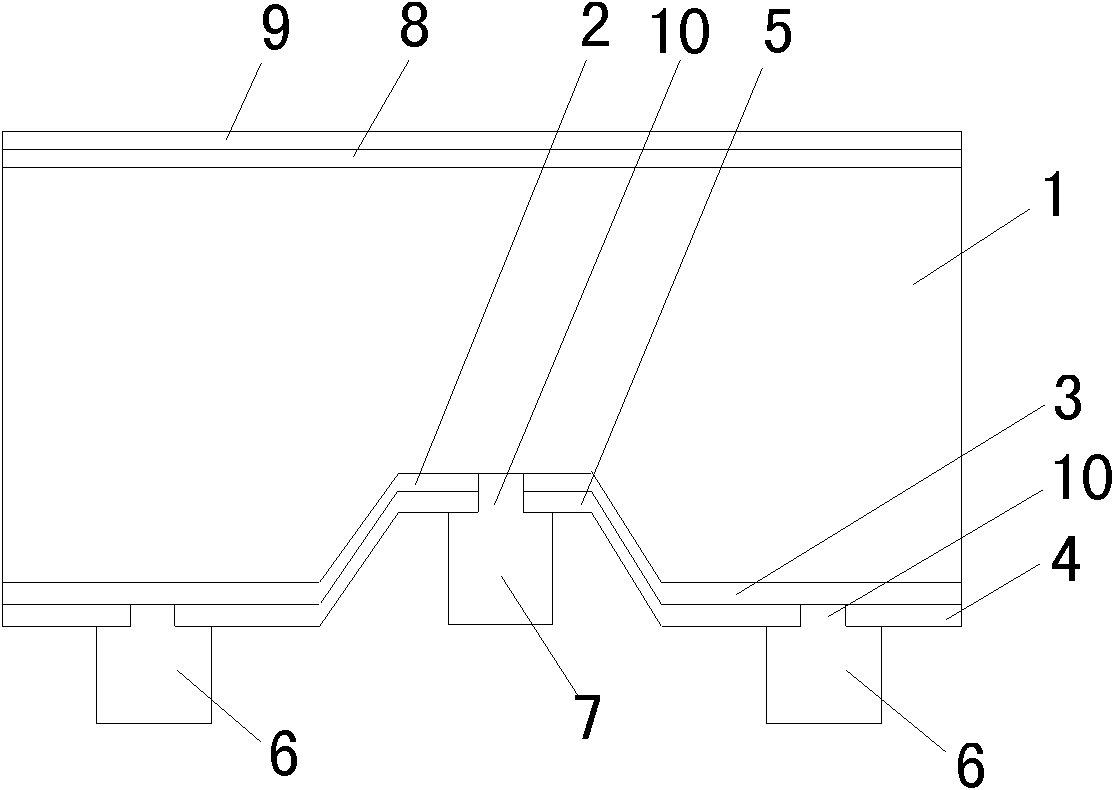

[0034] figure 1 It is a schematic cross-sectional structure diagram of a heterojunction solar cell manufactured by the manufacturing method of the present invention, figure 1 The fabrication method of the heterojunction solar cell shown includes the following steps:

[0035] (1) An N-type monocrystalline silicon wafer with a thickness of 150 μm and a resistivity of 0.3 Ωcm is used as the substrate 1 , and the surface of the substrate 1 is cleaned and textured by an alkali texturing method.

[0036] (2) On the front surface of the N-type silicon substrate 1, a layer of intrinsic amorphous silicon film is deposited by PECVD, and then a layer of N-type amorphous silicon film is deposited to form a silicon film layer 8 with a thickness of 30 nm. ;

[0037] (3) The P-type silicon thin film layer 3 and the N-type silicon thin film layer 2 are respectively deposited on the back surface of the N-type silicon substrate 1 by PECVD. Wherein the P-type silicon thin film layer 3 is a co...

Embodiment 2

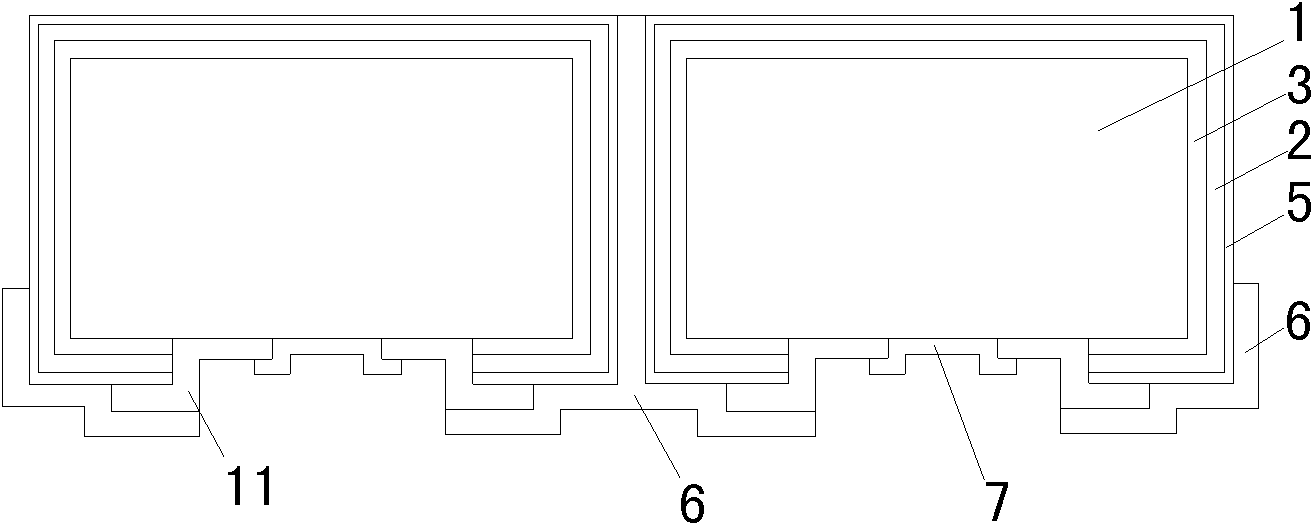

[0043] figure 2 is a schematic cross-sectional structure diagram of another heterojunction solar cell manufactured by the manufacturing method of the present invention, figure 2 The fabrication method of the heterojunction solar cell shown includes the following steps:

[0044] (1) A P-type single crystal silicon wafer with a thickness of 200 μm and a resistivity of 1 Ωcm is used as the substrate 1 , and a hole through the front and back is punched on the P-type silicon substrate 1 to form the electrode contact hole 10 .

[0045] (2) The surface of the P-type silicon substrate 1 is cleaned and textured by an alkali texturing method.

[0046] (3) The P-type silicon thin film layer 3 and the N-type silicon thin film layer 2 are respectively deposited by PECVD. Wherein the P-type silicon thin film layer 3 is a composite layer composed of the inner intrinsic amorphous silicon thin film and the outer P-type microcrystalline silicon thin film, and the N-type silicon thin film la...

Embodiment 3

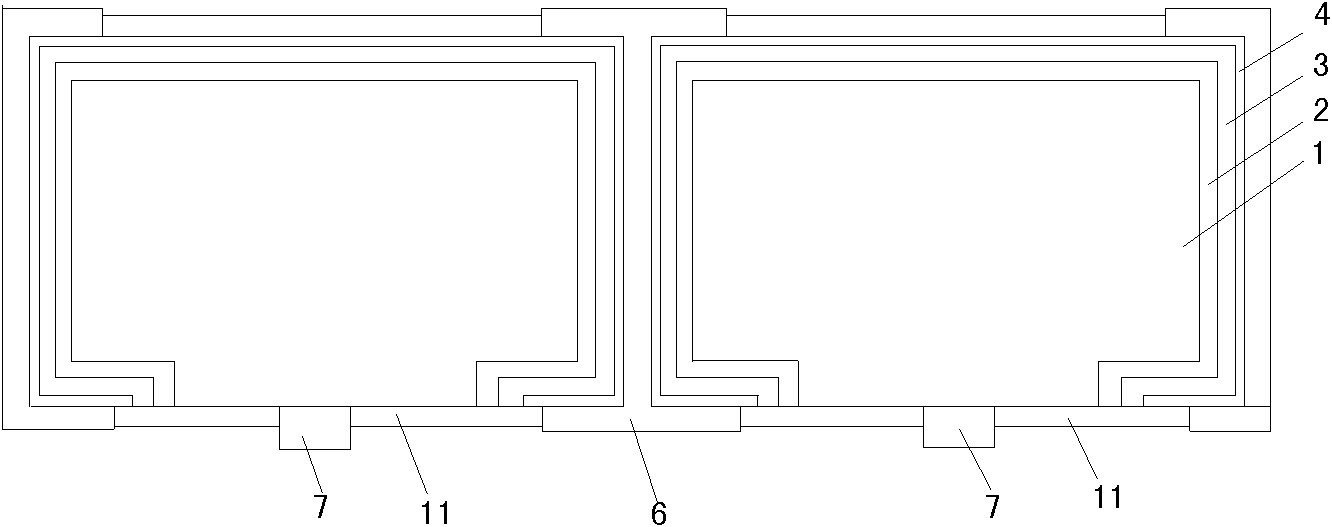

[0052] image 3 is a schematic cross-sectional structure diagram of another heterojunction solar cell manufactured by the manufacturing method of the present invention, image 3 The fabrication method of the heterojunction solar cell shown includes the following steps:

[0053] (1) A P-type monocrystalline silicon wafer with a thickness of 200 μm and a resistivity of 1 Ωcm is used as the substrate 1 , and a hole through the front and back is punched on the P-type silicon substrate 1 to form an electrode contact hole.

[0054] (2) The surface of the P-type silicon substrate 1 is cleaned and textured by an alkali texturing method.

[0055] (3) The N-type silicon thin film layer 2 and the P-type silicon thin film layer 3 are respectively deposited by PECVD. Wherein the N-type silicon film layer 2 is a composite layer composed of the inner layer intrinsic amorphous silicon film and the outer N-type nano-silicon film, and the P-type silicon film layer 3 is composed of the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com